Abstract

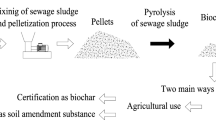

The huge amounts of sewage sludge produced by municipal wastewater treatment plants induce major environmental and economical issues, calling for advanced disposal methods. Traditional methods for sewage sludge disposal increase greenhouse gas emissions and pollution. Moreover, biochar created from sewage sludge often cannot be used directly in soil applications due to elevated levels of heavy metals and other toxic compounds, which alter soil biota and earthworms. This has limited the application of sewage sludge-derived biochar as a fertilizer. Here, we review biomass and sewage sludge co-pyrolysis with a focus on the stabilization of heavy metals and toxicity reduction of the sludge-derived biochar. We observed that co-pyrolyzing sewage sludge with biomass materials reduced heavy metal concentrations and decreased the environmental risk of sludge-derived biochar by up to 93%. Biochar produced from sewage sludge and biomass co-pyrolysis could enhance the reproduction stimulation of soil biota by 20‒98%. Heavy metals immobilization and transformation are controlled by the co-feed material mixing ratio, pyrolysis temperature, and pyrolysis atmosphere.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

There is a global increase in the amount of sewage sludge produced from municipal wastewater treatment plants because of the rapid growth in global population (Mohamed and Li 2022). Existing conventional management methods for the disposal and reuse of sewage sludge include composting, landfilling, and soil application (Buonocore et al. 2018; Alvarado et al. 2020; Morin-Crini et al. 2022). The conventional methods, however, have several environmental and safety concerns and thus contribute remarkably to secondary contamination and increase greenhouse gas emissions (Buonocore et al. 2018; Liu et al. 2021b; Huang et al. 2022). Furthermore, sewage sludge derived from wastewater contains elevated amounts of contaminants such as heavy metals (Zhang et al. 2023), microplastics (Khan et al. 2022; Stang et al. 2022), and emerging contaminants (Mohamed et al. 2022a), which cannot be completely removed by conventional management methods (Crini and Lichtfouse 2019; Padervand et al. 2020; Crini et al. 2022; Morin-Crini et al. 2022). Thus, researchers have embarked on the investigation of alternative methods that can alleviate the limitations and disadvantages of conventional sewage sludge management methods. Pyrolysis has been proposed as a potentially efficient and feasible treatment and disposal alternative for municipal sewage sludge (Leng et al. 2020; Huang et al. 2022; Mohamed et al. 2022b). During the pyrolysis process, non-condensable gases, bio-oil and biochar, are generated (Leng et al. 2022), thus avoiding the creation of secondary toxic contaminants (Mohamed et al. 2020, 2021a; Abou Rjeily et al. 2021; Suresh et al. 2021; Zhao et al. 2022). The transformation of biomass waste into biochar has several agronomic and environmental advantages.

Several studies found that biochar application in soil would neutralize soil acidity, improve water and nutrient retention and soil cation exchange capacity, and immobilize heavy metals and other organic contaminants (Bolan et al. 2014; Mohamed et al. 2016, 2017, 2021b, 2022b). Sludge-derived biochar, however, should not be used directly in soil applications because of the high heavy metal content that may pose high environmental risks as a result of soil and groundwater contamination (Wang et al. 2019b, 2020). Therefore, alternate technologies that could reduce heavy metals in sludge-derived biochar should be developed and investigated. Co-pyrolysis is a novel environmental technology, which can generate syngas that is rich in hydrogen and reduce the concentrations of heavy metals in the produced biochar (Ahmed et al. 2020; Zhang et al. 2021; Su et al. 2022). Several studies have focused on the role of sewage sludge co-pyrolysis in reducing the environmental risk of the sludge-derived biochar, and the transformation and migration behavior of heavy metals during the process (Liu et al. 2017; Leng et al. 2018; Min et al. 2022). Nevertheless, no review articles discussing the advances of sewage sludge co-pyrolysis and the role of the process in reducing biochar toxicity have been published. We review the co-pyrolysis of sewage sludge with waste biomass to produce high-quality biochar with reduced contaminant levels and understand the mechanisms of different approaches for reducing toxicity of sludge-derived biochar. Overall, our review contributes toward improving our understanding of sewage sludge co-pyrolysis technologies and provide important information for selecting the appropriate co-feed material for co-pyrolysis process.

Factors affecting heavy metals stabilization in biochar

Heavy metals in sewage sludge can be partitioned during pyrolysis into syngas, bio-oil, and biochar, and heavy metal transformation is mostly determined by the pyrolysis working parameters and metal forms. Recent research has shown that when the temperature higher than 600 °C, for instance, cadmium (Cd), can be volatilized into syngas and bio-oil. However, following the pyrolysis of sewage sludge at a moderate temperature, over 90% of other heavy metals will be remained in the biochar (Jin et al. 2017; Yang et al. 2021; Wang et al. 2022). Therefore, pyrolysis conditions, including temperature and atmosphere, play an important role in determining the distribution of heavy metals. Overall, heavy metals distribution can be affected by the co-feed material mixing ratio, pyrolysis temperature, and pyrolysis atmosphere.

Effect of the biomass mixing ratio

Several studies reported that the mixing ratio of the co-feed material plays a key role in reducing heavy metal concentrations and the toxicity of the produced biochars compared with biochar produced from sewage sludge singular pyrolysis (Kończak et al. 2019; Wang et al. 2019b). An adequate ratio of willow with sewage sludge during co-pyrolysis is necessary to reduce heavy metals content since a small amount of biomass will minimize the 'dilution effect' for heavy metals in the produced biochars (Kończak and Oleszczuk 2020). Note that at low willow to sewage sludge ratios, the effect of the reduced bioavailable proportion of heavy metals was also substantial (Kończak and Oleszczuk 2020). Wang et al. (2019a, b) found that, in addition to the effect of reducing heavy metal contents, the amount of metal leaching from biochar was also influenced by biomass quantity (Wang et al. 2019b). Lowering heavy metals leaching rate was further enhanced as willow mixing ratios increase (Kończak and Oleszczuk 2020). Increasing the amount of biomass during sewage sludge co-pyrolysis results in improved metal transformations from mobile forms to more stable fractions, indicating possible decreases in possible environmental risks resulting from heavy metals elevated concentrations in sewage sludge biochars.

Biomass incorporation with sewage sludge has synergistic effects on heavy metal immobilization during sewage sludge co-pyrolysis with biomass (Table 1). Wang and co-workers found that pyrolyzing sewage sludge with food waste digestate reduced the ecological risk assessment of the heavy metals in biochars obtained from sewage sludge co-pyrolysis compared with the biochar produced from single pyrolysis (Wang et al. 2022). The reduced ecological risk was due to the increase in the formation of more stable chemical fraction, including oxidizable fraction (F3), and residual fraction (F4), and the formations of residual fractions and oxidizable fractions increase with the increase in the mixing ratio of food waste digestate (Wang et al. 2022). Similarly, co-pyrolyzing sewage sludge with a hazelnut shell has been proposed as an effective and feasible method for reducing environmental toxicity and producing porous building materials (Zhao et al. 2017, 2018). Yang et al. (2020) found that the co-pyrolyzing rice husk and sewage sludge decreased the relative Pb and Cd contents in the produced biochar and decreased the environmental risk levels by 1–2 grades. Additionally, adding cotton stalk to sewage sludge was found to facilitate the transformation and migration of heavy metals from bioavailable to stable components, which reduces the possible toxic environmental impacts of heavy metals, achieving recycling substantially of sewage sludge (Wang et al. 2020). Various metals, Cu, Cr, Zn, Pb, Mn and Ni, are converted into relatively stable states following pyrolysis, resulting in substantial reductions in the immediate phytotoxicity and bioavailability of the biochar.

In contrast, high leaching rates of several heavy metals, including Zn, Cr, and Cu, were found in certain sewage sludge-derived biochars, which was attributable to mixing rice straw and sawdust during sewage sludge co-pyrolysis lowered the overall content of heavy metals in biochars (Huang et al. 2017). Despite reported lowered heavy metals content in the produced biochars, no clear decrease in the amounts of leachable leaching heavy metals was observed (Huang et al. 2017). In brief, sewage sludge and cotton stalk co-pyrolysis are found to be a viable approach for mitigating the possible environmental impacts of heavy metals in sewage sludge biochar-treated soils (Wang et al. 2020). In contrast to non-biomass, mixing sewage sludge and metal-loaded polyvinyl chloride microplastic was shown to have a good influence on heavy metal immobilization during the co-pyrolysis process, and the stable fraction of heavy metals increased with increasing polyvinyl chloride mixing ratio (Li et al. 2022b). Overall, sewage sludge and biomass co-pyrolysis are considered a practical treatment solution for disposing metal polluted waste sludge safely by producing biochar with reduced toxicity. The use of nontoxic catalyst can further enhance heavy metals immobilization and transformation into stable forms.

Effect of pyrolysis temperature

Several researchers studied the effects of different pyrolysis temperatures on heavy metals stabilization in biochars produced from sewage sludge co-pyrolysis. Generally, increasing pyrolysis temperature reduces the amount of extractable heavy metals due to partial fractionation and volatility of these metals at high temperatures, leading to reduced biochar toxicity (Table 1) (Gondek et al. 2014; Kończak and Oleszczuk 2020). Pyrolyzing sewage sludge at 400 °C is widely known to stabilize metals. According to the findings of He et al. (2010), pyrolysis temperatures higher than 350 °C result in better stability of trace heavy metals such as Cd, Pb, Zn, and Cu (He et al. 2010). The environmental damage and toxicity of metals in the co-pyrolyzed biochar decreased further, and co-pyrolysis at 600 °C was found to be suitable for sewage sludge nutrient recycling (Jin et al. 2017; Yang et al. 2021). High pyrolysis temperatures promote the creation of more permanent aromatic bonds and the elimination of transitory aliphatic bonds (Gondek et al. 2014).

Similarly, pyrolysis can stabilize heavy metals by transforming active extractable and exchangeable (F1) and reducible fractions (F2) into stable fractions including oxidizable (F3): metals bound to sulfides and organic matter, and residual fractions (F4): non-silicate bound metals, at low temperatures (300 °C) (Wang et al. 2020). Wang and co-workers evaluated multiple heavy metals in sediments, water, and soils, using the environmental risk index (Table 1). High pyrolysis temperatures were found to reduce the potential environmental concern of heavy metals, particularly copper (Wang et al. 2020).

Gondek and co-workers investigated the effects of low temperature, 200 °C, on the ecotoxicity of heavy metals and metals mobile forms in biochars produced by co-pyrolyzing sewage sludge with various biomass materials such as bark, sawdust, rape straw, and wheat straw. The concentrations of heavy metals in water-soluble form were substantially reduced in all of the tested co-feed materials as a result of thermal transformation (Gondek et al. 2014). The study also found low toxicity of heavy metal extracts from biomass feedstocks for Lepidium sativum and Vibrio fischeri, irrespective of the transformation mechanism of heavy metals. As a result, L. sativum was more sensitive to heavy metals in the analyzed extraction from biomass feedstocks than Vibrio fischeri, as confirmed by the strong correlations between metal concentration and L. sativum root development inhibition (Gondek et al. 2014).

Kończak and Oleszczuk (2020) studied the effects of different temperatures (500‒700 °C) on the toxicity of biochars produced from sewage sludge and willow co-pyrolysis, and the increased temperature, particularly to 700 °C, reduced the quantity of extractable metals for Al, Cu, Fe, Mn, and Zn. Similarly, Huang and co-workers studied the effects of different temperatures, 300 − 700 °C, on the leachable and total heavy metals from biochars and the physicochemical properties of biochars from sewage sludge co-pyrolysis with rice straw or sawdust. However, the increased pyrolysis temperature was found to concentrate heavy metals in the biochars, as shown in Fig. 1. The increased heavy metals in biochars might be related to heavy metals’ higher stability than other sewage sludge compositions (Huang et al. 2017). Further, when temperature increases, metals in the biochar become more concentrated, due to the increased mass loss rate during co-pyrolysis (Huang et al. 2017; Kończak and Oleszczuk 2020). Huang and co-workers also found that pyrolysis temperature has limited effects on heavy metals leachability, while Cd and Pb leachable levels in biochars were above the threshold limits. Several biochars are also have high levels of Zn (Huang et al. 2017).

Effects of pyrolysis temperatures, from 300 to 700 ºC, on the total content of heavy metals in biochar produced from sewage sludge (SS) single and co-pyrolysis with rice straw (RS) or sawdust (SD) (Data source: (Huang et al. 2017)). Rice straw (RS) or sawdust (SD) was mixed with sewage sludge (SS) at 50% mass ratio. Among different metals, lead (Pb) is the most affected metal with changing pyrolysis temperatures. When the pyrolysis temperature is increased, heavy metals are concentrated more in biochar because of organic devolatilization, leading to reduced biochar yield and increased ash content in biochar

Another important factor affecting biochar quality is the sample residence time; long residence periods during co-pyrolysis of sewage sludge usually have a positive impact on heavy metal immobilization, resulting in a sufficient reduction of the possible damage to the environment (Wang et al. 2019a). In the meantime, co-pyrolysis will change the bioavailability of heavy metals into stable compounds, leading to a substantial reduction in direct toxicity of biochar (Wang et al. 2019a; Yang et al. 2021). However, very long residence times will reduce the surface area because of the pore structure destruction (Wang et al. 2019a). Overall, pyrolysis temperatures and residence time can have significant effects on the stabilization of heavy metals, which should be further investigated.

Kończak et al. (2019) studied the effects of sewage sludge and willow co-pyrolysis at different mixing ratios of 8:2 and 6:4, wt:wt, different inert gases of N2 and CO2, and different temperatures of 500‒700 °C, on the physical and chemical biochar properties. Notably, replacing N2 with CO2 was found to affect the physicochemical properties of the produced biochars, as shown in Table 2. The biochars exhibited more favorable surface properties, which were reflected by the increased oxygen content by up to 300% increase, and specific surface area by up to 47%. Carbonization and aromatization degree was high, and the salinity and pH were lower than the biochars created with N2 environment (Kończak et al. 2019). Sewage sludge and willow co-pyrolysis using CO2 as a carrier gas were also found to affect the total concentration of heavy metals and reduce the leachable metals in biochars (Kończak and Oleszczuk 2020). In another study, Kończak and co-workers found that using CO2 as a carrier gas not only reduced the ecotoxicity effects of the produced biochar from sewage sludge and willow co-pyrolysis on bacteria: Vibrio fischeri, arthropods: Folsomia candida, and plants: Lepidium sativum, but also stimulated the growth of the tested plant (Fig. 2) and decreased luminescence inhibition of the bacteria by 75‒95% (Kończak et al. 2020).

Effect of N2 or CO2 on the ecotoxicity of biochar produced from single pyrolysis of sewage sludge (BCSSL) and co-pyrolysis of sewage sludge with willow (BCSSLW) at 500‒700 °C on Lepidium sativum a and Vibrio fischeri b. Note that the minus values for Fig. 2a refer to the growth stimulation, meaning no inhibition effects. Using CO2 as a carrier gas can produce biochar with lower toxicity, which could further enhance crop production. Redrawn from reference (Kończak et al. 2020) with permission from Elsevier

The findings showed that the produced biochars from the sewage sludge and willow in a CO2 environment demonstrate the characteristics most needed for materials which could be applied in agriculture and in the treatment of contaminated soil and water. However, limited studies have studied the effects of using different atmospheres on stabilizing heavy metals for the biochars derived from sewage sludge and biomass co-pyrolysis. Overall, more future studies might study the effect of using different atmospheres, CO2, N2, and different mixtures, with different biomass materials for sewage sludge co-pyrolysis. The effect of gas atmospheres might be dependent on co-feed selection, which should be further explored.

Table 3 summarizes the effects of mixing different biomass materials with sewage sludge on immobilizing heavy metals and reducing the ecological risks of the sludge-derived biochars in addition to the impacts on biochar phytochemical properties. As shown in Table 3, most of the biomass materials immobilized heavy metals and reduced the potential ecological risks. Some materials enhanced the physical and chemical properties of the derived biochar, which could also enhance biochar sorption efficiency. Among various feedstocks, cotton stalk, hazelnut shell, and coconut shell have more positive effects on reducing the toxicity of heavy metals and enhancing biochar characteristics. Thus, future studies could further explore the optimization of the co-pyrolysis process using different carrier gases in addition to the use of proper nontoxic catalysts.

Effect of co-pyrolysis on biochar yield and physiochemical properties

Table 4 shows the incorporation of several biomass materials into sewage sludge during the co-pyrolysis process markedly affects the element contents: C, H, N, S, and O, ash content, fixed carbon, and volatile organic matter in comparison with sewage sludge single pyrolysis. The incorporation of wheat straw with sewage sludge raises the carbon content of biochar and improves the carbon porous structures of the sewage sludge biochar, increasing biochar reactivity markedly (Deng et al. 2017). Elements include N, C, H, S, and O are devolatilized at different temperatures, whereas inorganic metals are not volatilized at temperatures above 500 °C, which is the primary explanation for the biochar's increased ash content. For wood-based feedstocks, carbon starts to volatilize at ~ 100 °C, nitrogen above 200 °C, S above 375 °C, K and P between 700 °C and 800 °C, and Mg, Ca, and Mn volatilize over 1000 °C during pyrolysis (Lehmann and Joseph 2009).

The biochar yield from co-pyrolysis of microalgae and sewage sludge ranged from 23.6% to 57.6% at 500 °C, and the biochar yield is highly correlated to H/C in biomass materials by the linear equation of y = −1147.1x + 198.6. Fitting accuracy (R2) is found to be as high as 0.998, which is in line with pine sawdust and sewage sludge co-pyrolysis. The same liner relationship has also been found for lignite and energy grass co-pyrolysis (Guan et al. 2015; Wang et al. 2016). For future research studies, the linear relationship may be utilized to forecast the pyrolysis char generation for microalgae and sewage sludge co-pyrolysis.

Additionally, mixing sewage sludge with cotton stalk increased the pH, carbon content, and adsorption efficiency, while the biochar yields, specific surface areas, ash contents, and molar H/C ratios were decreased in compression with the biochars obtained from sewage sludge single pyrolysis (Wang et al. 2020). Chen et al. (2019) found that the sewage sludge inherent moisture will have a gasification effect on the biochar structure produced from wood waste and sewage sludge co-pyrolysis, which in turn will increase biochar-specific surface area. The intrinsic moisture was beneficial for forming the biochar surface functional groups, mainly carbonyl, which was confirmed by Raman spectrum and X-ray diffraction (XRD) tests (Chen et al. 2019). The increased wood waste content contributed to the increased specific surface area of biochars from 68.49 to 119.5 cm2/g, which is because of the high specific surface area of wood waste biochar of 150.6 cm2/g. However, biochars from sewage sludge and wood waste co-pyrolysis have average pore sizes being less than 10 nm, suggesting that biochar produced from sewage sludge blocked the pores of wood waste-biochar (Chen et al. 2019). Kończak and co-workers found that mixing willow with sewage sludge increased the specific surface area of the produced biochars (Kończak et al. 2019). Similarly, adding rice straw to sewage sludge enhanced the formation of micropore structure with an average pore size values of 28.7 nm for sewage sludge-biochar and 2.51 nm for rice straw-biochar (Dong et al. 2020).

Biochar porosity is one of the important characteristics that affect biochar sorption affinity, where the adsorption happens mainly in micropores, whereas meso- and macro-pores play a crucial role in the adsorption mechanism, in which both serve as channels to micropores (Pastor-Villegas et al. 2006; Zhang and You 2013). Moreover, since biomass feedstocks are generally pyrolyzed in the biomass particles pores, the synergistic reactions are responsible for major changes in pore structures in biochars. Consequently, the pore structure changes influence the reactions level. Overall, biochar pore diameter and specific surface area may play a key role in the immobilization of heavy metal, which need to be investigated further.

Mechanism of heavy metals immobilization in biochar

Kończak and Oleszczuk studied the mechanism of stabilizing biochars heavy metals created from sewage sludge co-pyrolyzed with willow under different atmospheres of N2 and CO2. Note that several mechanisms could affect heavy metals stabilization, including the occlusion in minerals, the entrapment of heavy metals into biochar pores, and the formation of π-bonding with electron-rich domains on biochar aromatic groups (Kończak and Oleszczuk 2020).

Yang and co-workers conducted a Pearson correlation analysis to elucidate the potential mechanism of heavy metals transformation to evaluate the inherent association between the characteristics of biochar and the leachable heavy metal fractions. The pH levels, N concentrations, and chemical forms of Pb all had significant (p = 0.05) effects on the percentages of leachable Pb during pyrolysis. Whereas the quantities of leachable Cd correlated significantly with the contents of H and N, the N/C and H/C molar ratios, Cd chemical forms and the pH values at p = 0.01 (Yang et al. 2020). Heavy metal availability changes were mostly influenced by Cd and Pb chemical forms in the biochars, alkalinity of biochar, and aromatic structure formation (Yang et al. 2020).

For the catalytic effects, during CaSO4 and sewage sludge co-pyrolysis, various mechanisms of speciation change and immobilization of Cu, Cr, Ni, Zn, and Pb were hypothesized (Fig. 3). In general, crystals with chemical stability and high strength are generated because of the solid and liquid phase interactions during CaSO4 and sewage sludge co-pyrolysis (Fig. 3), resulting in heavy metal immobilization (Liu et al. 2021a). In addition, the sewage sludge organics are decomposed to produce carbon, gases and the formation of new organics, as well as numerous pores to aid in heavy metal immobilization (Sun et al. 2018). Simultaneously, inorganics in sewage sludge including silicates, phosphates, and iron oxides, in addition to other organic pyrolysis products (water, new organics, and carbon), would then react with heavy metals and convert them into other stable forms, including silicate minerals, carbonates, organometallics, and alkali (Liang et al. 2014; Liu et al. 2021a). In addition to the catalytic effects of inorganics in sewage sludge, CaSO4 can combine with other organic intermediate products and form CaCO3, Ca(OH)2, CaO, and CaS (Fig. 3), which are efficient in promoting heavy metals immobilization (Huang et al. 2017; Liu et al. 2021a). Additionally, high pyrolysis temperatures would increase the transformation of Cr, Pb, and Zn into silicates, iron and manganese oxides (Liu et al. 2017, 2021a). In contrast, Gu and co-workers studied the effects of co-pyrolyzing sewage sludge with different mixtures including 0, 15, and 30 wt.% of Ca(H2PO4)2 on immobilizing heavy metals and reducing metals leachability. The optimal blending ratio of Ca(H2PO4)2 is 15 wt%, which produced biochar with more stable heavy metals and reduced the environmental risks from 65.73 to 4.39 (Gu et al. 2022). The potential mechanisms for heavy metals stabilization include the formation of heavy metal chelating agents, e.g., metaphophates and polyphosphates, via condensation dehydration reactions of Ca(H2PO4)2, the formation of highly aromatic metallic compounds, and physical adsorption (Fig. 4). Equations 1, 2, 3 ,4, 5 show the possible reaction pathways for the formation of zinc pyrophosphate (Zn2P2O7), which is a stable form of zinc and insoluble in water (Gu et al. 2022). Phosphates can also help the formation of other stables forms of lead (Pb2P2O7) and pyromorphite-like minerals (Mohamed et al. 2017; Gu et al. 2022). X-ray diffraction (XRD) analysis confirmed the formation of Pb2P2O7, Fe2Pb3(PO4)4, Cd(PO3)2, (Cu, Zn)PbVO4(OH) (Mottramite), and Cu(OH)3PO4 after co-pyrolyzing sewage sludge with Ca(H2PO4)2 (Gu et al. 2022).

Heavy metals immobilization during sewage sludge and calcium sulfate (CaSO4) co-pyrolysis. As shown in the figure, pyrolysis temperature affects the mechanism of immobilization of heavy metals. Exchangeable fraction (F1), reducible fraction (F2), oxidizable fraction (F3), and residual fraction (F4). High pyrolysis temperatures with the use of CaSO4 promote the transformation of extractable heavy metals into more stable fractions, such as oxidizable fraction (F3) and residual fraction (F4). CaSO4 can react with organic intermediates and form carbonates, oxides, and hydroxides, which convert heavy metals into stable forms. Reprinted from reference (Liu et al. 2021a) with permission from Elsevier

Heavy metals immobilization during sewage sludge and monocalcium phosphate “Ca(H2PO4)2” co-pyrolysis. As shown in the figure, several mechanisms could affect the immobilization of heavy metals in sewage sludge. Ca(H2PO4)2 promoted the formation of metal phosphates, which react with heavy metals and form stable forms of phosphates, e.g., pyromorphite-like minerals and mottramite. Ca(H2PO4)2 also increased the surface porosity of biochar, which can immobilize heavy metals inside the internal pores of biochar via physical adsorption. Reprinted from reference (Gu et al. 2022) with permission from Elsevier

Min and co-workers studied the effect of using ZnCl2 for heavy metals stabilization in biochars obtained from camellia oleifera shells and sewage sludge co-pyrolysis. ZnCl2 impregnation reduced the overall heavy metal content through chlorination and formation of CdCl2 and PbCl2, whereas the heavy metals oxidizable fraction (F3) increased remarkably, with the most noticeable effects found in nickel (Ni) and copper (Cu). The findings of the ecological risk assessment revealed that the impregnation of ZnCl2 with sewage sludge and camellia oleifera co-pyrolysis had a high ability to diminish the sludge-derived biochars heavy metals environmental risk, which reduced the risk index from 407 for sewage sludge biochar to 224 after combining ZnCl2 impregnation (Min et al. 2022). However, zinc is also a heavy metal, and the authors neither reported the content of zinc in the produced biochars nor included the content of zinc in calculating the risk index assessment, which could be remarkably higher than the reported risk index value.

For the effect of carbonates on heavy metals stabilization, the activation with K2CO3 during the co-pyrolysis of sewage sludge and cotton stalks converted heavy metals further into stable compounds, including oxidizable (F3) and residual (F4) fractions. The leachability of heavy metals and the associated environmental concerns were significantly decreased by K2CO3 activation as well. Using K2CO3 raised the biochar's alkalinity and promoted the generation of CaO, CaCO3, and aluminosilicates, all of which helped to immobilize the heavy metals (Wang et al. 2021b). Mixing kaolin or zeolite with sewage sludge can stabilize heavy metals during sewage sludge co-pyrolysis via reacting oxygen ions of aluminosilicate additives and creating silicates (PbSiO3) and aluminates (CuAl2O4), converting heavy metals into stable fractions (Li et al. 2022a). Note that kaolin might dehydroxylate at high temperatures, making kaolin ideal for heavy metal ion reactions. Kaolin dehydroxylation might be one of the reasons why kaolin was more successful than zeolite in heavy metal stability (Li et al. 2022a).

In contrast, the overall mechanism should be related to the quantity of organic components in municipal solid waste, which might result in the creation of diverse organometallic complexes for varied heavy metals (Wang et al. 2021a). However, the actual pathways of heavy metal immobilization caused by sewage sludge co-pyrolysis have not been substantiated and may require more investigation. Based on the aforementioned information, many mechanisms could play a key role in affecting heavy metal stabilization, which could be affected by the co-feed mixing ratios, use of catalysts, and pyrolysis temperatures. Overall, using a nontoxic metal catalyst could be a promising approach to further reduce the toxicity of the sludge-derived biochars. Future studies should investigate the effect of using different catalysts at different mixing ratios on heavy metals stabilization.

Factors affecting biochar performance and toxicity in soil

Many interconnected factors play a role in determining biochar performance in soil. The type of soil minerals, parent material, temperature, soil texture, aeration, mycorrhizal growth, and soil organic matter (SOM) and water content are the most important aspects. Additionally, biochar's porous structure and huge specific surface area make biochar an ideal substrate for the adsorption of nutrients because of biochar high surface charge density and abundance of polar and nonpolar surface sites (Jin et al. 2017; Zhao et al. 2017; Yang et al. 2021). Increased cation exchange capacity and decreased leaching of nutrients have been linked to biochar application in soil. Plants can absorb nutrients from biochar that are released over time (Wang et al. 2019a; Yang et al. 2021).

Effect of biochar pH

Soil processes depend heavily on pH, stability, nutrient release, anion and cation solubility, nutrient leaching, and crop yields are all affected by biochar stability in the soil and the stability of soil organic matter (SOM). Slightly alkaline or neutral in pH, biochar is the norm (Wang et al. 2019a; Yang et al. 2021). With increasing pyrolysis temperature, biochar's basicity increases and varies with the feedstock. The liming effect of alkaline biochar has been proven to reduce the concentration and toxicity of Al3+ in acidic soils, while biochar has little impact or causes a reduction in pH when given to acidic soils. On the other hand, alkaline biochar may harm soils with low buffering capacity. Adding alkaline biochar derived from poultry litter to soil, which raises the pH above 8, has a detrimental effect on fertility. Plant nutrients may precipitate at alkaline pH, reducing nutrients availability for plant growth (Wang et al. 2019a; Yang et al. 2021), which emphasize the importance of determining biochar pH before using on potentially vulnerable soil types.

When dealing with metal-contaminated agricultural soil, special circumstances may occur. Increased soil pH may help reduce the mobility of potentially hazardous elements (Jin et al. 2017; Wang et al. 2019a; Yang et al. 2021). However, as prefers to bind in acidic soils to iron-oxide surfaces and can be liberated from the soil as the pH rises. The addition of biochar has resulted in mobilization in several experiments (Wang et al. 2019a; Yang et al. 2021). As concentrations in the porewater of alkaline (pH 10) biochar increased five to ninefold within one week, the absorption of Solanum Lycopersicum L. was inhibited. According to yet another study, using rice plant biochar with pH 8.1–11.3 increased bioaccumulation of heavy metals in rice shoots by up to 327% (Godlewska et al. 2021). Overall, further studies are still needed.

Effect of biochar nutrient content

Biochar may also contain nutrients, e.g., N, P, K, Mg, S, and Ca, and various micronutrients depending on feedstock type and the production method. However, some biochars are described as holding less nutrients to be utilized as fertilizers or even limiting the availability of nutrients for plants. Despite these conflicting results, biochar significantly impacts nutrient (bio)availability (Jin et al. 2017; Zhao et al. 2017; Yang et al. 2021).

In addition, the amount of total N in soil rises, but bioavailable N does not. Biochar can also impede the availability of N to plants, resulting in lower yields if fertilizer is not used in conjunction with biochar. Furthermore, using biochar and fertilizer together may increase the amount of biomass absorbed (Wang et al. 2019a; Yang et al. 2021). Impacts of biochar on soil phosphorus availability varies from one experiment to the next. Phosphorus adsorption on biochar is primarily responsible for controlling P availability, not biochar's ability to raise or decrease P availability. Even though biochar has a favorable impact on P values in severely weathered acidic soils, the response in alkaline soils is more complicated (Zhao et al. 2017; Wang et al. 2019a; Yang et al. 2021). For instance, the addition of alkaline biochar to calcareous soil improves P sorption while decreasing the availability of adsorbed P substantially.

When wheat straw biochar and fertilizer are combined and generate phosphate precipitation and sorption, biochar negatively impacts plant P availability in saline-sodic soil. According to the current data, biochar appears to have a major impact on soil nitrogen cycles (Jin et al. 2017; Zhao et al. 2017; Yang et al. 2021). However, biochar's strong sorption capacity may limit nutrients' bioavailability, even if the overall nutrient content increases, particularly when biochar and fertilizer are applied together. Biochar has so much promise, which have been studied as a technique for removing nitrogen and phosphorus contamination from the environment (Wang et al. 2019a; Yang et al. 2021). Biochar-soil systems must be evaluated for the overall nutrient content and the efficient bioavailability of these nutrients, which necessitates a series of bioassays.

An interesting correlation was found between soil ecosystem C/N and other nutrients ratios and biological ties and consistency in stoichiometry. A stoichiometric unbalance between C and N, according to the C health threshold model, could result in soil deterioration or a reduction in soil health (Wang et al. 2019a; Yang et al. 2021). As a result, the primary productivity of an ecosystem is affected by the coupling of C and N interactions. Overall, the use of biochar as a climate mitigation method may be undermined by the improper usage of biochar that reduces N bioavailability.

Effect of agrochemicals in soil

Because of the porous nature and large specific surface area of biochar, which can impact the efficacy of these agrochemicals, insecticides, herbicides, fungicides, and nematicides are examples of agrochemicals containing many pesticides. In addition to synthetic fertilizers, hormones and other chemical growth agents can affect soil biota. Reducing pesticide levels in non-target organisms and groundwater contamination by fixing pesticides on pesticide-affected plants is thus essential. Insecticides applied to soil directly may also harm biochar effectiveness, particularly for the pre-emergent pesticides that contact biochar in the soil directly (Jin et al. 2017; Zhao et al. 2017; Wang et al. 2019a; Yang et al. 2021). As a result of pesticides' strong interactions with biochar, bioavailability of pesticides may be lowered, requiring higher treatment rates to maintain adequate control. For example, to obtain the same weed control efficacy as non-treated soil, greater rates of the herbicide diuron, beginning at 0.1% of biochar in soil, must be administered. Even though when the dose of diuron is doubled, weeds cannot be effectively controlled in soils containing 0.5% biochar (Wang et al. 2019a; Yang et al. 2021).

Herbicide efficacy has been found to decline with increasing soil biochars doses, raising questions about such increased herbicide application's economic and environmental ramifications. Increased sorption also limits bioavailability for microbe degraders, reducing pesticide or herbicide decomposition while increasing persistency, which has several implications. Atrazine leaching, bioavailability, and mineralization are all reduced to a larger extent when fine biochar (2 mm) is applied to the soil rather than large-size biochar higher than 2 mm. As a result, a decrease in pesticide effectiveness following the use of fine high-temperature biochar is to be predicted. Furthermore, porosity, hydrophobic binding sites, and biochar surface area are crucial for sorption often rise with increasing temperature. Organic contaminants such as pesticides are more likely to associate with biochar produced over 500 °C (Yang et al. 2021).

The potential negative effects of biochars application in agricultural soils and the possible mitigation measures are presented in Table 5. Optimization of the co-pyrolysis process in addition to the proper selection of the co-feed material are essential to mitigate most of the negative impacts of biochar application in agricultural soils (Brtnicky et al. 2021). Overall, for pesticide sorption investigations in the laboratory and more sophisticated ones like microcosms and field trials, various biochars with well-defined sorption potential can be tested to see whether biochars characteristics affect pesticide sorption.

Effect of biochar application on soil biota and environmental risk assessment

Biochar can be applied to soil to mitigate the detrimental effects that could occur as a result of removing crop residues from soils and that would possibly ameliorate soil quality and plant productivity (Mohamed et al. 2017, 2021b, 2022c; Fakayode et al. 2020). However, several studies found that biochar has a negative effect on earthworms in most studies of soil macro- and microfauna because of the contents of polycyclic aromatic hydrocarbons and heavy metals (Li et al. 2011; Conti et al. 2018; Godlewska et al. 2021). To evaluate the environmental impact of the suitability and optimum rate of biochar application in soils, the bioavailability and phytotoxicity of metals in the sludge-derived biochar should be estimated (Devi and Saroha 2014; Zhao et al. 2017). The environmental ecological risk index is widely used to determine potential exposure for various metals in the sewage sludge and the sludge-derived biochars, by utilizing Hakanson's (1980) model (Jin et al. 2017; Yang et al. 2021). Extraction studies using Community Bureau of Reference recommended extraction procedures demonstrated that heavy metals have been immobilized in biochars after heavy metals are converted into stable chemical forms (Wang et al. 2019a; Xie et al. 2020; Godlewska et al. 2021). The Community Bureau of Reference classifies the extracted metals as exchangeable fraction (F1), reducible fraction (F2), oxidizable fraction (F3), and residual fraction (F4) (Xie et al. 2020; Godlewska et al. 2021).

Biochar's impacts on the survival and behavior of earthworm, reproduction and development were found to be inconsistent, which shows that our knowledge of the interactions of biochar organism is still limited. As with other groups of creatures, there have been a variety of findings. There was a significant drop in the density of both cocoons and juvenile earthworms, as well as a reduction in casting activity, when biochar was applied to Pontoscolex corethrurus compared to pure soil (Paz-Ferreiro et al. 2015). Many studies have reported that exposure to biochar has a negative impact on earthworm reproduction rates, toxicity, and growth and weight (Godlewska et al. 2021).

According to other researchers, E. fetida's degradation within five days of exposure to biochar may have been caused by a fast adjustment in soil pH following biochar addition (Conti et al. 2018). Using pre-moisturized biochar, the authors theorized that earthworm mortality was caused by biochar particles adhering to earthworm bodies and inflicting substantial physical injury. To avoid consuming biochar particles, earthworms often lose weight (Conti et al. 2018), which might be explained by earthworms cutting back on feeding activities to conserve energy. As a result of the decrease in earthworm numbers caused by biochar, the ecosystem services provided by earthworms may be compromised. For springtails, biochar has also been shown to have detrimental consequences.

Various forms of biochar increased mortality while decreasing reproduction in Folsomia candida (Conti et al. 2018; Godlewska et al. 2021). When biochar is applied at a 1 − 5% concentration, springtail populations are protected from poisoning, but when biochar concentration is increased to 10%, these positive effects are completely reversed. Soil microfauna can be stressed by alkaline biochar with pH 9 derived from wheat straw, according to this study (Conti et al. 2018). Some insect species are unable to survive in direct contact with biochar. For a variety of reasons, adding biochar can pose negative impacts on soil quality, including altering soil structure, decreasing mineral and vitamin availability due to sorption in biochar, and increasing the saltiness of biochar. Various types of hydrochar and biochar can affect soil invertebrates if the samples contain soluble organic compounds, while sewage sludge application increases the mortality of soil invertebrates (Li et al. 2011; Oleszczuk and Hollert 2011). As a result of soil communities' decreased potential resilience to environmental changes, the effects of intensive biochar application to agricultural soils should be investigated.

According to the findings, soil invertebrates may have detrimental effects and various inhibitory on their development, survival and reproduction, if larger dosages of biochar, higher than 0.5%, depending on biochar type, are applied. As a result of adding biochar to the soil, these negative impacts are partly caused by the soil's increased pH level but also by the presence of polycyclic aromatic hydrocarbons, dioxins, and other potential toxic elements (Kong et al. 2019; Brtnicky et al. 2021). However, biochar produced from sewage sludge and willow co-pyrolysis was found to reduce the ecotoxicity for arthropods, Lepidium sativum and Folsomia candida by up to 56% and enhanced reproduction stimulation by 20‒98% (Kończak et al. 2020). Producing biochars at high pyrolysis temperatures more than 500 °C could reduce the formation of dioxins (Brtnicky et al. 2021). If nematodes and springtails are abundant, biochar may have less of an effect on the microbial community's composition and, as a result, soil quality. Overall, because earthworms play such an important role in the formation of soil, any negative effects on them may be significantly more serious. Because of this, the earthworm population may be negatively affected by biochar.

Conclusion

This review discusses the latest advances in research experiments about the mechanisms and synergistic effects of co-pyrolysis as well as sewage sludge catalytic co-pyrolysis with a focus on reducing the environmental risk of the sludge-derived biochar. Co-pyrolyzing sewage sludge with biomass feedstocks was found to enhance heavy metals stabilization and reduce the toxicity of the sludge-derived biochar. Furthermore, the use of catalysts during co-pyrolysis significantly affects the pathways and mechanisms of heavy metals stabilization through the formation of stable compounds, including oxidizable and residual fractions, which reduced the environmental risk of sludge-derived biochar compared with sewage sludge singular pyrolysis. Pyrolysis temperatures and residence time have significant effects on the stabilization of heavy metals. Using CO2 as a carrier gas decreased the leachable metals in biochars and affect the total concentration of heavy metals. Sewage sludge-derived biochars could negatively affect soil biota, including earthworms. As a result, the toxicity of the sludge-derived biochar should be eliminated or reduced before applying biochar to the soil. Selection of the co-feed material and optimization of the co-pyrolysis process are key parameters to mitigate the negative impacts of biochar application in soil, which should be further investigated. As a result, future research might look at the impact of employing different atmospheres including CO2, N2, pyrolysis gas, and other mixes, with different biomasses for sewage sludge co-pyrolysis. Catalytic pyrolysis has the potential to decrease the operating costs of biorefineries that use biomass and sewage and to stabilize heavy metals in the sludge-derived biochars. Thus, more future studies are needed to explore the effects of nontoxic catalysts on the stabilization of heavy metals. Furthermore, the long-term interactions between soil biota and sludge-derived biochar applied in agricultural soils should be monitored. The long-term environmental implications of various co-pyrolysis models is still needed to demonstrate that co-pyrolysis should be considered as a viable solution to current technologies.

References

Abou Rjeily M, Gennequin C, Pron H et al (2021) Pyrolysis-catalytic upgrading of bio-oil and pyrolysis-catalytic steam reforming of biogas: a review. Environ Chem Lett 19:2825–2872. https://doi.org/10.1007/s10311-021-01190-2

Ahmed MHM, Batalha N, Mahmudul HMD et al (2020) A review on advanced catalytic co-pyrolysis of biomass and hydrogen-rich feedstock: Insights into synergistic effect, catalyst development and reaction mechanism. Biores Technol 310:123457. https://doi.org/10.1016/j.biortech.2020.123457

Alvarado VI, Hsu S-C, Lam C-M, Lee P-H (2020) Energy balance: environmental trade-offs of organics capture and low carbon-to-nitrogen ratio sewage treatment systems. Environ Sci Technol 54:4746–4757. https://doi.org/10.1021/acs.est.9b05755

Alvarez J, Amutio M, Lopez G et al (2015) Fast co-pyrolysis of sewage sludge and lignocellulosic biomass in a conical spouted bed reactor. Fuel 159:810–818. https://doi.org/10.1016/j.fuel.2015.07.039

Bolan N, Kunhikrishnan A, Thangarajan R et al (2014) Remediation of heavy metal(loid)s contaminated soils–to mobilize or to immobilize? J Hazard Mater 266:141–166. https://doi.org/10.1016/j.jhazmat.2013.12.018

Brtnicky M, Datta R, Holatko J et al (2021) A critical review of the possible adverse effects of biochar in the soil environment. Sci Total Environ 796:148756. https://doi.org/10.1016/j.scitotenv.2021.148756

Buonocore E, Mellino S, De Angelis G et al (2018) Life cycle assessment indicators of urban wastewater and sewage sludge treatment. Ecol Ind 94:13–23. https://doi.org/10.1016/j.ecolind.2016.04.047

Chen Q, Liu H, Ko JH et al (2019) Structure characteristics of bio-char generated from co-pyrolysis of wooden waste and wet municipal sewage sludge. Fuel Process Technol 183:48–54. https://doi.org/10.1016/j.fuproc.2018.11.005

Chen G, Tian S, Liu B et al (2020) Stabilization of heavy metals during co-pyrolysis of sewage sludge and excavated waste. Waste Manage 103:268–275. https://doi.org/10.1016/j.wasman.2019.12.031

Conti FD, Visioli G, Malcevschi A, Menta C (2018) Safety assessment of gasification biochars using Folsomia candida (Collembola) ecotoxicological bioassays. Environ Sci Pollut Res 25:6668–6679. https://doi.org/10.1007/s11356-017-0806-4

Crini G, Lichtfouse E (2019) Advantages and disadvantages of techniques used for wastewater treatment. Environ Chem Lett 17:145–155. https://doi.org/10.1007/s10311-018-0785-9

Crini G, Cosentino C, Bradu C et al (2022) Innovative technologies to remove alkylphenols from wastewater: a review. Environ Chem Lett 20:2597–2628. https://doi.org/10.1007/s10311-022-01438-5

Deng S, Tan H, Wang X et al (2017) Investigation on the fast co-pyrolysis of sewage sludge with biomass and the combustion reactivity of residual char. Biores Technol 239:302–310. https://doi.org/10.1016/j.biortech.2017.04.067

Devi P, Saroha AK (2014) Risk analysis of pyrolyzed biochar made from paper mill effluent treatment plant sludge for bioavailability and eco-toxicity of heavy metals. Biores Technol 162:308–315. https://doi.org/10.1016/j.biortech.2014.03.093

Dong Q, Zhang S, Wu B et al (2020) Co-pyrolysis of Sewage Sludge and Rice Straw: Thermal Behavior and Char Characteristic Evaluations. Energy Fuels 34:607–615. https://doi.org/10.1021/acs.energyfuels.9b03800

Fakayode OA, Aboagarib EAA, Zhou C, Ma H (2020) Co-pyrolysis of lignocellulosic and macroalgae biomasses for the production of biochar – A review. Biores Technol 297:122408. https://doi.org/10.1016/j.biortech.2019.122408

Godlewska P, Ok YS, Oleszczuk P (2021) THE DARK SIDE OF BLACK GOLD: Ecotoxicological aspects of biochar and biochar-amended soils. J Hazard Mater 403:123833. https://doi.org/10.1016/j.jhazmat.2020.123833

Gondek K, Baran A, Kopeć M (2014) The effect of low-temperature transformation of mixtures of sewage sludge and plant materials on content, leachability and toxicity of heavy metals. Chemosphere 117:33–39. https://doi.org/10.1016/j.chemosphere.2014.05.032

Gu W, Guo J, Bai J et al (2022) Co-pyrolysis of sewage sludge and Ca(H2PO4)2: heavy metal stabilization, mechanism, and toxic leaching. J Environ Manage 305:114292. https://doi.org/10.1016/j.jenvman.2021.114292

Guan Y, Ma Y, Zhang K et al (2015) Co-pyrolysis behaviors of energy grass and lignite. Energy Convers Manage 93:132–140. https://doi.org/10.1016/j.enconman.2015.01.006

He YD, Zhai YB, Li CT et al (2010) The fate of Cu, Zn, Pb and Cd during the pyrolysis of sewage sludge at different temperatures. Environ Technol 31:567–574. https://doi.org/10.1080/09593330903514466

Huang H, jun, Yang T, Lai F ying, Wu G qiang, (2017) Co-pyrolysis of sewage sludge and sawdust/rice straw for the production of biochar. J Anal Appl Pyrol 125:61–68. https://doi.org/10.1016/j.jaap.2017.04.018

Huang C, Mohamed BA, Li LY (2022) Comparative life-cycle assessment of pyrolysis processes for producing bio-oil, biochar, and activated carbon from sewage sludge. Resour Conserv Recycl 181:106273. https://doi.org/10.1016/j.resconrec.2022.106273

Jin J, Wang M, Cao Y et al (2017) Cumulative effects of bamboo sawdust addition on pyrolysis of sewage sludge: Biochar properties and environmental risk from metals. Biores Technol 228:218–226. https://doi.org/10.1016/j.biortech.2016.12.103

Khan NA, Khan AH, Lopez Maldonado EA et al (2022) Microplastics: occurrences, treatment methods, regulations and foreseen environmental impacts. Environ Res 114224. https://doi.org/10.1016/j.envres.2022.114224

Kończak M, Oleszczuk P (2020) Co-pyrolysis of sewage sludge and biomass in carbon dioxide as a carrier gas affects the total and leachable metals in biochars. J Hazard Mater 400:123144. https://doi.org/10.1016/j.jhazmat.2020.123144

Kończak M, Oleszczuk P, Różyło K (2019) Application of different carrying gases and ratio between sewage sludge and willow for engineered (smart) biochar production. J CO2 Util 29:20–28. https://doi.org/10.1016/j.jcou.2018.10.019

Kończak M, Pan B, Ok YS, Oleszczuk P (2020) Carbon dioxide as a carrier gas and mixed feedstock pyrolysis decreased toxicity of sewage sludge biochar. Sci Total Environ 723:137796. https://doi.org/10.1016/j.scitotenv.2020.137796

Kong L, Liu J, Zhou Q et al (2019) Sewage sludge derived biochars provoke negative effects on wheat growth related to the PTEs. Biochem Eng J 152:107386. https://doi.org/10.1016/j.bej.2019.107386

Lehmann J, Joseph S (2009) Biochar for Environmental Management – Science and Technology. Earthscan, London

Leng L, Leng S, Chen J et al (2018) The migration and transformation behavior of heavy metals during co-liquefaction of municipal sewage sludge and lignocellulosic biomass. Biores Technol 259:156–163. https://doi.org/10.1016/j.biortech.2018.03.019

Leng L, Yang L, Chen J et al (2020) A review on pyrolysis of protein-rich biomass: Nitrogen transformation. Biores Technol 315:123801. https://doi.org/10.1016/j.biortech.2020.123801

Leng L, Liu R, Xu S et al (2022) An overview of sulfur-functional groups in biochar from pyrolysis of biomass. J Environ Chem Eng 10:107185. https://doi.org/10.1016/j.jece.2022.107185

Li D, Hockaday WC, Masiello C (2011) Earthworm avoidance of biochar can be mitigated by wetting. Soil Biol Biochem 43:1732–1737. https://doi.org/10.1016/j.soilbio.2011.04.019

Li C, Xie S, Wang Y et al (2020) Simultaneous heavy metal immobilization and antibiotics removal during synergetic treatment of sewage sludge and pig manure. Environ Sci Pollut Res 27:30323–30332. https://doi.org/10.1007/s11356-020-09230-0

Li C, Xie S, You F et al (2021) Heavy metal stabilization and improved biochar generation via pyrolysis of hydrothermally treated sewage sludge with antibiotic mycelial residue. Waste Manage 119:152–161. https://doi.org/10.1016/j.wasman.2020.09.050

Li Q, Zhong Z, Du H et al (2022a) Co-pyrolysis of sludge and kaolin/zeolite in a rotary kiln: Analysis of stabilizing heavy metals. Front Environ Sci Eng 16:85. https://doi.org/10.1007/s11783-021-1488-1

Li W, Meng J, Zhang Y et al (2022b) Co-pyrolysis of sewage sludge and metal-free/metal-loaded polyvinyl chloride (PVC) microplastics improved biochar properties and reduced environmental risk of heavy metals. Environ Pollut 302:119092. https://doi.org/10.1016/j.envpol.2022.119092Received

Liang Y, Cao X, Zhao L, Arellano E (2014) Biochar- and phosphate-induced immobilization of heavy metals in contaminated soil and water: Implication on simultaneous remediation of contaminated soil and groundwater. Environ Sci Pollut Res 21:4665–4674. https://doi.org/10.1007/s11356-013-2423-1

Liu Y, Liu Q, Chen M et al (2017) Evaluation of migration of heavy metals and performance of product during co-pyrolysis process of municipal sewage sludge and walnut shell. Environ Sci Pollut Res 24:22082–22090. https://doi.org/10.1007/s11356-017-9858-8

Liu L, Huang L, Huang R et al (2021a) Immobilization of heavy metals in biochar derived from co-pyrolysis of sewage sludge and calcium sulfate. J Hazard Mater 403:123648. https://doi.org/10.1016/j.jhazmat.2020.123648

Liu X, Iqbal A, Huang H et al (2021b) Life cycle assessment of deploying sludge minimization with ( sulfidogenic- ) oxic-settling-anaerobic configurations in sewage-sludge management systems. Biores Technol 335:125266. https://doi.org/10.1016/j.biortech.2021.125266

Min X, Ge T, Li H et al (2022) Combining impregnation and co-pyrolysis to reduce the environmental risk of biochar derived from sewage sludge. Chemosphere 290:133371. https://doi.org/10.1016/j.chemosphere.2021.133371

Mohamed BA, Li LY (2022) Biofuel production by co-pyrolysis of sewage sludge and other materials: a review. Environ Chem Lett. https://doi.org/10.1007/s10311-022-01496-9

Mohamed BA, Ellis N, Kim CS, Bi X, Emam AEl (2016) Engineered biochar from microwave-assisted catalytic pyrolysis of switchgrass for increasing water-holding capacity and fertility of sandy soil. Sci Total Environ 566–567:387–397. https://doi.org/10.1016/j.scitotenv.2016.04.169

Mohamed BA, Ellis N, Kim CS, Bi X (2017) The role of tailored biochar in increasing plant growth, and reducing bioavailability, phytotoxicity, and uptake of heavy metals in contaminated soil. Environ Pollut 230:329–338. https://doi.org/10.1016/j.envpol.2017.06.075

Mohamed BA, Ellis N, Kim CS, Bi X (2020) Synergistic Effects of Catalyst Mixtures on Biomass Catalytic Pyrolysis. Frontiers Bioeng. Biotechnol. 8:615134. https://doi.org/10.3389/fbioe.2020.615134

Mohamed BA, Bi X, Li LY et al (2021a) Bauxite residue as a catalyst for microwave-assisted pyrolysis of switchgrass to high quality bio-oil and biochar. Chem Eng J 426:131294. https://doi.org/10.1016/j.cej.2021.131294

Mohamed BA, Ellis N, Kim CS et al (2021b) Engineered biochars from catalytic microwave pyrolysis for reducing heavy metals phytotoxicity and increasing plant growth. Chemosphere 271:129808. https://doi.org/10.1016/j.chemosphere.2021.129808

Mohamed BA, Fattah IMR, Yousaf B, Periyasamy S (2022a) Effects of the COVID‑19 pandemic on the environment, waste management, and energy sectors: a deeper look into the long‑term impacts. Environ Sci Pollut Res 29:46438–46457. https://doi.org/10.1007/s11356-022-20259-1

Mohamed BA, Li LY, Hamid H, Jeronimo M (2022b) Sludge-based activated carbon and its application in the removal of perfluoroalkyl substances: A feasible approach towards a circular economy. Chemosphere 294:133707. https://doi.org/10.1016/j.chemosphere.2022.133707

Mohamed BA, Liu Z, Bi X, Li LY (2022c) Co-production of phenolic-rich bio-oil and magnetic biochar for phosphate removal via bauxite-residue-catalysed microwave pyrolysis of switchgrass. J Clean Prod 333:130090. https://doi.org/10.1016/j.jclepro.2021.130090

Morin-Crini N, Lichtfouse E, Fourmentin M et al (2022) Removal of emerging contaminants from wastewater using advanced treatments. A Review Environ Chem Lett 20:1333–1375. https://doi.org/10.1007/s10311-021-01379-5

Oleszczuk P, Hollert H (2011) Comparison of sewage sludge toxicity to plants and invertebrates in three different soils. Chemosphere 83:502–509. https://doi.org/10.1016/j.chemosphere.2010.12.061

Padervand M, Lichtfouse E, Robert D, Wang C (2020) Removal of microplastics from the environment. A Review Environmental Chemistry Letters 18:807–828. https://doi.org/10.1007/s10311-020-00983-1

Pastor-Villegas J, Pastor-Valle JF, Rodríguez JMM, García MG (2006) Study of commercial wood charcoals for the preparation of carbon adsorbents. J Anal Appl Pyrol 76:103–108. https://doi.org/10.1016/j.jaap.2005.08.002

Paz-Ferreiro J, Liang C, Fu S et al (2015) The effect of biochar and its interaction with the earthworm Pontoscolex corethrurus on soil microbial community structure in tropical soils. PLoS ONE 10:1–11. https://doi.org/10.1371/journal.pone.0124891

Ruiz-Gómez N, Quispe V, Ábrego J et al (2017) Co-pyrolysis of sewage sludge and manure. Waste Manage 59:211–221. https://doi.org/10.1016/j.wasman.2016.11.013

Stang C, Mohamed BA, Li LY (2022) Microplastic removal from urban stormwater: Current treatments and research gaps. J Environ Manage 317:115510. https://doi.org/10.1016/j.jenvman.2022.115510

Su G, Ong HC, Gan YY et al (2022) Co-pyrolysis of microalgae and other biomass wastes for the production of high-quality bio-oil: Progress and prospective. Biores Technol 344:126096. https://doi.org/10.1016/j.biortech.2021.126096

Sun S, Huang X, Lin J et al (2018) Study on the effects of catalysts on the immobilization efficiency and mechanism of heavy metals during the microwave pyrolysis of sludge. Waste Manage 77:131–139. https://doi.org/10.1016/j.wasman.2018.04.046

Suresh A, Alagusundaram A, Kumar PS et al (2021) Microwave pyrolysis of coal, biomass and plastic waste: a review. Environ Chem Lett 19:3609–3629. https://doi.org/10.1007/s10311-021-01245-4

Wang X, Zhao B, Yang X (2016) Co-pyrolysis of microalgae and sewage sludge: Biocrude assessment and char yield prediction. Energy Convers Manage 117:326–334. https://doi.org/10.1016/j.enconman.2016.03.013

Wang Z, Liu K, Xie L et al (2019a) Effects of residence time on characteristics of biochars prepared via co-pyrolysis of sewage sludge and cotton stalks. J Anal Appl Pyrol 142:104659. https://doi.org/10.1016/j.jaap.2019.104659

Wang Z, Xie L, Liu K et al (2019b) Co-pyrolysis of sewage sludge and cotton stalks. Waste Manage 89:430–438. https://doi.org/10.1016/j.wasman.2019.04.033

Wang Z, Shu X, Zhu H et al (2020) Characteristics of biochars prepared by co-pyrolysis of sewage sludge and cotton stalk intended for use as soil amendments. Environ Technol 41:1347–1357. https://doi.org/10.1080/09593330.2018.1534891

Wang X, Chang VWC, Li Z et al (2021a) Co-pyrolysis of sewage sludge and organic fractions of municipal solid waste: Synergistic effects on biochar properties and the environmental risk of heavy metals. J Hazard Mater 412:125200. https://doi.org/10.1016/j.jhazmat.2021.125200

Wang Z, Tian Q, Guo J et al (2021b) Co-pyrolysis of sewage sludge/cotton stalks with K2CO3 for biochar production: Improved biochar porosity and reduced heavy metal leaching. Waste Manage 135:199–207. https://doi.org/10.1016/j.wasman.2021.08.042

Wang X, Wei-Chung Chang V, Li Z et al (2022) Co-pyrolysis of sewage sludge and food waste digestate to synergistically improve biochar characteristics and heavy metals immobilization. Waste Manage 141:231–239. https://doi.org/10.1016/j.wasman.2022.02.001

Xie S, Yu G, Li C et al (2020) Treatment of high-ash industrial sludge for producing improved char with low heavy metal toxicity. J Anal Appl Pyrol 150:104866. https://doi.org/10.1016/j.jaap.2020.104866

Yang YQ, Cui MH, Ren YG et al (2020) Towards understanding the mechanism of heavy metals immobilization in biochar derived from co-pyrolysis of sawdust and sewage sludge. Bull Environ Contam Toxicol 104:489–496. https://doi.org/10.1007/s00128-020-02801-4

Yang YQ, Cui MH, Guo JC et al (2021) Effects of co-pyrolysis of rice husk and sewage sludge on the bioavailability and environmental risks of Pb and Cd. Environ Technol 42:2304–2312. https://doi.org/10.1080/09593330.2019.1701562

Zhang J, You C (2013) Water holding capacity and absorption properties of wood chars. Energy Fuels 27:2643–2648. https://doi.org/10.1021/ef4000769

Zhang X, Yu Z, Lu X, Ma X (2021) Catalytic co-pyrolysis of microwave pretreated chili straw and polypropylene to produce hydrocarbons-rich bio-oil. Biores Technol 319:124191. https://doi.org/10.1016/j.biortech.2020.124191

Zhang Z, Ahmed AIS, Malik MZ et al (2023) Cellulose/inorganic nanoparticles-based eco-friendly nano-biocomposite with multifaceted potential for abatement of water and wastewater pollutants. Chemosphere 137483. https://doi.org/10.1016/j.chemosphere.2022.137483

Zhao B, Xu X, Xu S et al (2017) Surface characteristics and potential ecological risk evaluation of heavy metals in the bio-char produced by co-pyrolysis from municipal sewage sludge and hazelnut shell with zinc chloride. Biores Technol 243:375–383. https://doi.org/10.1016/j.biortech.2017.06.032

Zhao B, Xu X, Li H et al (2018) Kinetics evaluation and thermal decomposition characteristics of co-pyrolysis of municipal sewage sludge and hazelnut shell. Biores Technol 247:21–29. https://doi.org/10.1016/j.biortech.2017.09.008

Zhao A, Liu S, Yao J et al (2022) Characteristics of bio-oil and biochar from cotton stalk pyrolysis: Effects of torrefaction temperature and duration in an ammonia environment. Biores Technol 343:126145. https://doi.org/10.1016/j.biortech.2021.126145

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors have not disclosed any funding.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mohamed, B.A., Ruan, R., Bilal, M. et al. Co-pyrolysis of sewage sludge and biomass for stabilizing heavy metals and reducing biochar toxicity: A review. Environ Chem Lett 21, 1231–1250 (2023). https://doi.org/10.1007/s10311-022-01542-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10311-022-01542-6