Abstract

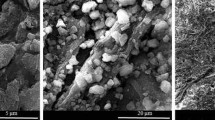

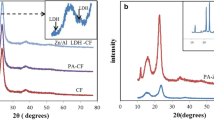

Handsheets with in situ generated cellulose nanoparticles were made from oxidized pulp fibers prepared by 2,2,6,6-tetramethylpiperidinyl-1-oxyl-mediated oxidation of kraft fiber with sodium hypochlorite and sodium bromide. The oxidized pulp fibers were blended prior to handsheet formation for short times (1–3 min). From gravimetric analysis of the supernatant, yield of cellulose nanoparticles generated from this blending process were up to 9.5 dry wt%. Scanning electron microscopy showed that the handsheets fabricated in a wetlay process had increased smoothness with increased blending time. A significant decrease in water vapor transmission rate for the sheets supported the hypothesis that cellulose nanoparticles fill the empty spaces between pulp fibers throughout the handsheet affording a more dense structure. Oxidation significantly enhanced the tensile index of the handsheets and this value was further improved by blending for 2 min. The handsheets were treated with a solution of octadecylamine (ODA) modifying the surface chemistry of the paper. Irreversibly adsorbed ODA on the oxidized cellulose surfaces after extensive extraction was confirmed by Fourier transform infrared spectroscopy and X-ray photoelectron spectroscopy. Sessile drop contact angle tests for modified handsheets illustrated its enhanced hydrophobicity with contact angles over 90°. Overall the study developed a novel route to make paper with enhanced functionality without the need to separately deposit nanocellulose onto the paper surface.

Similar content being viewed by others

References

Araki J, Wada M, Kuga S (2001) Steric stabilization of a cellulose microcrystal suspension by poly (ethylene glycol) grafting. Langmuir 17(1):21–27

Braun B, Dorgan JR (2008) Single-step method for the isolation and surface functionalization of cellulosic nanowhiskers. Biomacromolecules 10(2):334–341. doi:10.1021/bm8011117

DiFlavio J-L, Pelton R, Leduc M, Champ S, Essig M, Frechen T (2007) The role of mild TEMPO–NaBr–NaClO oxidation on the wet adhesion of regenerated cellulose membranes with polyvinylamine. Cellulose 14(3):257–268. doi:10.1007/s10570-006-9104-x

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45(1):1–33. doi:10.1007/S10853-009-3874-0

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux J-L, Heux L, Dubreuil F, Rochas C (2007) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromolecules 9(1):57–65

Eriksen O, Syverud K, Gregersen O (2008) The use of microfibrillated cellulose produced from kraft pulp as strength enhancer in TMP paper. Nord Pulp Pap Res J 23(3):299–304

Fujisawa S, Saito T, Isogai A (2012) Nano-dispersion of TEMPO-oxidized cellulose/aliphatic amine salts in isopropyl alcohol. Cellulose 19(2):459–466

Fujisawa S, Saito T, Kimura S, Iwata T, Isogai A (2013) Surface Engineering of Ultrafine Cellulose Nanofibrils toward Polymer Nanocomposite Materials. Biomacromolecules 14(5):1541–1546. doi:10.1021/bm400178m

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110(6):3479

Hu Y, Topolkaraev V, Hiltner A, Baer E (2001) Measurement of water vapor transmission rate in highly permeable films. J Appl Polym Sci 81(7):1624–1633. doi:10.1002/app.1593

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S (2003) A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 63(15):2223–2253. doi:10.1016/S0266-3538(03)00178-7

I’Anson SJ, Savani S, Sampson WW (2008) Density dependent influence of grammage on tensile properties of handsheets. J Pulp Pap 34(3):182–189

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3(1):71–85

Iwamoto S, Nakagaito AN, Yano H, Nogi M (2005) Optically transparent composites reinforced with plant fiber-based nanofibers. Appl Phys A Mater 81 (6):1109–1112. doi:10.1007/S00339-005-3316-Z

Jiang F, Han S, Hsieh Y-L (2013) Controlled defibrillation of rice straw cellulose and self-assembly of cellulose nanofibrils into highly crystalline fibrous materials. RSC Adv 3:12366–12375

Johansson L-S, Tammelin T, Campbell JM, Setala H, Osterberg M (2011) Experimental evidence on medium driven cellulose surface adaptation demonstrated using nanofibrillated cellulose. Soft Matter 7(22):10917–10924. doi:10.1039/C1SM06073B

Johnson RK, Zink-Sharp A, Renneckar SH, Glasser WG (2009) A new bio-based nanocomposite: fibrillated TEMPO-oxidized celluloses in hydroxypropylcellulose matrix. Cellulose 16(2):227–238. doi:10.1007/S10570-008-9269-6

Johnson RK, Zink-Sharp A, Glasser WG (2011) Preparation and characterization of hydrophobic derivatives of TEMPO-oxidized nanocelluloses. Cellulose 18(6):1599–1609

Katz SBR, Scallan AM (1984) The determination of strong and weak acidic groups in sulfite pulps. Svensk Papperstid 87(6):6

Li Q, Renneckar S (2009) Molecularly thin nanoparticles from cellulose: isolation of sub-microfibrillar structures. Cellulose 16(6):1025–1032

Li Z, Renneckar S, Barone JR (2010) Nanocomposites prepared by in situ enzymatic polymerization of phenol with TEMPO-oxidized nanocellulose. Cellulose 17(1):57–68

Li Q, McGinnis S, Sydnor C, Wong A, Renneckar S (2013) Nanocellulose life cycle assessment. ACS Sustain Chem Eng 1(18):919–928

Montibon E, Lestelius M, Jarnstrom L, Love KT (2010) Electroconductive paper—a study of polymer deposition and conductivity influenced by sheet forming and fibre beating. Nord Pulp Pap Res J 25(4):473–480

Moran JI, Alvarez VA, Cyras VP, Vazquez A (2008) Extraction of cellulose and preparation of nanocellulose from sisal fibers. Cellulose 15(1):149–159. doi:10.1007/S10570-007-9145-9

Morseburg K, Chinga-Carrasco G (2009) Assessing the combined benefits of clay and nanofibrillated cellulose in layered TMP-based sheets. Cellulose 16(5):795–806. doi:10.1007/S10570-009-9290-4

Saito T, Isogai A (2006) Introduction of aldehyde groups on surfaces of native cellulose fibers by TEMPO-mediated oxidation. Colloid Surf A 289(1–3):219–225. doi:10.1016/J.Colsurfa.2006.04.038

Saito T, Nishiyama Y, Putaux JL, Vignon M, Isogai A (2006) Homogeneous suspensions of individualized microfibrils from TEMPO-catalyzed oxidation of native cellulose. Biomacromolecules 7(6):1687–1691. doi:10.1021/Bm060154s

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8(8):2485–2491. doi:10.1021/Bm0703970

Salajkova M, Berglund LA, Zhou Q (2012) Hydrophobic cellulose nanocrystals modified with quaternary ammonium salts. J Mater Chem 22(37):19798–19805. doi:10.1039/C2JM34355J

Samyn P (2013) Wetting and hydrophobic modification of cellulose surfaces for paper applications. J Mater Sci 48(19):6455–6498. doi:10.1007/s10853-013-7519-y

Saxena A, Ragauskas AJ (2009) Water transmission barrier properties of biodegradable films based on cellulosic whiskers and xylan. Carbohydr Polym 78(2):357–360. doi:10.1016/J.Carbpol.2009.03.039

Saxena A, Elder TJ, Ragauskas AJ (2011) Moisture barrier properties of xylan composite films. Carbohydr Polym 84(4):1371–1377. doi:10.1016/J.Carbpol.2011.01.039

Syverud K, Stenius P (2009) Strength and barrier properties of MFC films. Cellulose 16(1):75–85. doi:10.1007/S10570-008-9244-2

Syverud K, Xhanari K, Chinga-Carrasco G, Yu Y, Stenius P (2011) Films made of cellulose nanofibrils: surface modification by adsorption of a cationic surfactant and characterization by computer-assisted electron microscopy. J Nanopart Res 13(2):773–782. doi:10.1007/s11051-010-0077-1

Taniguchi T, Okamura K (1998) New films produced from microfibrillated natural fibres. Polym Int 47(3):291–294. doi:10.1002/(Sici)1097-0126(199811)47:3<291:Aid-Pi11>3.0.Co;2-1

TAPPI TEST METHODS (1996). Tappi test methods. Tappi Press, Atlanta

Uetani K, Yano H (2011) Nanofibrillation of wood pulp using a high-speed blender. Biomacromolecules 12(2):348–353. doi:10.1021/Bm101103p

Wu C-N, Saito T, Fujisawa S, Fukuzumi H, Isogai A (2012) Ultrastrong and high gas-barrier nanocellulose/clay-layered composites. Biomacromolecules 13(6):1927–1932. doi:10.1021/bm300465d

Zhao HP, Feng XQ, Gao HJ (2007) Ultrasonic technique for extracting nanofibers from nature materials. Appl Phys Lett 90(7). doi:10.1063/1.2450666

Acknowledgments

Financial support for this work was provided by the United States Department of Agriculture National Institute of Food and Agriculture (USDA NIFA) grant 2010-65504-20429 and USDA NIFA 2010-34489-20784 that funds the Biobased Sustainable Materials as Resources for Tomorrow (BSMART) program and the Sustainable Engineered Materials Institute (SEMI), respectfully. Additional support was provided by Virginia Tech’s Interdisciplinary Graduate Education Program for Sustainable Nanotechnology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, W., Johnson, R.K., Lin, Z. et al. In situ generated cellulose nanoparticles to enhance the hydrophobicity of paper. Cellulose 20, 2935–2945 (2013). https://doi.org/10.1007/s10570-013-0062-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-0062-9