Abstract

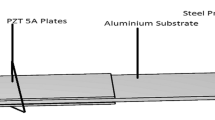

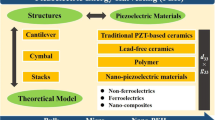

Cymbal transducers have been discovered as a viable design for piezoelectric energy harvesting under heavy impact loads. However, low-output voltage remains a source of concern; therefore, many promising approaches for enhancing performance efficiency are crucial in the field of piezoelectricity. This study presents a viable angular poling approach for flex tensional based cymbal structures solely for energy harvesting applications. Elementary and Euler angular poling are two types of angular poling introduced for cymbal piezoelectric transducers. Using the energy method, theoretical modelling is performed on a cymbal structure exposed to a 1000 N impact force. Pb(Mg1/3Nb2/3)O3-PbTiO3 (PMN-0.33 PT) is utilised as a piezoelectric material because of its strong piezoelectric properties in both tetragonal and rhombohedral symmetry. The findings show that Euler angular poling outperforms elementary angular poling due to its reliance on two angles. When elementary angular poling is used, the voltage and energy reach 108.9 V and 380.1 μJ, respectively, resulting in a 198.02% and 2800% enhancement over the original PMN-0.33PT material. Similarly, in Euler angular poling, voltage and energy reached 123.59 V and 450 μJ, respectively, resulting in increase of 238.1% and 3340%. Finally, potential applications include powering light-emitting diodes and charging small portable electronic devices such as digital cameras and cell phones. A large-scale system can be built using cymbal piezoelectric tiles, making it suitable for use in industrial applications such as ultrasonic welding, diesel fuel injectors, and robotic systems.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- \(a_{0}\) :

-

Distance from that apex to the top of the cavity [mm]

- \(a\) :

-

Radial distance from the imaginary apex of the cone to the outer edge [mm]

- \(\lambda\) :

-

Cavity angle [degree]

- \(C_{s}\) :

-

In-plane force per unit circumference [mm]

- \(\delta\) :

-

Angle between the vertical load axis and the slope of the end cap cavity [degree]

- \(d_{ij}\) :

-

Piezoelectric strain coefficient, i varies from 1 to 3 and j varies from 1 to 6 [C/N]

- \(\varepsilon_{c}\) :

-

Strain developed in laminar composite due to compression

- \(\varepsilon_{t}\) :

-

Strain developed in laminar composite due to tension

- \(E_{3}\) :

-

Electric field along third direction [V/m]

- \(F_{u}\) :

-

Edge load per unit length [N/m]

- \(h_{e}\) :

-

Thickness of metal end cap [mm]

- \(h_{c}\) :

-

Height of cavity [mm]

- \(h_{p}\) :

-

Thickness of piezoelectric material [mm]

- \(h_{s}\) :

-

Thickness of substrate material [mm]

- \(P\) :

-

Electric polarisation [Q/m2]

- \(R_{a}\) :

-

Radius of apex [mm]

- \(R_{c}\) :

-

Radius of cavity [mm]

- \(R\) :

-

Radius of end cap [mm]

- \(s_{ij}\) :

-

Compliance coefficients i and j ranges from 1 to 6 [m2/N]

- \(Y_{s}\) :

-

Elastic modulus of substrate material [Pa]

- \(Y_{p}\) :

-

Elastic modulus of piezoelectric material [Pa]

- \(Y_{c}\) :

-

Elastic modulus of laminar composite [Pa]

- \(\in_{ij}\) :

-

Electrical permittivity coefficient, i and j varies from 1 to 3 [C/Vm]

- \(\psi\),\(\chi\) :

-

Transformation matrices

- \(\sigma_{t}\),\(\sigma_{c}\) :

-

Tensile and compressive stresses generated in cymbal [Pa]

- \(\sigma_{tp}\) :

-

Tensile stress generated in piezoelectric material [Pa]

- \(\sigma_{ts}\) :

-

Tensile stress generated in substrate material [Pa]

- \(\sigma_{x}\) :

-

Stress generated in x direction [Pa]

- \(\sigma_{y}\) :

-

Stress generated in y direction [Pa]

- \(dU_{tp}\) :

-

Energy generated by tension for piezoelectric in a small volume of the inner cavity region [J]

- \(dU_{ts}\) :

-

Energy generated by tension for substrate in a small volume of the inner cavity region [J]

- \(dU_{cp}\) :

-

Energy developed for piezoelectric due to compression for small volume at outer region [J]

- \(dU_{cs}\) :

-

Energy developed for substrate due to compression for small volume at outer region [J]

- \(\eta\),\(\kappa\),\(\varphi\) :

-

Angular poling angles [degree]

- \(Q\) :

-

Total electrical charge [C]

- \(Q_{gen}\) :

-

Charge generated with no applied external electric field or voltage [C]

- \(C\) :

-

Capacitance of cymbal structure [F]

- \(V\) :

-

Voltage generated in cymbal structure [V]

- \(U\) :

-

Electrical energy generated in cymbal structure [J

7. References

S. Kumar, D. Singh, R. Kumar et al., No-wear vibration energy harvester based on a triboelectric mechanism. J. Electron. Mater. 50, 7057–7070 (2021)

W. Chen, Y. Liu, Y. Liu et al., Design and experimental evaluation of a novel stepping linear piezoelectric actuator. Sensors Actuators, A Phys. 276, 259–266 (2018)

C. Eichhorn, F. Goldschmidtboeing, P. Woias, Bidirectional frequency tuning of a piezoelectric energy converter based on a cantilever beam. J. Micromech. Microeng. (2009). https://doi.org/10.1088/0960-1317/19/9/094006

M. Leinonen, J. Palosaari, J. Juuti et al., Combined electrical and electromechanical simulations of a piezoelectric cymbal harvester for energy harvesting from walking. J. Intell. Mater. Syst. Struct. 25, 391–400 (2014)

Y. Kuang, A. Daniels, M. Zhu, A sandwiched piezoelectric transducer with flex end-caps for energy harvesting in large force environments. J. Phys. D Appl. Phys. (2017). https://doi.org/10.1088/1361-6463/aa7b28

H.W. Kim, A. Batra, S. Priya et al., Energy harvesting using a piezoelectric ‘cymbal’ transducer in dynamic environment. Jpn. J. Appl. Phys. 43, 6178–6183 (2004)

J. Palosaari, M. Leinonen, J. Hannu et al., Energy harvesting with a cymbal type piezoelectric transducer from low frequency compression. J. Electroceram. 28, 214–219 (2012)

C. Mo, D. Arnold, W.C. Kinsel et al., Modeling and experimental validation of unimorph piezoelectric cymbal design in energy harvesting. J. Intell. Mater. Syst. Struct. 24, 828–836 (2013)

J.B. Yuan, X.B. Shan, T. Xie et al., Energy harvesting with a slotted-cymbal transducer. J. Zhejiang Univ. Sci. A 10, 1187–1190 (2009)

E. Tufekcioglu, A. Dogan, A flextensional piezo-composite structure for energy harvesting applications. Sensors Actuators, A Phys. 216, 355–363 (2014)

G. Yesner, A. Jasim, H. Wang et al., Energy harvesting and evaluation of a novel piezoelectric bridge transducer. Sensors Actuators, A Phys. 285, 348–354 (2019)

Z. Yu, Z. Chu, J. Yang et al., A magneto-mechano-electric (MME) energy harvester based on rectangular cymbal structure. Sensors Actuators, A Phys. 316, 112400 (2020)

D. Arnold, W. Kinsel, W.W. Clark et al., Exploration of new cymbal design in energy harvesting. Act. Passiv. Smart Struct. Integr. Syst. 2011(7977), 79770T (2011)

D. Haller, A. Paetzold, N. Goldin, et al., Cymbal type Piezo-Polymer-Composite actuators for active cancellation of flow instabilities on airfoils. 2011 16th Int Solid-State Sensors, Actuators Microsystems Conf TRANSDUCERS’11 (2011), pp 494–497

W. Hou, Y. Zheng, W. Guo et al., Piezoelectric vibration energy harvesting for rail transit bridge with steel-spring floating slab track system. J. Clean Prod. 291, 125283 (2021)

F. Goldschmidtboeing, P. Woias, Characterization of different beam shapes for piezoelectric energy harvesting. J. Micromech. Microeng. (2008). https://doi.org/10.1088/0960-1317/18/10/104013

D. Cao, Y. Gao, W. Hu, Modeling and power performance improvement of a piezoelectric energy harvester for low-frequency vibration environments. Acta Mech. Sin. Xuebao 35, 894–911 (2019)

F. Wein, M. Kaltenbacher, M. Stingl, Topology optimization of a cantilevered piezoelectric energy harvester using stress norm constraints. Struct. Multidiscip. Optim. 48, 173–185 (2013)

H. Ghasemi, H.S. Park, X. Zhuang et al., Three-dimensional isogeometric analysis of flexoelectricity with MATLAB implementation. Comput. Mater. Contin. 65, 1157–1179 (2020)

H. Ghasemi, H.S. Park, N. Alajlan et al., A computational framework for design and optimization of flexoelectric materials. Int. J. Comput. Methods 17, 1–14 (2020)

K.M. Hamdia, H. Ghasemi, X. Zhuang et al., Multilevel Monte Carlo method for topology optimization of flexoelectric composites with uncertain material properties. Eng. Anal. Bound Elem. 134, 412–418 (2022)

M. Salavati, H. Ghasemi, T. Rabczuk, Electromechanical properties of boron nitride nanotube: atomistic bond potential and equivalent mechanical energy approach. Comput. Mater. Sci. 149, 460–465 (2018)

H.G. Yeo, S. Trolier-McKinstry, Effect of piezoelectric layer thickness and poling conditions on the performance of cantilever piezoelectric energy harvesters on Ni foils. Sensors Actuators, A Phys. 273, 90–97 (2018)

Y. Shindo, F. Narita, M. Sato, Effects of electric field and poling on the mode i energy release rate in cracked piezoelectric ceramics at cryogenic temperatures. Acta Mech. 224, 2547–2558 (2013)

E.M.A. Fuentes-Fernandez, B.E. Gnade, M.A. Quevedo-Lopez et al., The effect of poling conditions on the performance of piezoelectric energy harvesters fabricated by wet chemistry. J. Mater. Chem. A 3, 9837–9842 (2015)

N. Moriwaki, T. Kobayashi, Y. Suzuki et al., Influence of bipolar pulse poling technique for piezoelectric vibration energy harvesters using Pb(Zr, Ti)O3 films on 200 mm SOI wafers. J. Phys. Conf. Ser. (2013). https://doi.org/10.1088/1742-6596/476/1/012132

J. Guo, M. Nie, Q. Wang, Self-poling polyvinylidene fluoride-based piezoelectric energy harvester featuring highly oriented β-phase structured at multiple scales. ACS Sustain. Chem. Eng. 9, 499–509 (2021)

L. Qiao, G. Li, H. Tao et al., Full characterization for material constants of a promising KNN-based lead-free piezoelectric ceramic. Ceram. Int. 46, 5641–5644 (2020)

Z. Zhang, J. Xu, L. Yang, et al., The performance enhancement and temperature dependence of piezoelectric properties for Pb(Mg 1/3 Nb 2/3 )O 3 -0.30PbTiO 3 single crystal by alternating current polarization. J. Appl. Phys. 125, 0–7 (2019)

R. Kiran, A. Kumar, R. Kumar et al., Poling direction driven large enhancement in piezoelectric performance. Scr. Mater. 151, 76–81 (2018)

K. Larkin, A. Hunter, A. Abdelkefi, Size-dependent modeling and performance enhancement of functionally graded piezoelectric energy harvesters. J. Nanoparticle Res. (2020). https://doi.org/10.1007/s11051-020-04897-5

M.H. Malakooti, Z. Zhou, H.A. Sodano, Enhanced energy harvesting through nanowire based functionally graded interfaces. Nano Energy 52, 171–182 (2018)

J. Adhikari, A. Kumar, R. Kumar, et al. Performance enhancement of functionally graded piezoelectric tile by tailoring poling orientation. Mech. Based Des. Struct. Mach. 1–20 (2021)

S. Nomura, K. Kaneta, M. Yokosuka, et al. Related content Properties of an Interconnected Porous Pb ( Zr , Ti ) O 3 Ceramic. Jpn. J. Appl. Phys.

T. Zheng, H. Wu, Y. Yuan et al., The structural origin of enhanced piezoelectric performance and stability in lead free ceramics†. Energy Environ. Sci. 10, 528–537 (2017)

J.I. Roscow, R.W.C. Lewis, J. Taylor et al., Modelling and fabrication of porous sandwich layer barium titanate with improved piezoelectric energy harvesting figures of merit. Acta Mater. 128, 207–217 (2017)

D. Xu, W.L. Li, L.D. Wang et al., Large piezoelectric properties induced by doping ionic pairs in BaTiO 3 ceramics. Acta Mater. 79, 84–92 (2014)

K. Singh, S. Sharma, M. Talha et al., A 3-dimensional approach for evaluating the influence of poling orientation on piezoelectric characteristics. J. Electron. Mater. 50, 5846–5856 (2021)

J. Adhikari, R. Kumar, V Narain, et al. in Effect of Poling Orientation in Performance of Piezoelectric Materials BT - Machines, Mechanism and Robotics, ed by R. Kumar, V.S. Chauhan, M. Talha, et al. (Springer Singapore, Singapore, 2022), pp. 1721–1732

J. Adhikari, R. Kumar, S.C. Jain, Modeling and parametric analysis for performance improvement in piezoelectric energy harvesting tile. Ferroelectrics 573, 201–213 (2021)

S.V. Shah, S.K. Saha, J.K. Dutt, Denavit-Hartenberg parameterization of Euler angles. J. Comput. Nonlinear Dyn. 7, 1–10 (2012)

T. Granzow, A.B. Kounga, E. Aulbach et al., Electromechanical poling of piezoelectrics. Appl Phys Lett 88, 36–39 (2006)

Y.H. Huang, Y.J. Wu, W.J. Qiu et al., Enhanced energy storage density of Ba0.4Sr0.6TiO3-MgO composite prepared by spark plasma sintering. J. Eur. Ceram. Soc. 35, 1469–1476 (2015)

H. Guo, C. Ma, X. Liu et al., Electrical poling below coercive field for large piezoelectricity. Appl. Phys. Lett. 102, 1–5 (2013)

W.N.M. Jamil, M.A. Aripin, Z. Sajuri et al., Mechanical properties and microstructures of steel panels for laminated composites in armoured vehicles. Int. J. Automot. Mech. Eng. 13, 3741–3753 (2016)

S.C. Walpole, D. Prieto-Merino, P. Edwards et al., The weight of nations: An estimation of adult human biomass. BMC Public Health 12, 1 (2012)

H.M.J. McEwen, P.I. Barnett, C.J. Bell et al., The influence of design, materials and kinematics on the in vitro wear of total knee replacements. J. Biomech. 38, 357–365 (2005)

S. Sivarasu, L. Mathew, Structural responses of a novel high flexion knee (SS316-UHMWPE) used in total knee arthroplasty using finite element analysis. Biophys. Rev. Lett. 4, 289–298 (2009)

R. Zhang, W. Cao, Transformed material coefficients for single-domain 0.67Pb (Mg13 Nb23) O3–0.33 PbTiO3 single crystals under differently defined coordinate systems. Appl. Phys. Lett. 85, 6380–6382 (2004)

P. Biswas, N.A. Hoque, P. Thakur et al., Highly efficient and durable piezoelectric nanogenerator and photo-power cell based on CTAB modified montmorillonite incorporated PVDF film. ACS Sustain. Chem. Eng. 7, 4801–4813 (2019)

K.B. Kim, J.Y. Cho, J. Hamid et al., Optimized composite piezoelectric energy harvesting floor tile for smart home energy management. Energy Convers. Manag. 171, 31–37 (2018)

A. Pop-Vadean, P.P. Pop, T. Latinovic et al., Harvesting energy an sustainable power source, replace batteries for powering WSN and devices on the IoT. IOP Conf. Ser. Mater. Sci. Eng. (2017). https://doi.org/10.1088/1757-899X/200/1/012043

A. Aabid, M.A. Raheman, Y.E. Ibrahim et al., A systematic review of piezoelectric materials and energy harvesters for industrial applications. Sensors 21, 1–27 (2021)

A. Mathieson, D. Deangelis. Feasibility of lead-free piezoceramic based power ultrasonic transducers. IEEE Int Ultrason Symp IUS (2014), pp. 2075–2078

M. Han, H. Wang, Y. Yang et al., Three-dimensional piezoelectric polymer microsystems for vibrational energy harvesting, robotic interfaces and biomedical implants. Nat. Electron. 2, 26–35 (2019)

S. Klusáček, J. Fialka, Z. Havránek, et al. in Measurement of temperature dependence in the piezoelectric active element of a knock sensor. INTERNOISE 2014 - 43rd Int Congr Noise Control Eng Improv World Through Noise Control (2014), pp. 1–7

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors did not receive support from any organization for the submitted work. The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

\(\psi_{Z} ,\psi_{X} ,\psi_{Z}\) are the rotation matrices about Z, X and Z respectively

Substituting equations (A1–A3) in Eq. (46) to get

\(\chi_{Z} ,\chi_{X} ,\chi_{Z}\) are the transformation matrices for Z, X and Z respectively, given as follows:

Rights and permissions

About this article

Cite this article

Adhikari, J., Kumar, R. & Jain, S.C. Angular poling effect on cymbal piezoelectric structure using rhombohedral and tetragonal PMN-0.33PT for energy harvesting applications. Appl. Phys. A 128, 384 (2022). https://doi.org/10.1007/s00339-022-05512-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-022-05512-1