Abstract

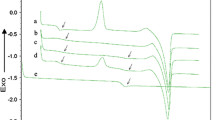

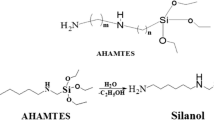

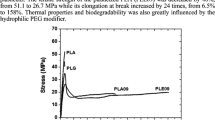

Poly(lactic acid) (PLA) was modified using a simple reactive blending method, where a low molecular weight poly(ethylene glycol) acrylate (PEGA) was blended with PLA in the presence of a radical initiator. To examine the initiation effect on the modification of PLA, various amounts of radical initiator (between 0 and 1.5 %) were added to the PLA/PEG acrylate mixture. The modified PLAs (PLMs) were characterized by gel permeation chromatography, Fourier transform infrared spectroscopy, wide-angle X-ray diffraction, and solvent extraction. The properties of the PLMs were investigated using tensile testing, differential scanning calorimetry, thermogravimetric analysis, scanning electron microscopy, and hydrolytic degradable analysis. The PEGA significantly influenced the molecular structure and properties of the modified PLA. The glass transition temperature of the PLMs was decreased by approximately 15 °C (for PLM15) from 59.3 °C of PLA, whereas their toughness increased considerably compared to PLA. In addition, PEG acrylate facilitates hydrolytic degradation, even after radical polymerization by reactive blending.

Similar content being viewed by others

References

Garlotta D (2001) A literature review of poly(lactic acid). J Polym Environ 9:63–84

Bordes P, Pollet E, Avérous L (2009) Nano-biocomposites: biodegradable polyester/nanoclay systems. Prog Polym Sci 34:125–155

Lim L-T, Auras R, Rubino M (2008) Processing technologies for poly(lactic acid). Prog Polym Sci 33:820–852

Jamshidi K, Hyon S-H, Ikada Y (1988) Thermal characterization of polylactides. Polymer 29:2229–2234

Mehta R, Kumar V, Bhunia H, Upadhyay SN (2005) Synthesis of poly(lactic acid): a review. J Macromol Sci Part C 45:325–349

Drumright RE, Gruber PR, Henton DE (2000) Polylactic acid technology. Adv Mater 12:1841–1846

Lunt J (1998) Large-scale production, properties and commercial applications of polylactic acid polymers. Polym Degrad Stab 59:145–152

Gorrasi G, Anastasio R, Bassi L, Pantani R (2013) Barrier properties of PLA to water vapour: effect of temperature and morphology. Macromol Res 21:1110–1117

Auras R, Harte B, Selke S, Hernandez R (2003) Mechanical, physical, and barrier properties of poly(lactide) films. J Plastic Film Sheeting 19:123–135

Lehermeier HJ, Dorgan JR, Way JD (2001) Gas permeation properties of poly(lactic acid). J Membr Sci 190:243–251

Conn RE, Kolstad JJ, Borzelleca JF, Dixler DS, Filer LJ Jr, LaDu BN (1995) Safety assessment of polylactide (PLA) for use as a food-contact polymer. Food Chem Toxicol 33:273–283

Auras R, Harte B, Selke S (2004) An overview of polylactides as packaging materials. Macromol Biosci 4:835–864

Hassouna F, Raquez J-M, Addiego F, Dubois P, Toniazzo V, Ruch D (2011) New approach on the development of plasticized polylactide (PLA): grafting of poly(ethylene glycol) (PEG) via reactive extrusion. Eur Polym J 47:2134–2144

Hassouna F, Raquez J-M, Addiego F, Dubois P, Toniazzo V, Ruch D (2012) New development on plasticized poly(lactide):chemical grafting of citrate on PLA by reactive extrusion. Eur Polym J 48:404–415

Martin O, Averous L (2001) Poly(lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer 42:6209–6219

Lui H, Zhang J (2011) Research progress in toughening modification of poly(lactic acid). J Polym Sci Polym Phys 49:1051–1083

Ljungberg N, Wesslén B (2005) Preparation and properties of plasticized poly(lactic acid) films. Biomacromolecules 6:1789–1796

Labrecque LV, Kumar RA, Davé V, Gross RA, Mccarthy SP (1997) Citrate esters as plasticizers for poly(lactic acid). J Appl Polym Sci 66:1507–1513

Jacobsen S, Fritz HG (1999) Plasticizing polylactide—the effect of different plasticizers on the mechanical properties. Polym Eng Sci 39:1303–1310

Ljungberg N, Andersson T, Wesslén B (2003) Film extrusion and filmweldability of poly(lactic acid) plasticized with triacetine and tributyl citrate. J Appl Polym Sci 88:3239–3247

Ljungberg N, Wesslén B (2002) The effects of plasticizers on the dynamic mechanical and thermal properties of poly(lactic acid). J Polym Sci Polym Phys 86:1227–1234

Hu Y, Hu YS, Topolkaraev V, Hiltner A, Baer E (2003) Crystallization and phase separation in blends of high stereoregular poly(lactide) with poly(ethylene glycol). Polymer 44:5681–5689

Hu Y, Topolkaraev V, Hiltner A, Baer E (2003) Aging of poly(lactide)/poly(ethylene glycol) blends. Part 1. Poly(lactide) with low stereoregularity. Polymer 44:5701–5710

Kulinski Z, Piorkowska E, Gadzinowska K, Stasiak M (2006) Plasticization of poly(l-lactide) with poly(propylene glycol). Biomacromolecules 7:2128–2135

Okamoto K, Ichikawa T, Yokohara T, Yamaguchi M (2009) Miscibility, mechanical and thermal properties of poly(lactic acid)/polyester-diol blends. Eur Polym J 45:2304–2312

Ljungberg N, Wesslén B (2003) Tributyl citrate oligomers as plasticizers for poly (lactic acid): thermo-mechanical film properties and aging. Polymer 44:7679–7688

Park JY, Hwang SY, Yoon WJ, Yoo ES, Im SS (2012) Compatibility and physical properties of poly(lactic acid)/poly(ethylene terephthalate glycol) blends. Macromol Res 20:1300–1306

Cho SY, Park HH, Yun YS, Jin H-J (2013) Influence of cellulose nanofibers on the morphology and physical properties of poly(lactic acid) foaming by supercritical carbon dioxide. Macromol Res 21:529–533

Yua L, Deana K, Li L (2006) Polymer blends and composites from renewable resources. Prog Polym Sci 31:576–602

Jun CL (2000) Reactive blending of biodegradable polymers: PLA and starch. J Polym Environ 8:33–37

Liu H, Song W, Chen F, Guo L, Zhang J (2011) Interaction of microstructure and interfacial adhesion on impact performance of polylactide (PLA) ternary blends. Macromolecules 44:1513–1522

Chen Y, Yuan D, Xu C (2014) Dynamically vulcanized biobased polylactide/natural rubber blend material with continuous cross-linked rubber phase. ACS Appl Mater Interfaces 6:3811–3816

Coltelli M-B, Bronco S, Chinea C (2010) The effect of free radical reactions on structure and properties of poly(lactic acid) (PLA) based blends. Polym Degrad Stab 95:332–341

Choi K, Choi M-C, Han D-H, Park T-S, Ha C-S (2013) Plasticization of poly(lactic acid) (PLA) through chemical grafting of poly(ethylene glycol) (PEG) via in situ reactive blending. Eur Polym J 49:2356–2364

Migliaresi C, Cohn D, De Lollis A, Fambri L (1991) Dynamic mechanical and calorimetric analysis of compression-molded PLLA of different molecular weights: effect of thermal treatments. J Appl Polym Sci 43:83–95

Carson D, Nie L, Narayan R, Dubois P (1999) Maleation of polylactide (PLA) by reactive extrusion. J Appl Polym Sci 72:477–485

Carlson D, Dubois P, Nie L, Narayan R (1998) Free radical branching of polylactide by reactive extrusion. Polym Eng Sci 38:311–321

Gao J, Duan L, Yang G, Zhang Q, Yang M, Fu Q (2012) Manipulating poly(lactic acid) surface morphology by solvent-induced crystallization. Appl Surf Sci 261:528–535

Chena B-K, Shiha C-C, Chenb AF (2012) Ductile PLA nanocomposites with improved thermal stability. Compos Part A Appl Sci Manuf 43:2289–2295

Ozkoc G, Kemaloglu S (2009) Morphology, biodegradability, mechanical, and thermal properties of nanocomposite films based on PLA and plasticized PLA. J Appl Polym Sci 114:2481–2487

Oyama HT (2009) Super-tough poly(lactic acid) materials: reactive blending with ethylene copolymer. Polymer 46:747–751

Sgnori F, Coltelli M-B, Simona Bronco S (2009) Thermal degradation of poly(lactic acid) (PLA) and poly(butylene adipate-co-terephthalate) (PBAT) and their blends upon melt processing. Polym Degrad Stab 94:74–82

Li SM, Rashkov I, Espartero L, Manolova N, Vert M (1996) Synthesis, characterization, and hydrolytic degradation of PLA/PEO/PLA triblock copolymers with long poly(l-lactic acid) blocks. Macromolecules 29:57–62

Acknowledgments

This study was supported by the National Research Foundation of Korea (NRF) Grant funded by The Ministry of Science, ICT & Future Planning, Korea (Acceleration Research Program (2009-0078791)); Pioneer Research Center Program (2010-0019308/2010-0019482) and BK 21 Plus Program (21A2013800002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Choi, KM., Lim, SW., Choi, MC. et al. Thermal and mechanical properties of poly(lactic acid) modified by poly(ethylene glycol) acrylate through reactive blending. Polym. Bull. 71, 3305–3321 (2014). https://doi.org/10.1007/s00289-014-1251-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-014-1251-x