Abstract

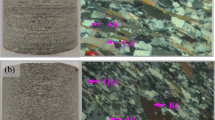

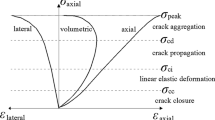

Phyllite is a low-grade, metamorphic rock with well-developed foliation. We characterized the fracture pattern and failure strength of phyllite specimens under Brazilian tests. The specimens were obtained from the Zhegu mountain tunnel in China and had different foliation-loading angles, namely 0°, 15°, 30°, 45°, 60°, 75° and 90°. The processes for the initiation and propagation of macro-cracks were recorded using high-speed photography. The evolution of micro-cracks was analyzed based on the results of acoustic emission (AE) tests. The failure process of the specimens during the Brazilian tests was simulated with a new numerical approach based on the particle discrete element method. The influence of foliation strength and the microstructure of the rock matrix were also studied numerically. The experimental results showed that the failure strength of the specimens was related to their fracture patterns and the areas of their fracture surfaces. The initial cracking point of the specimens appeared at the upper or lower loading position, and the cracks propagated to the boundaries of the specimens along or across foliation. The temporal distributions of the AE counts and AE energy of the specimens were affected predominantly by the fracture pattern, and we divided these distributions into two modes: the peak mode and the uniformly distributed mode. The numerical results indicated that the fracture surface was roughly parallel to the loading direction and that the surface was located in the central part of the disk specimens for rocks with loose structure (low coordination number or large crack density) or with strong foliation, i.e., foliation with high shear strength. The failure pattern and trends of variation in failure strength as a function of foliation-loading angles varied with the ratio of cohesion to the tensile strength of foliation, the crack density, and the coordination number.

Similar content being viewed by others

Abbreviations

- σ t :

-

Tensile strength (Pa)

- F :

-

Peak loading force (N)

- D :

-

Diameter of rock specimen (m)

- t :

-

Thickness of rock specimen (m)

- U :

-

Energy of AE signal (J)

- R :

-

Input impedance of preamplifier (Ω)

- V :

-

Voltage of AE signal (V)

- \(\bar{\sigma }_{c}\) :

-

Normal strength of flat-joint bond (Pa)

- \(\bar{\tau }_{c}\) :

-

Shear strength of flat-joint bond (Pa)

- \(\bar{k}^{\text{n}}\) :

-

Normal stiffness of flat-joint bond (Pa m−1)

- \(\bar{k}^{\text{s}}\) :

-

Shear stiffness of flat-joint bond (Pa m−1)

- \(k^{\text{n}}\) :

-

Normal stiffness of particle (Pa m−1)

- \(k^{\text{s}}\) :

-

Shear stiffness of particle (Pa m−1)

- \(\mu_{c}\) :

-

Friction coefficient between particles

- g ratio :

-

Installation gap ratio

- φ S :

-

Slit element fraction

- \(\bar{k}_{\text{n}}\) :

-

Normal stiffness of smooth joint bond (Pa m−1)

- \(\bar{k}_{\text{s}}\) :

-

Shear stiffness of smooth joint bond (Pa m−1)

- \(\bar{\lambda }\) :

-

Radius multiplier

- \(\mu\) :

-

Friction coefficient of smooth joint bond

- \(\sigma_{c}\) :

-

Normal strength of smooth joint bond (Pa)

- \(c_{b}\) :

-

Cohesion of smooth joint bond (Pa)

- \(\varphi_{b}\) :

-

Friction angle between particles (°)

References

Amadei B, Rogers JD, Goodman RE (1983) Elastic constants and tensile strength of anisotropic rocks. In: Proceedings of the 5th international congress on rock mechanics, Melbourne, Australia

Bahaaddini M, Sharrock G, Hebblewhite BK (2013) Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression. Comput Geotech 49:206–225

Barla G, Innaurato N (1973) Indirect tensile testing of anisotropic rocks. Rock Mech 5:215–230

Blümling P, Bernier F, Lebon P, Martin CD (2007) The excavation damaged zone in clay formations: time-dependent behavior and influence on performance assessment. Phys Chem Earth 32:588–599

Chen CS, Pan E, Amadei B (1998) Determination of deformability and tensile strength of anisotropic rock using Brazilian tests. Int J Rock Mech Min Sci 35:43–61

Cho JW, Kim H, Jeon S, Min KB (2012) Deformation and strength anisotropy of Asan gneiss, Boryeong shale, and Yeoncheon schist. Int J Rock Mech Min Sci 50:158–169

Dan DQ (2011) Brazilian test on anisotropic rocks-laboratory experiment, numerical simulation and interpretation. Dissertation, TU Bergakademie Freiberg

Debecker B (2009) Influence of planar heterogeneities on the fracture behavior of rock. Dissertation, University of Leuven

Duan K, Kwok CY (2015) Discrete element modeling of anisotropic rock under Brazilian test conditions. Int J Rock Mech Min Sci 78:46–56

Huang D, Wang JF, Liu S (2015) A comprehensive study on the smooth joint model in DEM simulation of jointed rock masses. Granul Matter 17:775–791

Khanlari GR, Heidari M, Sepahigero AA, Fereidooni D (2014) Quantification of strength anisotropy of metamorphic rocks of the Hamedan province, Iran, as determined from cylindrical punch, point load and Brazilian tests. Eng Geol 169:80–90

Kim H, Cho JW, Song I, Min KB (2012) Anisotropy of elastic moduli, P-wave velocities, and thermal conductivities of Asan Gneiss, Boryeong Shale, and Yeoncheon Schist in Korea. Eng Geol 147:68–77

Lekhnitskii SG (1968) Anisotropic plates. Gorden and Breach, New York

Lisjak A, Tatone BSA, Mahabadi OK, Grasselli G, Marschall P, Lanyon GW, Re Vaissiere, Shao H, Leung H, Nussbaum C (2016) Hybrid finite-discrete element simulation of the EDZ formation and mechanical sealing process around a microtunnel in opalinus clay. Rock Mech Rock Eng 49:1849–1873

Liu YS (2013) Brazilian splitting test theory and engineering application for anisotropic rock. Dissertation, Central South University, China

Lockner D (1993) The role of acoustic emission in the study of rock fracture. Int J Rock Mech Min Sci Geomech Abstr 30:883–899

Martin HR, Magnar NO, Jorn S, Erling F (2012) Static vs. dynamic behavior of shale. In: Bobet A (ed) 46th U.S. rock mechanics/geomechanics symposium, Chicago, USA

Park B, Min KB (2015) Bonded-particle discrete element modeling of mechanical behavior of transversely isotropic rock. Int J Rock Mech Min Sci 76:243–255

Pollock AA (2013) AE signal features: energy, signal strength, absolute energy and RMS (Rev. 1.2). Mistras Group INC, Minneapolis, pp 9–11

Potyondy DO (2012) PFC 2D flat joint contact model. Itasca Consulting Group Inc, Minneapolis

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41:1329–1364

Roy DG, Singh TN (2016) Effect of heat treatment and layer orientation on the tensile strength of a crystalline rock under Brazilian test condition. Rock Mech Rock Eng 49:1–15

Tan X, Konietzky H, Fruehwirt T, Dan DQ (2015) Brazilian tests on transversely isotropic rocks: laboratory testing and numerical simulations. Rock Mech Rock Eng 48:1341–1351

Tavallali A, Vervoort A (2010) Effect of layer orientation on the failure of layered sandstone under Brazilian test conditions. Int J Rock Mech Min Sci 47:313–322

Tsang CF, Barnichon JD, Birkholzer J, Li XL, Liu HH, Sillen X (2012) Coupled thermo-hydro-mechanical processes in the near field of a high-level radioactive waste repository in clay formations. Int J Rock Mech Min Sci 49:31–44

Valente S, Fidelibus C, Loew S, Cravero M, Iabichino G, Barpi F (2012) Analysis of fracture mechanics tests on Opalinus Clay. Rock Mech Rock Eng 45:767–779

Vallejos JA, Suzuki K, Brzovic A, Ivars DM (2016) Application of synthetic rock mass modeling to veined core-size samples. Int J Rock Mech Min Sci 81:47–61

Vervoort A, Min KB, Konietzky H et al (2014) Failure of transversely isotropic rock under Brazilian test conditions. Int J Rock Mech Min Sci 70:343–352

Wu SC, Xu XL (2016) A study of three intrinsic problems of the classic discrete element method using flat-joint model. Rock Mech Rock Eng 49:1813–1830

Yang XX, Kulatilake PHSW, Jing HW, Yang SQ (2015a) Numerical simulation of a jointed rock block mechanical behavior adjacent to an underground excavation and comparison with physical model test results. Tunn Undergr Space Technol 50:129–142

Yang ZP, He B, Xie LZ, Li CB, Wang J (2015b) Strength and failure modes of shale based on Brazilian test. Rock Soil Mech 36:3447–3464

Acknowledgements

This research was supported by the National key research and development program of China (Grant No. 2016YFC0802201).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Xu, G., He, C., Chen, Z. et al. Transverse Isotropy of Phyllite Under Brazilian Tests: Laboratory Testing and Numerical Simulations. Rock Mech Rock Eng 51, 1111–1135 (2018). https://doi.org/10.1007/s00603-017-1393-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-017-1393-x