Abstract

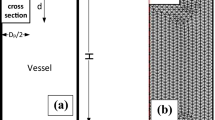

Sonication-assisted liquid-phase exfoliation of graphite makes facile, scalable, and low-cost graphene production possible, but there is little information about how sonication-related factors such as vessel diameter (D) and liquid height (H) affect this process and how to scale-up this technique. In this article, the dependence of the sonication-assisted few-layer graphene (FLG) production on D and H was investigated based on experiments and numerical simulation which was performed by finite element method to determine cavitation-related parameters. It was found that by essentially changing the cavitation phenomenon, D and H could critically affect the FLG concentration, FLG yield, injected power, and production efficiency. Combined experimental and simulational analyses reveal that though D and H can change both cavitation volume and cavitation volume fraction, it is the cavitation volume fraction that directly relates to the FLG concentration and production efficiency with a monotonically increasing trend, while the FLG yield and injected power are almost proportional to the cavitation volume, which in turn follows a linear increasing trend with the sample volume. The practical importance for industrial FLG production may lie in the following: (1) D and H should be carefully designed to obtain high cavitation volume fraction to gain high production efficiency and FLG concentration or output-input ratio and (2) large D, H, or sample volume is necessary for achieving large cavitation volume to enhance the FLG yield. Moreover, enhancement in pressure amplitude or cavitation intensity could also favor FLG production. These results have verified the importance of D and H which are often ignored when studying graphene production, and will provide important information on designing large-sized vessels for mass-producing graphene by sonication.

Similar content being viewed by others

References

Geim AK, Novoselov KS (2007) Nat Mater 6:183

Geim AK (2009) Science 324:1530

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2004) Science 306:666

Inagaki M, Kim YA, Endo M (2011) J Mater Chem 21:3280

Chung DDL (2002) J Mater Sci 37:1475. doi:10.1023/A:1014915307738

Choi W, Lahiri I, Seelaboyina R, Kang YS (2010) Crit Rev Solid State 35:52

Shao G, Lu Y, Wu F, Yang C, Zeng F, Wu Q (2012) J Mater Sci 47:4400. doi:10.1007/s10853-012-6294-5

Coleman JN (2009) Adv Funct Mater 19:1

Khvostikova O, Hermann H, Wendrock H, Gemming T, Thomas J, Ehrenberg H (2011) J Mater Sci 46:2422. doi:10.1007/s10853-010-5088-x

Cui X, Zhang C, Hao R, Hou Y (2011) Nanoscale 3:2118

Jang BZ, Zhamu A (2008) J Mater Sci 43:5092. doi:10.1007/s10853-008-2755-2

Liu WW, Wang JN (2011) Chem Commun 47:6888

Choi E-Y, Choi WS, Lee YB, Noh YY (2011) Nanotechnology 22:365601

Shih C-J, Vijayaraghavan A, Krishnan R et al (2011) Nat Nanotechnol 6:439

Li B, Zhong W-H (2011) J Mater Sci 46:5595. doi:10.1007/s10853-011-5572-y

Yoon S, In I (2011) J Mater Sci 46:1316. doi:10.1007/s10853-010-4917-2

Cravotto G, Cintas P (2010) Chem Eur J 16:5246

Skrabalak SE (2009) Phys Chem Chem Phys 11:4930

Cao JW, Lofaj F, Okada A (2001) J Mater Sci 36:1301. doi:10.1023/A:1004818901119

Torres-Sanchez C, Corney JR (2011) J Mater Sci 46:490. doi:10.1007/s10853-010-4944-z

Yi M, Li J, Shen Z, Zhang X, Ma S (2011) Appl Phys Lett 99:123112

Shen Z, Li J, Yi M, Zhang X, Ma S (2011) Nanotechnology 22:365306

Gogate PR, Tayal RK, Pandit AB (2006) Curr Sci India 91:35

Sutkar VS, Gogate PR (2009) Chem Eng J 155:26

Nanzai B, Okitsu K, Takenaka N, Bandow H, Tajima N, Maed Y (2009) Ultrason Sonochem 16:163

Kojima Y, Koda S, Nomura H (1998) Jpn J Appl Phys 37:2992

Asakura Y, Nishida T, Matsuoka T, Koda S (2008) Ultrason Sonochem 15:244

Khan U, O’Neill A, Lotya M, De S, Coleman JN (2010) Small 6:864

Nuvoli D, Valentini L, Alzari V, Scognamillo S, Bon SB, Piccinini M, Illescas J, Mariani A (2011) J Mater Chem 21:3428

Mason TJ, Lorimer JP, Bates DM (1992) Ultrasonics 30:40

Hernandez Y, Lotya M, Rickard D, Bergin SD, Coleman JN (2010) Langmuir 26:3208

Mason TJ, Lorimer JP (2002) Applied sonochemistry: uses of power ultrasound in chemistry and processing. Wiley–VCH, Weinheim

Koda S, Kimura T, Kondo T, Mitome H (2003) Ultrason Sonochem 10:149

Berlan J, Mason TJ (1992) Ultrasonics 30:203

Noltingk BE, Neppiras EA (1950) Proc Phys Soc B 63:674

Chen W, Gu C, Zhao K, Shen F (2006) J Mater Sci 41:2151. doi:10.1007/s10853-006-5209-8

Niemczewski B (1980) Ultrasonics 18:107

Herbert E, Balibar S, Caupin F (2006) Phys Rev E 74:041603

Acknowledgements

This work was supported by the Special Funds for Co-construction Project of Beijing Municipal Commission of Education, the “985” Project of Ministry of Education of China, and the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yi, M., Shen, Z., Zhang, X. et al. Vessel diameter and liquid height dependent sonication-assisted production of few-layer graphene. J Mater Sci 47, 8234–8244 (2012). https://doi.org/10.1007/s10853-012-6720-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6720-8