Abstract

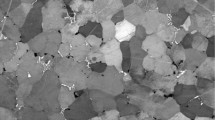

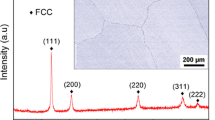

Creep and microstructure in ultrafine-grained (UFG) 5083 Al were investigated at 473 K. UFG 5083 Al was prepared by consolidating the cryomilled alloy powders via hot isostatic pressing followed by extrusion. The creep microstructure developed in the alloy was examined by means of transmission electron microscopy. The results show that the relationship between stress and strain is sigmoidal. Such a sigmoidal behavior is similar in trend to those reported for solid-solution alloys and superplastic alloys. An analysis of the mechanical data along with the consideration of several microstructural findings related to dislocation activity and configuration indicates that the alloy behaves as a superplastic alloy and not as a solid-solution alloy. Also, it is shown that the superplastic behavior of UFG 5083 Al is characterized by the presence of a threshold stress whose origin is most likely related to an interaction between impurities, which are able to segregate at nanoscale dispersion particles introduced as a result of processing, and dislocations, which are captured at the departure side of the particles.

Similar content being viewed by others

References

Valiev AZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103

Zhilyaev AP, Nurislamova GV, Kim BK, Baro MD, Szpunar JA, Langdon TG (2003) Acta Mater 51:753

Suryanarayana C (2004) Mechanical alloying and milling. Marcel Dekker, New York

Koch CC (1997) Nanostruct Mater 9:13

Roy I, Chauhan M, Lavernia EJ, Mohamed FA (2006) Metall Mater Trans A 37A:721

Han JH, Mohamed FA (2011) Metall Mater Trans A 42A:3969

Chauhan M, Roy I, Mohamed FA (2006) Metall Mater Trans A 37A:2715

Tellkamp VL, Dallek S, Cheng D, Lavernia EJ (2001) J Mater Res 16:938

Chirouze BY, Schwartz DM, Dorn JE (1967) ASM Trans Q 60:51

Murty KL, Mohamed FA, Dorn JE (1972) Acta Metall 20:1009

Park K-T, Lavernia EJ, Mohamed FA (1990) Acta Metall Mater 38:2149

Huang HIL, Sherby OD, Dorn JE (1956) Trans AIME 206:1385

Herrick RS, Weertman JP, Petkovic R, Luton MJ (1988) Scr Metall 22:1879

Schroder JH, Arzt E (1985) Scr Metall 19:1129

Li Y, Nutt SR, Mohamed FA (1997) Acta Mater 45:2607

Xun Y, Mohamed FA (2003) Philos Mag A 83:2247

Xun Y, Mohamed FA (2004) Acta Mater 52:4401

Abdu MT, Soliman MS, El-Danaf EA, Almajid AA, Mohamed FA (2012) Mater Sci Eng A 531:35

Yavari P, Mohamed FA, Langdon TG (1981) Acta Metall 29:1495

Soliman M, Mohamed FA (1984) Metall Mater Trans A 15:1893

Chaudhury P, Mohamed FA (1987) Metall Mater Trans A 18:2105

Chaudhury P, Mohamed FA (1988) Mater Sci Eng A 101:13

Mohamed FA, Langdon TG (1975) Acta Metall 23:117

Mohamed FA, Shei SA, Langdon TG (1975) Acta Metall 23:1443

Mohamed FA, Langdon TG (1975) Philos Mag 32:697

Vale SH, Eastgate DJ, Hazzledine PM (1979) Scr Metall 13:1157

Chaudhury PK, Mohamed FA (1988) Acta Metall 36:1099

Yan S, Earthman JC, Mohamed FA (1994) Philos Mag A 69:1017

Bird JE, Mukherjee AK, Dorn JE (1969) In: Brandon DG, Rosen A (eds) Quantitative relation between properties and microstructure. Israel University Press, Jerusalem

Mohamed FA, Langdon TG (1974) Acta Mater 22:779

Weertman J (1955) J Appl Phys 26:1213

Cannon WR, Sherby OD (1970) Metall Mater Trans B 1:1030

Mohamed FA, Langdon TG (1974) J Appl Phys 45:1965

Weertman J (1957) J Appl Phys 28:1185

Soliman MS, Mohamed FA (1982) Mater Sci Eng 55:111

Soliman M, Ginter T, Mohamed FA (1983) Philos Mag 48:63

Goel A, Ginter T, Mohamed FA (1983) Metall Trans A 14:2309

Kassner ME, Perez-Prado MT (2004) Fundamentals of creep in metals and alloys, 1st edn. Elsevier, San Francisco

Ishikawa H, Mohamed FA, Langdon TG (1975) Philos Mag 32:1269

Mohamed FA (1983) J Mater Sci 18:582. doi:10.1007/BF00560647

Gifkins RC (1980) In: Paton NE, Hamilton CH (eds) Proceedings of a symposium on superplastic forming of structural alloys. Metallurgical Society of AIME, San Diego

Sherby OD, Wadsworth J (1989) Prog Mater Sci 33:169

Falk LKL, Howell PR, Dunlop GL, Langdon TG (1986) Acta Metall 34:1203

Valiev RZ, Langdon TG (1993) Acta Metall 3:949

Ball A, Hutchinson MM (1969) Met Sci 3:1

Mukherjee AK (1971) Mater Sci Eng 8:83

Gifkins RC (1976) Metall Mater Trans A 7:1225

Gittus JH (1977) J Eng Mater Technol 99:244

Paidar V, Takeuchi S (1992) Acta Metall Mater 40:1773

Friedel J (1964) Dislocations. Pergamon Press, Oxford

Rosler J, Arzt E (1990) Acta Metall Mater 38:671

Jiang X, Yang S, Earthman JC, Mohamed FA (1966) Metall Mater Trans A 27:863

Mohamed FA, Ahmed MI, Langdon TG (1977) Metall Mater Trans A 8:933

Mohamed FA (1998) Mater Sci Eng A A245:242

Gleiter H, Chalmers B (1972) Prog Mater Sci 16:1

Frost HJ, Ashby MF (1982) Deformation mechanism maps: the plasticity and creep of metals and ceramics. Pergamon Press, Oxford

Langdon TG, Mohamed FA (1978) Mater Sci Eng 32:103

Acknowledgements

This study was supported in part by the National Science foundation under Grant number DMR-0702978. The authors affiliated with U.C. Davis gratefully acknowledge The Office of Naval Research (Contract No. ONR N00014-03-C-0163 and ONR N00014-12-C-0241) for funding to produce the material. Thanks are due to my graduate student, Ming-je Sung, for his assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abdu, M.T., Dheda, S.S., Lavernia, E.J. et al. Creep and microstructure in ultrafine-grained 5083 Al. J Mater Sci 48, 3294–3303 (2013). https://doi.org/10.1007/s10853-012-7115-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7115-6