Abstract

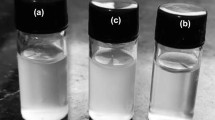

Nanocrystalline cellulose (NCC) was extracted from microcrystalline cellulose via low-intensity ultrasonic-assisted sulfuric acid hydrolysis process. NCC samples were characterized by scanning electron microscopy (SEM), transmission electron microscopy (TEM), particle size distribution (PSD) analysis, Fourier-transformed infrared spectra (FT-IR), X-ray diffraction (XRD), thermogravimetric analysis (TGA) and rheological measurement. It was found that NCC yield reached 40.4 % under the optimum process of low-intensity ultrasonic-assisted sulfuric acid hydrolysis, while it was only 33.0 % in the absence of ultrasonic treatment. Furthermore, the results showed that the two NCC samples obtained from ultrasonic-assisted hydrolysis and conventional hydrolysis were very similar in morphology, both exhibiting rod-like structures with widths and lengths of 10–20 and 50–150 nm, respectively. XRD result revealed that the NCC sample from ultrasonic-assisted hydrolysis contained a small amount of cellulose II and possessed a Segal Crystallinity Index of 90.38 % and a crystallite size of 58.99 Å, higher than those of the NCC sample from conventional hydrolysis. Moreover, PSD analysis demonstrated that the former exhibited a smaller value in average particle size than the latter. In addition, rheological measurements showed that the NCC suspensions from the ultrasonic-assisted process exhibited a lower viscosity over the range of shear rate from 0.1 to 100 s−1 in comparison with that prepared in the absence of ultrasonic treatment.

Similar content being viewed by others

References

Ahmadi F, McLoughlin IV, Chauhan S, Ter-Haar G (2012) Bio-effects and safety of low-intensity, low-frequency ultrasonic exposure. Prog Biophys Mol Biol 108(3):119–138

Bai W, Holbery J, Li K (2009) A technique for production of nanocrystalline cellulose with a narrow size distribution. Cellulose 16(3):455–465

Beck-Candanedo S, Roman M, Gray DG (2005) Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromolecules 6(2):1048–1054

Bondeson D, Mathew A, Oksman K (2006) Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 13(2):171–180

Brinchi L, Cotana F, Fortunati E, Kenny JM (2013) Production of nanocrystalline cellulose from lignocellulosic biomass: technology and applications. Carbohydr Polym 94(1):154–169

Cha R, He Z, Ni Y (2012) Preparation and characterization of thermal/pH-sensitive hydrogel from carboxylated nanocrystalline cellulose. Carbohydr Polym 88(2):713–718

Chen W, Yu H, Liu Y (2011a) Preparation of millimeter-long cellulose I nanofibers with diameters of 30–80 nm from bamboo fibers. Carbohydr Polym 86(2):453–461

Chen W, Yu H, Liu Y, Chen P, Zhang M, Hai Y (2011b) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr Polym 83(4):1804–1811

Chen W, Yu H, Liu Y, Hai Y, Zhang M, Chen P (2011c) Isolation and characterization of cellulose nanofibers from four plant cellulose fibers using a chemical-ultrasonic process. Cellulose 18(2):433–442

Chen P, Yu H, Liu Y, Chen W, Wang X, Ouyang M (2013) Concentration effects on the isolation and dynamic rheological behavior of cellulose nanofibers via ultrasonic processing. Cellulose 20(1):149–157

Cintas P, Luche J (1999) Green chemistry. The sonochemical approach. Green Chem 1(3):115–125

de Campos A, Correa AC, Cannella D, de Morais Teixeira E, Marconcini JM, Dufresne A, Mattoso LH, Cassland P, Sanadi AR (2013) Obtaining nanofibers from curauá and sugarcane bagasse fibers using enzymatic hydrolysis followed by sonication. Cellulose 20(3):1491–1500

de Morais Teixeira E, Corrêa AC, Manzoli A, de Lima LeiteF, de Oliveira CR, Mattoso LHC (2010) Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 17(3):595–606

Deepa B, Abraham E, Cherian BM, Bismarck A, Blaker JJ, Pothan LA, Leao AL, de Souza SF, Kottaisamy M (2011) Structure, morphology and thermal characteristics of banana nano fibers obtained by steam explosion. Bioresour Technol 102(2):1988–1997

Driemeier C, Calligaris GA (2010) Theoretical and experimental developments for accurate determination of crystallinity of cellulose I materials. J Appl Crystallogr 44(1):184–192

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux J, Heux L, Dubreuil F, Rochas C (2007) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromolecules 9(1):57–65

Eronen P, Österberg M, Heikkinen S, Tenkanen M, Laine J (2011) Interactions of structurally different hemicelluloses with nanofibrillar cellulose. Carbohydr Polym 86(3):1281–1290

Fan J, Li Y (2012) Maximizing the yield of nanocrystalline cellulose from cotton pulp fiber. Carbohydr Polym 88(4):1184–1188

Fatehi P, Liu X, Ni Y, Xiao H (2010) Interaction of cationic modified poly vinyl alcohol with high yield pulp. Cellulose 17(5):1021–1031

Filson PB, Dawson-Andoh BE (2009) Sono-chemical preparation of cellulose nanocrystals from lignocellulose derived materials. Bioresour Technol 100(7):2259–2264

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose. doi:10.1007/s10570-013-0030-4

French AD, Santiago Cintrón M (2013) Cellulose polymorphy, crystallite size, and the Segal Crystallinity Index. Cellulose 20(1):583–588

Hamad WY, Hu TQ (2010) Structure–process–yield interrelations in nanocrystalline cellulose extraction. Can J Chem Eng 88(3):392–402

Hamada H, Bousfield DW (2010) Nano-fibrillated cellulose as a coating agent to improve print quality of synthetic fiber sheets. In: TAPPI 11th advanced coating fundamentals symposium, Munich, TAPPI, Atlanta, GA, pp 7–16

Hashaikeh R, Abushammala H (2011) Acid mediated networked cellulose: preparation and characterization. Carbohydr Polym 83(3):1088–1094

Henriksson M, Henriksson G, Berglund LA, Lindström T (2007) An environmentally friendly method for enzyme-assisted preparation of microfibrillated cellulose (MFC) nanofibers. Eur Poly J 43(8):3434–3441

Ishida O, Kim D, Kuga S, Nishiyama Y, Brown RM (2004) Microfibrillar carbon from native cellulose. Cellulose 11(3–4):475–480

Jahan MS, Saeed A, He Z, Ni Y (2011) Jute as raw material for the preparation of microcrystalline cellulose. Cellulose 18(2):451–459

Johar N, Ahmad I, Dufresne A (2012) Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind Crop Prod 37(1):93–99

Klemm D, Schumann D, Udhardt U, Marsch S (2001) Bacterial synthesized cellulose—artificial blood vessels for microsurgery. Prog Polym Sci 26(9):1561–1603

Lam E, Male KB, Chong JH, Leung ACW, Luong JHT (2012) Applications of functionalized and nanoparticle-modified nanocrystalline cellulose. Trends Biotechnol 30(5):283–290

Langan P, Nishiyama Y, Chanzy H (2001) X-ray structure of mercerized cellulose II at 1 Å resolution. Biomacromolecules 2(2):410–416. doi:10.1021/bm005612q

Li J, Wei X, Wang Q, Chen J, Chang G, Kong L, Su J, Liu Y (2012) Homogeneous isolation of nanocellulose from sugarcane bagasse by high pressure homogenization. Carbohydr Polym 90(4):1609–1613

Li W, Yue J, Liu S (2012) Preparation of nanocrystalline cellulose via ultrasound and its reinforcement capability for poly(vinyl alcohol) composites. Ultrason Sonochem 19(3):479–485

Liu D, Chen X, Yue Y, Chen M, Wu Q (2011) Structure and rheology of nanocrystalline cellulose. Carbohydr Polym 84(1):316–322

Liu C, Xiao B, Dauta A, Peng G, Liu S, Hu Z (2009) Effect of low power ultrasonic radiation on anaerobic biodegradability of sewage sludge. Bioresour Technol 100(24):6217–6222

Lu P, Hsieh Y (2010) Preparation and properties of cellulose nanocrystals: rods, spheres, and network. Carbohydr Polym 82(2):329–336

Lu H, Gui Y, Zheng L, Liu X (2013) Morphological, crystalline, thermal and physicochemical properties of cellulose nanocrystals obtained from sweet potato residue. Food Res Int 50(1):121–128

Morais JPS, Rosa MDF, Nasciment LD, Nascimento DMD, Alexandre LC (2012) Extraction and characterization of nanocellulose structures from raw cotton linter. Carbohydr Polym 91(1):229–235

Morán JI, Alvarez VA, Cyras VP, Vázquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15(1):149–159

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 124(31):9074–9082

Nishiyama Y, Johnson GP, French AD (2012) Diffraction from nonperiodic models of cellulose crystals. Cellulose 19(2):319–336

Okahisa Y, Abe K, Nogi M, Nakagaito AN, Nakatani T, Yano H (2011) Effects of delignification in the production of plant-based cellulose nanofibers for optically transparent nanocomposites. Compos Sci Technol 71(10):1342–1347

Park S, Baker JO, Himmel ME, Parilla PA, Johnson DK (2010) Cellulose crystallinity index: measurement techniques and their impact on interpreting cellulase performance. Biotechnol Biofuels 3:1–10

Pirani S, Hashaikeh R (2012) Nanocrystalline cellulose extraction process and utilization of the byproduct for biofuels production. Carbohydr Polym 93(1):357–363

Pourbafarani S, Mozaffari M, Amighian J (2013) Investigation of phase formation and magnetic properties of Mn ferrite nanoparticles prepared via low-power ultrasonic assisted co-precipitation method. J Supercond Nov Magn 26(3):675–678

Qian L, Guan Y, Ziaee Z, He B, Zheng A, Xiao H (2009) Rendering cellulose fibers antimicrobial using cationic β-cyclodextrin-based polymers included with antibiotics. Cellulose 16(2):309–317

Qua EH, Hornsby PR, Sharma H, Lyons G (2011) Preparation and characterisation of cellulose nanofibres. J Mater Sci 46(18):6029–6045

Roman M, Winter WT (2004) Effect of sulfate groups from sulfuric acid hydrolysis on the thermal degradation behavior of bacterial cellulose. Biomacromolecules 5(5):1671–1677

Satyamurthy P, Jain P, Balasubramanya RH, Vigneshwaran N (2011) Preparation and characterization of cellulose nanowhiskers from cotton fibres by controlled microbial hydrolysis. Carbohydr Polym 83(1):122–129

Savadekar NR, Mhaske ST (2012) Synthesis of nano cellulose fibers and effect on thermoplastics starch based films. Carbohydr Polym 89(1):146–151

Scherrer P (1918) Bestimmung der Grösse und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachr Ges Wiss Göttingen 26:98–100

Sun XF, Xu F, Sun RC, Fowler P, Baird MS (2005) Characteristics of degraded cellulose obtained from steam-exploded wheat straw. Carbohydr Res 340(1):97–106

Tamada Y (2003) Sulfation of silk fibroin by sulfuric acid and anticoagulant activity. J App Poly Sci 87(14):2377–2382

Tang L, Huang B, Lu Q, Wang S, Ou W, Lin W, Chen X (2012) Ultrasonication-assisted manufacture of cellulose nanocrystals esterified with acetic acid. Bioresour Technol 127:100–105

Terinte N, Ibbett R, Schuster KC (2011) Overview on native cellulose and microcrystalline cellulose I structure studied by X-ray diffraction (WAXD): comparison between measurement techniques. Lenzingr Ber 89:118–131

Tischer PCF, Sierakowski MR, Westfahl H Jr, Tischer CA (2010) Nanostructural reorganization of bacterial cellulose by ultrasonic treatment. Biomacromolecules 11(5):1217–1224

Tonoli GHD, Teixeira EM, Corrêa AC, Marconcini JM, Caixeta LA, Pereira-da-Silva MA, Mattoso LHC (2012) Cellulose micro/nanofibres from Eucalyptus kraft pulp: preparation and properties. Carbohydr Polym 89(1):80–88

Torvinen K, Sievänen J, Hjelt T, Hellén E (2012) Smooth and flexible filler-nanocellulose composite structure for printed electronics applications. Cellulose 19(3):821–829

Urena-Benavides EE, Ao G, Davis VA, Kitchens CL (2011) Rheology and phase behavior of lyotropic cellulose nanocrystal suspensions. Macromolecules 44(22):8990–8998

Wang N, Ding E, Cheng R (2007) Thermal degradation behaviors of spherical cellulose nanocrystals with sulfate groups. Polymer 48(12):3486–3493

Wang N, Ding E, Cheng R (2008) Preparation and liquid crystalline properties of spherical cellulose nanocrystals. Langmuir 24(1):5–8

Yang Q, Pan X, Huang F, Li K (2011) Synthesis and characterization of cellulose fibers grafted with hyperbranched poly (3-methyl-3-oxetanemethanol). Cellulose 18(6):1611–1621

Zaman M, Liu H, Xiao H, Chibante F, Ni Y (2012a) Hydrophilic modification of polyester fabric by applying nanocrystalline cellulose containing surface finish. Carbohydr Polym 91(2):560–567

Zaman M, Xiao H, Chibante F, Ni Y (2012b) Synthesis and characterization of cationically modified nanocrystalline cellulose. Carbohydr Polym 89(1):163–170

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Grant No. 31100442), the Science and Technology Program of Hangzhou City of China (Grant No. 20120433B63), the Science and Technology Program of Zhejiang Environmental Protection Bureau of China (Grant No. 2012B008), Zhejiang Provincial Top Key Academic Discipline of Chemical Engineering and Technology and 521 Talent Cultivation Program of Zhejiang Sci-Tech University (Grant No. 11110132521310).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, Y., Yang, S., Zhang, N. et al. Preparation and characterization of nanocrystalline cellulose via low-intensity ultrasonic-assisted sulfuric acid hydrolysis. Cellulose 21, 335–346 (2014). https://doi.org/10.1007/s10570-013-0158-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-0158-2