Abstract

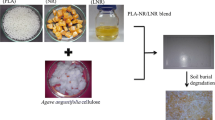

Fast and facile preparation of composite films containing natural rubber and Eucalyptus cellulose microfiber was achieved by the addition of carboxyl methyl cellulose to yield advantage properties such as chemical resistance, biodegradability and excellent tensile strength. It was found that carboxyl methyl cellulose can be employed as pre-agglomeration stabilizer to obtain high dispersion of hydrophilic cellulose fibers in hydrophobic natural rubber latex. The incorporation of cellulose fibers into the natural rubber matrix significantly improved the crystallinity of the composite films. At the highest loading content of cellulose at 50% w/w, the uptake toluene of the film was reduced to only 5%, whereas its tensile strength was increased to 100 times higher than the neat rubber film. Thermal stability was decreased slightly, depending on cellulose fiber loading content, but the glass transition temperature remained constant at about − 64 °C. According to the hydrophilic nature of cellulose, the water absorption capacity and water vapor transmission of the composite films were enhanced. In addition, it was shown that the biodegradability was considerably improved; the composite films degraded sufficiently in soil within 2 weeks.

Similar content being viewed by others

References

Abraham E, Deepa B, Pothan LA, John M, Narine SS, Thomas S, Anandjiwala R (2013) Physicomechanical properties of nanocomposites based on cellulose nanofibre and natural rubber latex. Cellulose 20(1):417–427. https://doi.org/10.1007/s10570-012-9830-1

Agarwal S (2020) Biodegradable polymers: present opportunities and challenges in providing a microplastic-free environment. Macromol Chem Phys 221(6):2000017. https://doi.org/10.1002/macp.202000017

Agrebi F, Ghorbel N, Bresson S, Abbas O, Kallel A (2019) Study of nanocomposites based on cellulose nanoparticles and natural rubber latex by ATR/FTIR spectroscopy: the impact of reinforcement. Polym Compos. https://doi.org/10.1002/pc.24989

Ali Shah A, Hasan F, Shah Z, Kanwal N, Zeb S (2013) Biodegradation of natural and synthetic rubbers: a review. Int Biodeter Biodegr 83:145–157. https://doi.org/10.1016/j.ibiod.2013.05.004

Bode HB, Kerkhoff K, Jendrossek D (2001) Bacterial degradation of natural and synthetic rubber. Biomacromol 2(1):295–303. https://doi.org/10.1021/bm005638h

Bras J, Hassan ML, Bruzesse C, Hassan EA, El-Wakil NA, Dufresne A (2010) Mechanical, barrier, and biodegradability properties of bagasse cellulose whiskers reinforced natural rubber nanocomposites. Ind Crop Prod 32(3):627–633. https://doi.org/10.1016/j.indcrop.2010.07.018

Brodhagen M, Peyron M, Miles C, Inglis DA (2015) Biodegradable plastic agricultural mulches and key features of microbial degradation. Appl Microbiol Biotechnol 99(3):1039–1056. https://doi.org/10.1007/s00253-014-6267-5

Cherian S, Ryu SB, Cornish K (2019) Natural rubber biosynthesis in plants, the rubber transferase complex, and metabolic engineering progress and prospects. Plant Biotechnol J 17(11):2041–2061. https://doi.org/10.1111/pbi.13181

Ferronato N, Torretta V (2019) Waste mismanagement in developing countries: a review of global issues. Int J Env Res Public Health. https://doi.org/10.3390/ijerph16061060

Flauzino Neto WP, Mariano M, da Silva ISV, Silvério HA, Putaux J-L, Otaguro H, Pasquini D, Dufresne A (2016) Mechanical properties of natural rubber nanocomposites reinforced with high aspect ratio cellulose nanocrystals isolated from soy hulls. Carbohydr Polym 153:143–152. https://doi.org/10.1016/j.carbpol.2016.07.073

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21(2):885–896. https://doi.org/10.1007/s10570-013-0030-4

Gleadall A (2015) 9: Mechanical properties of biodegradable polymers for medical applications. In: Pan J (ed) Modelling degradation of bioresorbable polymeric medical devices. Woodhead Publishing, United Kingdom, pp 163–199

Heinze T, Koschella A (2005) Carboxymethyl ethers of cellulose and starch: a review. Macromol Syst 223(1):13–40. https://doi.org/10.1002/masy.200550502

Holtzapple MT (2003) Cellulose. In: Caballero B (ed) Encyclopedia of food sciences and nutrition, 2nd edn. Academic Press, Oxford, pp 998–1007

Huang H, He P, Hu N, Zeng Y (2003) Electrochemical and electrocatalytic properties of myoglobin and hemoglobin incorporated in carboxymethyl cellulose films. Bioelectrochemistry 61(1):29–38. https://doi.org/10.1016/S1567-5394(03)00057-4

Ilyas RA, Sapuan SM, Sanyang ML, Ishak MR, Zainudin ES (2018) Nanocrystalline cellulose as reinforcement for polymeric matrix nanocomposites and its potential applications: a review. Curr Anal Chem 14(3):203–225. https://doi.org/10.2174/1573411013666171003155624

Imre B, Pukánszky B (2013) Compatibilization in bio-based and biodegradable polymer blends. Eur Polym J 49(6):1215–1233. https://doi.org/10.1016/j.eurpolymj.2013.01.019

Jayathilaka LPI, Ariyadasa TU, Egodage SM (2020) Development of biodegradable natural rubber latex composites by employing corn derivative bio-fillers. J Appl Polym Sci 137(40):49205. https://doi.org/10.1002/app.49205

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Edit 44(22):3358–3393. https://doi.org/10.1002/anie.200460587

Mariano M, El Kissi N, Dufresne A (2016) Cellulose nanocrystal reinforced oxidized natural rubber nanocomposites. Carbohydr Polym 137:174–183. https://doi.org/10.1016/j.carbpol.2015.10.027

Nawamawat K, Sakdapipanich JT, Ho CC, Ma Y, Song J, Vancso JG (2011) Surface nanostructure of Hevea brasiliensis natural rubber latex particles. Colloids Surf Physicochem Eng Asp 390(1):157–166. https://doi.org/10.1016/j.colsurfa.2011.09.021

Nawong C, Umsakul K, Sermwittayawong N (2018) Rubber gloves biodegradation by a consortium, mixed culture and pure culture isolated from soil samples. Braz J Microbiol 49(3):481–488. https://doi.org/10.1016/j.bjm.2017.07.006

Phomrak S, Phisalaphong M (2017) Reinforcement of natural rubber with bacterial cellulose via a latex aqueous microdispersion process. J Nanomater 2017:4739793. https://doi.org/10.1155/2017/4739793

Rolere S, Liengprayoon S, Vaysse L, Sainte-Beuve J, Bonfils F (2015) Investigating natural rubber composition with Fourier Transform Infrared (FT-IR) spectroscopy: a rapid and non-destructive method to determine both protein and lipid contents simultaneously. Polym Test 43:83–93. https://doi.org/10.1016/j.polymertesting.2015.02.011

Rose K, Steinbüchel A (2005) Biodegradation of natural rubber and related compounds: recent insights into a hardly understood catabolic capability of microorganisms. Appl Environ Microbiol 71(6):2803–2812. https://doi.org/10.1128/AEM.71.6.2803-2812.2005

Sarkawi SS, Dierkes WK, Noordermeer JWM (2014) Elucidation of filler-to-filler and filler-to-rubber interactions in silica-reinforced natural rubber by TEM network visualization. Eur Polym J 54:118–127. https://doi.org/10.1016/j.eurpolymj.2014.02.015

Siró I, Plackett D (2010) Microfibrillated cellulose and new nanocomposite materials: a review. Cellulose 17(3):459–494. https://doi.org/10.1007/s10570-010-9405-y

Song JH, Murphy RJ, Narayan R, Davies GBH (2009) Biodegradable and compostable alternatives to conventional plastics. Philos T R Soc B 364(1526):2127–2139. https://doi.org/10.1098/rstb.2008.0289

Taokaew S, Phisalaphong M, Newby BMZ (2016) Bacterial cellulose: biosyntheses, modifications, and applications. Appl Environ Mater Sci Sustain. https://doi.org/10.4018/978-1-5225-1971-3.ch012

Taokaew S, Phisalaphong M (2018) Fabrication of gelatin complexes/bio-nanocellulose nanostructured composite mats. Mater Sci Forum 936:142–147

Thompson RC, Moore CJ, Saal FSV, Swan SH (2009) Plastics, the environment and human health: Current consensus and future trends. Philos T R Soc 364(1526):2153–2166. https://doi.org/10.1098/rstb.2009.0053

Valera-Zaragoza M, Yescas-Yescas A, Juarez-Arellano EA, Aguirre-Cruz A, Aparicio-Saguilán A, Ramírez-Vargas E, Sepúlveda-Guzmán S, Sánchez-Valdes S (2014) Immobilization of TiO2 nanoparticles on montmorillonite clay and its effect on the morphology of natural rubber nanocomposites. Polym Bull 71(6):1295–1313. https://doi.org/10.1007/s00289-014-1123-4

Yao W, Weng Y, Catchmark JM (2020) Improved cellulose X-ray diffraction analysis using Fourier series modeling. Cellulose 27(10):5563–5579. https://doi.org/10.1007/s10570-020-03177-8

Yu P, He H, Luo Y, Jia D, Dufresne A (2017) Reinforcement of natural rubber: the use of in situ regenerated cellulose from alkaline–urea–aqueous system. Macromolecules 50(18):7211–7221. https://doi.org/10.1021/acs.macromol.7b01663

Funding

This research was funded by the 90th Anniversary of Chulalongkorn University Fund (Ratchadaphiseksomphot Endowment Fund). The authors also acknowledge the support from The Thailand Research Fund, TRF (RGU62).

Author information

Authors and Affiliations

Contributions

Conceptualization: MP and GS; methodology: MP and GS; validation: MP and ST; formal analysis: GS; investigation: MP and GS; resources: MP; data curation: GS; writing—original draft preparation: GS; writing—review and editing: MP and ST; supervision: MP; project administration: MP; funding acquisition: MP.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical approval

This paper does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Supanakorn, G., Taokaew, S. & Phisalaphong, M. Ternary composite films of natural rubber, cellulose microfiber, and carboxymethyl cellulose for excellent mechanical properties, biodegradability and chemical resistance. Cellulose 28, 8553–8566 (2021). https://doi.org/10.1007/s10570-021-04082-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-021-04082-4