Abstract

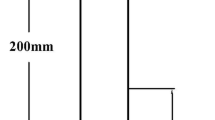

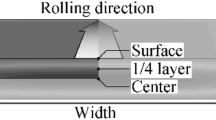

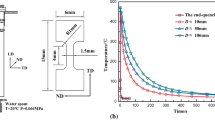

The occurrence of quench cracking in small cuboidal samples of aluminium alloy AA7150 was determined to be related to the maximum temperature difference (∆T max) between various locations within samples during quenching. When ∆T max between different locations is between 96 and 124 °C, there is some risk of quench cracking under various quenching conditions. When the ∆T max value is higher than 124 °C, quench cracks cannot be avoided. Quench cracks preferentially occur at sample corners and edges and are preferentially propagating in the short transverse direction–long transverse direction plane. Finite element modelling results indirectly indicate that the quench cracking should occur at the very early stages of the quenching process. Microscopy reveals that the quench cracking mode is intergranular, and cracks preferentially occur at high-angle grain boundaries with an average misorientation angle of ~42°. Moreover, quench cracks can penetrate through the whole thickness of a sample quenched from 495 into 20 °C water. Fractography reveals that no constituent particles exist in the quench fracture region, indicating that, unlike impact fracture, the occurrence of quench cracks is not dependent on the presence of coarse particles.

Similar content being viewed by others

References

Liu SD, Zhang XM, Chen MA, You JH (2008) Influence of aging on quench sensitivity effect of 7055 aluminum alloy. Mater Charact 59:53–60

Dumont D, Deschamps A, Brechet Y (2004) A model for predicting fracture mode and toughness in 7000 series aluminium alloys. Acta Mater 52:2529–2540

Paramatmuni RK, Chang KM, Kang BS, Liu XB (2004) Evaluation of cracking resistance of DC casting high strength aluminum ingots. Mater Sci Eng A 379:293–301

Morgeneyer TF, Starink MJ, Wang SC, Sinclair I (2008) Quench sensitivity of toughness in an Al alloy: direct observation and analysis of failure initiation at the precipitate-free zone. Acta Mater 56:2872–2884

Hattori H, Takekawa M, Furrer D, Noel R (1996) In: Kissinger RD, Deye DJ, Anton DL (eds) Superalloy. TMS-AIME, Warrendale, pp 705–711

Chang KM, Henry MF, Benz MG (1990) Metallurgical control of fatigue crack-propagation in superalloys. JOM 42:29–35

Earle TP, Robinson JS, Colvin JJ (2004) Investigating the mechanisms that cause quench cracking in aluminium alloy 7010. J Mater Process Technol 153–154:330–337

Jeanmart P, Bouvaist J (1985) Finite-element calculation and measurement of thermal-stresses in quenched plates of high-strength 7075 aluminum-alloy. Mater Sci Technol 1:765–769

Xu DK, Rometsch PA, Birbilis N (2012) Improved solution treatment for an as-rolled Al–Zn–Mg–Cu alloy. Part II. Microstructure and mechanical properties. Mater Sci Eng A 534:244–252

Chen KH, Liu HW, Zhang Z, Li S, Todd RI (2003) The improvement of constituent dissolution and mechanical properties of 7055 aluminum alloy by stepped heat treatments. J Mater Process Technol 142:190–196

Toda H, Kobayashi T, Takahashi A (2000) Mechanical analysis of toughness degradation due to premature fracture of course inclusions in wrought aluminium alloys. Mater Sci Eng A 280:69–75

Deshpande NU, Gokhale AM, Denzer DK, Liu J (1998) Relationship between fracture toughness, fracture path, and microstructure of 7050 aluminum alloy: part I. Quantitative characterization. Metall Mater Trans A 29:1191–1201

Hahn GT, Rosenfield AR (1975) Metallurgical factors affecting fracture toughness of aluminum-alloys. Metall Trans 6:653–668

Mori Y, Kaneko K, Wadati M (1991) Fracture dynamics by quenching 1. Crack patterns. J Phys Soc Jpn 60:1591–1599

Liu XY, Adams JB (1998) Grain-boundary segregation in Al–10 %Mg alloys at hot working temperatures. Acta Mater 46:3467–3476

Cundy SL, Metherell AJ, Whelan MJ, Unwin PNT, Nicholson RB (1968) Studies of segregation and initial stages of precipitation at grain boundaries in an aluminium 7 wt percent magnesium alloy with an energy analysis electron microscope. Proc R Soc A 307:267–281

Doig P, Edington JW (1974) Stress corrosion susceptibility of as-quenched Al–5.9 wt% Zn–3.2 wt% Mg alloy. Br Corros J 9:220–222

Scamans GM, Holroyd NJH, Tuck CDS (1987) The role of magnesium segregation in the intergranular stress-corrosion cracking of aluminum-alloys. Corros Sci 27:329–347

Song RG, Tseng MK, Zhang BJ, Liu J, Jin ZH, Shin KS (1996) Grain boundary segregation and hydrogen-induced fracture in 7050 aluminium alloy. Acta Mater 44:3241–3248

De Hass M, De Hosson JTM (2001) Grain boundary segregation and precipitation in aluminium alloy. Scr Mater 44:281–286

Brock AJ, Hein MA (1972) Formation of MgO crystals in anodic gamma-Al2O3 formed on aluminium 3 percent magnesium alloy. J Electrochem Soc 9:1124–1127

Acknowledgements

The authors thank the Aluminium Corporation of China Ltd. (Chalco) for supporting this work financially and for providing materials as part of the Australia–China International Centre for Light Alloy Research (ICLAR). This work was also supported by National Science Fund of China projects under Grant No. 51271183 and a National Basic Research Program of China (973 Program) project under Grant No. 2012CB067425 and an Innovation Fund of the Institute of Metal Research (IMR), Chinese Academy of Sciences (CAS). Use of the facilities at the ARC Centre of Excellence for Design in Light Metals, and the Monash Centre for Electron Microscopy (MCEM) is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, D.K., Rometsch, P.A., Li, L. et al. Critical conditions for the occurrence of quench cracking in an Al–Zn–Mg–Cu alloy. J Mater Sci 49, 4687–4697 (2014). https://doi.org/10.1007/s10853-014-8103-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8103-9