Abstract

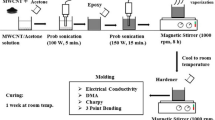

This study reports on the results of plasma-treated carbon nanotubes (CNTs) in the presence of oxygen and ammonia which can be scaled up for relatively large quantities of nanomaterials. The plasma treatment has been shown to change the surface chemistry and energy as well as the morphology of the carbon nanotubes. X-ray photoelectron spectroscopy analysis shows increases in oxygen and nitrogen groups on the oxygen- and ammonia-treated CNTs, respectively. Titration of the enhanced oxygen plasma-treated CNTs reveals an increased presence of carboxylic acid groups at 2.97 wt% whilst bulk density decreases from 151 kg/m3 for untreated carbon nanotubes to 76 kg/m3 after the enhanced oxygen treatment. The free surface energy has also been shown to increase from 33.70 up to 53.72 mJ/m2 determined using a capillary rise technique. The plasma-treated carbon nanotubes have been mixed in epoxy and have shown an improvement in dispersion, which was quantitatively evaluated using an optical coherence tomography (OCT) technique shown to be suitable for nanocomposite characterisation. This research has demonstrated that it is possible to surface functionalise large quantities of carbon nanotubes in a single process, and that this process improves the dispersion of the carbon nanotubes in epoxy.

Similar content being viewed by others

References

Gojny FH, Wichmann MH, Fiedler B, Schulte K (2005) Compos Sci Technol 65(1516):2300. doi:10.1016/j.compscitech.2005.04.021

Wang S, Liang Z, Liu T, Wang B, Zhang C (2006) Nanotechnology 17(6):1551. doi:10.1088/0957-4484/17/6/003

Zhu J, Kim J, Peng H, Margrave JL, Khabashesku VN, Barrera EV (2003) Nano Lett 3(8):1107. doi:10.1021/nl0342489

Ma PC, Siddiqui NA, Marom G, Kim JK (2010) Compos Part A 41(10):1345. doi:10.1016/j.compositesa.2010.07.003

Kim SD, Kim JW, Im JS, Kim YH, Lee YS (2007) J Fluorine Chem 128(1):60. doi:10.1016/j.jfluchem.2006.10.010

Kim YJ, Shin TS, Choi HD, Kwon JH, Chung YC, Yoon HG (2005) Carbon 43(1):23. doi:10.1016/j.carbon.2004.08.015

Hirsch A (2002) Angew Chem Int Ed 41(11):1853. doi:10.1002/1521-3773(20020603)41:111853::AID-ANIE18533.0.CO;2-N

Liu H, Cheng G, Zheng R, Zhao Y, Liang C (2005) J Mol Catal A 230(12):17. doi:10.1016/j.molcata.2004.12.003

Tkalya EE, Ghislandi M, de~With G, Koning CE (2012) Curr Opin Colloid Interface Sci 17(4): 225. doi:10.1016/j.cocis.2012.03.001

Kim KH, Jo WH (2008) Compos Sci Technol 68(9):2120. doi:10.1016/j.compscitech.2008.03.008

Loos M, Yang J, Feke D, Manas-Zloczower I (2012) Compos Sci Technol 72(4):482. doi:10.1016/j.compscitech.2011.11.034

Haggenmueller R, Rahatekar SS, Fagan JA, Chun J, Becker ML, Naik RR, Krauss T, Carlson L, Kadla JF, Trulove PC, Fox DF, DeLong HC, Fang Z, Kelley SO, Gilman JW (2008) Langmuir 24(9):5070. doi:http://pubs.acs.org/doi/abs/10.1021/la703008r.PMID:18442227

Wallace EJ, Sansom MSP (2009) Nanotechnology 20(4):045101. doi:10.1088/0957-4484/20/4/045101

Gong X, Liu J, Baskaran S, Voise RD, Young JS (2000) Chem Mater 12(4):1049. doi:10.1021/cm9906396

Moore VC, Strano MS, Haroz EH, Hauge RH, Smalley RE, Schmidt J, Talmon Y (2003) Nano Lett 3(10):1379. doi:10.1021/nl034524j

Krause B, Petzold G, Pegel S, Potschke P (2009) Carbon 47(3):602. doi:10.1016/j.carbon.2008.10.040

Vaisman L, Wagner HD, Marom G (2006) Adv Colloid Interface Sci 128–130:37. doi:10.1016/j.cis.2006.11.007

Rastogi R, Kaushal R, Tripathi S, Sharma AL, Kaur I, Bharadwaj LM (2008) J Colloid Interface Sci 328(2):421. doi:10.1016/j.jcis.2008.09.015

Wang H, Zhou W, Ho DL, Winey KI, Fischer JE, Glinka CJ, Hobbie EK (2004) Nano Lett 4(9):1789. doi:10.1021/nl048969z

Felten A, Bittencourt C, Pireaux JJ, Lier GV, Charlier JC (2005) J Appl Phys 98(7):074308. doi:10.1063/1.2071455

Ruelle B, Peeterbroeck S, Gouttebaron R, Godfroid T, Monteverde F, Dauchot JP, Alexandre M, Hecq M, Dubois P (2007) J Mater Chem 17:157. doi:10.1039/B613581C

Valentini L, Puglia D, Armentano I, Kenny J (2005) Chem Phys Lett 403(46):385. doi:10.1016/j.cplett.2005.01.042

Grasley ZC, Yazdanbakhsh A (2011) Compos Part A 42(12):2043. doi:10.1016/j.compositesa.2011.09.011

Tyson BM, Al-Rub RKA, Yazdanbakhsh A, Grasley Z (2011) Compos Part B 42(6):1395. doi:10.1016/j.compositesb.2011.05.020

Sul IH, Youn JR, Song YS (2011) Carbon 49(4):1473. doi:10.1016/j.carbon.2010.12.017

Koukoulas T, Broughton WR, Tedaldi M, Theobald PD (2011) Opt Meas Syst Indus Insp VII. doi:10.1117/12.889190

Siebold A, Walliser A, Nardin M, Oppliger M, Schultz J (1997) J Colloid Interface Sci 186(1):60. doi:10.1006/jcis.1996.4640

Shen Q, Mezgebe M, Li F, Dong JQ (2011) Colloids Surf A 390(13):212. doi:10.1016/j.colsurfa.2011.09.030

Mezgebe M, Shen Q, Zhang JY, Zhao YW (2012) Colloids Surf A 403(0):25. doi:10.1016/j.colsurfa.2012.03.045

Jackson P, Hunt J, Doherty P, Cannon A, Gilson P (2004) J Mater Sci: Mater Med 15:507. doi:10.1023/B:JMSM.0000021129.60818.ca

Washburn EW (1921) Phys Rev 17:273. doi:http://link.aps.org/doi/10.1103/PhysRev.17.273

Timmermans J (1950) In: Physico chemical constants of pure organic compounds. Elsevier, New York

Zenkiewicz M (2007) J Achiev Mater Manuf Eng 24:137

Fowkes FM (1964) Indus Eng Chem 56(12):40. doi:http://pubs.acs.org/doi/abs/10.1021/ie50660a008

Kukovecz A, Kanyo T, Konya Z, Kiricsi I (2005) Carbon 43(5):994. doi:10.1016/j.carbon.2004.11.030

Kim Y, Hayashi T, Fukai Y, Endo M, Yanagisawa T, Dresselhaus M (2002) Chem Phys Lett 355(34):279. doi:10.1016/S0009-2614(02)00248-8

Zapata-Massot C, Bolay NL (2008) Chem Eng Proc 47(8):1350. doi:10.1016/j.cep.2007.05.001

Acknowledgements

The authors would like to thank the Engineering and Physical Sciences Research Council (EPSRC) for supporting the Advanced Composites Centre for Innovation and Science (ACCIS) Doctoral Training Centre (DTC), grant number EP/G036772/1. We would also like to thank the Bristol Centre for Nanoscience and Quantum Information (NSQI) for the use of their specialist facilities in regards to handling and processing of the carbon nanotubes.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Williams, J., Broughton, W., Koukoulas, T. et al. Plasma treatment as a method for functionalising and improving dispersion of carbon nanotubes in epoxy resins. J Mater Sci 48, 1005–1013 (2013). https://doi.org/10.1007/s10853-012-6830-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6830-3