Abstract

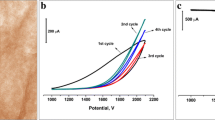

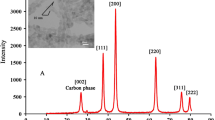

The detection of phenolic compounds with electrochemical sensors is still very exciting regarding their selectivity, sensitivity, and stability. There is a need yet to operate sensors for ferulic acid (FA) and other phenolic compounds that function reliably under environmental conditions. Herein, we present a FA chemical sensor based on molybdenum trioxide (MoO3) Radiofrequency magnetron-sputtered carbon cloth (CC) thin-film electrode (MoO3/CC). With the lowest limit of detection (LOD) value of 2.3 nM and sensitivity of 0.0249 µA/µM, the sensor performed admirably. The presence of aggregated crystallites with wedge-shaped nanostructures for an average length of 800 nm was discovered using field emission scanning electron microscopy of MoO3 thin films. The MoO3 thin-film X-ray diffraction (XRD) patterns showed an orthorhombic crystal structure. The presence of multiphonon vibrations of Mo sublattice and oxygen atoms was visible in the Raman spectrum. The chemical structure of the resulting film of Mo, O, and C atoms was discovered using X-ray photoelectron spectroscopy. Notably, the sensor was used to authenticate spiked tap water and pineapple juice samples, yielding recaptures ranging from 99.53 to 102.52%, indicating that it could be used as an alternative method for the quantitative identification of FA.

Similar content being viewed by others

References

R. Malik, N. Joshi, V.K. Tomer, Mater. Adv. 2, 4190 (2021). https://doi.org/10.1039/D1MA00374G

I. Castro, R. Datta, J. Ou, A. Gomez, S. Sriram, T. Daeneke, K. Kalantar, Int. J. Appl. Ceram. Technol. 18, 889 (2020). https://doi.org/10.1111/ijac.13684

Y. Gong, Y. Dong, B. Zhao, R. Yu, S. Hub, Z. Tan, J. Mater. Chem. A. 8, 978 (2020). https://doi.org/10.1039/C9TA12005J

H. Sun, H. Zhang, X. Jing, J. Hu, K. Shen, Z. Liang, J. Hu, Q. Tian, M. Luo, Z. Zhu, Z. Jiang, H. Huang, F. Song, Appl. Surf. Sci. 476, 789 (2019). https://doi.org/10.1016/j.apsusc.2019.01.169

T.N. Kovacs, L. Studnicka, I.E. Lukacs, K. Laszlo, P. Pasierb, I.M. Szilagyi, G. Pokol, Nanomaterials 10, 891 (2020). https://doi.org/10.3390/nano10050891

V. Kumar, X. Wang, P.S. Lee, Nanoscale 7, 11777 (2015). https://doi.org/10.1039/C5NR01505G

Y. Wang, X. Wang, X. Li, R. Liu, Y. Bai, H. Xiao, Y. Liu, G. Yuan, Nano-Micro Lett. 12, 115 (2020). https://doi.org/10.1007/s40820-020-00450-0

Y. Jiang, M. Sun, J. Ni, L. Li, A.C.S. Appl, Mater. Interfaces. 11, 37761 (2019). https://doi.org/10.1021/acsami.9b12858

D. Spetter, M.N. Tahir, J. Hilgert, I. Khan, A. Qurashi, H. Lu, T. Weidner, W. Tremel, ACS Sustain. Chem. Eng. 6, 12641 (2018). https://doi.org/10.1021/acssuschemeng.8b01370

D. Murugesan, K. Moulaee, G. Neri, N. Ponpandian, C. Viswanathan, Nanotechnology 30, 265501 (2019). https://doi.org/10.1088/1361-6528/ab0cb9

M. Zhang, R. Li, D. Hu, X. Huang, Y. Liu, K. Yan, J. Electroanal. Chem. 836, 102 (2019). https://doi.org/10.1016/j.jelechem.2019.01.065

N. Almutlaq, M.S. Zoromba, J. Mol. Struct. (2020). https://doi.org/10.1016/j.molstruc.2020.129712

M.S. Zoromba, M.H. Abdel-aziz, M. Bassyouni, A. Attar, A.F. Al-hossainy, J. Mol. Struct. 1225, 129131 (2020). https://doi.org/10.1016/j.molstruc.2020.129131

A.F. Al-Hossainy, M.S. Zoromba, Appl. Phys. A 127, 278 (2021). https://doi.org/10.1007/s00339-021-04434-8

A. Bourezgui, I.H. El Azab, F. Alresheedi, S.A. Mahmoud, J. Mater. Sci. Mater. Electron. 32, 5489 (2021). https://doi.org/10.1007/s10854-021-05271-4

M.S. Zoromba, A.F. Al-hossainy, M. Rzaigui, A. Abdelkader, F. Alresheedi, I.H. El Azab, F.M. Eissa, Opt. Mater. (Amst). 112, 110758 (2021). https://doi.org/10.1016/j.optmat.2020.110758

M.S. Zoromba, A.A. Alshehri, A.F. Al-Hossainy, M.H. Abdel-Aziz, Opt. Mater (Amst). (2020). https://doi.org/10.1016/j.optmat.2020.110621

N. Baghdadi, M.S. Zoromba, M. Bassyouni, Polymers 13, 278 (2021). https://doi.org/10.3390/polym13020278

A.F. Al-Hossainy, A. Ibrahim, Opt. Mater. (Amst). 46, 131 (2015). https://doi.org/10.1016/j.optmat.2015.04.011

A.F. Al-Hossainy, A. Ibrahim, Mater. Sci. Semicond. Process. 38, 13 (2015). https://doi.org/10.1016/j.mssp.2015.03.031

A.A.I. Abd-Elmageed, S.M. Ibrahim, A. Bourezgui, A.F. Al-Hossainy, New J. Chem. 44, 8621 (2020). https://doi.org/10.1039/D0NJ01719A

A.F. Al-Hossainy, M.S. Zoromba, O.A. El-Gammal, F.I. El-Dossoki, Struct. Chem. 30, 1365 (2019). https://doi.org/10.1007/s11224-019-1289-3

A.M. Badr, A.A. El-Amin, A.F. Al-Hossainy, J. Phys. Chem. C 112, 14188 (2008). https://doi.org/10.1021/jp801199a

S. Said, A.A. Abdelrahman, J Sol-Gel Sci Technol. 95, 308 (2020). https://doi.org/10.1007/s10971-020-05332-w

P. Sivasakthi, H. Amir, S. Sornambikai, N. Ponpandian, C. Viswanathan, Sens. Actuator A Phys. 315, 112368 (2020). https://doi.org/10.1016/j.sna.2020.112368

H. Amir, N. Ponpandian, C. Viswanathan, Mater. Lett. 300, 130175 (2021). https://doi.org/10.1016/j.matlet.2021.130175

B. Barrocas, S. Serio, A. Rovisco, Y. Nunes, A. de Sa, M.S. da Silva, M.M. Jorge, Electrochim. Acta. 137, 99 (2014). https://doi.org/10.1016/j.electacta.2014.05.123

D.K. Maurya, A. Sardarinejad, K. Alameh, Coatings 4, 756 (2014). https://doi.org/10.3390/coatings4040756

D. Murugesan, S. Prakash, N. Ponpandian, P. Manisankar, C. Viswanathan, Colloids Surf. A Physicochem. Eng. Asp. 569, 137 (2019). https://doi.org/10.1016/j.colsurfa.2019.02.062

V. Lobo, A. Patil, A. Phatak, N. Chandra, Pharmacogn. Rev. 4, 118 (2010). https://doi.org/10.4103/0973-7847.70902

H. Kikuzaki, M. Hisamoto, K. Hirose, K. Akiyama, H. Taniguchi, J. Agric. Food Chem. 50, 2161 (2002). https://doi.org/10.1021/jf011348w

O. Shiyi, K.C. Kwok, J Sci. Food Agric. 84, 1261 (2004). https://doi.org/10.1002/jsfa.1873

S. Das, A.B.H. Wong, Sci. Rep. 10, 12288 (2020). https://doi.org/10.1038/s41598-020-68732-6

P. Hassanzadeh, E. Arbabi, F. Atyabi, R. Dinarvand, Life Sci. 193, 64 (2018). https://doi.org/10.1016/j.lfs.2017.11.046

I. Navas, R. Vinodkumar, V.P.M. Pillai, Appl. Phys. A Mater. Sci. Process. 103, 373 (2011). https://doi.org/10.1007/s00339-011-6345-9

R. Naouel, H. Dhaouadi, F. Touati, N. Gharbi, Nano-Micro Lett. 1, 242 (2020). https://doi.org/10.1007/BF03353679

D. Remiens, L. Yang, F. Ponchel, J.F. Legier, D. Chateigner, G. Wang, X. Dong, J. Appl. Phys. 109, 114106 (2011). https://doi.org/10.1063/1.3592282

U. Pal, D. Samanta, S. Ghorai, B.K. Samantaray, A.K. Chaudhuri, J. Phys. D. Appl. Phys. 25, 1488 (1992). https://doi.org/10.1088/0022-3727/25/10/014

J. Sakaliuniene, J. Cyviene, B. Abakeviciene, J. Dudonis, Acta Phys. Pol. A. 120, 63 (2011). https://doi.org/10.12693/APhysPolA.120.63

T.A. Kareem, A.A. Kaliani, Plasma Sci. Technol. 15, 382 (2013). https://doi.org/10.1088/1009-0630/15/4/13

K. Inzani, T. Grande, T.V. Bruer, S.M. Selbach, J. Phys. Chem. C. 120, 8959 (2016). https://doi.org/10.1021/acs.jpcc.6b00585

I.K. Piltaver, I.J. Badovinac, I.P.R. Saric, M. Petravic, Appl. Surf. Sci. 425, 416 (2017). https://doi.org/10.1016/j.apsusc.2017.07.029

T. Xia, Q. Li, X. Liu, J. Meng, X. Cao, J. Phys. Chem. B. 110, 2006 (2006). https://doi.org/10.1021/jp055945n

L. Seguin, M. Figlarz, R. Cavagnat, J.C. Lassegues, Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 51, 1323 (1995). https://doi.org/10.1016/0584-8539(94)00247-9

M.F. Hassan, Z.P. Guo, Z. Chen, H.K. Liu, J. Power Sources. 195, 2372 (2010). https://doi.org/10.1016/j.jpowsour.2009.10.065

Y.C. Lin, W. Zhang, J.K. Huang, K.K. Liu, Y.H. Lee, C.T. Liang, C.W. Chu, L.J. Li, Nanoscale 4, 6637 (2012). https://doi.org/10.1039/C2NR31833D

S.S. Shar, E. Cevik, A. Bozkurt, C. Yaman, Z. Almutari, T.S. Kayed, Electrochim. Acta. 354, 136770 (2020). https://doi.org/10.1016/j.electacta.2020.136770

A.G.M. Ferrari, C.W. Foster, P.J. Kelly, D.A.C. Brownson, C.E. Banks, Biosensors 8, 1 (2018). https://doi.org/10.3390/bios8020053

H. Beitollahi, S.Z. Mohammadi, M. Safaei, S. Tajik, Anal. Methods. 12, 1547 (2020). https://doi.org/10.1039/C9AY02598G

H. Shi, G. Wen, Y. Nie, G. Zhang, H. Duan, Nanoscale 12, 5261 (2020). https://doi.org/10.1039/C9NR09785F

Acknowledgements

The Authors sincerely acknowledges to DST-SERB-CRG Grant No: CRG/2019/004547, The Rashtriya Uchchatar Shiksha Abhiyan (RUSA 2.0) Bharathiar Cancer and Theragnostic Research Centre (BCTRC), The Tamil Nadu State Council for Higher Education (TANSCHE) Grand No: RGP/2019-20/BU/HECP-0024 for financial assistance. Further, the authors sincerely admit they’re thanks to UGC-SAP, DST-PURSE and DST-FIST.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Murugesan, D., Amir, H., Ponpandian, N. et al. Development of RF magnetron-sputtered molybdenum oxide-modified carbon cloth thin film as a ferulic acid sensor. Appl. Phys. A 127, 805 (2021). https://doi.org/10.1007/s00339-021-04859-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-021-04859-1