Abstract

The high-temperature extensional viscosity of three commercially available linear, branched and hyper-branched polycarbonates (PCs) were measured using a high-temperature capillary breakup extensional rheometer (CaBER) in both air and nitrogen. The experiments were performed at temperatures ranging from T = 250 to 370 °C to a maximum Hencky strain of ten. At lower end of the temperature range, no significant degradation of the linear and branched PC was observed either in the shear or extensional measurements. Beyond, T > 300 °C degradation of the three different PCs was observed. Changes to the molecular structure of the PC were observed which resulted in a dramatic increase in the extensional viscosity. The rate of growth in the extensional viscosity was found to increase with temperature, time at temperature, and, in the case of the linear and branched PC, the presence of air. For the hyper-branched case, changes to the molecular structure of the PC were found to occur more quickly under nitrogen. At these high temperatures, the increase in extensional viscosity was found to grow large enough to stop the breakup of the fluid filament all together, essentially stopping all capillary drainage. This temperature-induced cross-linking and increase in the extensional viscosity of the PC can improve the anti-dripping properties of the polycarbonate by slowing and even restricting dripping from polymeric components near high heat surges. Through these experiments, we have demonstrated measurement of the extensional viscosity to be several orders of magnitude more sensitive to temperature-induced changes to the molecular structure than measurements of shear rheology.

Similar content being viewed by others

References

Anna SL, McKinley GH (2001) Elasto-capillary thinning and breakup of model elastic liquids. J Rheol 45:115–138

Bach A, Rasmussen HK, Hassager O (2003) Extensional viscosity for polymer melts measured in the filament stretching rheometer. J Rheol 47:429–441

Bazilevsky AV, Entov VM, Rozhkov AN. (1990) Liquid filament microrheometer and some of its applications. In: Oliver DR (ed) Proc. Third European Rheology Conference, Edinburgh. pp 41–43

Beyler CL, Hirschler MM (2002) Thermal decomposition of polymers SFPE handbook of fire protection engineering 2:32

Bischoff White E, Rothstein JP (2012) Extensional flow-induced crystallization of polypropylene. Rheol Acta 51:303–314

Carroccio S, Puglisi C, Montaudo G (2002) Mechanisms of thermal oxidation of poly (bisphenol a carbonate). Macromolecules 35:4297–4305

Chellamuthu M, Arora D, Winter HH, Rothstein JP (2011) Extensional flow-induced crystallization of isotactic poly(1-butene). J Rheol 55:901–920

Clasen C, Phillips PM, Palangetic L, Vermant J (2012) Dispensing of rheologically complex fluids: the map of misery. AICHE J 58:3242–3255

Clasen C, Plog JP, Kulicke WM, Owens M, Macosko C, Scriven LE, Verani M, McKinley GH (2006) How dilute are dilute solutions in extensional flows? J Rheol 50:849–881

DeMaio V, Dong D, Gupta A (2000) Using branched polypropylene as a melt strength modifier-improvement in sheet sag resistance (236). In: Technical papers of the annual technical conference-society of plastics engineers incorporated. pp 799–803

Entov VM, Hinch EJ (1997) Effect of a spectrum of relaxation times on the capillary thinning of a filament of elastic liquid. J Non-Newtonian Fluid Mech 72:31–53

Filippone G, Carroccio S, Curcuruto G, Passaglia E, Gambarotti C, Dintcheva NT (2015) Time-resolved rheology as a tool to monitor the progress of polymer degradation in the melt state–part II: thermal and thermo-oxidative degradation of polyamide 11/organo-clay nanocomposites. Polymer 73:102–110

He C, Costeux S, Wood-Adams P (2004) A technique to infer structural information for low level long chain branched polyethylenes. Polymer 45:3747–3754

Jang BN, Wilkie CA (2004) A TGA/FTIR and mass spectral study on the thermal degradation of bisphenol A polycarbonate. Polym Degrad Stab 86:419–430

Kandola B, Ndiaye M, Price D (2014) Quantification of polymer degradation during melt dripping of thermoplastic polymers. Polym Degrad Stab 106:16–25

Kandola B, Price D, Milnes G, Da Silva A (2013) Development of a novel experimental technique for quantitative study of melt dripping of thermoplastic polymers. Polym Degrad Stab 98:52–63

Kojic N, Bico J, Clasen C, McKinley GH (2006) Ex vivo rheology of spider silk. J Exp Biol 209:4355–4362

Kruse M, Wagner MH (2016) Time-resolved rheometry of poly (ethylene terephthalate) during thermal and thermo-oxidative degradation. Rheol Acta 55:789–800

Kulicke W-M, Kniewske R (1984) The shear viscosity dependence on concentration, molecular weight, and shear rate of polystyrene solutions. Rheol Acta 23:75–83

Laoutid F, Bonnaud L, Alexandre M, Lopez-Cuesta J-M, Dubois P (2009) New prospects in flame retardant polymer materials: from fundamentals to nanocomposites. Mater Sci Eng R Rep 63:100–125

Li XG, Huang MR (1999) Thermal degradation of bisphenol A polycarbonate by high-resolution thermogravimetry. Polym Int 48:387–391

Matzen M, Kandola B, Huth C, Schartel B (2015) Influence of flame retardants on the melt dripping behaviour of thermoplastic polymers. Materials 8:5621–5646

McKinley GH (2005) Visco-elasto-capillary thinning and break-up of complex fluids. In: Binding DM, Walters K (eds) Annual Rheology Reviews. The British Society of Rheology, Aberystwyth, Wales, UK, pp 1–49

McKinley GH, Tripathi A (2000) How to extract the Newtonian viscosity from capillary breakup measurements in a filament rheometer. J Rheol 44:653–670

McNeill I, Rincon A (1991) Degradation studies of some polyesters and polycarbonates—8. Bisphenol A polycarbonate. Polym Degrad Stab 31:163–180

Montaudo G, Puglisi C (1992) Thermal decomposition processes in bisphenol A polycarbonate. Polym Degrad Stab 37:91–96

Mun RP, Byars JA, Boger DV (1998) The effect of polymer concentration and molecular weight on the break-up of laminar capillary jets. J Non-Newtonian Fluid Mech 74:285–297

Najafi N, Heuzey M-C, Carreau PJ, Therriault D, Park CB (2014) Rheological and foaming behavior of linear and branched polylactides. Rheol Acta 53:779–790

Oba K, Ishida Y, Ito Y, Ohtani H, Tsuge S (2000) Characterization of branching and/or cross-linking structures in polycarbonate by reactive pyrolysis− gas chromatography in the presence of organic alkali. Macromolecules 33:8173–8183

Papageorgiou DT (1995) On the Breakup of Viscous Liquid Threads. Physics of Fluids 7:1529–1544

Plog JP, Kulicke WM, Clasen C (2005) Influence of the molar mass distribution on the elongational behaviour of polymer solutions in capillary breakup. Appl Rheol 15:28–37

Pretsch E, Buehlmann P, Affolter C, Pretsch E, Bhuhlmann P, Affolter C (2000) Structure determination of organic compounds. Springer,

Rayleigh L (1879) On the instability of jets. Proc Lond Math Soc 10:4–13

Renardy M (1995) A numerical study of the asymptotic evolution and breakup of Newtonian and viscoelastic jets. J Non-Newtonian Fluid Mech 59:267–282

Rodd LE, Scott TP, Cooper-White JJ, McKinley GH (2005) Capillary break-up rheometry of low-viscosity elastic fluids. Appl Rheol 15:12–27

Salehiyan R, Malwela T, Ray SS (2017) Thermo-oxidative degradation study of melt-processed polyethylene and its blend with polyamide using time-resolved rheometry. Polym Degrad Stab 139:130–137

Shangguan Y, Zhang C, Xie Y, Chen R, Jin L, Zheng Q (2010) Study on degradation and crosslinking of impact polypropylene copolymer by dynamic rheological measurement. Polymer 51:500–506

Stelter M, Brenn G, Yarin AL, Singh RP, Durst F (2000) Validation and application of a novel elongational device for polymer solutions. J Rheol 44:595–616

Stone HA (1994) Dynamics of drop deformation and breakup in viscous fluids. Annu Rev Fluid Mech 26:65–102

Wang Y, Jow J, Su K, Zhang J (2012) Dripping behavior of burning polymers under UL94 vertical test conditions. J Fire Sci 30:477–501

Wang Y, Zhang F, Chen X, Jin Y, Zhang J (2010) Burning and dripping behaviors of polymers under the UL94 vertical burning test conditions fire and materials. An Int J 34:203–215

Winter HH, Chambon F (1986) Analysis of linear viscoelasticity of a crosslinking polymer at the gel point. J Rheol 30:367–382

Yesilata B, Clasen C, McKinley GH (2006) Nonlinear shear and extensional flow dynamics of wormlike surfactant solutions. J Non-Newton Fluid Mech 133:73–90

Acknowledgments

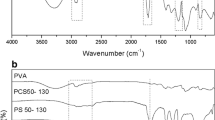

The authors would like to thank Christian Clasen of KU Leuven for the use of his Edgehog software, Zachary Anderson (SABIC) for his Shear rheology measurements, and M. D. Arifur Rahman (University of Massachusetts, Amherst) for the FTIR analysis.

Funding information

This research received funding from SABIC.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 426 kb)

Rights and permissions

About this article

Cite this article

Sur, S., Chellamuthu, M. & Rothstein, J. High-temperature extensional rheology of linear, branched, and hyper-branched polycarbonates. Rheol Acta 58, 557–572 (2019). https://doi.org/10.1007/s00397-019-01157-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-019-01157-9