Abstract

Conversion of lignocellulosic hydrolysates to lipids using oleaginous (high lipid) yeasts requires alignment of the hydrolysate composition with the characteristics of the yeast strain, including ability to utilize certain nutrients, ability to grow independently of costly nutrients such as vitamins, and ability to tolerate inhibitors. Some combination of these characteristics may be present in wild strains. In this study, 48 oleaginous yeast strains belonging to 45 species were tested for ability to utilize carbon sources associated with lignocellulosic hydrolysates, tolerate inhibitors, and grow in medium without supplemented vitamins. Some well-studied oleaginous yeast species, as well as some that have not been frequently utilized in research or industrial production, emerged as promising candidates for industrial use due to ability to utilize many carbon sources, including Cryptococcus aureus, Cryptococcus laurentii, Hannaella aff. zeae, Tremella encephala, and Trichosporon coremiiforme. Other species excelled in inhibitor tolerance, including Candida aff. tropicalis, Cyberlindnera jadinii, Metschnikowia pulcherrima, Schwanniomyces occidentalis and Wickerhamomyces ciferrii. No yeast tested could utilize all carbon sources and tolerate all inhibitors tested. These results indicate that yeast strains should be selected based on characteristics compatible with the composition of the targeted hydrolysate. Other factors to consider include the production of valuable co-products such as carotenoids, availability of genetic tools, biosafety level, and flocculation of the yeast strain. The data generated in this study will aid in aligning yeasts with compatible hydrolysates for conversion of carbohydrates to lipids to be used for biofuels and other oleochemicals.

Similar content being viewed by others

References

Li Q, Du W, Dehua L (2008) Perspectives of microbial oils for biodiesel production. Appl Microbiol Biotechnol 80:749–756

Rossi M, Amaretti A, Raimondi S, Leonardi A (2011) Getting lipids for biodiesel production from oleaginous fungi. biodiesel—feedstocks and processing technologies. InTech, Rijeka, pp 71–92

Shi S, Valle-Rodriguez J, Siewers V, Nielsen J (2011) Prospects for microbial biodiesel production. Biotechol J 6:277–285

Sitepu IR, Sestric R, Ignatia L, Levin D, Bruce German J, Gillies LA, Almada LA, Boundy-Mills KL (2013) Manipulation of culture conditions alters lipid content and fatty acid profiles of a wide variety of known and new oleaginous yeasts species. Bioresour Technol 144:360–369

Franklin S, Decker SM, Wee J (2011) Fuel and chemical production from oleaginous yeast. Google Patents

Rattray J (1988) Yeast. In: Ratledge C, Wilkinson S (eds) Microbial lipids, vol 1. Academic Press, London, pp 555–697

Rattray J, Scheibeci A, Kidby D (1975) Lipids of yeasts. Bacteriol Rev 39(3):197–231

Trimbur DE, Im C-S, Dillon HF, Day AG, Franklin S, Coragliotti A (2012) Renewable chemicals and fuels from oleaginous yeast. Google Patents

Huang C, Chen X-F, Xiong L, Chen X-D, Ma L–L, Chen Y (2013) Single cell oil production from low-cost substrates: the possibility and potential of its industrialization. Biotechnol Adv 31:129–139

Huang C, Chen X-F, Xiong L, Yang X-Y, Chen X-D, Ma L-L, Chen Y (2013) Microbial oil production from corncob acid hydrolysate by oleaginous yeast Trichosporon coremiiforme. Biomass Bioenergy 49:273–278

Huang C, Zong M-H, Wu H, Liu Q-P (2009) Microbial oil production from rice straw hydrolysate by Trichosporon fermentans. Bioresour Technol 100(19):4535–4538

Li M, Liu G-L, Chi Z, Chi Z-M (2010) Single cell oil production from hydrolysate of cassava starch by marine-derived yeast Rhodotorula mucilaginosa TJY15a. Biomass Bioenergy 34(1):101–107

Liu W, Wang Y, Yu Z, Bao J (2012) Simultaneous saccharification and microbial lipid fermentation of corn stover by oleaginous yeast Trichosporon cutaneum. Bioresour Technol 118:13–18

Tsigie YA, Wang C-Y, Truong C-T, Ju Y-H (2011) Lipid production from Yarrowia lipolytica Po1g grown in sugarcane bagasse hydrolysate. Bioresour Technol 102(19):9216–9222

Wang Q, Guo F-J, Rong Y-J, Chi Z-M (2012) Lipid production from hydrolysate of cassava starch by Rhodosporidium toruloides 21167 for biodiesel making. Renew Energy

Yu X, Zheng Y, Dorgan K, Chen S (2011) Oil production by oleaginous yeasts using the hydrolysate from pretreatment of wheat straw with dilute sulfuric acid. Bioresour Technol 102:6134–6140

Chen X, Li Z, Zhang X, Hu F, Ryu D, Bao J (2009) Screening of oleaginous yeast strains tolerant to lignocellulose degradation compounds. Appl Biochem Biotechnol 159:591–604

Palmqvist E, Hahn-Hagerdal B (2000) Fermentation of lignocellulosic hydrolysates. I: inhibition and detoxification. Bioresour Technol 74:17–24

Palmqvist E, Hahn-Hägerdal B (2000) Fermentation of lignocellulosic hydrolysates. II: inhibitors and mechanisms of inhibition. Bioresour Technol 74(1):25–33

Zha Y, Muilwijk B, Coulier L, Punt P (2012) Inhibitory compounds in lignocellulosic biomass hydrolysates during hydrolysate fermentation processes. J Bioprocess Biotech 2(1):112–122. doi:10.4172/2155-9821.1000112

Kurtzman C, Fell J, Boekhout T, Robert V (2011) Methods for isolation, phenotypic characterization and maintenance of yeasts, chap 7, vol 1. The yeasts: a taxonomic study. Elsevier, Amsterdam

Suutari M, Priha P, Laakso S (1993) Temperature shifts in regulation of lipids accumulated by Lipomyces starkeyi. J Am Oil Chem Soc 70:891–894

Suutari M, Priha P, Laakso S (1993) Temperature shifts in regulation of lipids accumulated by Lipomyces starkeyi. J Am Oil Chem Soc 70(9):891–894. doi:10.1007/BF02545349

Kurtzman CP (2011) Yarrowia van der Walt & von Arx (1980). In: Kurtzman CP, Fell J, Boekhout T (eds) The yeasts: a taxonomic study, vol 2, 5th edn. Elsevier, Amsterdam, pp 927–929

Kurtzman C, Fell J, Boekhout T (2011) The yeasts: a taxonomic study, 5th edn. Elsevier, Amsterdam

Boundy-Mills K (2008) The Phaff Yeast Culture Collection has found its niche. Soc Ind Microbiol News 58(2):49–56

Boundy-Mills K (2012) Yeast culture collections of the world: meeting the needs of industrial researchers. J Ind Microbiol Biotechnol 39(5):673–680

McCluskey K, Wiest A, Boundy-Mills K (2014) Genome data drives change at culture collections, chap 4. In: Nowrousian M (ed) Fungal genomics, 2nd edn. Springer, Heidelberg

Hu C, Zhao X, Zhao J, Wu S, Zongbao K (2009) Effects of biomass hydrolysis by-products on oleaginous yeast Rhodosporidium toruloides. Bioresour Technol 100(20):4843–4847

Huang C, Wu H, Liu Q-p, Li Y-y, Zong M-h (2011) Effects of aldehydes on the growth and lipid accumulation of oleaginous yeast Trichosporon fermentans. J Agric Food Chem 59(9):4606–4613

Huang C, Wu H, Liu Z, Cai J, Lou W, Zong M (2012) Effect of organic acids on the growth and lipid accumulation of oleaginous yeast Trichosporon fermentans. Biotechnol Biofuels 5:4

Yu X, Zeng J, Zheng Y, Chen S (2013) Effect of lignocellulose degradation products on microbial biomass and lipid production by the oleaginous yeast Cryptococcus curvatus. Process Biochem

Qin L, Liu Z-H, Li B-Z, Dale BE, Yuan Y-J (2012) Mass balance and transformation of corn stover by pretreatment with different dilute organic acids. Bioresour Technol 112:319–326

Zhang J, Zhu Z, Wang X, Wang N, Wang W, Bao J (2010) Biodetoxification of toxins generated from lignocellulose pretreatment using a newly isolated fungus, Amorphotheca resinae ZN1, and the consequent ethanol fermentation. Biotechnol Biofuels 3(26):1–15

Rumbold K, van Buijsen HJ, Overkamp KM, van Groenestijn JW, Punt PJ, van der Werf MJ (2009) Microbial production host selection for converting second-generation feedstocks into bioproducts. Microb Cell Fact 8:64

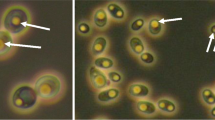

Sitepu I, Ignatia L, Franz A, Wong D, Faulina S, Tsui M, Kanti A, Boundy-Mills K (2012) An improved high-throughput Nile red fluorescence assay for estimating intracellular lipids in a variety of yeast species. J Microbiol Methods 91(2):321–328

Smith MT, Kurtzman CP (2011) Lipomyces Lodder & Kreger-van Rij (1952). In: Kurtzman CP, Fell J, Boekhout T (eds) The yeasts: a taxonomic study, vol 2, 5th edn. Elsevier, Amsterdam, pp 545–560

Andreevskaya V, Zalashko M (1979) Effect of addition of salts on growth and synthesis of lipid in yeasts cultured on peat oxidates. Prikladnaya Biokhimiya i Mikrobiologiya 15:522–527

Malkhas’ian S, Nechaev A, Gavrilova N, Zotova E, Doronina O (1982) Group and fatty acid composition of the lipids in yeasts of the genus Candida. Prikl Biokhim Mikrobiol 18(5):621–629

Eroshin V, Krylova N (1983) Efficiency of lipid synthesis by yeasts. Biotechnol Bioeng 25:1693–1700

Enebo L, Elander M, Berg F, Lundin H, Nilsson R, Myrbäck K (1944) Mikrobielle Fettsynthese durch Lufthefezuchtung von Rhodotorulaarten. I V A 6:1

Moon N, Hammond E, Glatz B (1978) Conversion of cheese whey and whey permeate to oil and single-cell protein. J Dairy Sci 61:1537–1547

Boulton C, Ratledge C (1981) Correlation of lipid accumulation in yeasts with possession of ATP:citrate lyase. Microbiology 127(1):169–176

Jigami Y, Suzuki O, Nakasato S (1979) Comparison of lipid composition of Candida guilliermondii grown on glucose, ethanol and methanol as the sole carbon source. Lipids 14(11):937–942

Kitcha S, Cheirsilp B (2011) Screening of oleaginous yeasts and optimization for lipid production using crude glycerol as a carbon source. Energy Proc 9:274–282

Stanier R (1946) Some aspects of microbiological research in Germany. B.I.O.S. Final Report No. 691, Item No. 24. British Intelligence Objectives Sub-Committee, London

Pan L-X, Yang D-F, Shao L, Li W, Chen G-G, Liang Z-Q (2009) Isolation of the oleaginous yeasts from the soil and studies of their lipid-producing capacities. Food Technol Biotechnol 47(2):215–220

Gill C, Hall J, Ratledge C (1977) Lipid accumulation in an oleaginous yeast (Candida 107) growing on glucose in single-stage continuous culture. Appl Environ Microbiol 33(2):231–239

Guerzoni M, Lambertini P, Lercker G, Marchetti R (1985) Technological potential of some starch degrading yeasts. Starch 37(2):52–57

Matsuo T, Terashima M, Hasimoto Y, Hasida W (1981) Method for producing cacao butter substitute. USA Patent 4(308):350

Sentheshanmuganathan S, Nickerson W (1962) Composition of cells and cell walls of triangular and ellipsoidal forms of Trigonopsis variabilis. J Gen Microbiol 27:451–464

Hopton J, Woodbine M (1960) Fat synthesis by yeasts. I. A comparative assessment of Hansenula species. J Appl Bacteriol 23(2):283–290

Bati N, Hammond E, Glatz B (1984) Biomodification of fats and oils: trials with Candida lipolytica. J Am Oil Chem Soc 61(11):1743–1746

Acknowledgments

Some yeasts used in this study were isolated and identified as part of a collaborative project with the Government of the Republic of Indonesia, funded by Grant Number U01TW008160 from the NIH Fogarty International Center, the NIH Office of Dietary Supplements, the National Science Foundation and the Department of Energy. This project was supported by the USDA Agricultural Food Research Initiative of the National Food and Agriculture, USDA, Grant #35621-04750. The content is solely the responsibility of the authors and does not necessarily represent the official views of the Fogarty International Center or the National Institutes of Health, the Office of Dietary Supplements, the National Science Foundation, the Department of Energy, or the Department of Agriculture. We appreciate the contribution of Elizabeth Widjaja, LIPI Center for Biology, Cibinong, Indonesia for identifying plant hosts of yeasts M076LWD and PLE1112RB. We appreciate the contribution of Nathan Schiff for identification of the insect host of yeast T2002RA. Eveline Tioniwar provided technical assistance. The anonymous reviewers provided valuable feedback that significantly improved the quality of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sitepu, I., Selby, T., Lin, T. et al. Carbon source utilization and inhibitor tolerance of 45 oleaginous yeast species. J Ind Microbiol Biotechnol 41, 1061–1070 (2014). https://doi.org/10.1007/s10295-014-1447-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-014-1447-y