Abstract

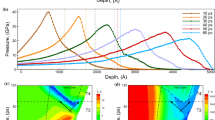

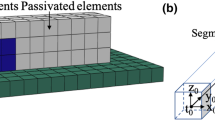

A multiscale simulation method is established to study the microstructural responses of near-surface grain boundary structures of copper subjected to ultrashort femtosecond laser pulse. By integrating a two-temperature model with molecular dynamics, the presented approach allows for incorporation of both laser processing parameters and microstructures, enabling systematic simulation studies on the process-properties link. Following a brief introduction of the simulation methodology, a detailed modeling study on the ultrashort laser-material interaction is presented. In particular, we highlight the effects of laser process parameters on the near-surface response and corresponding phase change, formation of voids and their growth, and mechanism of dislocation nucleating and propagating from grain boundary.

Similar content being viewed by others

References

Ivanov DS, Zhigilei LV (2003) Combined atomistic-continuum modeling of short-pulse laser melting and disintegration of metal films. Physi Rev B 68(6):064114

Ivanov DS, Zhigilei LV (2004) Combined atomistic-continuum model for simulation of laser interaction with metals: application in the calculation of melting thresholds in Ni targets of varying thickness. Appl Phys A 79(4–6):977–981

Koči L, Bringa EM, Ivanov DS, Hawreliak J, McNaney J, Higginbotham A, Zhigilei LV, Belonoshko AB, Remington BA, Ahuja R (2006) Simulation of shock-induced melting of Ni using molecular dynamics coupled to a two-temperature model. Phys Rev B Condens Matter Mater Phys 74(1):012101

Duff WH, Zhigilei LV (2007) Computational study of cooling rates and recrystallization kinetics in short pulse laser quenching of metal targets. J Phys Conf Ser 59(1):413–417

Lin Z, Leveugle E, Bringa EM, Zhigilei LV (2009) Molecular dynamics simulation of laser melting of nanocrystalline Au\({\dagger }\). J Phys Chem C 114(12):5686–5699

Karim ET, Shugaev M, Wu C, Lin Z, Hainsey RF, Zhigilei LV (2014) Atomistic simulation study of short pulse laser interactions with a metal target under conditions of spatial confinement by a transparent overlayer. J Appl Phys 115(18):183501

Zhigilei LV, Lin Z, Ivanov DS (2009) Atomistic modeling of short pulse laser ablation of metals: connections between melting, spallation, and phase explosion\({\dagger }\). J Phys Chem C 113(27):11892–11906

Cheng C, Xu X (2005) Mechanisms of decomposition of metal during femtosecond laser ablation. Phys Rev B 72(16):165415

Li X, Jiang L, Tsai H-L (2009) Phase change mechanisms during femtosecond laser pulse train ablation of nickel thin films. J Appl Phys 106(6):064906

Shen Y, Gan Y, Qi W, Shen Y, Chen Z (2015) Effect of the hot electron blast force on ultrafast laser ablation of nickel thin film. Appl Opt 54(7):1737–1742

Gan Y, Chen J (2010) Thermomechanical wave propagation in gold films induced by ultrashort laser pulses. Mech Mater 42(4):491–501

Ivanov DS, Rethfeld B, O’Connor GM, Glynn TJ, Volkov AN, Zhigilei LV (2008) The mechanism of nanobump formation in femtosecond pulse laser nanostructuring of thin metal films. Appl Phys A 92(4):791–796

Lin Z, Johnson RA, Zhigilei LV (2008) Computational study of the generation of crystal defects in a bcc metal target irradiated by short laser pulses. Phys Rev B 77(21):214108

Kaganov MI, Lifshitz IM, Tanatarov LV (1956) Relaxation between electrons and crystalline lattices. Zh Eksp Teor Fiz 31:232–237

Anisimov S, Kapeliovich B, Perelman T (1974) Electron emission from metal surfaces exposed to ultrashort laser pulses. Zh Eksp Teor Fiz 66(2):375–377

Chen G (2005) Nanoscale energy transport and conversion. Oxford University Press, New York

Jones RE, Templeton JA, Wagner GJ, Olmsted D, Modine NA (2010) Electron transport enhanced molecular dynamics for metals and semi-metals. Int J Numer Methods Eng 83(8–9):940–967

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117(1):1–19

Tschopp M, McDowell D (2007) Asymmetric tilt grain boundary structure and energy in copper and aluminium. Philos Mag 87(25):3871–3892

Bonny G, Pasianot RC, Castin N, Malerba L (2009) Ternary Fe–Cu–Ni many-body potential to model reactor pressure vessel steels: first validation by simulated thermal annealing. Philos Mag 89(34–36):3531–3546

Liu WK, Qian D, Gonella S, Li SF, Chen W, Chirputkar S (2010) Multiscale methods for mechanical science of complex materials: bridging from quantum to stochastic multiresolution continuum. Int J Numer Methods Eng 83(8–9):1039–1080

Zhang L, Wang X (2008) Hybrid atomistic-macroscale modeling of long-time phase change in nanosecond laser-material interaction. Appl Surf Sci 255(5):3097–3103

Zhigilei LV, Garrison BJ (1998) Pressure waves in microscopic simulations of laser ablation leonid. In: MRS Proceedings. Cambridge University Press

Hirayama Y, Obara M (2005) Heat-affected zone and ablation rate of copper ablated with femtosecond laser. J Appl Phys 97(6):064903

Lin Z, Zhigilei LV, Celli V (2008) Electron–phonon coupling and electron heat capacity of metals under conditions of strong electron–phonon nonequilibrium. Phys Rev B 77(7):075133

Schäfer C, Urbassek HM, Zhigilei LV (2002) Metal ablation by picosecond laser pulses: a hybrid simulation. Phys Rev B 66(11):115404

Stukowski A, Albe K (2010) Dislocation detection algorithm for atomistic simulations. Model Simul Mater Sci Eng 18(2):025016

Lillo T, Cole J, Frary M, Schlegel S (2009) Influence of grain boundary character on creep void formation in alloy 617. Metall Mater Trans A 40(12):2803–2811

Hull D, Bacon DJ (2011) Introduction to dislocations, 5th edn. Butterworth-Heinemann, London

Acknowledgements

The authors gratefully acknowledge the support from the National Science Foundation (Grant Nos. # DMR-0706161, CMMI-1335204, 1334538). Any opinions, findings, conclusions, or recommendations expressed in these documents are those of the authors and do not necessarily reflect the views of the NSF. This work was also supported in part by the start-up fund from the University of Texas at Dallas and an allocation of computing time from the Ohio Supercomputer Center and Texas Advanced Computing Center.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Karim, M.R., Kattoura, M., Mannava, S.R. et al. A computational study on the microstructural evolution in near-surface copper grain boundary structures due to femtosecond laser processing. Comput Mech 61, 105–117 (2018). https://doi.org/10.1007/s00466-017-1449-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00466-017-1449-5