Abstract

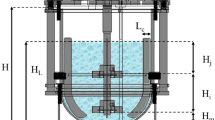

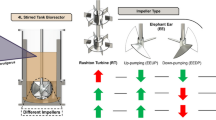

In biochemical processes involving filamentous microorganisms, the high shear rate may damage suspended cells leading to viability loss and cell disruption. In this work, the influence of the shear conditions in clavulanic acid (CA) production by Streptomyces clavuligerus was evaluated in a 4-dm3 conventional stirred tank (STB) and in 6-dm3 concentric-tube airlift (ALB) bioreactors. Batch cultivations were performed in a STB at 600 and 800 rpm and 0.5 vvm (cultivations B1 and B2) and in ALB at 3.0 and 4.1 vvm (cultivations A1 and A2) to define two initial oxygen transfer conditions in both bioreactors. The average shear rate (\( \dot{\gamma }_{\rm {av}} \)) of the cultivations was estimated using correlations of recent literature based on experimental data of rheological properties of the broth (consistency index, K, and flow index, n) and operating conditions, impeller speed (N) for STB and superficial gas velocity in the riser (UGR) for ALB. In the same oxygen transfer condition, the \( \dot{\gamma }_{\rm {av}} \) values for ALB were higher than those obtained in STB. The maximum \( \dot{\gamma }_{\rm {av}} \) presented a strong correlation with a maximum consistency index (K max) of the broth. Close values of maximum CA production were obtained in cultivations A1 and A2 (454 and 442 mg L−1) with similar maximum \( \dot{\gamma }_{\rm {av}} \) values of 4,247 and 4,225 s−1. In cultivations B1 and B2, the maximum CA production of 269 and 402 mg L−1 were reached with a maximum \( \dot{\gamma }_{\rm {av}} \) of 904 and 1,786 s−1. The results show that high values of average shear rate increase the CA production regardless of the oxygen transfer condition and bioreactor model.

Similar content being viewed by others

References

Lynch HC, Yang Y (2004) Degradation products of clavulanic acid promote clavulanic acid production in cultures of Streptomyces clavuligerus. Enzyme Microb Technol 34:48–54

Mayer AF, Deckwer WD (1996) Simultaneous production and decomposition of clavulanic acid during Streptomyces clavuligerus cultivations. Appl Microbiol Biotechnol 45:41–46

Roubos JA, Krabben P, Luiten RGM, Verbruggen HB, Heijnen JJ (2001) A quantitative approach to characterizing cell lysis caused by mechanical agitation of Streptomyces clavuligerus. Biotechnol Progr 17:336–347

Rosa JC, Baptista-Neto A, Hokka CO, Badino AC (2005) Influence of dissolved oxygen and shear conditions on clavulanic acid production by Streptomyces clavuligerus. Bioprocess Biosyst Eng 27:99–104

Teodoro JC, Baptista-Neto A, Cruz-Hernández IL, Hokka CO, Badino AC (2006) Influence of feeding conditions on clavulanic acid production in fed-batch cultivation with medium containing glycerol. Appl Microbiol Biotechnol 72:450–455

Ortiz SCA, Hokka CO, Badino AC (2007) Utilization of soybean derivatives on clavulanic acid production by Streptomyces clavuligerus. Enzyme Microb Technol 40:1071–1077

Teodoro JC, Baptista-Neto A, Araujo MLGC, Hokka CO, Badino AC (2010) Influence of glycerol and ornithine feeding on clavulanic acid production by Streptomyces clavuligerus. Braz J Chem Eng 27:499–506

Gouveia ER, Baptista-Neto A, Hokka CO, Badino AC (2000) Studies on the rheology and oxygen mass transfer in the clavulanic acid production by Streptomyces clavuligerus. Braz J Chem Eng 17:827–834

Cerri MO, Futiwaki L, Jesus CDF, Cruz AJG, Badino AC (2008) Average shear rate for non-Newtonian fluids in a concentric-tube airlift bioreactor. Biochem Eng J 39:51–57

Campesi A, Cerri MO, Hokka CO, Badino AC (2009) Determination of the average shear rate in a stirred and aerated tank bioreactor. Bioprocess Biosyst Eng 32:241–248

Thomasi SS, Cerri MO, Badino AC (2010) Average shear rate in three pneumatic bioreactors. Bioprocess Biosyst Eng 33:979–988

Träger M, Qazi GN, Onken U, Chopra CL (1989) Comparison of airlift and stirred reactors for fermentation with Aspergillus niger. J Ferment Bioeng 68:112–116

Siedenberg D, Gerlach SR, Weigel B, Schugerl K, Giuseppin MLF, Hunik J (1997) Production of xylanase by Aspergillus awamori on synthetic medium in stirred tank and airlift tower loop reactors: the influence of stirrer speed and phosphate concentration. J Biotechnol 56:103–114

Burkert JFM, Maldonado RR, Maugeri Filho F, Rodrigues MI (2005) Comparison of lipase production by Geotrichum candidum in stirring and airlift fermenters. J Chem Technol Biotechnol 80:61–67

Xu CP, Kim SW, Hwang HJ, Yun JW (2006) Production of exopolysaccharides by submerged culture of an enthomopathogenic fungus, Paecilomyces tenuipes C240 in stirred-tank and airlift reactors. Bioresour Technol 97:770–777

Saravaman P, Pakshirajan K, Saha P (2008) Performance of batch stirred tank bioreactor and internal loop airlift bioreactor in degrading phenol using Pseudomonas spp.—a comparative study performance. J Environ Prot Sci 2:81–86

Fontana RC, Polidoro TA, Silveira MM (2009) Comparison of stirred tank and airlift bioreactors in the production of polygalacturonases by Aspergillus oryzae. Bioresour Technol 100:4493–4498

Gouveia ER, Baptista-Neto A, Badino AC, Hokka CO (2001) Optimisation of medium composition for clavulanic acid production by Streptomyces clavuligerus. Biotechnol Lett 23:157–161

Wang YH, Yang B, Ren J, Dong ML, Liang D, Xu AL (2005) Optimization of medium composition for the production of clavulanic acid by Streptomyces clavuligerus. Process Biochem 40:1161–1166

Maranesi GL, Baptista-Neto A, Hokka CO, Badino AC (2005) Utilization of vegetable oil in the production of clavulanic acid by Streptomyces clavuligerus ATCC 27064. World J Microbiol Biotechnol 21:509–514

Baptista-Neto A, Hirata DB, Cassiano Filho LCM, Bellão C, Badino AC, Hokka CO (2005) A study on clavulanic acid production by Streptomyces clavuligerus in batch, fed-batch and continuous processes. Braz J Chem Eng 22:557–563

Baptista-Neto A, Teodoro JC, Cassiano Filho LCM, Badino AC, Hokka CO (2005) Comparisons between continuous and batch processing to produce clavulanic acid by Streptomyces clavuligerus. Braz Arch Biol Technol 45:97–104

Lavarda SCS, Hokka CO, Araujo MLGC (2008) Clavulanic acid production processes in a tower bioreactor with immobilised cells. Biochem Eng J. 39:131–136

Badino AC, Hokka CO, Cerri MO (2006) Pneumatic reactor with an inner and a transparent outer cylinder gas injection for circulation and temperature control of the enclosed reaction mixture. Brazilian Patent BR200404703-A

Blažej M, Annus J, Markŏs J (2004) Comparison of gassing-out and pressure-step dynamic methods for kLa measurement in an airlift reactor with internal loop. Chem Eng Res Des 82:1375–1382

Reading C, Cole M (1977) Clavulanic acid: a beta-lactamase-inhibiting beta-lactam from Streptomyces clavuligerus. Antimicrob Agents Chemother 11:852–857

Foulstone M, Reading C (1982) Assay of amoxicillin and clavulanic acid, the components of Augmentin, in biological fluids with high performance chromatography. Antimicrob Agents Chemother 22:753–762

Hersbach GJM, Van der Beek LP, Van Dijck PWM (1984) The penicillins: properties, biosynthesis and fermentation. In: Vandamme EJ (ed) Biotechnology of industrial antibiotics. Marcel Dekker, New York

Acknowledgments

The authors gratefully acknowledge FAPESP (Grant Proc. no. 2011/23807-1), CAPES (Coordenação de Aperfeiçoamento de Pessoal de Nível Superior) and CNPQ (Conselho Nacional de Desenvolvimento Científico e Tecnológico), Grant Proc. 478472/2011-0 (Brazil) for their financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cerri, M.O., Badino, A.C. Shear conditions in clavulanic acid production by Streptomyces clavuligerus in stirred tank and airlift bioreactors. Bioprocess Biosyst Eng 35, 977–984 (2012). https://doi.org/10.1007/s00449-012-0682-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-012-0682-8