Abstract

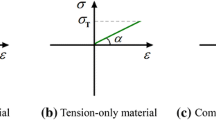

Many materials show asymmetric performance under tension and compression and their mechanical property can be well simulated by a so-called bi-modulus type constitutive relation. The underlying non-smoothness nature associated with this kind of constitutive behavior, however, makes it extremely difficult to investigate structural topology optimization problems involving bi-modulus materials. In the present paper, rigorous sensitivity results and efficient solution procedure for topology optimization problems involving a single-phase bi-modulus material are established and generalized to two-phase bi-modulus materials case. The validity and effectiveness of the proposed approach are verified by analytical solutions and numerical results. It is also found that the optimal structural topologies may be highly dependent on the tension to compression modulus ratios and quite different from the one obtained under the assumption of linear elasticity. Besides, the present results can be successfully used for engineering applications such as design of no-tension/no-compression structures and strut-and-tie models.

Similar content being viewed by others

References

Yang XW, Lee JS, Kim YY (2016) Effective mass density based topology optimization of locally resonant acoustic metamaterials for bandgap maximization. J Sound Vib 383:89–107

Alexandersen J, Sigmund O, Aage N (2016) Large scale three-dimensional topology optimisation of heat sinks cooled by natural convection. Int J Heat Mass Transf 100:876–891

Xue R, Li R, Du Z, Zhang W, Zhu Y, Sun Z, Guo X (2017) Kirigami pattern design of mechanically driven formation of complex 3D structures through topology optimization. Extreme Mech Lett 15:139–144

Bendsøe MP, Kikuchi N (1988) Generating optimal topologies in structural design using a homogenization method. Comput Methods Appl Mech Eng 71:197–224

Bendsøe MP (1989) Optimal shape design as a material distribution problem. Struct Multidiscip Optim 1:193–202

Zhou M, Rozvany GIN (1991) The COC algorithm, Part II: topological, geometrical and generalized shape optimization. Comput Methods Appl Mech Eng 89:309–336

Bendsøe MP, Sigmund O (2013) Topology optimization: theory, methods, and applications. Springer, Berlin

Wang MY, Wang X, Guo D (2003) A level set method for structural topology optimization. Comput Methods Appl Mech Eng 192:227–246

Allaire G, Jouve F, Toader AM (2004) Structural optimization using sensitivity analysis and a level-set method. J Comput Phys 194:363–393

Suzuki K, Kikuchi N (1991) A homogenization method for shape and topology optimization. Comput Methods Appl Mech Eng 93:291–318

Xie YM, Steven GP (1993) A simple evolutionary procedure for structural optimization. Comput Struct 49:885–896

Querin OM, Steven GP, Xie YM (1998) Evolutionary structural optimisation (ESO) using a bidirectional algorithm. Eng Comput 15:1031–1048

Guo X, Zhang W, Zhong W (2014) Doing topology optimization explicitly and geometrically: a new moving morphable components based framework. J Appl Mech 81:081009

Guo X, Zhang W, Zhang J, Yuan J (2016) Explicit structural topology optimization based on moving morphable components (MMC) with curved skeletons. Comput Methods Appl Mech Eng 310:711–748

Zhang W, Yang W, Zhou J, Li D, Guo X (2017) Structural topology optimization through explicit boundary evolution. J Appl Mech 84:011011

Ambartsumyan SA (1986) Elasticity theory of different moduli. China Railway Publishing House, Beijing

Janmey PA, McCormick ME, Rammensee S, Leight JL, Georges PC, MacKintosh FC (2007) Negative normal stress in semiflexible biopolymer gels. Nat Mater 6:48–51

Ambartsumyan SA (1965) The axisymmetric problem of circular cylindrical shell made of materials with different stiffnesses in tension and compression. Izv Akad Nauk SSSR Mekh 4:77–85

Ambartsumyan SA, Khachatryan AA (1966) Basic equations in the theory of elasticity for materials with different stiffness in tension and compression. Mech Solids 1:29–34

Sun JY, Xia S, Moon MW, Oh KH, Kim KS (2012) Folding wrinkles of a thin stiff layer on a soft substrate. Proc R Soc A 468:932–953

Notbohm J, Lesman A, Rosakis P, Tirrell DA, Ravichandran G (2015) Microbuckling of fibrin provides a mechanism for cell mechanosensing. J R Soc Interface 12:20150320

Tibert G (2002) Deployable tensegrity structures for space applications (Ph.D. thesis). Royal Institute of Technology, Stockholm

Kanno Y (2011) Nonsmooth mechanics and convex optimization. CRC Press, Boca Raton

Du Z, Guo X (2014) Variational principles and the related bounding theorems for bi-modulus materials. J Mech Phys Solids 73:183–211

Zhang HW, Zhang L, Gao Q (2011) An efficient computational method for mechanical analysis of bimodular structures based on parametric variational principle. Comput Struct 89:2352–2360

Zhang L, Gao Q, Zhang HW (2014) Analysis of 2-D bimodular materials and wrinkled membranes based on the parametric variational principle and co-rotational approach. Int J Numer Methods Eng 98:721–746

Zhang L, Zhang HW, Wu J, Yan B (2016) A stabilized complementarity formulation for nonlinear analysis of 3D bimodular materials. Acta Mech Sin 32:481–490

Zhang L, Dong KJ, Zhang HT, Yan B (2016) A 3D PVP co-rotational formulation for large-displacement and small-strain analysis of bi-modulus materials. Finite Elem Anal Des 110:20–31

Zhong WX (1986) On parametric complementary energy variational principle in soil mechanics. Acta Mech Sin 18:253–258

Zhong WX, Zhang RL (1988) The parametric variational principle for elastoplasticity. Acta Mech Sin 4:134–137

Zhong WX, Zhang RL (1988) Parametric variational principles and their quadratic programming solutions in plasticity. Comput Struct 30:887–896

Zhong WX, Zhang HW, Wu CW (1997) Parametric variational principle and its applications in engineering. Scientific and Technical Publishers, Beijing

Du Z, Zhang Y, Zhang W, Guo X (2016) A new computational framework for materials with different mechanical responses in tension and compression and its applications. Int J Solids Struct 100:54–73

Ran C, Yang H, Zhang G (2018) A gradient based algorithm to solve inverse plane bimodular problems of identification. J Comput Phys 355:78–94

Achtziger W (1996) Truss topology optimization including bar properties different for tension and compression. Struct Multidiscip Optim 12:63–74

Jia H, Misra A, Poorsolhjouy P, Liu C (2017) Optimal structural topology of materials with micro-scale tension–compression asymmetry simulated using granular micromechanics. Mater Des 115:422–432

Ramos AS Jr, Paulino GH (2015) Convex topology optimization for hyperelastic trusses based on the ground-structure approach. Struct Multidiscip Optim 51:287–304

Zhang X, Ramos AS Jr, Paulino GH (2017) Material nonlinear topology optimization using the ground structure method with a discrete filtering scheme. Struct Multidiscip Optim 55:2045–2072

Chang CJ, Zheng B, Gea HC (2007) Topology optimization for tension/compression only design. In: Proceedings of the 7th WCSMO, Korea, pp. 2488–2495

Liu S, Qiao H (2011) Topology optimization of continuum structures with different tensile and compressive properties in bridge layout design. Struct Multidiscip Optim 43:369–380

Querin OM, Victoria M, Martí P (2010) Topology optimization of truss-like continua with different material properties in tension and compression. Struct Multidiscip Optim 42:25–32

Cai K (2011) A simple approach to find optimal topology of a continuum with tension-only or compression-only material. Struct Multidiscip Optim 43:827–835

Cai K, Gao Z, Shi J (2013) Compliance optimization of a continuum with bimodulus material under multiple load cases. Comput Aided Des 45:195–203

Cai K, Qin QH, Luo Z, Zhang AJ (2013) Robust topology optimisation of bi-modulus structures. Comput Aided Des 45:1159–1169

Cai K, Gao Z, Shi J (2014) Topology optimization of continuum structures with bi-modulus materials. Eng Optim 46:244–260

Cai K, Cao J, Shi J, Liu L, Qin QH (2016) Optimal layout of multiple bi-modulus materials. Struct Multidiscip Optim 53:801–811

Alfano G, Rosati L, Valoroso N (2000) A numerical strategy for finite element analysis of no-tension materials. Int J Numer Methods Eng 48:317–350

Angelillo M, Cardamone L, Fortunato A (2010) A numerical model for masonry-like structures. J Mech Mater Struct 5:583–615

Bruggi M (2014) Finite element analysis of no-tension structures as a topology optimization problem. Struct Multidiscip Optim 50:957–973

Bruggi M, Duysinx P (2013) A stress-based approach to the optimal design of structures with unilateral behavior of material or supports. Struct Multidiscip Optim 48:311–326

Guan H, Steven GP, Xie YM (1999) Evolutionary structural optimisation incorporating tension and compression materials. Adv Struct Eng 2:273–288

Bruggi M (2009) Generating strut-and-tie patterns for reinforced concrete structures using topology optimization. Comput Struct 87:1483–1495

Victoria M, Querin OM, Martí P (2011) Generation of strut-and-tie models by topology design using different material properties in tension and compression. Struct Multidiscip Optim 44:247–258

Gaynor AT, Guest JK, Moen CD (2012) Reinforced concrete force visualization and design using bilinear truss-continuum topology optimization. J Struct Eng 139:607–618

He XT, Zheng ZL, Sun JY, Li YM, Chen SL (2009) Convergence analysis of a finite element method based on different moduli in tension and compression. Int J Solids Struct 46:3734–3740

Crisfield MA, Remmers JJ, Verhoosel CV (2012) Nonlinear finite element analysis of solids and structures. Wiley, New York

Bagley R (1989) Power law and fractional calculus model of viscoelasticity. AIAA J 27:1412–1417

Guo X, Jin F, Gao H (2011) Mechanics of non-slipping adhesive contact on a power-law graded elastic half-space. Int J Solids Struct 48:2565–2575

Andreassen E, Clausen A, Schevenels M, Lazarov BS, Sigmund O (2011) Efficient topology optimization in MATLAB using 88 lines of code. Struct Multidiscip Optim 43:1–16

Svanberg K (1987) The method of moving asymptotes: a new method for structural optimization. Int J Numer Methods Eng 24:359–373

Sigmund O (2001) Design of multiphysics actuators using topology optimization—Part II: two-material structures. Comput Methods Appl Mech Eng 190:6605–6627

Gao T, Zhang W (2011) A mass constraint formulation for structural topology optimization with multiphase materials. Int J Numer Methods Eng 88:774–796

Zhang XS, Paulino GH, Ramos AS (2017) Multi-material topology optimization with multiple volume constraints: a general approach applied to ground structures with material nonlinearity. Struct Multidiscip Optim 57:161–182

Zhang XS, Paulino GH, Ramos AS (2018) Multimaterial topology optimization with multiple volume constraints: Combining the ZPR update with a ground-structure algorithm to select a single material per overlapping set. Int J Numer Methods Eng 114:1053–1073

Zhang W, Song J, Zhou J, Du Z, Zhu Y, Sun Z, Guo X (2018) Topology optimization with multiple materials via Moving Morphable Component (MMC) method. Int J Numer Methods Eng 113:1653–1675

Du Z, Guo X (2016) Symmetry analysis for structural optimization problems involving reliability measure and bi-modulus materials. Struct Multidiscip Optim 53:973–984

Wang MY, Wang X (2004) “Color” level sets: a multi-phase method for structural topology optimization with multiple materials. Comput Methods Appl Mech Eng 193:469–496

Guo X, Zhang W, Wang MY, Wei P (2011) Stress-related topology optimization via level set approach. Comput Methods Appl Mech Eng 200:3439–3452

Cheng GD, Guo X (1997) \(\varepsilon \)-relaxed approach in structural topology optimization. Struct Multidiscip Optim 13:258–266

Duysinx P, Bendsøe MP (1998) Topology optimization of continuum structures with local stress constraints. Int J Numer Methods Eng 43:1453–1478

Acknowledgements

The financial support from the National Key Research and Development Plan (2016YFB0201600, 2016YFB0201601, 2017YFB0202800, 2017YFB0202802), the National Natural Science Foundation (11402048, 11732004, 11772026), Program for Changjiang Scholars, Innovative Research Team in University (PCSIRT) and 111 Project (B14013) are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Proof of the lemma for sensitivity analysis in Sect. 3.1

Appendix: Proof of the lemma for sensitivity analysis in Sect. 3.1

Proof

For a general conservative non-linear elastic system, the displacement field in equilibrium state can be determined according to the minimum potential energy principle as:

where \({\varvec{v}}\) is the feasible displacement filed; \({\Pi }\left( {\varvec{v}} \right) \) denotes the total potential energy, i.e.,

According to Eqs. (21) and (22), we have:

and

Hence, the objective function can be expressed as:

On the other hand, the first order variation of mean compliance with respect to density field is:

In the above equation, the first order differentiability of \(c\left( {{\varvec{u}},\rho } \right) \) with respect to arbitrary \(\rho \) and \({\varvec{u}}\) is used.

With use of Eq. (A5), the first term in Eq. (A6) can be simplified as:

where the fact of Eq. (A1) is used. Then Eq. (A6) becomes

Furthermore, if finite element method is adopted to discretize the corresponding continuum topology optimization problem, we have:

and Eq. (A8) has the following form:

or

where \(\rho _i \) denotes the density of the ith element.

Finally, it should be pointed out that the non-smooth property of the bi-modulus constitutive relation results in the non-differentiability of the second order of the strain energy density, however, the first order partial derivatives of the strain energy density or the mean compliance are still continuous, i.e., \(w\left( {\varvec{u}} \right) \in H^{1}\left( {\varvec{u}} \right) \), \(c\left( {\varvec{u}} \right) \in H^{1}\left( {\varvec{u}} \right) \). Specifically, in one dimensional case,

and

\(\square \)

Rights and permissions

About this article

Cite this article

Du, Z., Zhang, W., Zhang, Y. et al. Structural topology optimization involving bi-modulus materials with asymmetric properties in tension and compression. Comput Mech 63, 335–363 (2019). https://doi.org/10.1007/s00466-018-1597-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-018-1597-2