Abstract

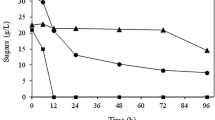

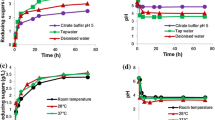

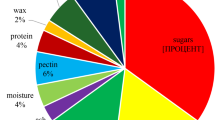

2,3-Butanediol (2,3-BD) synthesis by a nonpathogenic bacterium Bacillus licheniformis NCIMB 8059 from enzymatic hydrolysate of depectinized apple pomace and its blend with glucose was studied. In shake flasks, the maximum diol concentration in fed-batch fermentations was 113 g/L (in 163 h, from the hydrolysate, feedings with glucose) while in batch processes it was around 27 g/L (in 32 h, from the hydrolysate and glucose blend). Fed-batch fermentations in the 0.75 and 30 L fermenters yielded 87.71 g/L 2,3-BD in 160 h, and 72.39 g/L 2,3-BD in 94 h, respectively (from the hydrolysate and glucose blend, feedings with glucose). The hydrolysate of apple pomace, which was for the first time used for microbial 2,3-BD production is not only a source of sugars but also essential minerals.

Similar content being viewed by others

References

Afschar AS, Bellgardt KH, Vaz Rossell CE, Czok A, Schaller K (1991) The production of 2,3-butanediol by fermentation of high test molasses. Appl Microbiol Biotechnol 34:582–585. doi:10.1007/BF00167903

Barham D, Trinder P (1972) An improved color reagent for the determination of blood glucose by the oxidase system. Analyst 97:142–145. doi:10.1039/AN9729700142

Biswas R, Yamaoka M, Nakayama H, Kondo T, Yoshida K, Bisaria VS, Kondo A (2012) Enhanced production of 2,3-butanediol by engineered Bacillus subtilis. Appl Microbiol Biotechnol 94:651–658. doi:10.1007/s00253-011-3774-5

Budsławski J, Drabant Z (1972) Food analysis methods. WNT, Warsaw, p 276

Celińska E, Grajek W (2009) Biotechnological production of 2,3-butanediol: current state and prospects. Biotechnol Adv 27:715–725. doi:10.1016/j.biotechadv.2009.05.002

Cheng K-K, Liu Q, Zhang J-A, Li J-P, Xu J-M, Wang G-H (2010) Improved 2,3-butanediol production from corncob acid hydrolysate by fed-batch fermentation using Klebsiella oxytoca. Process Biochem 45:613–616. doi:10.1016/j.procbio.2009.12.009

Dai J-Y, Zhao P, Cheng X-L, Xiu Z-L (2015) Enhanced production of 2,3-butanediol from sugarcane molasses. Appl Biochem Biotechnol 175:3014–3024. doi:10.1007/s12010-015-1481-x

Gao J, Xu H, Li Q, Feng X, Li S (2010) Optimization of medium for one-step fermentation of inulin extract from Jerusalem artichoke tubers using Paenibacillus polymyxa ZJ-9 to produce R, R-2,3-butanediol. Bioresour Technol 101:7076–7082. doi:10.1016/j.biortech.2010.03.143

Ji X-J, Huang H, Ouyang P-K (2011) Microbial 2,3-butanediol production: a state-of-the-art review. Biotechnol Adv 29:351–364. doi:10.1016/j.biotechadv.2011.01.007

Jung MY, Park BS, Lee J, Oh MK (2013) Engineered Enterobacter aerogenes for efficient utilization of sugarcane molasses in 2,3-butanediol production. Bioresour Technol 139:21–27. doi:10.1016/j.biortech.2013.04.003

Jurchescu I-M, Hamann J, Zhou X, Ortmann T, Kuenz A, Prüße U, Lang S (2013) Enhanced 2,3-butanediol production in fed-batch cultures of free and immobilized Bacillus licheniformis DSM 8785. Appl Microbiol Biotechnol 97:6715–6723. doi:10.1007/s00253-013-4981-z

Krauze S (1962) Laboratory manual of food analyst. PZWL, Warsaw

Li D, Dai J-Y, Xiu Z-L (2010) A novel strategy for integrated utilization of Jerusalem artichoke stalk and tuber for production of 2,3-butanediol by Klebsiella pneumoniae. Bioresour Technol 101:8342–8347. doi:10.1016/j.biortech.2010.06.041

Li L, Chen Ch, Li K, Wang Y, Gao Ch, Ma C, Xu P (2014) Efficient simultaneous saccharification and fermentation of inulin to 2,3-butanediol by thermophilic Bacillus licheniformis ATCC 14580. Appl Environ Microbiol 80:6458–6464. doi:10.1128/AEM.01802-14

Li L, Li K, Wang K, Chen Ch, Gao Ch, Ma C, Xu P (2015) Efficient production of 2,3-butanediol from corn stover hydrolysate by using a thermophilic Bacillus licheniformis strain. Bioresour Technol 170:256–261. doi:10.1016/j.biortech.2014.07.101

Ma C, Wang A, Qin J, Li L, Ai X, Jiang T, Tang H, Xu P (2009) Enhanced 2,3-butanediol production by Klebsiella pneumoniae SDM. Appl Microbiol Biotechnol 82:49–57. doi:10.1007/s00253-008-1732-7

Mazumdar S, Lee J, Oh MK (2013) Microbial production of 2,3-butanediol from seaweed hydrolysate using metabolically engineered Escherichia coli. Bioresour Technol 136:329–336. doi:10.1016/j.biortech.2013.03.013

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:420–428. doi:10.1021/ac60147a030

Nawirska A, Kwaśniewska M (2005) Dietary fiber fractions from fruit and vegetable processing waste. Food Chem 91:221–225. doi:10.1016/j.foodchem.2003.10.005

Nilegaonkar SS, Bhosale SB, Dandage CN, Kapadi AH (1996) Potential of Bacillus licheniformis for the production of 2,3-butanediol. J Ferment Bioeng 82:408–410. doi:10.1016/0922-338X(96)89161-6

Perego P, Converti A, Del Borghi M (2003) Effects of temperature, inoculum size and starch hydrolyzate concentration on butanediol production by Bacillus licheniformis. Bioresour Technol 89:125–131. doi:10.1016/S0960-8524(03)00063-4

Petrov K, Petrova P (2010) Enhanced production of 2,3-butanediol from glycerol by forced pH fluctuations. Appl Microbiol Biotechnol 87:943–949. doi:10.1007/s00253-010-2545-z

Pyć R, Antczak T, Bratkowska H (2011) A method of enzymatic preparation production. Polish Patent no. 209161

Shrivastav A, Lee J, Kim H-Y, Kim Y-R (2013) Recent insights in the removal of Klebsiella pathogenicity factors for the industrial production of 2,3-butanediol. J Microbiol Biotechnol 23:885–896. doi:10.4014/jmb.1302.02066

Slutter A, Hames B, Ruiz R, Scarlata C, Slutter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. NREL/TP-510-42618

Sun H-L, Wang X-D, Dai J-Y, Xiu Z-L (2009) Microbial production of 2,3-butanediol from Jerusalem artichoke tubers by Klebsiella pneumoniae. Appl Microbiol Biotechnol 82:847–852. doi:10.1007/s00253-008-1823-5

Vendruscolo F, Albuquerque PM, Streit F, Esposito E, Ninow JL (2008) Apple pomace: a versatile substrate for biotechnological applications. Crit Rev Biotechnol 28:1–12. doi:10.1080/07388550801913840

Wang A, Wang Y, Jiang T, Li L, Ma C, Xu P (2010) Production of 2,3-butanediol from corncob molasses a waste by-product in xylitol production. Appl Microbiol Biotechnol 87:965–970. doi:10.1007/s00253-010-2557-8

Wang A, Xu Y, Ma C, Gao C, Li L, Wang Y, Tao F, Xu P (2012) Efficient 2,3-butanediol production from cassava powder by a crop-biomass-utilizer, Enterobacter cloacae subsp. dissolvens SDM. PLoS ONE 7:e40442. doi:10.1371/journal.pone.0040442

Wang Z, Wang Y, Xie F, Chen S, Li J, Li D, Chen X (2014) Improvement of acetoin reductase activity enhances bacitracin production by Bacillus licheniformis. Proc Biochem 49:2039–2043. doi:10.1016/j.procbio.2014.08.017

Zhang L, Ja S, Hao Y, Chu J, Wei D, Shen Y (2010) Microbial production of 2,3-butanediol by a surfactant (serrawettin)-deficient mutant of Serratia marcescens H30. J Ind Microbiol Biotechnol 37:857–862. doi:10.1007/s10295-010-0733-6

Zhang L, Yang Y, Ja S, Shen Y, Wei D, Zhu J, Chu J (2010) Microbial production of 2,3-butanediol by a mutagenized strain of Serratia marcescens H30. Bioresour Technol 101:1961–1967. doi:10.1016/j.biortech.2009.10.052

Acknowledgments

The presented results were obtained within the scope of the international ERA-IB project (2009–2011) with the acronym PUBB. Financial support was provided by the Polish National Center for Research and Development (NCBiR).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Białkowska, A.M., Gromek, E., Krysiak, J. et al. Application of enzymatic apple pomace hydrolysate to production of 2,3-butanediol by alkaliphilic Bacillus licheniformis NCIMB 8059. J Ind Microbiol Biotechnol 42, 1609–1621 (2015). https://doi.org/10.1007/s10295-015-1697-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-015-1697-3