Abstract

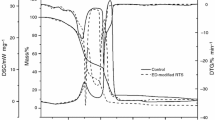

Addition of precipitated calcium carbonate (PCC) to cellulosic products can reduce production costs and modify their physical properties. This study investigated the effects of adding PCC on the properties of reconstituted tobacco sheet (RTS), a cellulosic product. Scanning electron microscopy (SEM) analysis showed that adding PCC to the coating could modify the surface microstructure of RTS. With increasing PCC addition, the strength and tar release per cigarette of RTS decreased. However, the filling capacity, bulk, and CO release content in the mainstream smoke reached optimal values when the proportion of PCC in the coating was 8%. Thermogravimetry (TG) and differential thermogravimetry (DTG) analysis indicated that the main thermal pyrolysis stage occurred in the range of 200–400 °C, similar to cellulosic components. The Coats–Redfern equation was used to analyze the thermal pyrolysis mechanism. The fitting results showed that, in the range of 200–280 °C, the best fit model for RTS with 4 or 8% PCC was diffusion-controlled reaction (D1) with fitting correlation coefficient (r 2) of 0.9630 and 0.9576, respectively. Meanwhile, in the range of 280–400 °C, the most reliable fitting model for RTS with 4% PCC was chemical reaction (F2) with r 2 = 0.9681. One reaction model could not describe the thermal pyrolysis of RTS with 12% PCC in the main decomposition stage. The thermal kinetic parameters suggested that addition of PCC to RTS coatings could modify the thermal pyrolysis mechanism, but did not change the peak temperatures in the main thermal decomposition stage. This study demonstrates that addition of PCC to RTS coating is a promising method to improve its quality.

Similar content being viewed by others

Abbreviations

- PCC:

-

Precipitated calcium carbonate

- RTS:

-

Reconstituted tobacco sheet

References

Ceylan S, Topcu Y, Ceylan Z (2014) Thermal behaviour and kinetics of alga Polysiphonia elongata biomass during pyrolysis. Bioresour Technol 171:193–198

Chandra RP, Lehtonen LK, Ragauskas AJ (2004) Modification of high lignin content kraft pulps with laccase to improve paper strength properties. 1. Laccase treatment in the presence of gallic acid. Biotechnol Progr 20(1):255–261

Chen M, Xu Z, Chen G, Ge S, Yin C, Zhou Z, Sun W, Li Y, Zhong F (2014a) The generation of carbon monoxide and carbonyl compounds in reconstituted tobacco sheet. J Therm Anal Calorim 115(1):961–970

Chen M, She S, Xu Z, Yin C, Zhou Z, Sun W, Li Y, Zhong F (2014b) Effect of exogenous softwood on thermal decomposition of reconstituted tobacco sheet. J Therm Anal Calorim 117(2):893–900

Eriksson M, Notley SM, Wågberg L (2005) The influence on paper strength properties when building multilayers of weak polyelectrolytes onto wood fibres. J Colloid Interface Sci 292(1):38–45

Gao W, Chen K, Xiang Z, Yang F, Zeng J, Li J, Yang R, Rao G, Tao H (2013) Kinetic study on pyrolysis of tobacco residues from the cigarette industry. Ind Crop Prod 44:152–157

Gao W, Chen K, Yang R, Yang F (2014) Rheological property of reconstituted tobacco coatings. Ind Crop Prod 60:45–51

Gao W, Chen K, Yang R, Yang F (2015) Process for coating of reconstituted tobacco sheet with citrates. J Anal Appl Pyrol 114:138–142

Ge S, Xu Y, Tian Z, Zhou S, She S, Hu Y, Sheng L (2013) Effect of urea phosphate on thermal decomposition of reconstituted tobacco and CO evolution. J Anal Appl Pyrol 99:178–183

Green CR, Schumacher JN, Lloyd R, Rodgman A (2007) Comparisons of the composition of tobacco smoke and the smokes from various tobacco substitutes. Beiträge zur Tabakforschung/Contributions to Tobacco Research 22(4):258–289

Holik H (2006) Handbook of paper and board. Wiley, New York

Kelly TK, Savitz DA (1976) Extruded tobacco sheet. US Patent 3968804

Kumar A, Gomes J (2001) Method and apparatus for producing reconstituted tobacco sheets. US Patent 6216706

McAdam K, Gregg E, Liu C, Dittrich D, Duke M, Proctor C (2011) The use of a novel tobacco-substitute sheet and smoke dilution to reduce toxicant yields in cigarette smoke. Food Chem Toxicol 49(8):1684–1696

Nellen WJ (1985) Tobacco product with high filling power and process of making same. US Patent 4497331

Potts RJ, Bombick BR, Meckley DR, Ayres PH, Pence DH (2010) A summary of toxicological and chemical data relevant to the evaluation of cast sheet tobacco. Exp Toxicol Pathol 62(2):117–126

Sánchez-Jiménez PE, Pérez-Maqueda LA, Perejón A, Pascual-Cosp J, Benítez-Guerrero M, Criado JM (2011) An improved model for the kinetic description of the thermal degradation of cellulose. Cellulose 18(6):1487–1498

Shen J, Song Z, Qian X, Liu W (2009) Modification of papermaking grade fillers: a brief review. BioResources 4(3):1190–1209

Shen J, Li J, Qian X, Ren W, Fatehi P (2014) A review on engineering of cellulosic cigarette paper to reduce carbon monoxide delivery of cigarettes. Carbohyd Polym 101:769–775

Sung YJ, Seo YB (2009) Thermogravimetric study on stem biomass of Nicotiana tabacum. Thermochim Acta 486(1):1–4

Wang W, Wang Y, Yang L, Liu B, Lan M, Sun W (2005) Studies on thermal behavior of reconstituted tobacco sheet. Thermochim Acta 437(1):7–11

Wang L, Wen YB, Sun DP, Mao Y, Yao YJ (2011) Study on the decrease of harmful substance in paper-process reconstituted tobacco sheet. Adv Mater Res 314:2338–2343

Wang J, Qiu Y, Liu J (2012) Study on physical and chemical properties of domestic and imported paper-process reconstituted tobacco. Adv Mater Res 356:1984–1999

Wanna J, Hicks D, Monsalud L, Mua J-P (2004) Modified reconstituted tobacco sheet. US Patent 20050056294

Wochnowski W, Forster H, Koehn J, Hohm R (1976) Method and apparatus for changing the moisture content of tobacco. US Patent 3948277

Xiang Z, Runge T (2014) Co-production of feed and furfural from dried distillers’ grains to improve corn ethanol profitability. Ind Crop Prod 55:207–216

Xiang Z, Runge T (2016) Emulsifying properties of succinylated arabinoxylan-protein gum produced from corn ethanol residuals. Food Hydrocolloid 52:423–430

Xiang Z, Anthony R, Lan W, Runge T (2016) Glutaraldehyde crosslinking of arabinoxylan produced from corn ethanol residuals. Cellulose 23(1):307–321

Zhao D, Chen K, Yang F, Feng GL, Sun Y, Dai Y (2013) Thermal degradation kinetics and heat properties of cellulosic cigarette paper: influence of potassium carboxylate as combustion improver. Cellulose 20(6):3205–3217

Zhong W, Zhu C, Shu M, Sun K, Zhao L, Wang C, Ye Z, Chen J (2010) Degradation of nicotine in tobacco waste extract by newly isolated Pseudomonas sp. ZUTSKD. Bioresour Technol 101(18):6935–6941

Zhou S, Ning M, Xu Y, Hu Y, Shu J, Wang C, Ge S, Tian Z, She S, He Q (2013) Thermal degradation and combustion behavior of reconstituted tobacco sheet treated with ammonium polyphosphate. J Anal Appl Pyrol 100:223–229

Acknowledgments

This work was supported by the National Natural Science Foundation of China (31400512) and the Foundation of the Key Laboratory of Pulp and Paper Science and Technology of Ministry of Education/Shandong Province of China (KF201613).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gao, W., Chen, K. Physical properties and thermal behavior of reconstituted tobacco sheet with precipitated calcium carbonate added in the coating process. Cellulose 24, 2581–2590 (2017). https://doi.org/10.1007/s10570-017-1270-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1270-5