Abstract

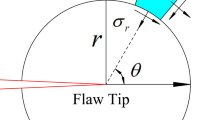

Frictional contact is an important component of rock cutting with a blunt cutter. There has been a gap in knowledge of frictional contact between experimental tests conducted on quasi-brittle rocks and previous numerical and analytical analyses on elastoplastic rocks. The average contact stress between a sliding wear flat and a rock is generally overestimated in previous studies without considering material length scales. This study analyzes the contact stress using an elasto-plastic-damage model that accounts for the material length scales of quasi-brittle materials. The constitutive model is developed for quasi-brittle materials by incorporating fracture energy, and it is implemented in the commercial finite element software ABAQUS as a user-defined material model. The implemented constitutive model is verified under uniaxial tension and compression. The average contact stress in frictional contact is mainly governed by a dimensionless elastoplastic parameter \( \eta \) for an elastoplastic rock, while it is predominantly governed by two dimensionless parameters: an elastoplastic parameter \( \eta \) and a brittleness number \( \xi \) for a quasi-brittle rock. The dimensionless elastoplastic parameter \( \eta \) contrasts the magnitude of a characteristic elastic contact stress to the yield strength of a material, and the brittleness number \( \xi \) is the ratio of a geometrical length scale to a material length scale. The tool–rock interface can be approximately divided into an elastic zone and a damage process zone. The contact stress generally increases in the elastic zone and then decreases in the damage process zone towards the tip of the slider. The average contact stress generally increases with the dimensionless elastoplastic parameter \( \eta \) and then levels off at a limit value, and it generally decreases with the brittleness number \( \xi \). This study reduces the gap in previous studies to some extent by introducing the brittleness number \( \xi \) in frictional contact. The current numerical results of the average contact stress are generally consistent with typical experimental results conducted on quasi-brittle rocks, despite limitations in the finite element modeling.

Similar content being viewed by others

References

Abu Al-Rub RK, Kim S-M (2010) Computational applications of a coupled plasticity-damage constitutive model for simulating plain concrete fracture. Eng Fract Mech 77(10):1577–1603

Abu Al-Rub RK, Voyiadjis GZ (2009) Gradient-enhanced coupled plasticity-anisotropic damage model for concrete fracture: computational aspects and applications. Int J Damage Mech 18(2):115–154

Adachi J (1996) Frictional contact in rock cutting with blunt tools. MS thesis, University of Minnesota, Minneapolis, MN

Alehossein H, Detournay E, Huang H (2000) An analytical model for the indentation of rocks by blunt tools. Rock Mech Rock Eng 33(4):267–284

Almenara R (1992) Investigation of the cutting process in sandstones with blunt PDC cutters. Ph.D. thesis, Imperial College, London, UK

Almenara R, Detournay E (1992) Cutting experiments in sandstones with blunt PDC cutters. In: ISRM symposium: Eurock 92, Chester, UK

Amri M, Pelfrene G, Jahangir E, Tijani M, Sellami H (2018) Numerical and analytical study of rate effects on drilling forces under bottomhole pressure. Int J Rock Mech Min Sci 110:189–198

Borri-Brunetto M, Carpinteri A, Invernizzi S (2003) Characterization and mechanical modeling of the abrasion properties of sintered tools with embedded hard particles. Wear 254(7–8):635–644

Carpinteri A, Invernizzi S (2005) Numerical analysis of the cutting interaction between indenters acting on disordered materials. Int J Fract 131(2):143–154

Carpinteri A, Chiaia B, Invernizzi S (2004) Numerical analysis of indentation fracture in quasi-brittle materials. Eng Fract Mech 71(4–6):567–577

Cervera M, Chiumenti M (2009) Size effect and localization in J2 plasticity. Int J Solids Struct 46(17):3301–3312

Cervera M, Chiumenti M, Agelet de Saracibar C (2004) Softening, localization and stabilization: capture of discontinuous solutions in J2 plasticity. Int J Numer Anal Meth Geomech 28(5):373–393

Challen JM, Oxley PLB (1979) An explanation of the different regimes of friction and wear using asperity deformation models. Wear 53(2):229–243

Cicekli U, Voyiadjis GZ, Abu Al-Rub RK (2007) A plasticity and anisotropic damage model for plain concrete. Int J Plast 23(10–11):1874–1900

Detournay E, Defourny P (1992) A phenomenological model for the drilling action of drag bits. Int J Rock Mech Min Sci Geomech Abstr 29(1):13–23

Geoffroy H, Minh DN, Bergues J, Putot C (1998) Frictional contact on cutters wear flat and evaluation of drilling parameters of a PDC bit. In: SPE/ISRM rock mechanics in petroleum engineering. Society of Petroleum Engineers, Trondheim, Norway

Gerbaud L, Menand S, Sellami H (2006) PDC bits: all comes from the cutter rock interaction. In: IADC/SPE drilling conference, Miami, FL

Gladwell GM (1980) Contact problems in the classical theory of elasticity. Sijthoff & Noordhoff, Alphen aan den Rijn

Glowka D (1989) Use of single-cutter data in the analysis of PDC bit designs: part 1—development of a PDC cutting force model. J Pet Technol 41:797–799

Hibbitt HD, Karlsson BI, Sorensen P (2001) ABAQUS/standard user’s manual. Hibbitt, Karlsson & Sorensen, Inc., Pawtucket

Hillerborg A (1985) The theoretical basis of a method to determine the fracture energy Gf of concrete. Mater Struct 18(4):291–296

Huang H, Detournay E (2008) Intrinsic length scales in tool–rock interaction. Int J Geomech 8:39–44

Huang H, Detournay E (2013) Discrete element modeling of tool–rock interaction II: rock indentation. Int J Numer Anal Methods Geomech 37(13):1930–1947

Huang H, Lecampion B, Detournay E (2013) Discrete element modeling of tool–rock interaction I: rock cutting. Int J Numer Anal Meth Geomech 37(13):1913–1929

Johnson KL (1970) The correlation of indentation experiments. J Mech Phys Solids 18(2):115–126

Johnson KL (1987) Contact mechanics. Cambridge University Press, London

Kupfer H, Hilsdorf HK, Rusch H (1969) Behavior of concrete under biaxial stresses. ACI J 66(8):656–666

Labuz J, Dai S (2000) Residual strength and fracture energy from plane-strain testing. J Geotech Geoenviron Eng 126(10):882–889

Lee J, Fenves GL (1998) Plastic-damage model for cyclic loading of concrete structures. J Eng Mech 124(8):892–900

Lubliner J, Oliver J, Oller S, Onate E (1989) A plastic-damage model for concrete. Int J Solids Struct 25(3):299–326

Marck J, Detournay E (2016) Influence of rotary-steerable-system design on borehole spiraling. SPE J 21(01):293–302

Murray YD (2007) User manual for LS-DYNA concrete material model 159. Federal Highway Administration, Mclean

Oliver J, Cervera M, Oller S, Lubliner J (1990) Isotropic damage models and smeared crack analysis of concrete. In: 2nd International conference on computer aided analysis and design of concrete structures, Zell am See, Austria, pp 945–957

Prandtl L (1921) Hauptaufsätze: Über die eindringungsfestigkeit (härte) plastischer baustoffe und die festigkeit von schneiden. ZAMM Z Angew Math Mech 1(1):15–20

Richard T, Germay C, Detournay E (2007) A simplified model to explore the root cause of stick–slip vibrations in drilling systems with drag bits. J Sound Vib 305(3):432–456

Richard T, Dagrain F, Poyol E, Detournay E (2012) Rock strength determination from scratch tests. Eng Geol 147:91–100

Rostamsowlat I (2018) Effect of cutting tool properties and depth of cut in rock cutting: an experimental study. Rock Mech Rock Eng 51(6):1715–1728

Rostamsowlat I, Akbari B, Evans B (2018a) Analysis of rock cutting process with a blunt PDC cutter under different wear flat inclination angles. J Pet Sci Eng 171:771–783

Rostamsowlat I, Richard T, Evans B (2018b) Experimental investigation on the effect of wear flat inclination on the cutting response of a blunt tool in rock cutting. Acta Geotech. https://doi.org/10.1007/s11440-018-0674-1

Rostamsowlat I, Richard T, Evans B (2018c) An experimental study of the effect of back rake angle in rock cutting. Int J Rock Mech Min Sci 107:224–232

Saucedo L, Yu RC, Gonzalo R (2012) Fully-developed FPZ length in quasi-brittle materials. Int J Fract 178(1–2):97–112

Shen B, Stephansson O (1994) Modification of the G-criterion for crack propagation subjected to compression. Eng Fract Mech 47(2):177–189

Shi G, Voyiadjis GZ (1997) A new free energy for plastic damage analysis. Mech Res Commun 24(4):377–383

Tao X, Phillips DV (2005) A simplified isotropic damage model for concrete under bi-axial stress states. Cem Concr Compos 27(6):716–726

Taqieddin ZN, Voyiadjis GZ (2009) Elastic plastic and damage model for concrete materials: part II—implementation and application to concrete and reinforced concrete. Int J Struct Chang Solids 1(1):187–209

Voyiadjis GZ, Abu-Lebdeh TM (1994) Plasticity model for concrete using the bounding surface concept. Int J Plast 10(1):1–21

Voyiadjis GZ, Taqieddin ZN (2009) Elastic plastic and damage model for concrete materials: part I—theoretical formulation. Int J Struct Chang Solids 1(1):31–59

Voyiadjis GZ, Taqieddin ZN, Kattan PI (2008) Anisotropic damage—plasticity model for concrete. Int J Plast 24(10):1946–1965

Voyiadjis GZ, Taqieddin ZN, Kattan PI (2009) Theoretical formulation of a coupled elastic–plastic anisotropic damage model for concrete using the strain energy equivalence concept. Int J Damage Mech 18(7):603–638

Wu JY, Li J, Faria R (2006) An energy release rate-based plastic-damage model for concrete. Int J Solids Struct 43(3–4):583–612

Zhang J, Li J (2014) Elastoplastic damage model for concrete based on consistent free energy potential. Sci China Technol Sc 57(11):2278–2286

Zhou Y (2017a) The applicability of correspondence rule with inclined load. Rock Mech Rock Eng 50(1):233–240

Zhou Y (2017b) Misinterpretation of friction as fracture in shallow scratch tests with classical and universal size effect laws. Eng Fract Mech 184:14–21

Zhou Y, Detournay E (2014) Analysis of the contact forces on a blunt PDC bit. In: 48th US rock mechanics/geomechanics symposium, Minneapolis, MN

Zhou Y, Detournay E (2019) Elastoplastic model of a blunt rigid tool sliding on rock (in preparation)

Zhou Y, Lin J-S (2013) On the critical failure mode transition depth for rock cutting. Int J Rock Mech Min Sci 62:131–137

Zhou Y, Zhang W, Gamwo IK, Lin J-S (2017) Mechanical specific energy versus depth of cut in rock cutting and drilling. Int J Rock Mech Min Sci 100:287–297

Acknowledgements

This work was funded by the Center for GeoInformatics (C4G) at the Louisiana State University. The second author acknowledges gratitude to Professor Emmanuel Detournay at the University of Minnesota for the benefit of stimulating discussions that inspired this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Voyiadjis, G.Z., Zhou, Y. Numerical Modeling of Frictional Contact Between a Blunt Tool and Quasi-Brittle Rock. Rock Mech Rock Eng 52, 3771–3790 (2019). https://doi.org/10.1007/s00603-019-01800-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-019-01800-0