Abstract

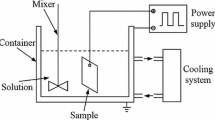

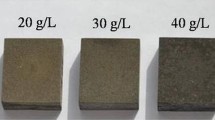

Micro-arc oxidation coatings were prepared on Ti6Al4V alloy in Na3PO4-based electrolyte with different additives such as FeSO4, Co(CH3COO)2, Ni(CH3COO)2, and K2ZrF6. The composition, structure, surface morphology, and chemical state of the coatings were characterized by X-ray diffraction, scanning electron microscopy, energy dispersive X-ray analysis system, and X-ray photoelectron spectroscopy, respectively. The spectral emissivity of the coating was measured by Fourier transform spectrometer apparatus. The bonding strength between the ceramic coating and substrate was studied by tensile strength test and shear strength test. The thermal shock resistance of the coatings was evaluated too. The results showed that the thermal emission of the coatings increased significantly with adding additives. The average spectral emissivity value of the coating with adding Co(CH3COO)2 is about 0.91 at wavelength of 3–20 μm. All the coatings showed a tensile strength higher than 30 MPa, and a shear strength higher than 10 MPa. In addition, after subjected to severe thermal shocking for 40 cycles, there was no peeling off of the coating occurred, the coatings possessed good thermal shock resistance.

Similar content being viewed by others

References

Padture NP, Gell M, Jordan EH (2002) Scinece 296:280

Naumenko D, Shemet V, Singheiser L, Quadakkers WJ (2009) J Mater Sci 44:1687. doi:10.1007/s10853-009-3284-3

Gleeson B, Mu N, Hayashi S (2009) J Mater Sci 44:1704. doi:10.1007/s10853-009-3251-z

Armelin E, Marti M, Liesa F, Iribarren JI, Aleman C (2010) Prog Org Coat 69:26

Brandt R, Bird C, Neuer G (2008) Measurement 41:731

He B, Li F, Zhou H, Dai YB, Sun BD (2008) J Mater Sci 43:893. doi:10.1007/s10853-007-2204-7

Zukerman I, Zhitomirsky VN, Yaakov GB, Boxman RL, Raveh A, Kim SK (2010) J Mater Sci 45:6379. doi:10.1007/s10853-010-4734-7

Yi J, He XD, Sun Y (2008) J Alloys Compd 416:L11

Alfano D, Scatteia L, Cantoni S, Balat-Pichelin M (2009) J Eur Ceram Soc 29:2045

Shin D, Gitzhofer F, Moreau C (2007) J Mater Sci 42:5915. doi:10.1007/s10853-007-1772-x

Wu XH, Qin W, Cui B, Jiang ZH, Lu WQ (2007) Int J Appl Ceram Technol 4(3):269

Park YJ, Shin KH, Song HJ (2007) Appl Surf Sci 253:6013

Li JX, Zhang YM, Han Y, Zhao YM (2010) Surf Coat Technol 204:1252

Wang YM, Guo LX, Ouyang JH, Zhou Y, Jia DC (2009) Appl Surf Sci 255:6875

Srinivasan PB, Liang J, Blawert C, Stormer M, Dietzel W (2010) J Mater Sci 45:1406. doi:10.1007/s10853-009-4093-4

Goueffon Y, Arurault L, Mabru C, Tonond C, Guigue P (2009) J Mater Process Technol 209:5145

Jin FY, Wang K, Zhu M, Shen LR, Li J, Hong HH, Chu PK (2009) Mater Chem Phys 114:398

Liu F, Xu JL, Yu DZ, Wang FP, Zhao LC (2010) Mater Chem Phys 121:172

Wang YL, Jiang ZH, Yao ZP (2009) Appl Surf Sci 256:650

Dai JM, Wang XB, Yuan GB (2005) J Phys Conf Ser 13:63

Yerokhin AL, Nie X, Leyland A, Matthews A, Dowey SJ (1999) Surf Coat Technol 122:73

Bayati MR, Moshfegh AZ, Golestani-Fard F (2010) Electrochim Acta 55:2760

Reddy BM, Reddy GK, Rao KN, Ganesh I, Ferreira JMF (2009) J Mater Sci 44:4874. doi:10.1007/s10853-009-3743-x

Liang J, Hu LT, Hao JC (2007) Electrochim Acta 52:4836

Kok WH, Sun X, Shi L, Wong K, Mitchell KAR, Foster T (2001) J Mater Sci 36:3941. doi:10.1023/A:1017970205276

Han ZY, Zhang JC, Yang XY, Zhu H, Cao WL (2010) J Mater Sci 45:3866. doi:10.1007/s10853-010-4442-3

Desai JD, Pathan HM, Min SK, Jung KD, Joo OS (2005) Appl Surf Sci 252:1870

Foelske A, Strehblow HH (2002) Surf Interface Anal 34:125

Wang Y, Sun L, Kong LG, Kang JF, Zhang X, Han RQ (2006) J Alloys Compd 423:256

Tan L, Crone WC (2002) Acta Mater 50:4449

Bakar WAWA, Othman MY, Ali R, Yong CK (2009) Catal Lett 128:127

Zhang XT, Zhang RH, Hu SM, Liu T (2007) J Mater Sci 42:5632. doi:10.1007/s10853-006-0746-8

Sun CW, Hui R, Qu W, Yick S, Sun C, Qian WM (2010) J Mater Sci 45:6235. doi:10.1007/s10853-010-4718-7

Shen DJ, Wang YL, Nash P, Xing GZ (2008) J Mater Process Technol 205:477

Campo LD, Perez-Saez RB, Gonzolez-Fernandez L, Esquisabel X, Fernondez I, Gonzalez-Martind P, Tello MJ (2010) J Alloys Compd 489:482

Paternoster C, Fabrizi A, Cecchini R, Mehtedi ME, Choquet P (2008) J Mater Sci 43:3377. doi:10.1007/s10853-007-2392-1

Wen CD, Mudawar I (2005) J Heat Mass Transf 48:1316

Ziegler M, Tomm JW, Elsaesser T, Monte C, Hollandt J, Kissel H, Biesenbach J (2008) J Appl Phys 103:104508

Alaruri SD, Bianchini L, Brewington A, Jilg T, Belcher B (1996) Opt Eng 35:2736

Ferguson LG, Dogan F (2001) Mater Sci Eng B 83:35

Smith GB, Gentle A, Swift PD, Earp A, Mronga N (2003) Sol Energy Mater Sol Cells 79:179

Cockeram BV, Measures DP, Mueller AJ (1999) Thin Solid Films 355–336:17

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, H., Sun, Q., Yi, C.G. et al. High emissivity coatings on titanium alloy prepared by micro-arc oxidation for high temperature application. J Mater Sci 47, 2162–2168 (2012). https://doi.org/10.1007/s10853-011-6017-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-6017-3