Abstract

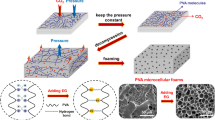

In comparison with unfoamed polymers, polymer foams find extensive application in various civil and industrial fields such as packaging, sports equipment, absorbents, and automotive components due to their advantages of lightweight, high strength-to-weight ratio, excellent insulation properties, high thermal stability, high impact strength, toughness, and long fatigue life. The preparation of conventional polymer foam typically necessitates the incorporation of chemical foaming agents into the polymer, raising environmental issues, which pave the way for the utilization of supercritical fluids. Supercritical fluids exemplified by supercritical carbon dioxide or supercritical nitrogen, are renowned for their environmentally friendly and non-toxic characteristics, thus offering a viable alternative to conventional chemical foaming agents. Supercritical fluids exhibit gas-like diffusion and liquid-like density, offering excellent plasticization effects on polymer melts. This substantially reduces the melt viscosity, melting point, and glass transition temperature of the polymer, facilitating the preparation of uniformly distributed, smaller-sized, and higher-density microcellular foams. This review first provides an overview of the characteristics of supercritical fluids and commonly used supercritical fluid foaming agents. Subsequently, the dissolution, diffusion, and interactions of supercritical fluids in polymers were discussed, followed by a focused elucidation of the cell nucleation (homogeneous and heterogeneous) and growth (island model and cell model). Finally, the application of supercritical fluids in the foam manufacturing techniques is highlighted, including batch foaming, extrusion foaming, and injection foaming, while emphasizing the challenges that still exist in polymer foaming.

Similar content being viewed by others

Data availability

The data will be available upon proper request.

References

Suh KW, Park CP, Maurer MJ, Tusim MH, Genova RD, Broos R, Sophiea DP (2000) Lightweight cellular plastics. Adv Mater 12(23):1779–1789

Tomasko DL, Li H, Liu D, Han X, Wingert MJ, Lee LJ, Koelling KW (2003) A review of CO2 applications in the processing of polymers. Ind Eng Chem Res 42(25):6431–6456

Collias DI, Baird DG, Borggreve RJ (1994) Impact toughening of polycarbonate by microcellular foaming. Polymer 35(18):3978–3983

Kumar V (1993) Microcellular polymers: novel materials for the 21st century. Cell Polym 12(3):207–223

Krause B, Sijbesma HJP, Münüklü P, van der Vegt NFA, Wessling M (2001) Bicontinuous Nanoporous Polymers by Carbon Dioxide Foaming. Macromolecules 34(25):8792–8801

Doroudiani S, Park CB, Kortschot MT (1996) Effect of the crystallinity and morphology on the microcellular foam structure of semicrystalline polymers. Polym Eng Sci 36(21):2645–2662

Zhao Y, Hou J, Bai Z, Yang Y, Guo X, Cheng H, Zhao Z, Zhang X, Chen J, Shen C (2020) Facile preparation of lightweight PE/PVDF/Fe3O4/CNTs nanocomposite foams with high conductivity for efficient electromagnetic interference shielding. Compos A Appl Sci Manuf 139:106095

Jia S, Song S, Zhao X (2021) Selective adsorption and separation of dyes from aqueous solution by a zirconium-based porous framework material. Appl Organomet Chem 35(9):6314

Shi G, Yu F, Wang Y, Pan D, Yan X, Li R (2018) Facile synthesis of micro-mesoporous alumina-zirconia nanocrystals with tailoring texture. Chem Phys Lett 709:41–45

Zhao X, Zheng M, Gao X, Zhang J, Wang E, Gao Z (2021) The application of MOFs-based materials for antibacterials adsorption. Coord Chem Rev 440:213970

Zhao X, Wang Y, Li Y, Xue W, Li J, Wu H, Zhang Y, Li B, Liu W, Gao Z, Huang H (2019) Synergy Effect of Pore Structure and Amount of Carboxyl Site for Effective Removal of Pb2+ in Metal-Organic Frameworks. J Chem Eng Data 64(6):2728–2735

Zhao X, Wei Y, Zhao H, Gao Z, Zhang Y, Zhi L, Wang Y, Huang H (2018) Functionalized metal-organic frameworks for effective removal of rocephin in aqueous solutions. J Colloid Interface Sci 514:234–239

Wang C, Liu X, Yang T, Sridhar D, Algadi H, Xu BB, El-Bahy ZM, Li H, Ma Y, Li T, Guo Z (2023) An overview of metal-organic frameworks and their magnetic composites for the removal of pollutants. Sep Purif Technol 320:124144

Ruan J, Chang Z, Rong H, Alomar TS, Zhu D, AlMasoud N, Liao Y, Zhao R, Zhao X, Li Y, Xu BB, Guo Z, El-Bahy ZM, Li H, Zhang X, Ge S (2023) High-conductivity nickel shells encapsulated wood-derived porous carbon for improved electromagnetic interference shielding. Carbon 213:118208

Long Y, An J, Xie X (2020) CO2-releasing blowing agents from modified polyethylenimines slightly consume isocyanate groups while foaming polyurethanes. Arab J Chem 13(1):3226–3235

Ramya G, Crittenden B, Smith M, Camus O, Chew YJ, Perera S (2019) Synthesis of novel regenerable 13X zeolite-polyimide adsorbent foams. Chem Eng J 361:736–750

Sadik T, Pillon C, Carrot C, Ruiz JA (2018) Dsc studies on the decomposition of chemical blowing agents based on citric acid and sodium bicarbonate. Thermochim Acta 659:74–81

Laguna-Gutierrez E, Escudero J, Rodriguez-Perez MA (2018) Analysis of the mechanical properties and effective diffusion coefficient under static creep loading of low-density foams based on polyethylene/clays nanocomposites. Compos B Eng 148:156–165

Sun G, Wang W, Wang L, Yang Z, Liu L, Wang J, Ma N, Wei H, Han S (2017) Effects of aramid honeycomb core on the flame retardance and mechanical property for isocyanate-based polyimide foams. J Appl Polym Sci 134(28):45041

Liu C, Long Y, Xie J, Xie X (2017) Towards green polyurethane foams via renewable castor oil-derived polyol and carbon dioxide releasing blowing agents from alkylated polyethylenimines. Polymer 116:240–250

Najafi N, Heuzey M-C, Carreau PJ, Therriault D, Park CB (2014) Rheological and foaming behavior of linear and branched polylactides. Rheol Acta 53:779–790

Vardar-Sukan F (1998) Foaming: consequences, prevention and destruction. Biotechnol Adv 16(5–6):913–948

Hill C, Eastoe J (2017) Foams: From nature to industry. Adv Colloid Interface Sci 247:496–513

Schilling K, Zessner M (2011) Foam in the aquatic environment. Water Res 45(15):4355–4366

Forest C, Chaumont P, Cassagnau P, Swoboda B, Sonntag P (2015) Polymer nano-foams for insulating applications prepared from CO2 foaming. Prog Polym Sci 41:122–145

Costeux S (2014) CO2‐blown nanocellular foams. J Appl Polym Sci 131(23)

Okolieocha C, Raps D, Subramaniam K, Altstädt V (2015) Microcellular to nanocellular polymer foams: Progress (2004–2015) and future directions-A review. Eur Polym J 73:500–519

Wan C, Sun G, Gao F, Liu T, Esseghir M, Zhao L, Yuan W (2017) Effect of phase compatibility on the foaming behavior of LDPE/HDPE and LDPE/PP blends with subcritical CO2 as the blowing agent. J Supercrit Fluids 120:421–431

Kong W-L, Bao J-B, Wang J, Hu G-H, Xu Y, Zhao L (2016) Preparation of open-cell polymer foams by CO2 assisted foaming of polymer blends. Polymer 90:331–341

Mi H-Y, Chen J-W, Geng L-H, Chen B-Y, Jing X, Peng X-F (2016) Formation of nanoscale pores in shish-kebab structured isotactic polypropylene by supercritical CO2 foaming. Mater Lett 167:274–277

Tang M, Wang T-C (2017) Foaming of poly(vinylidene fluoride-co-hexafluoropropylene) using supercritical carbon dioxide. J Taiwan Inst Chem Eng 73:146–153

Meng L, Liu H, Yu L, Khalid S, Chen L, Jiang T, Li Q (2017) Elastomeric foam prepared by supercritical carbon dioxide. J Appl Polym Sci 134(4)

Yoon TJ, Kong W, Kwon DE, Park BK, Lee WI, Lee Y-W (2017) Preparation of solid-state micro- and nanocellular acrylonitrile-butadiene-styrene (ABS) foams using sub- and supercritical CO2 as blowing agents. J Supercrit Fluids 124:30–37

Forest C, Chaumont P, Cassagnau P, Swoboda B, Sonntag P (2015) Generation of nanocellular foams from ABS terpolymers. Eur Polym J 65:209–220

Cafiero L, Iannace S, Sorrentino L (2016) Microcellular foams from high performance miscible blends based on PEEK and PEI. Eur Polym J 78:116–128

Gedler G, Antunes M, Velasco JI (2016) Low density polycarbonate-graphene nanocomposite foams produced by supercritical carbon dioxide two-step foaming. Thermal stability. Compos Part B Eng 92:299–306

Ganjyal G, Reddy N, Yang Y, Hanna M (2004) Biodegradable packaging foams of starch acetate blended with corn stalk fibers. J Appl Polym Sci 93(6):2627–2633

Marrazzo C, Maio ED, Iannace S (2007) Foaming of synthetic and natural biodegradable polymers. J Cell Plast 43(2):123–133

Villamil Jiménez JA, Le Moigne N, Bénézet JC, Sauceau M, Sescousse R, Fages J (2020) Foaming of PLA composites by supercritical fluid-assisted processes: A review. Molecules 25(15):3408

Girard E, Tassaing T, Marty J-D, Destarac M (2016) Structure-Property Relationships in CO2-philic (Co)polymers: Phase Behavior, Self-Assembly, and Stabilization of Water/CO2 Emulsions. Chem Rev 116(7):4125–4169

Eckert CA, Knutson BL, Debenedetti PG (1996) Supercritical fluids as solvents for chemical and materials processing. Nature 383(6598):313–318

Li D, Liu Z, Han B, Song L, Yang G, Jiang T (2002) Preparation of nanometer dispersed polypropylene/polystyrene interpenetrating network using supercritical CO2 as a swelling agent. Polymer 43(19):5363–5367

Zirkel L, Jakob M, Münstedt H (2009) Foaming of thin films of a fluorinated ethylene propylene copolymer using supercritical carbon dioxide. J Supercrit Fluids 49(1):103–110

Nalawade SP, Picchioni F, Janssen L (2006) Supercritical carbon dioxide as a green solvent for processing polymer melts: Processing aspects and applications. Prog Polym Sci 31(1):19–43

Cooper AI (2000) Polymer synthesis and processing using supercritical carbon dioxide. J Mater Chem 10:207

Alsoy S, Duda JL (1999) Processing of polymers with supercritical fluids. Chem Eng Technol: Ind Chem-Plant Equip-Process Eng-Biotechnol 22(11):971–973

Kendall JL, Canelas DA, Young JL, DeSimone JM (1999) Polymerizations in supercritical carbon dioxide. Chem Rev 99:543

Salerno A, Domingo C (2019) Polycaprolactone foams prepared by supercritical CO2 batch foaming of polymer/organic solvent solutions. J Supercrit Fluids 143:146–156

Chen X, Feng JJ, Bertelo CA (2006) Plasticization effects on bubble growth during polymer foaming. Polym Eng Sci 46(1):97–107

Royer JR, DeSimone JM, Khan SA (2001) High‐pressure rheology and viscoelastic scaling predictions of polymer melts containing liquid and supercritical carbon dioxide. J Polym Sci Part B: Polym Phys 39(23):3055–3066

Royer JR, Gay YJ, Adam M, DeSimone JM, Khan SA (2002) Polymer melt rheology with high-pressure CO2 using a novel magnetically levitated sphere rheometer. Polymer 43(8):2375–2383

Royer JR, Gay YJ, Desimone JM, Khan SA (2000) High‐pressure rheology of polystyrene melts plasticized with CO2: Experimental measurement and predictive scaling relationships. J Polym Sci Part B: Polym Phys 38(23):3168–3180

Areerat S, Funami E, Hayata Y, Nakagawa D, Ohshima M (2004) Measurement and prediction of diffusion coefficients of supercritical CO2 in molten polymers. Polym Eng Sci 44(10):1915–1924

Duarte ARC, Mano JF, Reis RL (2009) Supercritical fluids in biomedical and tissue engineering applications: a review. Int Mater Rev 54(4):214–222

Li Y, Gong P, Liu Y, Niu Y, Park CB, Li G (2021) Environmentally friendly and zero-formamide EVA/LDPE microcellular foams via supercritical carbon dioxide solid foaming. ACS Appl Polym Mater 3(8):4213–4222

Santos-Rosales V, Ardao I, Goimil L, Gomez-Amoza JL, García-González CA (2021) Solvent-free processing of drug-loaded poly (ε-caprolactone) scaffolds with tunable macroporosity by combination of supercritical foaming and thermal porogen leaching. Polymers 13(1):159

Shao Y, Luo C, Deng B-W, Yin B, Yang M-B (2020) Flexible porous silicone rubber-nanofiber nanocomposites generated by supercritical carbon dioxide foaming for harvesting mechanical energy. Nano Energy 67:104290

Sun L, Gao M, Tang S (2021) Porous amino acid-functionalized poly(ionic liquid) foamed with supercritical CO2 and its application in CO2 adsorption. Chem Eng J 412:128764

Sauceau M, Fages J, Common A, Nikitine C, Rodier E (2011) New challenges in polymer foaming: A review of extrusion processes assisted by supercritical carbon dioxide. Prog Polym Sci 36(6):749–766

Michaeli W, Westermann K, Sitz S (2011) Extrusion of physically foamed rubber profiles. J Cell Plast 47(5):483–495

Ishikawa T, Taki K, Ohshima M (2012) Visual observation and numerical studies of N2 vs. CO2 foaming behavior in core‐back foam injection molding. Polym Eng Sci 52(4):875–883

Tsivintzelis I, Pavlidou E, Panayiotou C (2007) Biodegradable polymer foams prepared with supercritical CO2-ethanol mixtures as blowing agents. J Supercrit Fluids 42(2):265–272

Mi HY, Jing X, Salick MR, Peng XF, Turng LS (2014) A novel thermoplastic polyurethane scaffold fabrication method based on injection foaming with water and supercritical carbon dioxide as coblowing agents. Polym Eng Sci 54(12):2947–2957

Hu D-D, Gu Y, Liu T, Zhao L (2018) Microcellular foaming of polysulfones in supercritical CO2 and the effect of co-blowing agent. J Supercrit Fluids 140:21–31

Wong A, Mark LH, Hasan MM, Park CB (2014) The synergy of supercritical CO2 and supercritical N2 in foaming of polystyrene for cell nucleation. J Supercrit Fluids 90:35–43

Feng D, Li L, Wang Q (2019) Fabrication of three-dimensional polyetherimide bead foams via supercritical CO2/ethanol co-foaming technology. RSC Adv 9(7):4072–4081

Tsivintzelis I, Sanxaridou G, Pavlidou E, Panayiotou C (2016) Foaming of polymers with supercritical fluids: A thermodynamic investigation. J Supercrit Fluids 110:240–250

Goel SK, Beckman EJ (1994) Generation of microcellular polymeric foams using supercritical carbon dioxide. I: Effect of pressure and temperature on nucleation. Polym Eng Sci 34(14):1137–1147

Frank X, Dietrich N, Wu J, Barraud R, Li HZ (2007) Bubble nucleation and growth in fluids. Chem Eng Sci 62(24):7090–7097

Thompson RB, Park CB, Chen P (2010) Reduction of polymer surface tension by crystallized polymer nanoparticles. J Chem Phys 133(14)

Panploo K, Chalermsinsuwan B, Poompradub S (2019) Natural rubber latex foam with particulate fillers for carbon dioxide adsorption and regeneration. RSC Adv 9(50):28916–28923

Klopffer M, Flaconneche B (2001) Transport properties of gases in polymers: bibliographic review. Oil Gas Sci Technol 56(3):223–244

Miller D, Chatchaisucha P, Kumar V (2009) Microcellular and nanocellular solid-state polyetherimide (PEI) foams using sub-critical carbon dioxide I. Processing and structure. Polymer 50(23):5576–5584

Mahmood SH, Keshtkar M, Park CB (2014) Determination of carbon dioxide solubility in polylactide acid with accurate PVT properties. J Chem Thermodyn 70:13–23

Liu D, Tomasko DL (2007) Carbon dioxide sorption and dilation of poly(lactide-co-glycolide). J Supercrit Fluids 39(3):416–425

Pini R, Storti G, Mazzotti M, Tai H, Shakesheff KM, Howdle SM (2008) Sorption and swelling of poly (DL‐lactic acid) and poly (lactic‐co‐glycolic acid) in supercritical CO2: An experimental and modeling study. J Polym Sci Part B: Polym Phys 46(5):483–496

Handa YP, Zhang Z, Wong B (2001) Solubility, Diffusivity, and Retrograde Vitrification in PMMA-CO2, and Development of Sub-micron Cellular Structures. Cell Polym 20(1):1–16

Marchese J, Garis E, Anson M, Ochoa NA, Pagliero C (2003) Gas sorption, permeation and separation of ABS copolymer membrane. J Membr Sci 221(1):185–197

Pantoula M, Panayiotou C (2006) Sorption and swelling in glassy polymer/carbon dioxide systems: Part I Sorption. J Supercrit Fluids 37(2):254–262

Vitoux P, Tassaing T, Cansell F, Marre S, Aymonier C (2009) In Situ IR Spectroscopy and Ab Initio Calculations To Study Polymer Swelling by Supercritical CO2. J Phys Chem B 113:897

Sato Y, Fujiwara K, Takikawa T, Takishima S, Masuoka H (1999) Solubilities and diffusion coefficients of carbon dioxide and nitrogen in polypropylene, high-density polyethylene, and polystyrene under high pressures and temperatures. Fluid Phase Equilib 162(1):261–276

Sato Y, Yurugi M, Fujiwara K, Takishima S, Masuoka H (1996) Solubilities of carbon dioxide and nitrogen in polystyrene under high temperature and pressure. Fluid Phase Equilib 125(1):129–138

Sato Y, Takikawa T, Takishima S, Masuoka H (2001) Solubilities and diffusion coefficients of carbon dioxide in poly(vinyl acetate) and polystyrene. J Supercrit Fluids 19(2):187–198

Cohen MH, Turnbull D (1959) Molecular transport in liquids and glasses. J Chem Phys 31(5):1164–1169

Vrentas JS, Duda JL (1977) Diffusion in polymer-solvent systems. I. Reexamination of the free‐volume theory. J Polym Sci Polym Phys Ed 15(3):403–416

Vrentas JS, Vrentas CM (1994) Solvent Self-Diffusion in Glassy Polymer-Solvent Systems. Macromolecules 27(20):5570–5576

Vrentas JS, Vrentas CM (1994) Solvent Self-Diffusion in Rubbery Polymer-Solvent Systems. Macromolecules 27(17):4684–4690

Naito Y, Kamiya Y, Terada K, Mizoguchi K, Wang JS (1996) Pressure dependence of gas permeability in a rubbery polymer. J Appl Polym Sci 61(6):945–950

Kamiya Y, Mizoguchi K, Naito Y, Hirose T (1986) Gas sorption in poly (vinyl benzoate). J Polym Sci Part B: Polym Phys 24(3):535–547

Wong B, Zhang Z, Handa YP (1998) High‐precision gravimetric technique for determining the solubility and diffusivity of gases in polymers. J Polym Sci Part B: Polym Phys 36(12):2025–2032

Kamiya Y, Mizoguchi K, Terada K, Fujiwara Y, Wang J-S (1998) CO2 Sorption and Dilation of Poly(methyl methacrylate). Macromolecules 31(2):472–478

Lee JG, Flumerfelt RW (1995) Nitrogen solubilities in low-density polyethylene at high temperatures and high pressures. J Appl Polym Sci 58(12):2213–2219

Kleinrahm R, Wagner W (1986) Measurement and correlation of the equilibrium liquid and vapour densities and the vapour pressure along the coexistence curve of methane. J Chem Thermodyn 18(8):739–760

Areerat S, Hayata Y, Katsumoto R, Kegasawa T, Egami H, Ohshima M (2002) Solubility of carbon dioxide in polyethylene/titanium dioxide composite under high pressure and temperature. J Appl Polym Sci 86(2):282–288

Li G, Li H, Wang J, Park C (2006) Investigating the solubility of CO2 in polypropylene using various EOS models. Cell Polym 25(4):237–248

Li G, Gunkel F, Wang J, Park C, Altstädt V (2007) Solubility measurements of N2 and CO2 in polypropylene and ethene/octene copolymer. J Appl Polym Sci 103(5):2945–2953

Xie H, Simha R (1997) Theory of solubility of gases in polymers. Polym Int 44(3):348–355

Sanchez IC, Lacombe RH (1978) Statistical thermodynamics of polymer solutions. Macromolecules 11(6):1145–1156

Simha R, Somcynsky T (1969) On the statistical thermodynamics of spherical and chain molecule fluids. Macromolecules 2(4):342–350

Flory PJ (1953) Principles of polymer chemistry, Cornell university press

Hildebrand J, Scott R (1950) The Solubility of Nonelectrolytes, third edit. Reinhold, New York

Williams LL, Rubin JB, Edwards HW (2004) Calculation of hansen solubility parameter values for a range of pressure and temperature conditions including the supercritical fluid region. Ind Eng Chem Res 43(16):4967–4972

Strauss W, D’Souza NA (2004) Supercritical CO2 processed polystyrene nanocomposite foams. J Cell Plast 40(3):229–241

Garcia-Leiner M, Lesser AJ (2004) CO2-assisted polymer processing: A new alternative for intractable polymers. J Appl Polym Sci 93(4):1501–1511

Kazarian SG, Vincent MF, Bright FV, Liotta CL, Eckert CA (1996) Specific Intermolecular Interaction of Carbon Dioxide with Polymers. J Am Chem Soc 118:1729

Hansen CM (2004) Aspects of solubility, surfaces and diffusion in polymers. Prog Org Coat 51(1):55–66

Lindvig T, Michelsen ML, Kontogeorgis GM (2002) A Flory-Huggins model based on the Hansen solubility parameters. Fluid Phase Equilib 203(1):247–260

Kasturirangan A, Koh CA, Teja AS (2011) Glass-Transition Temperatures in CO2 + Polymer Systems: Modeling and Experiment. Ind Eng Chem Res 50(1):158–162

Andre P, Lacroix-Desmazes P, Taylor DK, Boutevin B (2006) Solubility of fluorinated homopolymer and block copolymer in compressed CO2. J Supercrit Fluids 37:263

Ribaut T, Oberdisse J, Annighofer B, Fournel B, Sarrade S, Haller H, Lacroix-Desmazes P (2011) Solubility and Self-Assembly of Amphiphilic Gradient and Block Copolymers in Supercritical CO2. J Phys Chem B 115:836

Kilic S, Michalik S, Wang Y, Johnson JK, Enick RM, Beckman EJ (2007) Phase Behavior of Oxygen-Containing Polymers in CO2. Macromolecules 40:1332

Fink R, Hancu D, Valentine R, Beckman EJ (1999) Toward the Development of “CO2-philic” Hydrocarbons. 1. Use of Side-Chain Functionalization to Lower the Miscibility Pressure of Polydimethylsiloxanes in CO2. J Phys Chem B 103(31):6441–6444

Kilic S, Wang Y, Johnson JK, Beckman EJ, Enick RM (2009) Influence of tert-amine groups on the solubility of polymers in CO2. Polymer 50:2436

Kirby CF, McHugh MA (1999) Phase behavior of polymers in supercritical fluid solvents. Chem Rev 99(2):565–602

Fried J, Li W (1990) High-pressure FTIR studies of gas-polymer interactions. J Appl Polym Sci 41(5–6):1123–1131

Shieh Y-T, Liu K-H (2003) The effect of carbonyl group on sorption of CO2 in glassy polymers. J Supercrit Fluids 25(3):261–268

Reglero JA, Viot P, Dumon M (2011) Foaming of amorphous polymers and blends in supercritical CO2: Solubility versus block copolymers addition. J Cell Plast 47(6):535–548

Colton J, Suh N (1987) The nucleation of microcellular thermoplastic foam with additives: Part I: Theoretical considerations. Polym Eng Sci 27(7):485–492

Colton J, Suh N (1987) The nucleation of microcellular thermoplastic foam with additives: Part II: Experimental results and discussion. Polym Eng Sci 27(7):493–499

Colton JS, Suh NP (1987) Nucleation of microcellular foam: Theory and practice. Polym Eng Sci 27(7):500–503

Kim Y, Park CB, Chen P, Thompson RB (2011) Origins of the failure of classical nucleation theory for nanocellular polymer foams. Soft Matter 7(16):7351–7358

Oxtoby DW (1998) Nucleation of first-order phase transitions. Acc Chem Res 31(2):91–97

Xu X, Cristancho DE, Costeux S, Wang Z-G (2013) Bubble nucleation in polymer-CO2 mixtures. Soft Matter 9(40):9675–9683

Costeux S, Khan I, Bunker SP, Jeon HK (2015) Experimental study and modeling of nanofoams formation from single phase acrylic copolymers. J Cell Plast 51(2):197–221

Di Y, Iannace S, Maio ED, Nicolais L (2005) Poly (lactic acid)/organoclay nanocomposites: thermal, rheological properties and foam processing. J Polym Sci Part B: Polym Phys 43(6):689–698

Jin W, Xingguo C, Mingjun Y, Jiasong H (2001) An investigation on the microcellular structure of polystyrene/LCP blends prepared by using supercritical carbon dioxide. Polymer 42(19):8265–8275

Shen J, Zeng C, Lee LJ (2005) Synthesis of polystyrene-carbon nanofibers nanocomposite foams. Polymer 46(14):5218–5224

Yu K, Jiang H, Zhou H, Mi J, He Y, Wang X (2018) Evolution of double crystal melting peak in polypropylene foam assisted by β-nucleating agent and supercritical CO2. J Appl Polym Sci 135(12):46007

Fu L, Li K, Qin H, Hou J, Zhang X, He G, Liu B, Ren C, Chen J (2022) Sandwich structured iPP/CNTs nanocomposite foams with high electromagnetic interference shielding performance. Compos Sci Technol 220:109297

Zuo K, Xu J, Xie S, Zhang S, Hou J, Yang Y, Zhang X, Chen J (2021) Microcellular foaming and mechanical properties of iPPF reinforced PPR composites. J Supercrit Fluids 170:105161

Zhang X, Wang X, Dong B, Zheng G, Chen J, Shen C, Park CB (2021) Synergetic effect of crystal nucleating agent and melt self-enhancement of isotactic polypropylene on its rheological and microcellular foaming properties. J Cell Plast 57(1):101–121

Wang B, Lin F-H, Li X-Y, Ji X-R, Liu S-X, Han X-J, Yuan Z-Q, Luo J (2019) Transcrystallization of isotactic polypropylene/bacterial cellulose hamburger composite. Polymers 11(3):508

Wang B, Lin F-H, Li X-Y, Zhang Z-W, Xue X-R, Liu S-X, Ji X-R, Yu Q, Yuan Z-Q, Chen X-D (2018) Isothermal crystallization and rheology properties of isotactic polypropylene/bacterial cellulose composite. Polymers 10(11):1284

Gao C, Liao J, Lu J, Ma J, Kianfar E (2021) The effect of nanoparticles on gas permeability with polyimide membranes and network hybrid membranes: a review. Rev Inorg Chem 41(1):1–20

Baldwin DF, Park CB, Suh NP (1996) A microcellular processing study of poly (ethylene terephthalate) in the amorphous and semicrystalline states. Part I: Microcell nucleation. Polym Eng Sci 36(11):1437–1445

Taki K, Kitano D, Ohshima M (2011) Effect of Growing Crystalline Phase on Bubble Nucleation in Poly(L-Lactide)/CO2 Batch Foaming. Ind Eng Chem Res 50(6):3247–3252

Yu K, Wang D, Hou J, Zhang X, Chen J (2023) Fabrication of poly(lactic acid) foam with high expansion ratio and oriented cellular structure by restricting cold crystallization. Int J Biol Macromol 251:126463

Fu L, Shi Q, Ji Y, Wang G, Zhang X, Chen J, Shen C, Park CB (2020) Improved cell nucleating effect of partially melted crystal structure to enhance the microcellular foaming and impact properties of isotactic polypropylene. J Supercrit Fluids 160:104794

Zhang X, Li B, Wang X, Li K, Wang G, Chen J, Park CB (2018) Modification of iPP microcellular foaming behavior by thermal history control and nucleating agent at compressed CO2. J Supercrit Fluids 133:383–392

Wang B, Lin F-H, Zhao Y-Y, Li X-Y, Liu Y-C, Li J-B, Han X-J, Liu S-X, Ji X-R, Luo J (2019) Isotactic polybutene-1/bamboo powder composites with excellent properties at initial stage of molding. Polymers 11(12):1981

Wang B, Zhang H-R, Huang C, Xiong L, Luo J (2017) Study on non-isothermal crystallization behavior of isotactic polypropylene/bacterial cellulose composites. RSC Adv 7(67):42113–42122

Yu K, Wu Y, Zhang X, Hou J, Chen J (2022) Microcellular open-cell poly (L-lactic acid)/poly (D-lactic acid) foams for oil-water separation prepared via supercritical CO2 foaming. J CO2 Util 65:102219

Park CB, Cheung LK, Song S-W (1998) The effect of talc on cell nucleation in extrusion foam processing of polypropylene with CO2 and isopentane. Cell Polym 17(4):221–251

Chen L, Blizard K, Straff R, Wang X (2002) Effect of filler size on cell nucleation during foaming process. J Cell Plast 38(2):139–148

Ramesh N, Lee S (2005) Do nanoparticles really assist in nucleation of fine cells in polyolefin foams? Cell Polym 24(5):269–277

Fletcher NH (1958) Size effect in heterogeneous nucleation. J Chem Phys 29(3):572–576

Leung SN, Park CB, Li H (2010) Effects of nucleating agents’ shapes and interfacial properties on cell nucleation. J Cell Plast 46(5):441–460

Müller M, MacDowell L, Virnau P, Binder K (2002) Interface properties and bubble nucleation in compressible mixtures containing polymers. J Chem Phys 117(11):5480–5496

Yu K, Zhou H, Wang X, Du Z, Mi J (2019) From thermodynamics to kinetics: Theoretical study of CO2 dissolving in poly (lactic acid) melt. J Mol Liq 280:97–103

Yu K, Ni J, Zhou H, Wang X, Mi J (2020) Effects of in-situ crystallization on poly (lactic acid) microcellular foaming: Density functional theory and experiment. Polymer 200:122539

Ren R-R, Lv C-Q, Liu J-H, Wang G-C (2022) Investigation of the oxygen coverage of propylene epoxidation on Ag(111) surfaces from DFT. Comput Theor Chem 1214:113739

Zhang J, Yang J, Cheng L, Wang Y, Feng G (2020) Adsorption of acetylene on Sn-doped Ni (111) surfaces: a density functional study. J Mol Model 26:1–8

Zhang J, Wang Y, Wang Y, Zhang M (2017) Catalytic activity for oxygen reduction reaction on CoN2 embedded graphene: a density functional theory study. J Electrochem Soc 164(12):F1122

Zhi C, Wang Q, Wang B, Li D, Zhang R (2015) Insight into the mechanism of methane synthesis from syngas on a Ni (111) surface: a theoretical study. RSC Adv 5(82):66742–66756

Epstein PS, Plesset MS (1950) On the stability of gas bubbles in liquid-gas solutions. J Chem Phys 18(11):1505–1509

Hobbs S (1976) Bubble growth in thermoplastic structural foams. Polym Eng Sci 16(4):270–275

Song S, Hao Z, Dong L, Li J, Fang Y (2016) A bubble-based EMMS model for pressurized fluidization and its validation with data from a jetting fluidized bed. RSC Adv 6(112):111041–111051

Han CD, Yoo HJ (1981) Studies on structural foam processing. IV. Bubble growth during mold filling. Polym Eng Sci 21(9):518–533

Papanastasiou AC, Scriven LE, Macosko CW (1984) Bubble growth and collapse in viscoelastic liquids analyzed. J Non-Newtonian Fluid Mech 16(1):53–75

Amon M, Denson CD (1984) A study of the dynamics of foam growth: analysis of the growth of closely spaced spherical bubbles. Polym Eng Sci 24(13):1026–1034

Amon M, Denson CD (1986) A study of the dynamics of foam growth: Simplified analysis and experimental results for bulk density in structural foam molding. Polym Eng Sci 26(3):255–267

Brujan EA (1999) A first-order model for bubble dynamics in a compressible viscoelastic liquid. J Non-Newtonian Fluid Mech 84(1):83–103

Joshi K, Lee JG, Shafi MA, Flumerfelt RW (1998) Prediction of cellular structure in free expansion of viscoelastic media. J Appl Polym Sci 67(8):1353–1368

Venerus DC, Yala N, Bernstein B (1998) Analysis of diffusion-induced bubble growth in viscoelastic liquids. J Non-Newtonian Fluid Mech 75(1):55–75

Otsuki Y, Kanai T (2005) Numerical simulation of bubble growth in viscoelastic fluid with diffusion of dissolved foaming agent. Polym Eng Sci 45(9):1277–1287

Agarwal US (2002) Simulation of bubble growth and collapse in linear and pom-pom polymers. e-Polymers 2(1):013

Lee JG, Flumerfelt RW (1996) A Refined Approach to Bubble Nucleation and Polymer Foaming Process: Dissolved Gas and Cluster Size Effects. J Colloid Interface Sci 184(2):335–348

Kim KY, Kang SL, Kwak HY (2004) Bubble nucleation and growth in polymer solutions. Polym Eng Sci 44(10):1890–1899

Shafi MA, Joshi K, Flumerfelt RW (1997) Bubble size distributions in freely expanded polymer foams. Chem Eng Sci 52(4):635–644

Goel SK, Beckman EJ (1995) Nucleation and growth in microcellular materials: supercritical CO2 as foaming agent. AlChE J 41(2):357–367

Feng JJ, Bertelo CA (2004) Prediction of bubble growth and size distribution in polymer foaming based on a new heterogeneous nucleation model. J Rheol 48(2):439–462

Antunes M, Velasco JI, Realinho V, Martinez AB, Rodríguez-Pérez MÁ, de Saja JA (2009) Heat Transfer in Polypropylene-Based Foams Produced Using Different Foaming Processes. Adv Eng Mater 11(10):811–817

Wang J, Zhai W, Ling J, Shen B, Zheng W, Park CB (2011) Ultrasonic Irradiation Enhanced Cell Nucleation in Microcellular Poly(lactic Acid): A Novel Approach to Reduce Cell Size Distribution and Increase Foam Expansion. Ind Eng Chem Res 50(24):13840–13847

Richards E, Rizvi R, Chow A, Naguib H (2008) Biodegradable Composite Foams of PLA and PHBV Using Subcritical CO2. J Polym Environ 16(4):258–266

Qiu Y, Lv Q, Wu D, Xie W, Peng S, Lan R, Xie H (2018) Cyclic tensile properties of the polylactide nanocomposite foams containing cellulose nanocrystals. Cellulose 25(3):1795–1807

Zhou C, Wang P, Li W (2011) Fabrication of functionally graded porous polymer via supercritical CO2 foaming. Compos B Eng 42(2):318–325

Guo H, Kumar V (2015) Some thermodynamic and kinetic low-temperature properties of the PC-CO2 system and morphological characteristics of solid-state PC nanofoams produced with liquid CO2. Polymer 56:46–56

Goel SK, Beckman EJ (1994) Generation of microcellular polymeric foams using supercritical carbon dioxide. II: Cell growth and skin formation. Polym Eng Sci 34(14):1148–1156

Costeux S, Zhu L (2013) Low density thermoplastic nanofoams nucleated by nanoparticles. Polymer 54(11):2785–2795

Yang J, Huang L, Zhang Y, Chen F, Zhong M (2013) Mesoporous silica particles grafted with polystyrene brushes as a nucleation agent for polystyrene supercritical carbon dioxide foaming. J Appl Polym Sci 130(6):4308–4317

Zhang C, Zhu B, Li D, Lee LJ (2012) Extruded polystyrene foams with bimodal cell morphology. Polymer 53(12):2435–2442

Larsen Å, Neldin C (2013) Physical extruder foaming of poly (lactic acid)-processing and foam properties. Polym Eng Sci 53(5):941–949

Zhang C, Zhu B, Lee LJ (2011) Extrusion foaming of polystyrene/carbon particles using carbon dioxide and water as co-blowing agents. Polymer 52(8):1847–1855

Okolieocha C, Köppl T, Kerling S, Tölle FJ, Fathi A, Mülhaupt R, Altstädt V (2015) Influence of graphene on the cell morphology and mechanical properties of extruded polystyrene foam. J Cell Plast 51(4):413–426

Wang J, Zhu W, Zhang H, Park CB (2012) Continuous processing of low-density, microcellular poly(lactic acid) foams with controlled cell morphology and crystallinity. Chem Eng Sci 75:390–399

Li J, Chen Z, Wang X, Liu T, Zhou Y, Luo S (2013) Cell morphology and mechanical properties of microcellular mucell® injection molded polyetherimide and polyetherimide/fillers composite foams. J Appl Polym Sci 130(6):4171–4181

Guo MC, Heuzey MC, Carreau PJ (2007) Cell structure and dynamic properties of injection molded polypropylene foams. Polym Eng Sci 47(7):1070–1081

Yuan M, Song Q, Turng LS (2007) Spatial orientation of nanoclay and crystallite in microcellular injection molded polyamide-6 nanocomposites. Polym Eng Sci 47(6):765–779

Yuan M, Winardi A, Gong S, Turng LS (2005) Effects of nano-and micro-fillers and processing parameters on injection-molded microcellular composites. Polym Eng Sci 45(6):773–788

Kramschuster A, Cavitt R, Ermer D, Chen Z, Turng LS (2005) Quantitative study of shrinkage and warpage behavior for microcellular and conventional injection molding. Polym Eng Sci 45(10):1408–1418

Chandra A, Gong S, Turng L-S, Gramann P (2004) Cell development in microcellular injection molded polyamide-6 nanocomposite and neat resin. J Cell Plast 40(5):371–382

Yuan M, Turng L-S, Gong S, Winardi A, Caulfield D (2004) Crystallization behavior of polyamide-6 microcellular nanocomposites. J Cell Plast 40(5):397–409

Yuan M, Turng LS, Caulfield DF (2006) Crystallization and thermal behavior of microcellular injection-molded polyamide-6 nanocomposites. Polym Eng Sci 46(7):904–918

Pilla S, Kramschuster A, Yang L, Lee J, Gong S, Turng L-S (2009) Microcellular injection-molding of polylactide with chain-extender. Mater Sci Eng, C 29(4):1258–1265

Pilla S, Kramschuster A, Lee J, Clemons C, Gong S, Turng L-S (2010) Microcellular processing of polylactide-hyperbranched polyester-nanoclay composites. J Mater Sci 45:2732–2746

Hwang SS, Hsu PP, Yeh JM, Chang KC, Lai YZ (2009) The mechanical/thermal properties of microcellular injection-molded poly-lactic-acid nanocomposites. Polym Compos 30(11):1625–1630

Funding

This work is financially supported by the Natural Science Foundation of Chongqing, China (No. cstc2020jcyj-msxmX1035) and the Doctoral Program of Chongqing, China (No. CSTB2022BSXM-JCX0167). The authors would also like to acknowledge the supports from Youth Project of Science and Technology Research Program of Chongqing Education Commission of China (No.KJQN202103223) and Doctoral Research Fund of Chongqing Industry Polytechnic College (2022GZYBSZK1-08).

Author information

Authors and Affiliations

Contributions

Mengyao Dong: Conceived and designed the review, wrote the main text. Gang Wang: Formal analysis and editing. Xiangning Zhang: Formal analysis and editing. Daqing Tan: Data collection and curation. Jaya Prasanna Kumar D: Data collection and curation. Juanna Ren: Data collection and curation. Henry Colorado: Prepared figures and visualization. Hua Hou: Supervision and proofreading the manuscript. Zhexenbek Toktarbay: review and editing. Zhanhu Guo: review and editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dong, M., Wang, G., Zhang, X. et al. An overview of polymer foaming assisted by supercritical fluid. Adv Compos Hybrid Mater 6, 207 (2023). https://doi.org/10.1007/s42114-023-00790-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42114-023-00790-6