Abstract

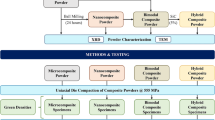

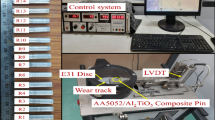

Laminated composites of IN718-95% IN718 + 5% (Cr2O3 + 25% TiO2) were fabricated by directed energy deposition, which were subjected to different posttreatment methods. The interfacial microstructures and mechanical properties of the laminated composites were studied by room temperature tensile tests and impact tests and analyzed by SEM and XRD. The interfacial morphology of the laminated composites after different treatment methods was compared. The effects of different treatment temperatures on the microstructure morphology and precipitate composition were analyzed. The results show that the precipitated strengthening phases improve the microhardness of solution by double aging (SA) treatment and homogenization, solution and double aging (HSA) treatment. The impact toughness and tensile strength are closely related to the heat treatment temperature and time. The impact toughness of the laminated composites reached 53.13 J/cm2, and the ultimate tensile strength reached 1339.85 MPa after HSA treatment.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article.

Code Availability

Not applicable.

References

D. Gu, X. Shi, R. Poprawe, D.L. Bourell, R. Setchi, and J. Zhu, Material-Structure-Performance Integrated Laser-Metal Additive Manufacturing, Science, 2021, 80, p 372.

G. Liu, X. Zhang, X. Chen, Y. He, L. Cheng, M. Huo, J. Yin, F. Hao, S. Chen, and P. Wang, Additive Manufacturing of Structural Materials, Mater. Sci. Eng. R Rep., 2021, 145, p 100596.

S. Wang, J. Ning, L. Zhu, Z. Yang, W. Yan, Y. Dun, P. Xue, P. Xu, S. Bose, and A. Bandyopadhyay, Role of Porosity Defects in Metal 3D Printing: Formation Mechanisms, Impacts on Properties and Mitigation Strategies, Mater. Today., 2022 https://doi.org/10.1016/j.mattod.2022.08.014

P. Li, J. Liu, B. Liu, L. Li, J. Zhou, X. Meng and, J. Lu, Microstructure and Mechanical Properties of In-Situ Synthesized Ti (N, C) Strengthen IN718 / 1040 Steel Laminate by Directed Energy Deposition, Mater. Sci. Eng. A., 2022 https://doi.org/10.1016/j.msea.2022.143247

P. Xue, L. Zhu, J. Ning, P. Xu, S. Wang, Z. Yang, Y. Ren, and G. Meng, The crystallographic Texture and Dependent Mechanical Properties of the CrCoNi Medium-Entropy Alloy by Laser Remelting Strategy, J. Mater. Sci. Technol., 2022, 111, p 245–255. https://doi.org/10.1016/j.jmst.2021.08.094

Z. Yang, S. Wang, L. Zhu, J. Ning, B. Xin, Y. Dun, and W. Yan, Manipulating Molten Pool Dynamics During Metal 3D Printing by Ultrasound, Appl. Phys. Rev., 2022, 9, p 21416.

P. Li, J. Zhou, L. Li, Y. Gong, J. Lu and, X. Meng, Influence of Depositing Sequence and Materials on Interfacial Characteristics and Mechanical Properties of Laminated Composites, Mater. Sci. Eng. A., 2021, 827, p 142092. https://doi.org/10.1016/j.msea.2021.142092

C. Dharmendra, S. Shakerin, G.D.J. Ram, and M. Mohammadi, Wire-Arc Additive Manufacturing of Nickel Aluminum Bronze/Stainless Steel Hybrid Parts – Interfacial Characterization, Prospects, and Problems, Materialia., 2020, 13, p 100834. https://doi.org/10.1016/j.mtla.2020.100834

J.D. Avila, M. Isik, and A. Bandyopadhyay, Titanium-Silicon on CoCr Alloy for Load-Bearing Implants Using Directed Energy Deposition-Based Additive Manufacturing, ACS Appl. Mater. Interfaces., 2020, 12, p 51263–51272. https://doi.org/10.1021/acsami.0c15279

Y. Zhang and A. Bandyopadhyay, Influence of Compositionally Graded Interface on Microstructure and Compressive Deformation of 316L Stainless Steel to Al12Si Aluminum Alloy Bimetallic Structures, ACS Appl. Mater. Interfaces., 2021, 13, p 9174–9185. https://doi.org/10.1021/acsami.0c21478

J. Chen, Y. Yang, C. Song, M. Zhang, S. Wu and, D. Wang, Interfacial Microstructure and Mechanical Properties of 316L /CuSn10 Multi-Material Bimetallic Structure Fabricated by Selective Laser Melting, Mater. Sci. Eng. A., 2019, 752, p 75–85. https://doi.org/10.1016/j.msea.2019.02.097

C. Tan, Y. Chew, R. Duan, F. Weng, S. Sui, F.L. Ng, Z. Du and, G. Bi, Additive Manufacturing of Multi-Scale Heterostructured High-Strength Steels, Mater. Res. Lett., 2021, 9, p 291–299. https://doi.org/10.1080/21663831.2021.1904299

L. Zhu, S. Wang, H. Pan, C. Yuan, and X. Chen, Research on Remanufacturing Strategy for 45 Steel Gear Using H13 Steel Powder Based on Laser Cladding Technology, J. Manuf. Process., 2020, 49, p 344–354. https://doi.org/10.1016/j.jmapro.2019.12.009

P. Xue, L. Zhu, J. Ning, Y. Ren, Z. Yang, S. Wang, P. Xu, G. Meng, Z. Liu and, B. Xin, Effect of Laser Incident Energy on the Densification and Structure–Property Relationships of Additively Manufactured CrCoNi Medium-Entropy Alloy, Virtual Phys. Prototyp., 2021, 16, p 404–416.

Y.K. Kim and S.I. Hong, Influence of Interface Structure and Stress Distribution on Fracture and Mechanical Performance of STS439/Al1050/STS304 Clad Composite, Mater. Sci. Eng. A., 2019, 749, p 35–47. https://doi.org/10.1016/j.msea.2019.02.004

S. Singh, A.N. Jinoop, I.A. Palani, C.P. Paul, K.P. Tomar and, K.G. Prashanth, Microstructure and Mechanical Properties of NiTi-SS Bimetallic Structures Built Using Wire Arc Additive Manufacturing, Mater. Lett., 2021, 303, p 130499. https://doi.org/10.1016/j.matlet.2021.130499

S. Wang, L.J. Huang, Q. An, S. Jiang, R. Zhang, L. Geng, S.X. Qu, and H.X. Peng, (2019). Regulating Crack Propagation in Laminated Metal Matrix Composites through Architectural Control. Compos. Part B Eng. 178 107503 doi:https://doi.org/10.1016/j.compositesb.2019.107503.

P.M. Bazhin, A.S. Konstantinov, A.P. Chizhikov, A.I. Pazniak, E.V. Kostitsyna, A.D. Prokopets, and A.M. Stolin, Laminated Cermet Composite Materials: The Main Production Methods, Structural Features and Properties (Review), Ceram. Int., 2021, 47, p 1513–1525. https://doi.org/10.1016/j.ceramint.2020.08.292

S. Wang, L.J. Huang, Q. An, L. Geng, and B.X. Liu, Dramatically Enhanced Impact Toughness of Two-Scale Laminate-Network Structured Composites, Mater. Des., 2018, 140, p 163–171. https://doi.org/10.1016/j.matdes.2017.11.067

E. Ghasali, K. Baghchesaraee, and Y. Orooji, Study of the Potential Effect of Spark Plasma Sintering on the Preparation of Complex FGM/laminated WC-based cermet, Int. J. Refract. Met. Hard Mater., 2020, 92, p 105328. https://doi.org/10.1016/j.ijrmhm.2020.105328

A. Hosseini Monazzah, H. Pouraliakbar, M.R. Jandaghi, R. Bagheri, and S.M. Seyed Reihani, Influence of interfacial adhesion on the damage tolerance of Al6061/SiCp laminated composites. Ceram. Int. 43, 2632–2643 (2017) doi:https://doi.org/10.1016/j.ceramint.2016.11.074

P. Li, J. Liu, J. Zhou, A. Feng, Y. Gong, and J. Lu, In-Situ and Off-Line Deformations of Cylindrical Walls Manufactured by Directed Energy Deposition with Different Dwell Times, Measurement, 2022, 198, p 111402. https://doi.org/10.1016/j.measurement.2022.111402

O. Gokcekaya, T. Ishimoto, S. Hibino, J. Yasutomi, T. Narushima, and T. Nakano, Unique Crystallographic Texture Formation in Inconel 718 by Laser Powder Bed Fusion and its Effect on Mechanical Anisotropy, Acta Mater., 2021, 212, p 116876.

A. De Bartolomeis, S.T. Newman, I.S. Jawahir, D. Biermann, and A. Shokrani, Future Research Directions in the Machining of Inconel 718, J. Mater. Process. Technol., 2021, 297, p 117260.

J.P. Collier, S.H. Wong, J.K. Tien, J.C. Phillips, and J.K. Tein, Effect of Varying Al, Ti, and Nb Content on the Phase Stability of Inconel 718, Metall. Trans. A Physical Metall. Mater. Sci. 19 A 1657–1666(1988) doi:https://doi.org/10.1007/bf02645133.

R. Cozar and A. Pineau, Morphology of Gamma Prime and Gamma Double Prime Precipitates and Thermal Stability of Inconel 718 Type Alloys, Metall. Mater. Trans. B., 1973, 4, p 47–59.

P. Li, J. Zhou, Y. Gong, X. Meng, and J. Lu, Effect of Post-Heat Treatment on the Microstructure and Mechanical Properties of Laser Metal Deposition Inconel 718, J. Mech. Sci. Technol., 2021, 35, p 2871–2878. https://doi.org/10.1007/s12206-021-0610-4

M. Sundararaman, P. Mukhopadhyay, and S. Banerjee, Precipitation of the δ-Ni3Nb Phase in Two Nickel Base Superalloys, Metall. Trans. A., 1988, 19, p 453–465. https://doi.org/10.1007/BF02649259

P. Koštial, P. Jonšta, I. Kopal, Z.K. Jančíková, I. Špička, T. Kulová, and I. Vlčková, Influence of Gama Prime Changes on the Heat Transport Phenomena of a Nickel Super Alloy, Defect Diffus, Forum, 2017, 379, p 1–11. https://doi.org/10.4028/www.scientific.net/DDF.379.1

D. Cai, W. Zhang, P. Nie, W. Liu, and M. Yao, Dissolution Kinetics of δ Phase and its Influence on the Notch Sensitivity of Inconel 718, Mater. Charact., 2007, 58, p 220–225. https://doi.org/10.1016/j.matchar.2006.04.020

Y. Sun, L. Jin, Y. Gong, X. Wen, G. Yin, Q. Wen, and B. Tang, Experimental Evaluation of Surface Generation and Force Time-Varying Characteristics of Curvilinear Grooved Micro End Mills Fabricated by EDM, J. Manuf. Process., 2022, 73, p 799–814.

M. Danish, M.K. Gupta, S. Rubaiee, A. Ahmed, and M. Sarikaya, Influence of Graphene Reinforced Sunflower Oil on Thermo-Physical, Tribological and Machining Characteristics of Inconel 718[J], J. Mater. Res. Technol., 2021, 15, p 135–150.

C.E. Seow, H.E. Coules, G. Wu, R.H.U. Khan, X. Xu, and S. Williams, Wire + Arc Additively Manufactured Inconel 718: Effect of Post-Deposition Heat Treatments on Microstructure and Tensile Properties, Mater. Des., 2019, 183, p 108157. https://doi.org/10.1016/j.matdes.2019.108157

Y. Zhang, L. Yang, T. Chen, W. Zhang, X. Huang, and J. Dai, Investigation on the Optimized Heat Treatment Procedure for Laser Fabricated IN718 Alloy, Opt. Laser Technol., 2017, 97, p 172–179. https://doi.org/10.1016/j.optlastec.2017.06.027

Z. Wang, K. Guan, M. Gao, X. Li, X. Chen, and X. Zeng, The Microstructure and Mechanical Properties of Deposited-IN718 by Selective Laser Melting, J. Alloys Compd., 2012, 513, p 518–523. https://doi.org/10.1016/j.jallcom.2011.10.107

R.G. Ding, Z.W. Huang, H.Y. Li, I. Mitchell, G. Baxter, and P. Bowen, Electron Microscopy Study of Direct Laser Deposited IN718, Mater. Charact., 2015, 106, p 324–337. https://doi.org/10.1016/j.matchar.2015.06.017

U.K. Tarai, P.S. Robi, and S. Pal, Thermal Properties of Ni–Cr–Si–B–Fe Based Interlayer Material and Its Application in TLP Bonding of IN 718 Superalloy, Acta Metall Sinica., 2020, 33(12), p 1666–1680. https://doi.org/10.1007/s40195-020-01089-x

X. Yao, S.K. Moon, B.Y. Lee, and G. Bi, Effects of Heat Treatment on Microstructures and Tensile Properties of IN718/TiC Nanocomposite Fabricated by Selective Laser Melting, Int. J. Precis. Eng. Manuf., 2017, 18, p 1693–1701. https://doi.org/10.1007/s12541-017-0197-y

B. Diepold, N. Vorlaufer, S. Neumeier, T. Gartner, and M. Göken, Optimization of the Heat Treatment of Additively Manufactured Ni-Base Superalloy IN718, Int. J. Miner. Metall. Mater., 2020, 27, p 640–648. https://doi.org/10.1007/s12613-020-1991-6

Funding

This work was supported by the National Natural Science Foundation of China (No. 51875265), the Key Laboratory of Vibration and Control of Aero-Propulsion System, Ministry of Education, Northeastern University (VCAME202208), the National Science Foundation of Jiangsu Province (No. BK20210758), China Postdoctoral Science Foundation Funded Project (No. 2022M710060) and Postgraduate Research & Practice Innovation Program of Jiangsu Province (Nos. KYCX22_3626 and SJCX22_1849).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that they have no competing interests.

Ethical Approval

Not applicable.

Consent to Participate

Not applicable.

Consent to Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, J., Li, P., Huai, Y. et al. Interface Characteristics and Mechanical Properties of Post-treated Directed Energy Deposition Laminated Composites. J. of Materi Eng and Perform 32, 7260–7274 (2023). https://doi.org/10.1007/s11665-022-07651-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07651-1