Abstract

Increased assembly complexity is one of the main challenges in manufacturing as it can induce an increase in time, cost, and defects. Several approaches have been proposed in the literature to predict product defects using assembly complexity as a predictor. However, most of these are not directly applicable because they rely on experts’ prior subjective knowledge and are designed for specific industrial applications. To overcome this issue, the present research proposes a novel approach to predict product defects from a purely objective assessment of product complexity, without the need for expert evaluations and assembly experience. A recent conceptual paradigm of complexity that considers only structural properties of assembly parts and their architectural structure is adopted in the proposed approach. The novel model is applied to a real assembly process in the electromechanical field and is compared with one of the most accredited in the literature, i.e., the Shibata–Su model. Empirical results show that, despite the super-linear relationship between defect rates and complexity in both models, the objective approach used in the novel model leads to more accurate and precise predictions of defectiveness rates, as it does not include the variability introduced by expert subjective assessments. Adopting this novel model can effectively improve the estimate of product defects and support designers’ decisions for assembly quality-oriented design and optimization, especially in early design phases.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Global competition in manufacturing has forced many companies to improve and diversify their product range, increasing the number of product variants and their fabrication options. This has inevitably led to increased product and manufacturing complexity [1, 2]. In manual assembly, the complexity of the assembly process is a fundamental driver affecting the usability of the equipment, the acquisition of dynamic skills, operation safety and human performance [3]. As a result, if assembly complexity is not managed adequately at early stages of process planning, it can lead to increased assembly time and errors and reduced assembly quality [4,5,6,7].

In the literature, assembly complexity is often linked to the physical attributes of the products to be assembled, e.g., in Design for Assembly (DFA) or Hitachi Assembly Evaluation Method (AEM) [8, 9]. It is also associated with both product variety and assembly process information. In this case, the complexity is defined as “operator choice complexity” [10]. A second set of approaches evaluates the complexity of assembly and analyzes the cause–effect relationship between task parameters and assembly errors through statistical methods [11, 12]. Furthermore, a third set of methods uses information about system components (e.g., the number of flow paths and travel distance) and system elements (e.g., the number of components, setup time, cycle time and reliability) to measure sources of task or system complexity [13,14,15]. Apart from the objective characteristics, complexity is also affected by the context and the observer [16]. This subjective nature has prompted some authors to evaluate it based on interviews and questionnaires [17,18,19,20,21].

A growing number of studies linked product complexity with defects occurring in the manual assembly [6, 11, 20, 22,23,24,25,26,27]. Although these predictions models play a crucial role in improving the quality of product and production process of companies in various industrial contexts, most of them present some criticalities. First of all, in some cases, the methodologies used to evaluate assembly complexity are designed for specific industrial applications and, as a result, a lack of a general applicability across different production contexts. For instance, in the studies of Hinckley [11] and Shibata [22], context-dependent factors such as the ease-of-assembly factor defined by Westinghouse and Sony’s Design for Assembly (DFA) methods were used for semiconductors and audio equipment, respectively. For more details on these models, see Sect. 2.1. A second limit of published research can be found in the subjectivity of some approaches used to evaluate assembly complexity. As shown in the study of Alkan [4], perceived complexity does not correspond precisely to product complexity. Operators start to perceive the assembly operations as complex when the product complexity reaches a stagnation point.

Therefore, the two above limitations of the approaches typically used for defect prediction make their applicability in the early stages of product design not so straightforward. To overcome these issues, the present paper aims to develop a novel approach to predict assembly defects in manufacturing by adopting a different paradigm of complexity that uses only an objective perspective and does not depend on the application field. In detail, the structural complexity paradigm proposed by Alkan [4] and Sinha [28] is adopted as the predictor of the model. Such complexity is evaluated considering structural properties associated with handling and insertion of assembly parts and their architectural structure [4]. The structural complexity paradigm was adopted in previous studies for a dual purpose: (i) to quantify product complexity in an objective manner, hence avoiding subjective expert evaluations [29, 30], and (ii) to predict assembly times [4]. Unlike previous investigations, this study introduces for the first time the concept of structural complexity to predict the defect rate generated during assembly. Depending solely on physical design information, this approach can be considered more practical from the design point of view, especially in the early design stages, when real production data or the physical mockup are not available. The following two are the research questions (RQ) addressed in this paper:

RQ1: Is there a relationship between product defects and its structural complexity?

RQ2: How much does the use of different methods to assess product complexity affect the prediction of defects?

In order to answer these questions, a novel defect prediction model based on the structural complexity paradigm is developed, using a low-volume production of wrapping machines as a case study. The novel model is then compared with one of the most accredited in the literature, i.e., the Shibata–Su model, that was successfully implemented in previous studies [20, 22, 25, 27, 31]. In this approach, complexity is divided into a process-based and a design-based complexity, according to the studies of Shibata [22] and Su [20]. Empirical results showed that the novel defect prediction model allows for more accurate and precise estimates of defectiveness rates with respect to the Shibata–Su model.

The authors believe that the novel approach based on the structural complexity paradigm can better support designers in the assembly quality-oriented design and optimization process. Furthermore, the novel prediction model can effectively help designers to get reliable defect estimates at early design stages and support decisions in the planning of quality inspections [31,32,33]. Besides, by providing new insights into defects prediction, the present research should make a useful contribution to the field of low-volume production, where the inadequacy of traditional statistical approaches makes quality control and inspection planning challenging [27, 31, 33,34,35,36].

The rest of the paper is arranged as follows. In Sect. 2, the conceptual background is presented, including a brief review of assembly complexity criteria and defect prediction models in the literature. Section 3 describes the novel defect prediction model that uses as predictor the structural complexity paradigm. A pedagogical example illustrating the comparison of the models by means of two sample products is presented in Sect. 4. In Sect. 5, the novel model is applied to the assembly process of wrapping machines and compared with the Shibata–Su model. Finally, Sect. 6 concludes the paper.

2 Conceptual background

2.1 Assembly complexity paradigms

The scientific literature proposes different approaches to assess assembly complexity, based on the product to be assembled or the process sequence for the assembly [29]. Several methods are built upon the concept of easy of assembly, e.g., Design for Assembly and Manufacture (DFMA) [8, 9]. Such approaches aim at enhancing the product design by reducing part numbers, optimizing part handling and insertion attributes, and penalizing inefficient design [29].

Moreover, a growing body of literature provides an assessment of assembly complexity by using different design complexity criteria and time estimation methodologies [11, 20, 22, 29]. Hinckley [11] defined an assembly complexity factor based on the Westinghouse DFA worksheet suggesting a theoretical time required to assemble a product. Shibata [22] proposed to evaluate process complexity based on the method of Sony Standard Time (SST) and design complexity through the Design for Assembly/Disassembly Cost-effectiveness (DAC) method. Although these approaches provide a robust assessment of assembly complexity, the methodologies used are designed for specific assembly products. For instance, Hinckley (1994) based his study on the Westinghouse Database, specifically designed for semiconductor products. Moreover, the DAC method used by Shibata as a measure of design assemblability is a Sony’s methodology specific for audio equipment. Therefore, in order to extend the methodologies proposed by these authors to other contexts, it is necessary to adapt them to the specific case study, either by slightly modifying them or by identifying more suitable approaches.

Further approaches consider physical and cognitive elements to calculate the relative effort of each manufacturing task to define an “operational complexity index” [13]. Such an index is designed as a function of the quantity and diversity of both product and process elements and the relative complexity coefficient. In a later study, Samy and ElMaraghy [15] extended the approach mentioned above by adding DFA criteria to evaluate the assembly complexity of individual product parts. Besides, Richardson et al. [37] proposed a practical model to predict the difficulty of assembly of an object based on its physical attributes. However, this approach is dependent on the specific application it is developed for and, therefore, requires further efforts to produce a more general model.

Extensive research has shown that complexity may have a subjective nature and depends on the specific context and operator who perceives it [38]. Accordingly, survey-based methods are often adopted to assess the perceived level of complexity arising from human–system interactions and manufacturing systems [17, 19, 24].

Recent studies tried to overcome the above restrictions (specific industrial domain and applications, subjective elements, etc.) proposing a method based on structural complexity that allows supporting early design phases of assembly products [4, 28, 29, 39].

2.2 Defect prediction models

A growing number of studies adopted the assembly complexity to predict the occurrence of defects in the final product [6, 11, 20, 22,23,24,25,26,27].

In the electromechanical assembly, Shibata [22] proposed a power law defect rate prediction model based on two factors, i.e., process- and design-based complexity factors. Su et al. [20] developed a new defect model to match the characteristics of copier assembly. Besides, Antani [23] successfully tested that manufacturing complexity can be used to predict product quality reliably. By focusing on mixed-model automotive assembly, manufacturing complexity was estimated incorporating variables driven by design, process and human factors [23]. In later studies, Krugh et al. [6, 40] adapted the approach proposed by Antani to be implemented with automotive electromechanical connections in a large complex system. Falck et al. [24] designed a tool to predict and control operator-induced quality errors by developing a method for predictive assessment of the complexity of manual assembly.

As mentioned, the application fields of these models are multiple, ranging from the electromechanical to the automotive sector. The identification of suitable defect prediction models for such industrial domains and applications is a crucial factor for practical assistance in the design, improvement and optimization of assembly quality [20]. Furthermore, the adoption of reliable estimates of defect rate can successfully help inspection designers in the inspection process planning, also in the early design phase [32, 34, 41].

2.3 Process- and design-based complexity model (Shibata–Su model)

This section reviews one of the most accredited prediction models developed in the literature, i.e., the Shibata–Su model. Such a model combines the approaches developed by Shibata [22] and Su et al. [20] and has also been successfully implemented in recent studies by the authors [25, 27, 31, 42].

According to Shibata [22], a series of process steps, or workstations, defined through sheets of operation standards compose the product assembly process. Furthermore, a certain number of job elements, i.e., elementary operations, are performed in each workstation [22, 43]. The job elements are the minimum components of a specific task and should have easily identifiable starting and stopping points and be repeatable regularly throughout the workday. To predict the process complexity, Shibata defined a process-based complexity factor for each workstation, as follows:

where

-

the index i refers to the generic ith workstation (i = 1,…,m);

-

Na,i is the number of job elements in the workstation i;

-

SSTij is the Sony Standard Time spent on the job element j in the workstation i;

-

TATi is the total assembly time related to the workstation i;

-

t0 is the threshold assembly time, i.e., the time required to perform the most straightforward assembly operation, below which neither assembly operations nor assembly defects exist [22].

It is worth noting that the assembly times SSTij are evaluated according to the Sony Standard Time (SST), a commonly used time estimation tool for electronic products. Thus, these are the standard times in which the operators should complete each job element and not the actual assembly times.

Since CfP,i is a time-related measure, Shibata [22] claimed that it may not capture all the sources of defects. For this reason, he introduced a second predictor, a design-based assembly complexity factor [22]. Such a design factor was defined as the ratio between a calibration coefficient and the ease of assembly (EOA) coefficient of each workstation, estimated through the assembly/disassembly cost-effectiveness (DAC) method developed in Sony Corporation [44].

In a subsequent study, Su et al. [20] remarked that the DAC method, which was developed specifically for Sony electronic products, may not be directly suitable for other types of products, such as electromechanical products. Therefore, he proposed a different method to evaluate the design complexity to cope with this issue [20]. The methodology developed by Su et al. [20] relies on the approach developed by Ben-Arieh to assess the degree of difficulty of assembly operations [45]. In accordance with Ben-Arieh (1994), assembly operations can be associated with parameters related to the geometry of the parts (geometry-based parameters) and the type of contact between the components (non-geometry-based parameters); see Table 1.

A number l of parameters should be selected as criteria to evaluate the design-based complexity, according to the characteristics of the products to be assembled. Next, for deriving an integrated index, the weights wq of the l parameters are assigned using the analytic hierarchy process (AHP) approach [45,46,47], as follows:

where

-

\({w}_{q}\) is the weight of parameter q;

-

\({a}_{qr}\) is the relative importance of parameter q over parameter r (r = 1, …, l);

-

l is the number of parameters.

Then, an evaluation of the degree of difficulty of each parameter in each workstation is obtained by a number e of experts. More specifically, the degree of difficulty Dkqi is the evaluation of the parameter q in the workstation i estimated by the expert k. The values Dkqi are scores between 0 and 10. Depending on the weight wq of the l parameters (Eq. (2)) and the degrees of difficulty Dkqi, the design-based complexity factors can be defined as [20]:

The relationship between defects per unit (DPU) and the two complexity factors, i.e., CfP and CfD, was proved to follow a power law behavior (see Eq. (4)) by previous research in the electromechanical field [22, 27, 31]:

where a, b and c are nonlinear regression coefficients.

3 A novel defect prediction model based on structural complexity

The novel defect prediction model developed in this study is similar from an architectural point of view to the Shibata–Su model described in Sect. 2.3, but totally differs in the evaluation of product complexity. In the novel model, complexity is evaluated from an objective perspective using the structural complexity paradigm proposed in the studies of Sinha et al. [39] and Alkan [4], i.e., the Sinha–de Weck–Alkan model.

In this model, the Huckel’s molecular orbital theory [48] is applied to the engineering domain to analyze the complexity of cyber-physical systems. According to Sinha et al. [39], any engineering system can be represented by several components that are connected in different ways. Each component can be thought of as an atom and the interfaces between them as inter-atomic interactions, i.e., chemical bonds [29]. Through this analogy, product complexity can be associated with the system’s inherent structure and, therefore, with individual system entities and the effects of the system connectivity pattern [30]. This approach was successfully validated using pressure recording devices [29] and printing systems [28] as case studies. Accordingly, in the present paper, the authors decided to apply the approach in the electromechanical manufacturing field, slightly amended it to reflect the division of the process into workstations.

Assembly complexity Ci related to each ith workstation can be defined as [4, 28]:

In Eq. (5), \({C}_{1,i}\) represents the sum of complexities of individual product parts in each ith workstation and is calculated as follows:

where, for each ith workstation (i = 1, …, m), \({N}_{i}\) is the total number of product parts and \({\gamma }_{pi}\) is the handling complexity of part p. Each complexity \({\gamma }_{pi}\) may be intended as the ergonomic difficulty to interact with the part and can be measured according to the structural characteristics that cause difficulties during its handling [4]. As suggested by Alkan [4], handling complexity \({\gamma }_{pi}\) can be estimated as a function of the standard handling time of the part p that involves the localization of the relevant box, moving arm to pick position, picking the relevant part, and returning arm to work position.

\({C}_{2,i}\) is the complexity of liaisons related to the ith workstation and is the sum of the complexities of pairwise connections that exist in the product structure assembled in the workstation, as follows:

where, for each ith workstation (i = 1,…,m), \({\varphi }_{pri}\) is the complexity in achieving a liaison between parts p and r and can be expressed by the relationships between the linked components and the nature of the connection, and \({A}_{pri}\) defines the binary adjacency matrix representing the connectivity structure of the system, as indicated in Eq. (8):

The interface complexity \({\varphi }_{pri}\) may be estimated based on the standard completion time of the liaison between parts p and r in isolated conditions. In addition to the handling the connections, the completion time includes locating the connection areas, orienting and positioning the parts and the connector, placing the connectors and joining the parts, adjusting the connections, and a final check [4].

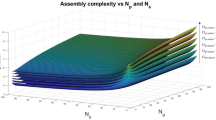

Finally, \({C}_{3,i}\) is the topological complexity of the ith workstation and represents the complexity related to the architectural pattern of the assembled product. According to Sinha [28], it can be obtained from the matrix energy (also called graph energy) EAi of the adjacency matrix related to the ith workstation [49], as shown in Eq. (9). EAi is designated by the sum of singular values \({\delta }_{pi}\) of the adjacency matrix of the product assembled in the ith workstation

where \({N}_{i}\) is the total number of singular values of the product connectivity matrix related to ith workstation (i.e., the number of parts—or nodes—in the ith workstation). It is recalled that, given an adjacency matrix A, which is symmetric of size Ni with the diagonal elements being all zeros, the singular values correspond to the absolute eigenvalues of the adjacency matrix [28, 50].

As observed by Sinha [28], matrix energy regime for graphs with a given number of nodes can be divided into (i) hyperenergetic and (ii) hypoenergetic. An intermediate or transition regime between these two also exists [50]. The hyperenergetic regime is defined by graph energy greater than or equal to that of a fully connected graph, and the hypoenergetic regime is defined as shown in Eq. (10):

Hence, in terms of topological complexity metric, the regimes are defined as

Note that for hyperenergetic regimes, \({C}_{3,i}\) can be approximated to 2 when \({N}_{i}\) is sufficiently large [50]. Translating the graph structures to system architectural pattern, typical topological complexity metric \({C}_{3,i}\) values can be associated with those forms, again when \({N}_{i}\) is sufficiently large: (i) \({C}_{3,i}<1\) for a centralized architecture, (ii) \({1\le C}_{3,i}<2\) for a hierarchical/layered architecture, and (iii) \({C}_{3,i}\ge 2\) for a distributed architecture [28]. Accordingly, \({C}_{3,i}\) increases as the system topology shifts from centralized architectures to more distributed architectures, as shown in Fig. 1 [4, 39].

Spectrum of architectural patterns based on topological complexity metric with their respective reference values (adapted from [28])

Therefore, \({C}_{3,i}\) represents the intricateness of structural dependency among assembly and requires knowledge of the complete architecture of the system and, in this sense, contrary to the previous terms \({C}_{1,i}\) and \({C}_{2,i}\), denotes a global effect whose influence could be perceived during the system integration phase (Sinha, 2014). Therefore, the term \({C}_{2,i}\cdot {C}_{3,i}\) in Eq. (5) can be referred to as a general indicator of the system integration effort that allows distinguishing product architectures with similar parts and connections complexities.

In the proposed model, the structural complexity defined in Eq. (5) is used as predictor for the DPU occurring in each ith workstation (\(DP{U}_{i}\)). To construct the prediction model, a preliminary set of historical data is necessary. To this aim, an adequate quantity of production units in each workstation should be examined (indicatively, at least fifteen to twenty units for each workstation). This amount of data is reasonably acceptable for the statistical data analysis [51]. Clearly, increasing the number of units collected will increase the accuracy of the statistical analysis, but it will also increase the associated costs.

As described in Sect. 5, the relationship between the structural complexity Ci, defined in Eq. (5), and \(DP{U}_{i}\) was studied by using empirical data belonging to a low-volume production of wrapping machines. The model that best interpolates experimental data is the following:

where d and e are nonlinear regression coefficients.

These results are in line with the preliminary findings obtained by Alkan [4] and Sinha [28], where the complexity was found to be in a super-linear relationship with real assembly time, evaluated also considering possible errors and reworks.

The structure of the proposed defect prediction model reflects that of Shibata–Su model (see Eq. 4). Both models use complexity factors as predictors. The Shibata–Su model highlights two complexity contributions: (i) the process-based complexity by the CfP,i factor and (ii) the design-based complexity by the CfD,i factor. On the other side, the structural complexity factor, Ci (see Eq. 5), incorporates in a single element both the complexity of the process and the design. However, there is a deep conceptual difference between the two approaches. In the Shibata–Su model, while CfP,i is estimated by objective process data (i.e., standard times), CfD,i is obtained from a subjective inspector evaluation. In the proposed model, instead, Ci is based only on an objective estimation of the structural product characteristics. The first method uses a mix of objective and subjective information; the second one uses only objective information to describe product complexity. Therefore, despite the similarity of the predictors, the two models are profoundly different from an operational point of view.

Moreover, it should be noted that decoupling the complexity into two distinct factors can be considered as an artificial operation. In practical applications, there is no clear distinction between the complexity due to the process and the complexity due to the design, as these are often related. To make this concept clearer, just think of the times for handling components or connecting parts. These are not only process-related but are also closely associated with the design characteristics of the parts to be assembled and the nature of their connections. Therefore, since process and design coexist together, the novel model seems to be more suitable to evaluate the complexity of a product as a whole. The structural complexity factor Ci considers the complexity of individual components, connections and product topology, without directly making a distinction between process and design.

As a result, the proposed approach, depending solely on physical design information, can be considered more useful than the Shibata–Su model, especially in the early design stages when real production data or the physical mockup is not available.

As mentioned above, in the following section, the proposed model is applied to a case study of wrapping machines assembly and compared with the Shibata–Su model described in Sect. 2.3.

4 A pedagogical example

In order to exemplify the methodologies illustrated in Sects. 2.3 and 3, a simple pedagogical example is proposed in which two different sample products are assembled, each one in a single workstation.

The first product is composed of four parts, as represented in Fig. 2. For simplicity, suppose that the four parts, as well as the connections between the parts, are identical. The standard handling time of each pth part is \({\gamma }_{p}\) = 5 s (with p = 1, …, 4), while the standard completion time of the connection between parts p and r is \({\varphi }_{pr}\) = 30 s (with p = 1, …, 3 and r = p + 1, …, 4). According to Eq. (6), the handling complexity is \({C}_{1}=\sum_{p=1}^{4}{\gamma }_{p}\) = 20 s = 0.33 min. The complexity of connections is, by implementing Eq. (7), \({C}_{2}=\sum_{p=1}^{3}\sum_{r=p+1}^{4}{\varphi }_{pr}\cdot {A}_{pr}\) = 90 s = 1.5 min, as three connections between the parts exist.

The graph energy of the associated adjacency matrix A, represented in Fig. 2, is computed as the sum of its singular values that are the absolute values of the eigenvalues of the matrix A. In detail, the eigenvalues of the matrix A are -1.73, 1.73 and 0 with multiplicity 2. Thus, \({E}_{A}=2\cdot 1.73=3.46\). According to Eq. (9), it is obtained that \({C}_{3}=\frac{3.46}{4}=0.87\). Since \({C}_{3}<1\), the product topology can be qualified as a centralized architecture. Finally, by applying Eq. (5), the structural complexity is \({C}={C}_{1}+{C}_{2}\cdot {C}_{3}=1.64\) min.

On the contrary, by applying the Shibata–Su model, the assembly is decomposed into elementary operations. Consider five elementary operations, i.e., (1) taking the four parts, (2) taking the three connections, (3) performing a subassembly with parts b and a, (4) connecting c with the subassembly a-b, and (5) connecting d with subassembly a-b-c. In such a case, the simplest assembly operation is taking a single part, which is performed in 5 s, and thus t0 = 5 s. By Eq. (1), the process-based complexity factor obtained is CfP = 1.41 min, as reported in Table 2. Regarding the design-based complexity factor, for the sake of simplicity, two design parameters are selected from those listed in Table 1, i.e., (A) shape and (B) force required; see Table 3. A pair of engineers compares the relative importance of each parameter in determining the difficulty in assembling a part into a product using a scale ranging from 1 (equal importance) to 9 (dominant importance). Supposing that the two engineers consider both parameters of equal importance, by Eq. (2) the weights wq are, respectively, w(A) = w(B) = 0.5. Then, the two engineers assign a degree of difficulty for each design parameter using a scale ranging from 0 (no difficulty) to 10 (maximum difficulty), as reported in Table 3. As a result, the design-based complexity factor is derived by performing a weighted sum of the mean degrees of difficulty according to Eq. (3), obtaining CfD = 5.

The second product is a simple assembly of two parts. In such a case, considering the same standard times of parts and connections of the previous product, the resulting complexity components C1, C2 and C3 are listed in Table 2. The structural complexity in such a case is \({C}={C}_{1}+{C}_{2}\cdot {C}_{3}=1.17\) min. The product is assembled in three elementary operations: (1) taking the two parts, (2) taking the connection, and (3) assembling the product. According to the Shibata–Su model, the process- and design-based factors are derived. For the latter, the same evaluations of the two engineers are used as the parts and connections of the two products can be considered comparable (see Table 3).

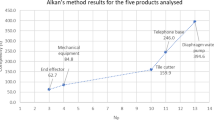

The comparison of the two prediction models is performed, as a first approximation, by using the models derived for electromechanical products, as described in Sect. 5. The 95% prediction intervals of DPU are represented in Fig. 3, obtained by using both models. The novel model results in higher accuracy than the Shibata–Su model as the prediction bands for both products are smaller. In particular, the accuracy of the prediction results to be slightly higher for product 2, which is the product characterized by less complexity.

Such a pedagogical example highlighted the ease and rapidity of implementation of the new model being based on purely objective assessment of complexity, without requiring expert evaluations. A more extensive and comprehensive discussion is presented in Sect. 5.

5 Case study

5.1 Assembly process of wrapping machines

In the proposed case study, wrapping machines, and specifically the rotating ring wrapping machines, are analyzed [52]. Such machines are electromechanical devices adopted at the end of production lines to pack palletized loads with a stretch plastic film by using a rotating ring. This study considers the rotating ring wrapping machines produced by the Italian company Tosa Group S.p.A. (see Fig. 4). The process to manufacture these wrapping machines can be classified as a low-volume production because, in a typical year, about 50 highly tailored units are assembled.

Three central units compose the rotating wrapping machines: (i) mechanical, (ii) electrical and electronic and (iii) software. A fixed and a moving part are distinguished in the mechanical unit, as shown in Fig. 4. In detail, the fixed part consists of (i) a frame, (ii) a cutting–hooking–welding unit and (iii) a pantograph presser. The frame is a load-bearing structure, dimensioned to guarantee strength and durability, composed of boxes and profiles in high-strength sheet steel. The cutting–hooking–welding unit automatically cuts the plastic film by a heated metal wire and heat-seals the last tail to the load with a specific plate. Finally, the pantograph presser stabilizes the palletized load, exerting pressure on its top during the wrapping process.

On the other hand, two devices are assembled in the moving part, namely a rotating ring and a pre-stretching device. The rotating ring is made of a calendered steel profile, which is light but very strong and suitable for high speeds. It is moved by a belt connected to an electric motor. The rotation of the ring around the palletized load is combined, during the wrapping cycle, with vertical sliding. The pre-stretching device is attached to the rotating ring and enables the machine to perform the following three functions: (i) the pulling/unwinding, (ii) the pre-stretching and positioning of the plastic film, and (iii) the wrapping of the pallet with the required number of wraps.

The wiring of the components, sensors and onboard motors and the general electric panel are included in the electrical and electronic unit. The software unit, whose programming is handled by a specialized external supplier, aims at controlling the machine and communicating with the operator.

A typical work cycle of a wrapping machine is described below. The palletized load is transported by a roller or belt conveyor system into the area bounded by the carriage. Next, the pantograph presser descends by pressing down on the top of the palletized load to ensure stability during the film wrapping phase. The carriage descends, the ring begins to rotate, and, simultaneously, the plastic film moves through the pretensioner and is distributed around the load. After a number of wrappings that depend on the palletized load, the wrapping cycle ends, the cutting–hooking–welding unit removes the tail of the plastic film, and the load is left free to be transported to the next production station. Finally, a new pallet enters the ring perimeter of the machine and the cycle repeats.

Because of the complex nature and the high number of wrapping machine components, this article focuses on only one device, i.e., the pre-stretching device. The primary reason is that although each machine differs from the others in some details, this device is common to all rotating ring wrapping machines. The proposed approach, however, can be extended and implemented to the whole wrapping machine.

As illustrated in Fig. 5, the pre-stretching device is installed on a support structure called “frame plate.” The stretch film moves through two rubber rollers, each connected by a belt transmission system to a brushless motor: The speeds of the two rollers are therefore independent of each other. When coming into contact with the surface of the two rollers, the film stretches proportionally to the difference in speed, thus significantly increasing the film’s length. The electronic system measures the speed through dedicated sensors and keeps the film tension constant during its application over the entire surface of the pallet. In addition, the pre-stretching device can be equipped with a patented mandrel that replaces the empty film reel automatically.

The breakdown of the pre-stretching device assembly process into 29 workstations is shown in Table 4. These workstations are assembly steps defined within operation standards, i.e., instruction sheets for work procedure [20, 22]. The first nine workstations are assembled on the bench, while the remaining ones are assembled on the frame plate. Table 4 also reports the experimental DPU values occurring under stable process conditions in each workstation, obtained by drawing on the company’s historical data collected over the past 5 years. Such values can thus be considered an indication of the average defect rate of the assembly process under optimal working conditions.

5.2 The novel defect prediction model: DPU vs structural complexity

The novel prediction model that uses the structural complexity paradigm as a predictor is empirically derived in this section.

Table 5 reports, for each ith workstation, the complexities \({C}_{1,i}\), \({C}_{2,i}\) and \({C}_{3,i}\), evaluated according to Eqs. (6), (7) and (9), respectively, and the final assembly complexity Ci derived by Eq. (5). Specifically, \({C}_{1,i}\) is estimated considering the standard handling time of the parts that are assembled in the corresponding workstation, and \({C}_{2,i}\) the standard completion time of the connection between the parts. Finally, \({C}_{3,i}\) is obtained from the graph energy of the adjacency matrix related to the ith workstation and the number of parts assembled Ni. For instance, in workstation no. 14, only two parts are assembled: the driven wheel and the drive belt. As shown in Table 5, the standard handling time of the two parts is 0.14 min and the time for connecting them is 0.44 min. For these two parts, the adjacency matrix is A = \(\left(\begin{array}{cc}0& 1\\ 1& 0\end{array}\right)\) and its graph energy EA is 2. (The eigenvalues of the matrix A are 1 and −1.) Thus, the resulting complexity \({C}_{3}\) is 1. Consequently, by applying Eq. (5), product complexity of this workstation is 0.58 min.

To relate DPUi versus Ci, different models were tested and compared (see Table 6). The adequacy of the models was assessed through the analysis of regression residuals and the S value as a measure of goodness of fit. A power curve fitting (model no. 3 in Table 6) was the best model to define such a relationship. Accordingly, the final model developed for wrapping machines assembly is the following:

Figure 6 plots the new defect prediction model defined in Eq. (13) and the residual plots. The normal probability plot indicates that the residuals do not show significant deviations from the normal distribution. The normality of residuals is also not rejected by performing the Anderson–Darling test at a significance level of 5% [53]. The plot of residuals versus order exhibits a horizontal band around the line of residuals (value 0), and neither systematic effects in the data due to time or collection order are shown. To evaluate the goodness of fit of a nonlinear regression model, the S value (standard error of the regression—also called standard error of the estimate) should be used instead of R2 [54, 55]. For the model provided in Eq. (13), the S value is equal to 0.018, indicating that the experimental values of DPU fall an average absolute distance of 0.018 units from the DPU values predicted by the model.

5.3 Shibata–Su model: DPU vs process- and design-based complexity

This section presents the implementation of the Shibata–Su model, described in Sect. 2.3, in order to compare the obtained predictions with those obtained by using the new model shown in Eq. (13). The development of the defect prediction model using the Shibata–Su approach was addressed in detail in a previous study by the authors [52], and a summary of the results is provided below.

Regarding the first predictor, CfP,i (see Eq. (1)), each workstation was subdivided into a number of elementary operations (i.e., job elements), Na,i, ranging from 1 to 12 (see Table 7). With regard to assembly times, rather than using Sony Standard Time—typical of Sony’s home audio products—the time of each job element was estimated by the average value of three measurements of the assembly standard time spent by the operator in the job element. The threshold assembly time t0 was set at 0.04 min, which corresponds to the time required to perform the least complex job element. The assembly time TATi is shown in Table 7, as well as the final value of the first predictor, CfP,i, calculated according to Eq. (1), separately for each ith workstation.

The methodology used to evaluate the second predictor, CfD, is the one developed by Su et al. [20] for electromechanical products as the wrapping machine is essentially an electromechanical device. In this case, regarding Eqs. (2) and (3), l = 11 design parameters were selected by adapting Ben Arieh’s approach to the case of wrapping machines; see Table 7. The relative importance of each parameter in assessing the difficulty of assembling a part into a product was obtained from interviews with a pair of engineers and four assembly operators. The scores used to assess the relative importance between each pair of parameters ranged from a minimum of 1, representing equal importance between the two parameters, to a maximum of 9, indicating the dominant importance of the parameter considered over the other [20]. The resulting output is a pairwise comparison matrix for each expert, for a total of six matrices. The individual ratings were then aggregated by the geometric mean, according to Dong and Saaty [56], into a single pairwise comparison matrix representative of group judgment (see Table 9). From this matrix, by implementing Eq. (2), the final weights wq of the 11 parameters (P1–P11) are derived, as shown in Table 8.

Besides, e = 6 experts were asked to evaluate the degree of difficulty of each design parameter in each workstation. More in detail, the question asked to the experts was the following [52]: “What is the effect of the qth parameter on the assembly difficulty in the ith workstation on a scale from 0 to 10, where 0 corresponds to no difficulty and 10 corresponds to the maximum difficulty?”. To cope with the alignment of the assessment scales, the framework provided in Table 10 was provided and explained to each expert. This tool entailed the adoption of a standard scale of judgments by defining conventional degrees of difficulty [52].

For each expert, a degree of difficulty matrix was obtained. Accordingly, six total matrices were derived after the interviews. A final matrix of the degrees of difficulty —see Table 11—was derived by averaging the evaluations of the six experts for each qth parameter in each ith workstation.

The design-based complexity factor of each workstation, \(C{f}_{D,i}\), is finally obtained by applying Eq. (3) and by combining the weights of the parameters and the degrees of difficulty matrix reported, respectively, in Tables 8 and 11. The obtained values are listed in Table 7.

Experimental DPU were analyzed using the power law regression model shown in Eq. (4) by using the software MATLAB®. The defect prediction model obtained, which will be marked henceforth with an asterisk (*) to distinguish it from the novel model reported in Eq. (13), is the following [52] (see also Fig. 7):

(a) DPU vs CfP and CfD: defect prediction model and experimental data; residual plots: (b) normal probability plot and (c) residuals vs order (adapted from [52])

The DPU predicted by using Eq. (14) are listed in Table 7. The analysis of the residuals plots shows that the model describes well the trend of the DPU as a function of the two assembly complexity factors. The normal probability plot shows a slight hypernormality, indicating a higher concentration of residuals around the central value. However, by performing the Anderson–Darling test, the normality of residuals cannot be rejected at a significance level of 5%. Furthermore, no systematic effects are evidenced by the plot of residuals versus order. The S value is 0.024, representing that the experimental values of DPU fall a standard distance of 0.024 units from the DPU values predicted by Eq. (14).

5.4 Comparison between the two models

Figure 8 illustrates the 95% prediction interval obtained for the DPU estimated using defect prediction models shown in Eqs. (13) and (14), separately for each workstation. In detail, the upper and lower prediction limits, the predicted values and the experimental values are reported. The complete list of the prediction ranges and their width is provided in Table 12. These prediction intervals, obtained by MINITAB®, represent the ranges in which the predicted responses for single new observations are expected to fall. It should be noted that negative values of the lower limits of prediction intervals of DPU are set equal to zero. Accordingly, for most workstations, the prediction interval is not symmetric with respect to the predicted DPUi.

According to results provided in Fig. 8 and Table 12 and by comparing Figs. 6 and 7, it is observed that the model proposed in this study allows obtaining more accurate estimates of DPU because the average absolute distance between experimental values and the regression model is 0.018, while for the other model is 0.024. Furthermore, DPU values estimated by implementing the novel model are also generally more precise since the related uncertainty in the estimate is tendentially lower. (See the limits and the width of the prediction intervals in Fig. 8 and Table 12.)

6 Conclusions

Although defect prediction is of utmost importance from the earliest stages of product design and related quality inspection design, most approaches are not directly applicable because they rely on operators' prior subjective knowledge and are designed for specific industrial applications. Addressing this problem, the present paper proposes a new approach to predict product defects from a more objective complexity assessment. This is one of the first attempts to predict product defects and improve product quality with a purely objective assessment of the complexity of the assembled product, without the need for operator evaluations and assembly expertise.

The proposed defect prediction model, suitable for manufacturing assembly, is based on the relationship between defect rates and the structural complexity paradigm developed by Sinha [28] and Alkan [4]. The predictor of such a model is the structural product complexity which is formulated by considering both complexities of product elements and effects of product assembly topology. This novel prediction model is compared with one of the most accredited models in the literature, i.e., the Shibata–Su model. The following two are the main differences between the two approaches:

-

Firstly, the two approaches rely on two different complexity assessment models. In the novel model, product complexity is approached based on purely objective product characteristics (i.e., number of parts and connections and related complexities, and architectural structure). On the other hand, in the Shibata–Su model, the complexity is evaluated through a mix of objective (i.e., standard times and number of elementary operations) and subjective data (i.e., expert evaluations).

-

Secondly, in the novel model, the structural complexity paradigm combines in a unique factor both the process complexity and the design complexity, without separating the two contributions.

In light of these operational differences, the novel model, based only on objective physical product characteristics, can be considered more usable than the Shibata–Su model by design and/or process engineers, especially in the early design stages, when real production data or the physical mockup of the product are not yet available.

The assembly of wrapping machines was used as a case study for developing and testing the novel prediction model. This process belongs to the category of low-volume productions (production rate: 50 machines assembled each year). In this situation, identifying an appropriate defect prediction model is essential since traditional statistical methods are generally not suitable or not applicable. The comparison between the novel model and the Shibata–Su model pointed out that, despite the architectural similarities, the former allows for more accurate and precise estimates of DPU. The novel model, providing reliable and accurate defectiveness previsions, can act both as a tool for quantitatively estimating defects of newly developed products and as a decision support tool for the assembly quality-oriented design and optimization. Indeed, engineers can employ this prediction model to get a quantitative estimation of DPU and accordingly design or redesign the process trying to minimize the defectiveness rates, by reducing assembly complexity.

The main limitation of the applicability of this method in real applications concerns the construction of the probabilistic model, which requires a preliminary estimate of the DPU in each workstation. In the case of assembly of electromechanical products, the model developed for wrapping machines can be considered a suitable equation to model DPU. However, the two regression coefficients may vary according to the specific industrial application. As a first approximation, it is acceptable to apply the proposed model to obtain a preliminary prediction of DPU and, when real experimental data are collected, update the model to refine the regression parameter estimates and improve the accuracy of the predictions.

Future research will be aimed at exploiting this novel defect prediction to support the design of quality inspection strategies in low-volume manufacturing and evaluate its effect on the inspection planning process.

Availability of data and materials

Not applicable.

Change history

21 July 2022

Missing Open Access funding information has been added in the Funding Note.

Abbreviations

- \({Cf}_{P,i}\) :

-

Process-based complexity factor of workstation i

- SST ij :

-

Sony Standard Time spent on the job element j in the workstation i

- \({t}_{0}\) :

-

Threshold assembly time, i.e., the time required to perform the simplest assembly operation

- \({N}_{a,i}\) :

-

Number of job elements in the workstation i

- \({TAT}_{i}\) :

-

Total assembly time related to the workstation i

- \(C{f}_{D,i}\) :

-

Design-based complexity factor of workstation i

- \({w}_{q}\) :

-

Weight of parameter q

- \({a}_{qr}\) :

-

Relative importance of parameter q over parameter r

- L :

-

Total number of parameters

- \({D}_{kqi}\) :

-

Degree of difficulty of the parameter q in the workstation i estimated by the expert k

- C i :

-

Assembly complexity of workstation i

- \({C}_{1,i}\) :

-

Part complexity in workstation i

- \({C}_{2,i}\) :

-

Connection complexity in workstation i

- \({C}_{3,i}\) :

-

Topological complexity in workstation i

- \({\gamma }_{pi}\) :

-

Handling complexity of part p in workstation i

- \({N}_{i}\) :

-

Total number of product parts in workstation i

- \({\varphi }_{pri}\) :

-

Insertion complexity of part p to r in workstation i

- \({A}_{pri}\) :

-

Connectivity between parts p and r in workstation i

- E Ai :

-

Matrix energy (or graph energy) of the adjacency matrix related to the workstation i

- \({\delta }_{pi}\) :

-

pTh singular value of the adjacency matrix of the product assembled in the workstation i

- \({N}_{Si}\) :

-

Total number of singular values of the product connectivity matrix related to workstation i

- WS:

-

Workstation

- DPU i :

-

Defects per unit in the workstation i

- S :

-

Standard error of the regression

References

Bednar S, Rauch E (2019) Modeling and application of configuration complexity scale: concept for customized production. Int J Adv Manuf Technol 100:485–501

Shoval S, Efatmaneshnik M (2019) Managing complexity of assembly with modularity: a cost and benefit analysis. Int J Adv Manuf Technol 105:3815–3828

Bedny GZ, Karwowski W, Bedny IS (2012) Complexity evaluation of computer-based tasks. Int J Hum Comput Interact 28:236–257

Alkan B (2019) An experimental investigation on the relationship between perceived assembly complexity and product design complexity. Int J Interact Des Manuf 13:1145–1157

Falck A-C, Örtengren R, Rosenqvist M, Söderberg R (2017) Basic complexity criteria and their impact on manual assembly quality in actual production. Int J Ind Ergon 58:117–128

Krugh M, Antani K, Mears L, Schulte J (2016) Prediction of defect propensity for the manual assembly of automotive electrical connectors. Procedia Manuf 5:144–157

Hasan SM, Baqai AA, Butt SU, quz Zaman UK, (2018) Product family formation based on complexity for assembly systems. Int J Adv Manuf Technol 95:569–585

Boothroyd G, Alting L (1992) Design for assembly and disassembly. CIRP Ann 41:625–636

Miyakawa S (1986) The Hitachi Assemblability Evaluation Method (AEM). In: Proceedings of 1st International Conference on Product Design for Assembly, 1986

Zhu X, Hu SJ, Koren Y et al (2007) Sequence planning to minimize complexity in mixed-model assembly lines. In: 2007 IEEE International Symposium on Assembly and Manufacturing. IEEE, pp 251–258

Hinckley CM (1994) A global conformance quality model. A new strategic tool for minimizing defects caused by variation, error, and complexity. PhD dissertation, Mechanical Engineering Department, Stanford University

Shibata H, Cheldelin B, Ishii K (2003) Assembly quality methodology: a new method for evaluating assembly complexity in globally distributed manufacturing. In: ASME 2003 International Mechanical Engineering Congress and Exposition. The American Society of Mechanical Engineers, November 15–21, 2003 Washington, DC, USA, pp 335–344

ElMaraghy WH, Urbanic RJ (2004) Assessment of manufacturing operational complexity. CIRP Ann 53:401–406

Zaeh MF, Wiesbeck M, Stork S, Schubö A (2009) A multi-dimensional measure for determining the complexity of manual assembly operations. Prod Eng 3:489

Samy SN, ElMaraghy H (2010) A model for measuring products assembly complexity. Int J Comput Integr Manuf 23:1015–1027

Alkan B, Vera D, Chinnathai MK, Harrison R (2017) Assessing complexity of component-based control architectures used in modular automation systems. Int J Comput Electr Eng 9:393–402

Mattsson S (2013) What is perceived as complex in final assembly? PhD dissertation, Department of Product and Production Development, Chalmers University of Technology

Falck A-C, Tarrar M, Mattsson S et al (2017) Assessment of manual assembly complexity: a theoretical and empirical comparison of two methods. Int J Prod Res 55:7237–7250

Falck A-C, Örtengren R, Rosenqvist M (2012) Relationship between complexity in manual assembly work, ergonomics and assembly quality. In: Ergonomics for Sustainability and Growth, NES 2012 (Nordiska Ergonomisällskapet) konferens, Saltsjöbaden, Stockholm, 19–22 augusti, 2012

Su Q, Liu L, Whitney DE (2010) A systematic study of the prediction model for operator-induced assembly defects based on assembly complexity factors. IEEE Trans Syst Man Cybern - Part A Syst Humans 40:107–120

Falck A-C, Örtengren R, Rosenqvist M, Söderberg R (2016) Criteria for assessment of basic manual assembly complexity. Procedia CIRP 44:424–428

Shibata H (2002) Global assembly quality methodology: a new methodology for evaluating assembly complexities in globally distributed manufacturing. PhD dissertation, Mechanical Engineering Department, Stanford University

Antani KR (2014) A study of the effects of manufacturing complexity on product quality in mixed-model automotive assembly. PhD dissertation, Mechanical Engineering Department, Clemson University

Falck A-C, Örtengren R, Rosenqvist M, Söderberg R (2017) Proactive assessment of basic complexity in manual assembly: development of a tool to predict and control operator-induced quality errors. Int J Prod Res 55:4248–4260

Galetto M, Verna E, Genta G (2020) Accurate estimation of prediction models for operator-induced defects in assembly manufacturing processes. Qual Eng 32:595–613

Le Y, Qiang S, Liangfa S (2012) A novel method of analyzing quality defects due to human errors in engine assembly line. In: Information Management, Innovation Management and Industrial Engineering (ICIII), 2012 International Conference on Information Management, Innovation Management and Industrial Engineering (ICIII). IEEE, 20–21 October 2012, Sanya, China, pp 154–157

Verna E, Genta G, Galetto M, Franceschini F (2021) Defect prediction models to improve assembly processes in low-volume productions. Procedia CIRP 97:148–153

Sinha K (2014) Structural complexity and its implications for design of cyber-physical systems. PhD dissertation, Engineering Systems Division, Massachusetts Institute of Technology

Alkan B, Vera D, Ahmad B, Harrison R (2017) A method to assess assembly complexity of industrial products in early design phase. IEEE Access 6:989–999

Alkan B, Harrison R (2019) A virtual engineering based approach to verify structural complexity of component-based automation systems in early design phase. J Manuf Syst 53:18–31

Galetto M, Verna E, Genta G, Franceschini F (2020) Uncertainty evaluation in the prediction of defects and costs for quality inspection planning in low-volume productions. Int J Adv Manuf Technol 108:3793–3805

Verna E, Genta G, Galetto M, Franceschini F (2021) Towards zero defect manufacturing: probabilistic model for quality control effectiveness. In: 2021 IEEE International Workshop on Metrology for Industry 4.0 & IoT (MetroInd4.0&IoT). IEEE, 7–9 June 2021, Rome, Italy, pp 522–526. https://doi.org/10.1109/MetroInd4.0IoT51437.2021.948

Verna E, Genta G, Galetto M, Franceschini F (2021) Inspection planning by defect prediction models and inspection strategy maps. Prod Eng 15:897–915. https://doi.org/10.1007/s11740-021-01067-x

Verna E, Genta G, Galetto M, Franceschini F (2020) Planning offline inspection strategies in low-volume manufacturing processes. Qual Eng 32:705–720

Koons GF, Luner JJ (1991) SPC in low-volume manufacturing: a case study. J Qual Technol 23:287–295

Galetto M, Genta G, Maculotti G, Verna E (2020) Defect probability estimation for hardness-optimised parts by selective laser melting. Int J Precis Eng Manuf 21:1739–1753

Richardson M, Jones G, Torrance M, Baguley T (2006) Identifying the task variables that predict object assembly difficulty. Hum Factors 48:511–525

Lee T-S (2003) Complexity theory in axiomatic design. PhD dissertation, Department of Mechanical Engineering, Massachusetts Institute of Technology

Sinha K, de Weck OL, Onishi M, et al (2012) Structural complexity metric for engineered complex systems and its application. In: Gain Competitive Advantage by Managing Complexity: Proceedings of the 14th International DSM Conference Kyoto, Japan. pp 181–194

Krugh M, Antani K, Mears L, Schulte J (2016) Statistical modeling of defect propensity in manual assembly as applied to automotive electrical connectors. Procedia CIRP 44:441–446

Franceschini F, Galetto M, Genta G, Maisano DA (2018) Selection of quality-inspection procedures for short-run productions. Int J Adv Manuf Technol 99:2537–2547

Genta G, Galetto M, Franceschini F (2018) Product complexity and design of inspection strategies for assembly manufacturing processes. Int J Prod Res 56:4056–4066

Aft LS (2000) Work measurement and methods improvement. John Wiley & Sons, Hoboken, NJ, USA

Yamagiwa Y (1988) An assembly ease evaluation method for product designers: DAC. Techno Japan 21:26–29

Ben-Arieh D (1994) A methodology for analysis of assembly operations’ difficulty. Int J Prod Res 32:1879–1895

Wei CC, Chien CF, Wang MJJ (2005) An AHP-based approach to ERP system selection. Int J Prod Econ 96:47–62

Saaty TL (1980) The analytic hierarchy process. McGraw-Hill, New York

Hückel E (1932) Quantentheoretische Beiträge zum Problem der aromatischen und ungesättigten Verbindungen. III Zeitschrift für Phys 76:628–648

Nikiforov V (2007) The energy of graphs and matrices. J Math Anal Appl 326:1472–1475

Li X, Shi Y, Gutman I (2012) Hyperenergetic and equienergetic graphs. Graph Energy. Springer, New York, NY, pp 193–201

Montgomery DC (2019) Introduction to statistical quality control, 8th ed. Wiley Global Education

Verna E, Genta G, Galetto M, Franceschini F (2020) Defect prediction model for wrapping machines assembly. In: Proceedings of the 4th International Conference on Quality Engineering and Management. 21–22 September, University of Minho, Braga, Portugal, pp 115–134. ISSN: 21843481, ISBN: 978–989549110–0

Devore JL (2011) Probability and statistics for engineering and the sciences. Cengage Learning, Boston, USA

Bates DM, Watts DG (1988) Nonlinear regression analysis and its applications. John Wiley & Sons Inc, Hoboken, NJ, USA

Spiess AN, Neumeyer N (2010) An evaluation of R2 as an inadequate measure for nonlinear models in pharmacological and biochemical research: A Monte Carlo approach. BMC Pharmacol 10:1–11

Dong Q, Saaty TL (2014) An analytic hierarchy process model of group consensus. J Syst Sci Syst Eng 23:362–374

Acknowledgements

The authors gratefully acknowledge the company Tosa Group S.p.A. (Italy) for the collaboration in this project.

Funding

Open access funding provided by Politecnico di Torino within the CRUI-CARE Agreement. This work has been partially supported by the “Italian Ministry of Education, University and Research,” Award “TESUN‐83486178370409 finanziamento dipartimenti di eccellenza CAP. 1694 TIT. 232 ART. 6.”

Author information

Authors and Affiliations

Contributions

The authors have provided an equal contribution to the drafting of the paper.

Corresponding author

Ethics declarations

Ethical approval

The authors respect the Ethical Guidelines of the Journal.

Consent to participate

Not applicable.

Consent to publish

Not applicable.

Competing interests

The authors do not have conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Verna, E., Genta, G., Galetto, M. et al. Defect prediction for assembled products: a novel model based on the structural complexity paradigm. Int J Adv Manuf Technol 120, 3405–3426 (2022). https://doi.org/10.1007/s00170-022-08942-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08942-6