Abstract

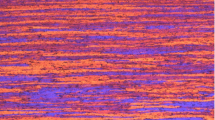

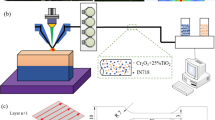

Ni:Al laminate composites were fabricated by repeatedly cold-rolling Al and Ni foils that were stacked together with initial thicknesses of 25 and 18 μm, respectively. The rolling process consisted of multiple 50 % thickness reductions wherein the first reduction was followed by cutting, restacking, and rerolling to achieve a total of three, six or nine 50 % thickness reductions. However, some of the laminates also received a more mild series of six 20 % thickness reductions without restacking. An analysis program was written and used to quantify the distribution of layer thicknesses, bilayer thicknesses and local chemistries for the complex laminate microstructures, while also preserving positional information for the constituent layers. The resulting distributions show that while we see no clustering of very large bilayers in any of the composites, the heavily rolled laminates with only 50 % thickness reductions have a higher percentage of very large bilayers, relative to the volume mean bilayer, compared to laminates with the additional 20 % thickness reductions. This phenomenon is attributed to less uniform layer deformation and more layer pinch-off with 50 % thickness reductions compared to the more gradual 20 % thickness reductions. Differential scanning calorimetry was performed on the laminates to determine the exothermic peak temperatures and the total energy released during controlled heating. Peak temperatures correlate with the volume average bilayer thickness, while the energy release correlates with the bilayer thickness distribution. The velocity and maximum temperature of self-propagating reactions were measured for the laminates and were found to vary according to processing conditions but not according to the volume average bilayer thickness. Foils with 20 % thickness reductions have both hotter and faster reactions compared to samples with only 50 % thickness reductions. The distributions of layer thicknesses, bilayer thicknesses, and local chemistries within the laminates are used to predict the maximum temperature during reaction. The velocities of the unsteady reaction propagations, though, could not be predicted effectively, at least with current analytical models.

Similar content being viewed by others

References

Inoue J, Nambu S, Ishimoto Y, Koseki T (2008) Scripta Mater 59:1055

Severin GE (1980) Body armor laminate. U.S. Patent 519,644

Weihs TP (1998) In: Handbook of thin film process technology. TOP, Bristol

Floro JA (1986) J Vac Sci Technol A Vac Surf Films 4:631

Gavens AJ, Van Heerden D, Mann AB, Reiss ME, Weihs TP (2000) J Appl Phys 87:1255

Ma E, Thompson CV, Clevenger LA, Tu KN (1990) J Appl Phys Lett 57:1262

Anselmi-Tamburini U, Munir ZA (1989) J Appl Phys 66:5039

Wickersham CE (1988) J Vac Sci Technol A Vac Surf Films 6:1699

Dyer TS, Munir ZA, Ruth V (1994) Scr Metall Mater 30:1281

Reiss ME, Esber CM, Van Heerden D, Gavens AJ, Williams ME, Weihs TP (1999) Mater Sci Eng A 261:217

Arzt E (1998) Acta Mater 46:5611

Li Q, Anderson PM (2005) Acta Mater 53:1121

Salloum M, Knio OM (2010) Combust Flame 157:288

Salloum M, Knio OM (2010) Combust Flame 157:436

Salloum M, Knio OM (2010) Combust Flame 157:1154

Knepper R, Snyder MR, Fritz G, Fisher K, Knio OM, Weihs TP (2009) J Appl Phys 105:083504

Besnoin E, Cerutti S, Knio OM, Weihs TP (2002) J Appl Phys 92:5474

Rogachev AS, Grigoryan AÉ, Illarionova EV, Kanel IG, Merzhanov AG, Nosyrev AN, Sachkova NV, Khvesyuk VI, Tsygankov PA (2004) Combust Explos Shock Waves 40:166

Hebert RJ, Perepezko JH (2004) Scripta Mater 50:807

Sieber H, Wilde G, Perepezko J (1999) J Non-Cryst Solids 250–252:611

Sieber H, Park JS, Weissmüller J, Perepezko JH (2001) Acta Mater 49:1139

Saito Y, Utsunomiya H, Tsuji N, Sakai T (1999) Acta Mater 47:579

Eizadjou M, Kazemi Talachi A, Danesh Manesh H, Shakur Shahabi H, Janghorban K (2008) Compos Sci Technol 68:2003

Mozaffari A, Danesh Manesh H, Janghorban K (2010) J Alloy Compd 489:103

Qiu X, Liu R, Guo S, Graeter JH, Kecskes L, Wang J (2009) Metall Mater Trans A 40:1541

Dreizin EL (2009) Prog Energy Combust Sci 35:141

Bazyn T, Glumac N, Krier H, Ward TS, Schoenitz M, Dreizin EL (2007) Combust Sci Technol 179:457

Badiola C, Schoenitz M, Zhu X, Dreizin EL (2009) J Alloy Compd 488:386

Stamatis D, Jiang X, Beloni E, Dreizin EL (2010) Propellants Explos Pyrotech 35:260

Michaelsen C, Barmak K, Weihs TP (1997) J Phys D Appl Phys 30:3167

Barron SC, Knepper R, Walker N, Weihs TP (2011) J Appl Phys 109:013519

McDonald JP, Hodges VC, Jones ED, Adams DP (2009) Appl Phys Lett 94:034102

Bordeaux F, Yavari R (1990) Z Metallkde 81:130

Dinda GP, Rösner H, Wilde G (2005) Scripta Mater 52:577

Mann AB, Gavens AJ, Reiss ME, Van Heerden D, Bao G, Weihs TP (1997) J Appl Phys 82:1178

Battezzati L, Pappalepore P, Durbiano F, Gallino I (1999) Acta Mater 47:1901

Boer RF, Boom R, Mattens WCM, Miedema AR, Niessen AK (1988) In: Cohesion in metals. Elsevier Ltd, Amsterdam

Armstrong M, Koszykowski R (1990) In: Combustion and plasma synthesis of high-temperature materials. VCH, New York

Du Y (2003) Mater Sci Eng A 363:140

Gunduz IE, Fadenberger K, Kokonou M, Rebholz C, Doumanidis CC, Ando T (2009) J Appl Phys 105:074903

Makino A, Law CK (1992) In: Twenty-fourth symposium on combustion. The Combustion Institute, p 1883

Makino A, Law CK (1995) Combust Flame 101:551

Law CK (2006) Combust Sci Technol 178:335

Hardt AP, Phung PV (1973) Combust Flame 21:77

Atzmon M (1992) Metall Mater Trans A 23:49

Alawieh L, Knio OM, Weihs TP (2011) J Appl Phys 110:013509

Acknowledgements

The authors are grateful to Mark Koonz for his help in acquiring the SEM images. This study was supported by the Office of Naval Research through Award N00014-07-1-0740. TPW is an inventor of a related technology that has been licensed by Johns Hopkins University. The terms of this arrangement are being managed by Johns Hopkins University in accordance with its conflict of interest policies.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stover, A.K., Krywopusk, N.M., Fritz, G.M. et al. An analysis of the microstructure and properties of cold-rolled Ni:Al laminate foils. J Mater Sci 48, 5917–5929 (2013). https://doi.org/10.1007/s10853-013-7387-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7387-5