Abstract

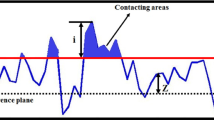

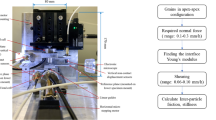

The behaviour of granular material can be predicted numerically with the discrete element method. This method potentially uses material properties to describe the behaviour of a particle and its interactions with other particles or walls. One characteristic property is the particle contact stiffness. The work described herein reviews on one hand shortly different types of stiffness in particle mechanics and on the other hand, with regard to the experimental work, an overview of the newly developed method to examine the contact behaviour between two particles is given. The advantage of this approach is the exclusion of possible equipment deformation and is, thus, only referring to the deformation of two particles in contact. Therefore, especially the deformation of asperities on the particles’ surface can be taken into account. A variety of contact experiments on single and two particles were conducted to validate the new method. Glass beads with a particle diameter from \(\hbox {d}_\mathrm{p}=\) 0.8 to \(3.0\hbox { mm}\) were chosen and a maximum compression force of \(\hbox {F}= 80\hbox { N}\). While only one material type was studied, this work has the broader implication to present a method for determining a material’s contact stiffness and its evolution during increasing contact. This study is part of the PARDEM research network: www.pardem.eu.

Similar content being viewed by others

References

Nedderman, R.M.: Statics and Kinematics of Granular Materials. Cambridge University Press, Cambridge (2005)

Ennis, B.J., Green, J., Davies, R.: The legacy of neglect in the US. Chem. Eng. Prog. 90(4), 32–43 (1994)

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. Geotechnique 29, 47–65 (1979)

Johnstone, M.W.: Calibration of DEM Models for Granular Materials Using Bulk Physical Tests. Doctor of Philosophy, The University of Edinburgh (2010)

Kruggel-Emden, H., Simsek, E., Rickelt, S., Wirtz, S., Scherer, V.: Review and extension of normal force models for the discrete element method. Powder Technol. 171(3), 157–173 (2007). doi:10.1016/j.powtec.2006.10.004

Mann, A.B., Pethica, J.B.: The role of atomic size asperities in the mechanical deformation of nanocontacts. Appl. Phys. Lett. 69(7), 907–909 (1996)

Bobji, M.S., Biswas, S.K.: Deconvolution of hardness from data obtained from nanoindentation of rough surfaces. J. Mater. Res. 14(6), 2259–2268 (1999)

Fischer-Cripps, A.C.: Introduction to Contact Mechanics. Springer, New York (2000)

Pharr, G.M., Oliver, W.C., Brotzen, F.R.: On the generality of the relationship among contact stiffness, contact area, and elastic modulus during indentation. J. Mater. Res. 7(3), 613–617 (1992)

Li, X., Bhushan, B.: A review of nanoindentation continuous stiffness measurement technique and its applications. Mater. Charact. 48(1), 11–36 (2002). doi:10.1016/s1044-5803(02)00192-4

Antonyuk, S., Palis, S., Heinrich, S.: Breakage behaviour of agglomerates and crystals by static loading and impact. Powder Technol. 206(1–2), 88–98 (2011). doi:10.1016/j.powtec.2010.02.025

Müller, P., Antonyuk, S., Tomas, J.: Simulation of the compression and impact behavior of zeolith 4A granules [Simulation des Druck- und Stoßvorgangs von Zeolith 4A-Granulaten]. Chemie Ingenieur Technik 83(5), 643–651 (2011). doi:10.1002/cite.201000212

Cavarretta, I., Coop, M., O’Sullivan, C.: The influence of particle characteristics on the behaviour of coarse grained soils. Geotechnique 60(6), 413–423 (2010). doi:10.1680/geot.2010.60.6.413

Mader-Arndt, K., Kutelova, Z., Fuchs, R., Meyer, J., Staedler, T., Hintz, W., Tomas, J.: Single particle contact versus particle packing behavior: model based analysis of chemically modified glass particles. Granul. Matter, 1–17 (2014). doi:10.1007/s10035-013-0478-9

Robinson, A.M., Drinkwater, B.W., Dwyer-Joyce, R.S., Payne, J.F.B.: Measurement of the stiffness of joints in graphite brick assembly. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 215(2), 167–178 (2001). doi:10.1243/0954406011520599

Shi, X., Polycarpou, A.A.: Measurement and modeling of normal contact stiffness and contact damping at the meso scale. J. Vib. Acoust. Trans. ASME 127(1), 52–60 (2005). doi:10.1115/1.1857920

Mullier, M., Tüzün, U., Walton, O.R.: A single-particle friction cell for measuring contact frictional properties of granular materials. Powder Technol. 65(1–3), 61–74 (1991)

Cole, D.M., Peters, J.F.: A physically based approach to granular media mechanics: grain-scale experiments, initial results and implications to numerical modeling. Granul. Matter. 9(5), 309–321 (2007)

Heim, L.O., Blum, J., Preuss, M., Butt, H.J.: Adhesion and friction forces between spherical micrometer-sized particles. Phys. Rev. Lett. 83(16), 3328–3331 (1999)

Daeinabi, K., Korayem, M.H.: Indentation analysis of nano-particle using nano-contact mechanics models during nano-manipulation based on atomic force microscopy. J. Nanopart. Res. 13(3), 1075–1091 (2011). doi:10.1007/s11051-010-0096-y

Cohen, M.L.: Calculation of bulk moduli of diamond and zinc-blende solids. Phys. Rev. B 32(12), 7988–7991 (1985). doi:10.1103/PhysRevB.32.7988

Gaith, M.S., Alhayek, I.: The measurement of overall elastic stiffness and bulk modulus in anisotropic materials: semiconductors. In: Lake Buena Vista, FL 2010. 2009 ASME International Mechanical Engineering Congress and Exposition, IMECE2009, pp. 29–34

Kruyt, N.P., Agnolin, I., Luding, S., Rothenburg, L.: Micromechanical study of elastic moduli of loose granular materials. J. Mech. Phys. Solids 58(9), 1286–1301 (2010)

Walton, K.: The effective elastic moduli of a random packing of spheres. J. Mech. Phys. Solids 35(2), 213–226 (1987)

Lätzel, M., Luding, S., Herrmann, H.J.: Macroscopic material properties from quasi-static, microscopic simulations of a two-dimensional shear-cell. Granul. Matter. 2(3), 123–135 (2000)

Derjaguin, B.V., Muller, V.M., Toporov, Y.P.: Effect of contact deformations on the adhesion of particles. J. Colloid Interface Sci. 53(2), 314–326 (1975)

Walton, O.R., Braun, R.L.: Viscosity, granular-temperature, and stress calculations for shearing assemblies of inelastic, frictional disks. J. Rheol. 30(5), 949–980 (1986)

Thornton, C., Ning, Z.: A theoretical model for the stick/bounce behaviour of adhesive, elastic-plastic spheres. Powder Technol. 99(2), 154–162 (1998)

Brilliantov, N.V., Spahn, F., Hertzsch, J.M., Pöschel, T.: Model for collisions in granular gases. Phys. Rev. E 53(5 SUPPL. B), 5382–5392 (1996)

Hertz, H.: Über die Berührung fester elastischer Körper. J. Für die reine Angew Math. 92, 156–171 (1881)

Johnson, K.L.: Contact Mech. Cambridge University Press, Cambridge (1985)

Tomas, J.: Adhesion of ultrafine particles—a micromechanical approach. Chem. Eng. Sci. 62(7), 1997–2010 (2007). doi:10.1016/j.ces.2006.12.055

Yap, S.F., Adams, M.J., Seville, J.P.K., Zhang, Z.: Single and bulk compression of pharmaceutical excipients: evaluation of mechanical properties. Powder Technol. 185(1), 1–10 (2008)

Samimi, A., Hassanpour, A., Ghadiri, M.: Single and bulk compressions of soft granules: experimental study and DEM evaluation. Chem. Eng. Sci. 60(14), 3993–4004 (2005). doi:10.1016/j.ces.2005.02.036

Yoshida, M., Ogiso, H., Nakano, S., Akedo, J.: Compression test system for a single submicrometer particle. Rev. Sci. Instrum. 76(9), 093905 (2005)

Romeis, S., Paul, J., Ziener, M., Peukert, W.: A novel apparatus for in situ compression of submicron structures and particles in a high resolution SEM. Rev. Sci. Instrum. 83(9) (2012). doi:10.1063/1.4749256

Paul, J., Romeis, S., Tomas, J., Peukert, W.: A review of models for single particle compression and their application to silica microspheres. Adv. Powder Technol. 25(1), 136–153 (2014). doi:10.1016/j.apt.2013.09.009

Russell, A., Müller, P., Tomas, J.: Multiple compression of moist spherical elastic-plastic zeolite 4A granules. Chem. Eng. Technol. 36(7), 1240–1248 (2013). doi:10.1002/ceat.201300109

Bierwisch, C.S.: Numerical Simulations of Granular Flow and Filling. Albert-Ludwigs-Universität Freiburg, Freiburg im Breisgau (2009)

Moreno-Atanasio, R., Xu, B.H., Ghadiri, M.: Computer simulation of the effect of contact stiffness and adhesion on the fluidization behaviour of powders. Chem. Eng. Sci. 62(1–2), 184–194 (2007). doi:10.1016/j.ces.2006.08.036

Antony, S.J., Moreno-Atanasio, R., Hassanpour, A.: Influence of contact stiffnesses on the micromechanical characteristics of dense particulate systems subjected to shearing. Appl. Phys. Lett. 89(21) (2006). doi:10.1063/1.2396894

Coetzee, C.J., Els, D.N.J., Dymond, G.F.: Discrete element parameter calibration and the modelling of dragline bucket filling. J. Terramech. 47(1), 33–44 (2010). doi:10.1016/j.jterra.2009.03.003

Lowery, M., Zeghal, M.: Effects of particle and mix characteristics on performance of some granular materials. In: CANCAM 2003, Calgary, Alberta, June 1–6, 2003, pp. 302–303 (2003)

Park Systems Corporation: XE-100 User’s Manual, vol. Version 1.0. (2002)

Carpick, R.W., Ogletree, D.F., Salmeron, M.: Lateral stiffness: a new nanomechanical measurement for the determination of shear strengths with friction force microscopy. Appl. Phys. Lett. 70(12), 1548–1550 (1997)

Antonyuk, S., Heinrich, S., Tomas, J., Deen, N.G., Van Buijtenen, M.S., Kuipers, J.A.M.: Energy absorption during compression and impact of dry elastic-plastic spherical granules. Granul. Matter. 12(1), 15–47 (2010). doi:10.1007/s10035-009-0161-3

Antonyuk, S.: Deformations- und Bruchverhalten von kugelförmigen Granulaten bei Druck- und Stoßbeanspruchung. Docupoint-Verlag, Magdeburg (2006)

Acknowledgments

The authors would like to express their gratitude to the European Community under the Marie Curie Actions Initial Training Network and to the Deutsch-Französische Hochschule for the support. We would also like to thank Prof. Ugur Tüzün, Stefan Strege, Mar Combarros and Dr.-Ing. Carsten Schilde for the discussions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Paulick, M., Morgeneyer, M. & Kwade, A. A new method for the determination of particle contact stiffness. Granular Matter 17, 83–93 (2015). https://doi.org/10.1007/s10035-014-0537-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10035-014-0537-x