Abstract

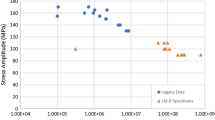

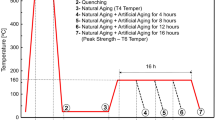

Crack extension in commercial aluminum alloys proceeds by the “ductile” or fibrous mode. The process involves the large, ~1 μm to ~10μm, Fe-, Si-, and Cu-bearing inclusions which break easily, and the growth of voids at the cracked particles. The linking-up of the voids is accomplished by the rupture of the intervening ligaments, and this is affected by the fine, ~0.01μm precipitate particles that strengthen the matrix. The ~0.1μm Cr-, Mn-, and Zr-rich intermediate particles are more resistant to cracking and may enter the process in the linking-up stage. The fracture toughness of aluminum alloys therefore depends on a) the extent of the heavily strained region ahead of the crack tip, which is a function of the yield strength arad modulus, b) the size of the ligaments which is related tof c, the volume fraction of cracked particles, and c) the work of rupturing the ligaments. An approximate analysis predicts KIc varies asf c-1/6, and this is in agreement with measurements on alloys with comparable yield strength levels. Studies in which the aging conditions are altered for the samef cshow that the toughness decreases with increasing yield strength level. This degradation in toughness is related to the localization of plastic deformation. The tendency for localization is illustrated with the help of “plane strain” tension and bend specimens whose behavior is related to the toughness. Measurements of the strain distribution on the microscale show that slip is relatively uniformly distributed in a 7000-type alloy with low inclusion and particle content when the material is in the as-quenched and overaged conditions. In contrast the distribution is highly nonuniform in the peak aged condition where slip is concentrated in widely spaced superbands involving coarse slip bands with large offsets that crack prematurely. The connection between the tendency for slip localization and the fine precipitate particles which strengthen the matrix remains to be established. In overaged alloys grain boundary ruptures occur within the superbands. The amount of intergranular failure increases with grain size and is accompanied by a loss of fracture toughness.

Similar content being viewed by others

References

R. Develay:Metals and Materials, 1972, vol. 6, p. 404.

A. R. Rosenfield:Met. Rev., 1968, no. 121, p. 29.

G. T. Hahn, M. F. Kanninen, and A. R. Rosenfield:Ann. Rev. Mater. Sci., 1972, vol. 2, p. 381.

D. Broek:Eng. Fract. Mech., 1973, vol. 5, p. 55.

D. Broek: Report NLR-TR-72029-u; Nat. Aerospace Lab., The Netherlands (n.d.)

J. P. Tanaka, C. A. Pampillo, and J. R. Low, Jr.: ASTM-STP, 1970, vol. 463, p.191.

J. R. Low, Jr., R. H. Van Stone, and R. H. Merchant: NASA Tech. Rep. No. 2, Research Grant NCR 38-087-003, Carnegie-Mellon Univ., 1972.

S. N. Singh and M. C. Flemings:Trans. AIME, 1969, vol. 245, p. 1811.

J. H. Mulherin and H. Rosenthal:Met. Trans., 1971, vol. 2, p. 427.

D. S. Thompson and S. A. Levy: AFML-TR-70-171, Wright-Patterson AFB, Ohio, 1970.

J. A. Nock, Jr. and H. Y. Hunsickler:J. Metals, 1963, vol. 15, p. 216.

C. J. Peel, R. N. Wilson, and P. J. E. Forsyth:Metal Sci. J., 1972, vol. 6, p. 102.

P. N. T. Uhwin and G. C. Smith:J. Inst. Met., 1969, vol. 97, p. 299.

S. N. Singh and M. C. Flemings:Trans. AIME, 1969, vol. 245, p. 1803.

K. R. VanWorn, ed:.Aluminum, 1967, vol. 1, ASM, Metals Park, Ohio.

L. F.Mondolfo:Met. Rev., 1971, vol. 16, p. 95.

S. M. El-Soudani and R. M. Pelloux:Met. Trans., 1973, vol. 4, p. 519.

A. R. Rosenfield, C.W. Price, C.J.Martin, D. N. Williams, D.C. Drennen, D. S. Thompson, and R. E, Zinkham: Semiannual Progress Report on Con-tract F33615-71-C-1805 to AFMLJLLS, 1972.

A. S. Argon, J. 1m, and R. Safoglu: Massachusetts Institute of Technology, private communication.

T. B. Cox and J. R. Low, Jr.: NASA Tech. Rep. No. 3 on Research Grant NGR-39-087-003, Carnegie-Mellon Univ., 1972.

J. Gurland:Acta Met., 1972, vol. 20, p. 735.

T. Liu and J. Gurland:Trans. ASM, 1968, vol. 61, p. 156.

B. I. Edelson and W. M. Baldwin, Jr.:Trans. ASM, 1962, vol. 53, p. 230.

J. J. Hauser and M. G. Wells: Tech. Rep. AFML-TR-69-339, Wright Patterson AFB, Ohio, 1969.

A. J. Birkle, R. P. Wei, and G. E. Pellesier:Trans. ASM, 1966, vol. 59, p. 981.

G. T. Hahn, P. N. Mincer, and A. R. Rosenfield:Exp. Mech., 1971, vol. 11, p. 248.

J. R. Rice and M. A. Johnson:Inelastic Behavior of Solids, M. F. Kanninen, et al., eds., p.641, McGraw-Hill, New York, 1970.

J. W. Hutchinson:J. Mech. Phys. Solids, 1968, vol. 16, p. 13.

N. Levy, P. V. Marcal, W. J. Ostergren, and J. R. Rice:Int. J. Fract. Mech., 1971, vol.7, p. 143.

F. A. McClintock:Fracture, H. Liebowitz, ed., vol. 3, p. 106, Academic Press, New York, 1971.

J. R. Rice and D. M. Tracey:J. Mech. Phys. Solids, 1969, vol. 17, p. 201.

J.M. Krafft:Appl. Mater. Res., 1964, vol. 3, p. 88.

F. A. McClintock:Fracture, H. Liebowitz, ed., vol. 3, p. 47, Academic Press, New York, 1971.

P. F. Thomasson:Int. J. Fract. Mech., 1971, vol. 7, p. 409.

G. T. Hahn and A. R. Rosenfield: Paper PL-III-211, Third Int. Conf. Fracture, Munich, 1973.

T. B. Cox and J. R. Low, Jr.: NASA Tech. Rep. No. 4 on Research Grant NGR-39-087-003, Carnegie-Mellon Univ., 1972.

F. A. McClintock, S. M. Kaplan, and C. A. Berg:Int. J. Fract. Mech., 1966, vol. 2, p. 615.

C. A. Berg:Inelastic Behavior of Solids, M.F. Kanninen,et al, eds., p. 171, McGraw-Hill, New York, 1970.

C. A. Griffis and J. W. Spretnak:J Iron Steel Inst. Japan, 1969, vol. 9, p. 372.

M. S. Hunter and J. C. McMillan: ASTM-STP, 1968, vol. 436, p. 196.

A. Kelly and R. B. Nicholson:Prog. Mater. Sci, 1963, vol. 10, p. 151.

J. D. Embury and R. B. Nicholson:Acta Met, 1965, vol. 13, p. 403.

M. O. Speidel:Fundamental Aspects of Stress Corrosion Cracking, p. 561, Nat. Assn. Corr. Engs., Houston, 1969.

R. N. Wilson and P. G. Partridge:Acta Met., 1965, vol. 13, p. 1321.

R. N. Wilson, D. M. Moore, and P. J. E. Forsythe:J. Inst. Metals, 1967, vol. 95, p. 177.

N. Sen and D. R. F. West:The Mechanism of Phase Transformations in Crystalline Solids, p. 49, Inst. Met., London, 1969.

R. E. Zinkham, J. H. Dedrick, and J. H. Jackons: Proceedings of 5th International Leichtmetalltagung Leoben Austria, 1968, Aluminium-Verlag GMBH, Dusseldorf, Germany.

T. M. F. Ronald and D. P. Voss: Metals and Ceramics Synthesis Branch, LLS, Wright-Patterson AFB, Ohio, unpublished research.

D. P. Clausing:Int. J. Fract. Mech., 1970, vol. 6, p. 71.

D. P. Clausing: Tech. Rep. on Project No. 35.066-001(2), U.S. Steel Corp., Research Lab., 1972.

S. A. Mohamed and A. S. Tetelman: Proceedings of the Third Int. Conf. on Fracture, Vol. III, Verein Deutscher Eisenhuttenleute, Dusseldorf, Germany, April, 1973, Paper II-511.

D. L. McGarry: M.S. Thesis, Ohio State University, 1972.

A. S. Tetelman: Univ. of Cal. at L. A., private communication, 1973.

V. Weiss and N. Sengupta: Proceedings of the Third Int. Conf. on Fracture, Vol. IV, Verein Deutscher Eisenhuttenleute, Dusseldorf, Germany, April, 1973, Paper III-341.000

J. D. Boyd, D. S. Thompson, D. N. Williams, and D. C. Drennen: First Semi- annual Progress Report on Contract F33615-71-C1805 to AFMLJLLS, January 31, 1972.

I. Kirman:Met. Trans., 1971, vol. 2, p. 1761.

D. S.Thompson, R. E. Zinkham, and C. W. Price: unpublished research on Contract No. F33615-71-C-1805.

C. J. Beevers and W. K. Honeycomb:Phil. Mag., 1962, vol. 7, p. 763.

R. J. Price and A. Kelly:Acta Met., 1964, vol. 2, p. 979.

D. Harkness and J.J. Hren:Met. Trans., 1970, vol. 1, p. 43.

I. G. Palmer and G. C. Smith:Oxide Dispersion Strengthening, p. 253, Gordon and Breach, 1968.

G. T. Hahn and A. R. Rosenfield: unpublished research.

T. B. Cox and J. R. Low, Jr.: NASA Technical Report No. 5, Dept. of Metallurgy and Materials Science, Carnegie-Mellon Univ., 1973.

Author information

Authors and Affiliations

Additional information

This paper is based on an invited presentation made at a symposium on “Advances in the Physical Metallurgy of Aluminum Alloys” held at the Spring Meetings of TMS-IMD in Philadelphia, Pennsylvania, on May 29 to June 1, 1973. The symposium was co-sponsored by the Physical Metallurgy Committee and the Non-Ferrous Metals Committee of TMS-IMD

Rights and permissions

About this article

Cite this article

Hahn, G.T., Rosenfield, A.R. Metallurgical factors affecting fracture toughness of aluminum alloys. Metall Trans A 6, 653–668 (1975). https://doi.org/10.1007/BF02672285

Issue Date:

DOI: https://doi.org/10.1007/BF02672285