Abstract

Ti-6Al-4V alloy is characterised by having excellent mechanical properties and corrosion resistance combined with low specific weight and biocompatibility. This material is ideal for many high-performance engineering applications. It is increasingly used in additive manufacturing (AM) thanks to the possibility of producing very complex lightweight structures, often not achievable with conventional manufacturing techniques, as well as to easily customise products according to specific customer requirements. In powder bed fusion (PBF) processes, only a small percentage of the powder is actually melted and solidified to achieve the final part while most is left after the build. Since the surface morphology and chemistry, the shape and size distribution of the un-melted particles are inevitably modified during the process, and this may affect the resulting properties of the final products, many companies tend to use virgin powders for AM builds to keep compliance with manufacturing requirements and minimise risk. From both an economic and environmental point of view, it results crucial to develop recycling methods to reuse the metal powder as many times as possible while maintaining compliance with manufacturing standards. In this work, the effect of Ti-6Al-4V powder reuse on the evolution of powder characteristics and mechanical properties of final products additively manufactured is investigated through a systematic approach based on design of experiments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Although early use of additive manufacturing in the form of rapid prototyping was almost limited to the production of visualisation models, it is nowadays being used to fabricate end-use products in many different fields, spreading from aerospace and automotive, to the production of biomedical implants and biological tissues, and even fashion goods. AM allows not only to reduce the delivery time and total cost of complex components, but also to enhance the performance, weight and functionality of the components themselves [1, 2].

Direct metal laser sintering (DMLS) is based on the laser powder bed fusion technique and uses a Yb (Ytterbium) fiber laser to locally melt a powdered metal to build up highly complex solid structures additively layer by layer [3,4,5].

Along with the well-known repeatability, reproducibility [6] and anisotropy [7, 8] issues, a drawback of all PBF processes is that only a small percentage of the powder is actually melted and solidified to achieve the final part while most is left after the build. However, the surface morphology and chemistry, the shape and size distribution of the un-melted particles are inevitably modified during the process, so that the resulting properties of the final products may be negatively affected [9,10,11]. Therefore, many companies tend to use virgin powders for AM builds to keep compliance with manufacturing requirements and minimise risk, thus resulting in a huge amount of out-of-spec powder, either stored or wasted. This policy contributes to higher costs and a larger environmental footprint of AM processes, so it results crucial to develop qualified methods to reuse the metal powder as many times as possible while maintaining compliance with manufacturing standards [12,13,14].

Both academic and industrial research works have faced this issue, focusing on the most widely used materials, from steels [15,16,17,18,19,20,21,22,23,24,25,26] and aluminium alloys [15, 27,28,29,30,31,32] to Inconel [29, 33,34,35,36,37,38,39,40] and titanium alloys [29, 33,34,35, 39, 41,42,43,44,45,46,47,48,49,50,51,52,53,54,55]. Generally speaking, some of the results obtained for the effects of metal powder reusing seem to be inconsistent across the studies. This is ascribable to the large number of side factors involved, such as the specific AM equipment or brand of powder used, the process parameters, the procedure for reuse, etc. [56].

This work addresses the effect of EOS Ti64 (Ti-6Al-4V) powder reuse on the evolution of powder characteristics and mechanical properties of final products additively manufactured. A systematic approach based on design of experiments (DOE) and analysis of variance (ANOVA) was used to ensure effectiveness and reliability of the experimental results [57,58,59,60,61].

2 Materials and methods

2.1 Virgin powder and powder reusing method

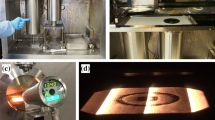

All the specimens for mechanical characterisation were produced on an EOSINT M280 using the optimised processing parameters provided by the producer, the EOS Part Property Profile Ti64 Performance 30 \(\mu\)m, and heat treated at 650 \(^\circ\)C for 3 hours. Both DMLS process and heat treatment were performed in Argon inert atmosphere.

Different strategies can be used to recycle metal powder in PBF processes. In this work, the same procedure implemented by the authors in [16] was executed. It consists in producing a first DMLS build using virgin powder only, after which the un-melted powder left over in the build volume and the overflow compartment is collected, sieved and then loaded above the residual powder in the feeding compartment to start the subsequent run, and so on for each DMLS run up to the last one.

2.2 Samples and testing standards for the evaluation of powder characteristics and mechanical properties

Before starting each DMLS run, powder samples were collected, in compliance with ASTM B215-15 [62], from the feeding compartment to undergo physical/chemical characterisation, as suggested in [63].

Particle size distribution (PSD) was determined according to ASTM B822-17 [64] using a Malvern MS2000 laser diffraction analyser, while powder chemical composition was evaluated through inductively coupled plasma, infrared absorption and inert gas fusion techniques (depending on the chemical elements to be detected) according to ASTM E2371-13 [65] and ASTM E1019-11 [66].

To evaluate the mechanical properties of parts additively manufactured with virgin and reused powder, ten subsequent DMLS builds were produced according the aforementioned procedure. Each build hosted six cylindrical bars to be used for the tensile tests and six near net shape samples for the high cycle fatigue (HCF) tests. Downstream of DMLS process, all specimens were machined to comply with ISO 6892-1:2016 [67] and DIN EN 6072:2011 [68] testing standards.

Tensile tests were executed at room temperature on an Instron 1185, with a cross head speed of 0.45 mm/min, according to ASTM E8/E8M-16a [69], while HCF tests were executed on a MTS Load Frame Model 312.21 with Kt=1 and R=0.1, according to ASTM E466-15 [70], and terminated at 107 cycles. The corresponding Wohler curves were obtained according to ASTM E739-10 [71].

3 Results and discussion

The 10th, 50th and 90th percentiles of the particle diameter (referred to as D10, D50 and D90, respectively) are reported in Fig. 1a, showing how the variability of particle size distribution over the number of reuses can be considered substantially physiological. Conversely, Fig. 1b points out an anomalous variation of chemical composition, in particular in terms of iron content, in the last reuse cycles.

The Minitab®18 software was used to perform one-way ANOVA, with a significance level \(\alpha =0.05\), on tensile properties, after diagnostic check of residuals. Once the ANOVA has been performed, the effect of a source of variability can be defined as statistically significant with respect to a particular response variable if the corresponding p-value results lower than \(\alpha\) [57, 72].

The obtained results for yield strength (YS0.2%), ultimate tensile strength (UTS) and elongation at break (A) are reported in Table 1: the effect of powder resuse resulted to significantly affect yield strength and ultimate tensile strength (p-value \(\ll \alpha\)), but negligible with respect to elongation at break (p-value \(\gg \alpha\)).

From Fig. 2, that shows the trend of the mechanical properties over the number of reuses, it is possible to see how the effect of powder reuse is actually confined to the last three runs and how it involves a slight enhancement, rather than a decay, of material performance. However, it is worth noting that the differences highlighted by the ANOVA can be considered relatively small from a technological point of view. Indeed, the corresponding stress–strain curves resulted almost overlapable, as shown in Fig. 3. In addition, the measured values resulted all consistent with those guaranteed by the supplier and required by the company.

Figure 4 shows the Wohler curves of specimens produced with virgin and reused powder. The fatigue behaviour remained substantially stable, with minimum a high cycle fatigue strength (\(\Delta \sigma\)) of 400 MPa.

The abnormal mechanical properties of samples produced within the last DMLS runs are ascribable to the aforementioned change in powder chemical composition. The observed increase of iron content was found to be caused by a steel contamination [73] of powder during sieving operations: the sieve used in this work was made of AISI 316L steel, that is characterised by a much lower hardness than titanium, and the continuous rubbing of the powder against sieve walls had caused a kind of erosion effect, resulting in the inclusion of steel powder in the titanium one. This is confirmed by both the increase of Fe content in the powder samples analysed (see Fig. 1b) and by the chemical analysis of additively manufactured material. Indeed, Fig. 5 shows the evident increase of Fe, Cr, and Ni concentrations in the alloy for the last DMLS runs. It is worth considering that these three elements, in which the AISI 316L is particularly rich, belong to the class of \(\beta\)-eutectoids with a very low solubility in \(\alpha\)-Ti [74,75,76]. When these elements exceed this level of solubility, they form (Cr,Fe,Ni)2Ti intermetallics [77], which can significantly modify the resulting mechanical properties of the alloy [78, 79]. Given that this is a contamination, it is not surprising that the content of these elements does not exhibit a real trend upstream and downstream of the seventh run (where the first contamination probably occurred) but rather appears as a random fluctuation. In fact, what is nevertheless evident is a substantial shift in Fe content downstream of the sixth run. The presence of these intermetallics was further highlighted by scanning electron microscope-mounted electron probe X-ray microanalysis (SEM-EPMA) and energy dispersive X-ray spectrometry (EDS). Figure 6a shows the presence of a thin precipitate inside the Ti-6Al-4V lamellar matrix. It is worth noting that a thin shrinkage crack is also evident within the precipitate: this crack does not extend to the surrounding metal matrix, which is further evidence of the embrittlement effect due to the presence of Cr and Fe. The colour maps presented in Fig. 6b-e further confirm the higher concentration of Cr and Fe in the precipitate compared to the Ti-6Al-4V matrix. Finally, in the EDS spectrum of the precipitate, presented in Fig. 7a, both Fe (peak at 6.404 keV) and Cr (peak at 5.415 keV) are clearly visible. Conversely, as shown in Fig. 7b, neither of these two peaks is detectable in the EDS spectrum of the Ti-6Al-4V matrix.

4 Conclusions

Mechanical properties of titanium parts did not see a drastic variation due to powder reuse, which turned out to affect them only marginally, and in this specific case positively. The erosive effect of titanium powders on the walls of steel sieve, that caused the inclusion of steel powder in the titanium one, suggests the use of a sieve of the same material as the powder to be processed, or at least a harder one. In the specific case analysed in this work, the number of reuses was small enough not to show such detrimental changes in mechanical properties, but a higher number of reuses could have caused more significant, and probably negative, variation.

Obtained results confirm the reusability of AM powders, at least for a certain number of cycles, while maintaining compliance with manufacturing standards, contributing to the possibility for AM processes to affirm themselves as more affordable and environmentally friendly. On the other hand, these results also suggest the use of measures to minimise the undesirable effect of external contaminants, especially in the case of material that are very susceptible to contamination, such as titanium and titanium alloys.

The powder recycling strategy and the procedures for part quality assurance and data analysis proposed in this work can be adapted to other similar processes and other materials.

Data availability

Not applicable.

References

Gibson I, Rosen D, Stucker (2015) Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing. Springer Science+Business Media: New York, NY, USA. ISBN 978-1-4939-2112-6

Yang L, Hsu K, Baughman B, Godfrey D, Medina F, Menon M, Wiener S (2017) Additive Manufacturing of Metals: The Technology, Materials, Design and Production. Springer International Publishing AG, Cham, Switzerland. 978-3-319-55127-2

eos.info (2013) Additive Manufacturing, Laser-Sintering and industrial 3D printing - Benefits and Functional Principle. http://www.eos.info/additive_manufacturing/for_technology_interested

Khaing MW, Fuh JYH, Lu L (2001) Direct Metal Laser Sintering for rapid tooling: Processing and characterization of EOS parts. J Mater Process Technol 113(1-3):269-272. http://doi.org/10.1016/S0924-0136(01)00584-2

Calleja-Ochoa A, Ganzalez-Barrio H, Lopez de Lacalle LN, Martinez S, Albizuri J, Lamikiz A (2021) A new approach in the design of microstructured ultralight components to achieve maximum functional performance. Materials 14(7):1588. http://doi.org/10.3390/ma14071588

Dowling L, Kennedy J, O’Shaughnessy S, Trimble D (2020) A review of critical repeatability and reproducibility issues in powder bed fusion. Mater Des 186:108346. http://doi.org/10.1016/j.matdes.2019.108346

Perez-Ruiz JD, Lopez de Lacalle LN, Urbikain G, Pereira O, Martinez S, Bris J (2021) On the relationship between cutting forces and anisotropy features in the milling of LPBF Inconel 718 for near net shape parts. Int J Mach Tools Manuf 170:103801. http://doi.org/10.1016/j.ijmachtools.2021.103801

Del Re F, Scherillo F, Contaldi V, Palumbo B, Squillace A, Corrado P, Di Petta P (2019) Mechanical properties characterisation of AlSi10Mg parts produced by laser powder bed fusion additive manufacturing. Int J Mater Res 110(5):436-446. http://doi.org/10.3139/146.111761

Lutter-Gunther M, Gebbe C, Camps T, Seidel C, Gunter R (2018) Powder recycling in laser beam melting: strategies, consumption modeling and influence on resource efficiency. Prod Eng 12(3-4):377-389. http://doi.org/10.1007/s11740-018-0790-7

Gasper AND, Hickman D, Aschcroft I, Sharma S, Wang X, Szost B, Johns D, Clare AT (2019) Oxide and spatter powder formation during laser powder bed fusion of Hastelloy X. Powder Technol 354:333-337. http://doi.org/10.1016/j.powtec.2019.06.004

Santecchia E, Spigarelli S, Cabibbo M (2020) Material reuse in laser powder bed fusion: side effects of the laser-metal powder interaction. Metals 10:341. http://doi.org/10.3390/met10030341

Sames WJ, List FA, Pannala S, Dehoff RR, Babu SS (2016)The metallurgy and processing science of metal additive manufacturing. Int Mater Rev 61(5):315-360. http://doi.org/10.1080/09506608.2015.1116649

Slotwinski JA (2013) Materials Standards for Additive Manufacturing. Engineering Lab NIST. http://www.nist.gov/document/slotwinski-nist-am-materialspdf

Arrizubieta JI, Ukar O, Ostolaza M, Mugica A (2020) Study of the environmental implications of using metal powder in additive manufacturing and its handling. Metals 10:261. http://doi.org/10.3390/met10020261

Mohod Yusuf S, Choo E, Gao N (2020) Comparison between virgin and recycled 316L SS and AlSi10Mg powders used for laser powder bed fusion additive manufacturing. Metals 10:1625. http://doi.org/10.3390/met10121625

Contaldi V, Del Re F, Palumbo B, Squillace A, Corrado P, Di Petta P (2019) Mechanical characterisation of stainless steel parts produced by direct metal laser sintering with virgin and reused powder. Int J Adv Manuf Technol 105:3337-3351. http://doi.org/0.1007/s00170-019-04416-4

Quinn PT, O’Halloran S, Lawlor J, Raghavendra R (2019) The effect of metal EOS 316L stainless steel additive manufacturing powder recycling on part characteristics and powder reusability. Adv Mater Process Technol 5(2):348-359. http://doi.org/10.1080/2374068X.2019.1594602

Sartin B, Pond T, Griffith B, Everhart W, Elder L, Wenski E, Cook C, Wieliczka D, King W, Rubenchik A, Wu S, Brown B, Johnson C, Crow J (2017) 316L Powder Reuse for Metal Additive Manufacturing. SFF Symp Procedia 28:351-364. http://sffsymposium.engr.utexas.edu/sites/default/files/2017/Manuscripts/316LPowderReuseforMetalAdditiveManufacturing.pdf

Slotwinski JA, Garboczi EJ, Stutzman PE, Ferraris CF, Watson SS, Peltz MA (2014) Characterization of Metal Powders Used for Additive Manufacturing. J Res Natl Inst Stand Technol 119:460-493. http://doi.org/10.6028/jres.119.018

Gorji NE, O’Connor R, Brabazon D (2019) XPS, XRD, and SEM characterization of the virgin and recycled metallic powders for 3D printing applications. IOP Conf Ser: Mater Sci Eng 591:012016. http://doi.org/10.1088/1757-899X/591/1/012016

Gorji NE, O’Connor R, Mussatto A, Snelgrove M, Gonzalez PGM, Brabazon D (2019) Recyclability of stainless steel (316L) powder within the additive manufacturing process. Materialia 8:100489. http://doi.org/10.1016/j.mtla.2019.100489

Heiden MJ, Deibler LA, Rodelas JM, Koepke JR, Tung DJ, Saiz DJ, Jared BH (2019) Evolution of 316L stainless steel feedstock due to laser powder bed fusion process. Addit Manuf 25:84-103. http://doi.org/10.1016/j.addma.2018.06.003

Pinto FC, Souza Filho IR, Sandim MJR, Sandim HRZ (2020) Defects in parts manufactured by selective laser melting caused by \(\delta\)-ferrite in reused 316L steel powder feedstock. Addit Manuf 31:100979 http://doi.org/10.1016/j.addma.2019.100979

Sutton AT, Kriewall CS, Karnati S, Leu MC, Newkirk JW (2020) Characterization of AISI 304L stainless steel powder recycled in the laser powder-bed fusion process. Addit Manuf 32:100981. http://doi.org/10.1016/j.addma.2019.100981

Ahmed F, Ali U, Sarker D, Marzbanrad E, Choi K, Mahmoodkhani Y, Toyserkani E (2020) Study of powder recycling and its effect on printed parts during laser powder-bed fusion of 17-4 PH stainless steel. J Mater Process Technol 278:116522. http://doi.org/10.1016/j.jmatprotec.2019.116522

Jacob G, Brown C, Donmez A, Watson S, Slotwinski J (2017) Effects of powder recycling on stainless steel powder and built material properties in metal powder bed fusion processes. NIST AMS 100-6. http://doi.org/10.6028/NIST.AMS.100-6

Del Re F, Contaldi V, Astarita A, Palumbo B, Squillace A, Corrado P, Di Petta P (2018) Statistical approach for assessing the effect of powder reuse on the final quality of AlSi10Mg parts produced by laser powder bed fusion. Int J Adv Manuf Technol 97(5-8):2231-2240. http://doi.org/10.1007/s00170-018-2090-y

Palumbo B, Centofanti F, Del Re F (2020) Function-on-function regression for assessing production quality in industrial manufacturing. Qual Reliab Eng Int 36(8):2738-2753. http://doi.org/10.1002/qre.2786

Cordova L, Campos M, Tinga T (2019) Revealing the effects of powder reuse for selective laser melting by powder characterization. JOM 71(3):1062-1072. http://doi.org/10.1007/s11837-018-3305-2

Hadadzadeh A, Baxter C, Shalchi Amirkhiz B, Mohammadi M (2018) Strengthening mechanisms in direct metal laser sintered AlSi10Mg: Comparison between virgin and recycled powders. Addit Manuf 23:108-120. http://doi.org/10.1016/j.addma.2018.07.014

Maamoun AH, Elbestawi M, Dosbaeva GK, Veldhuis SC (2018) Thermal post-processing of AlSi10Mg parts produced by selective laser melting using recycled powder. Addit Manuf 21:234-2470. http://doi.org/10.1016/j.addma.2018.03.014

Cordova L, Bor T, de Smit M, Carmignato S, Campos M, Tinga T (2020) Effects of powder reuse on the microstructure and mechanical behaviour of Al-Mg-Sc-Zr alloy processed by laser powder bed fusion (LPBF). Addit Manuf 32:101625. http://doi.org/10.1016j.addma.2020.101625

LPW Technology Ltd (2016) Case Study 05: Powder degradation. LPW Technology Ltd: Runcorn WA7 1TQ, UK. www.lpwtechnology.com/wp-content/uploads/2016/09/LPW-Case-Study-05.pdf

Nandwana P, Peter WH, Dehoff RR, Lowe LE, Kirka MM, Medina F, Babu SS (2016) Recyclability study on inconel 718 and Ti-6Al-4V powders for use in electron beam melting. Metall Mater Trans B 47(1):754-762. http://doi.org/10.1007/s11663-015-0477-9

Strondl A, Lyckfeldt O, Brodin H, Ackelid U (2015) Characterization and control of powder properties for additive manufacturing. JOM 67(3):549-554. http://doi.org/10.1007/s11837-015-1304-0

Waterman P (2017) Reusing IN625 Powder for 3D Printing: What Does the Test Data Say?. http://www.digitalengineering247.com/article/stratasys3dprintingsinteringpowderreusestudy/

Hann B (2016) Powder reuse and its effects on laser based powder fusion additive manufactured alloy 718. SAE Int J Aerosp 9(2):209-213. http://doi.org/10.4271/2016-01-2071

Ardila LC, Garciandia F, Gonzalez-Diaz JB, Alvarez P, Echeverria A, Petite MM, Deffley R, Ochoa J (2014) Effect of IN718 recycled powder reuse on properties of parts manufactured by means of Selective Laser Melting. Phys Procedia 56:99-107. http://doi.org/10.1016/j.phpro.2014.08.152

Chandrasekar S, Coble JB, Yoder S, Nandwana P, Dehoff RR, Paquit VC, Babu SS (2020) Investigating the effect of metal powder recycling in electron beam powder bed fusion using process log data. Addit Manuf 32:100994. http://doi.org/10.1016/j.addma.2019.100994

Rock C, Ledford C, Garcia-Avila M, West H, Miller VM, Pankow M, Dehoff R, Horn T (2021) The influence of powder reuse on the properties of nickel super alloy ATI 718TM in laser powder bed fusion additive manufacturing. Metall Mater Trans B 5B:676-688. http://doi.org/10.1007/s11663-020-02040-2

Park SB, Road B (2016) White paper: Investigating the effects of multiple re-use of Ti6Al4V powder in Additive Manufacturing. Renishaw Plc: Wotton-under-Edge, UK. http://resources.renishaw.com/download.aspx?lang=en&data=83164&btn=1

Consalvo A (2015) Metal powder reuse in additive manufacturing. NanoInnovation Conference spsampsps Exhibition. http://www.nanoitaly.it/nanoitaly/images/presentazioni/IV_2_1-Consalvo.pdf

Tang HP, Qian M, Liu N, Zhang XZ, Yang GY, Wang J (2015) Effect of powder reuse times on additive manufacturing of Ti-6Al-4V by selective electron beam melting. JOM 67(3):555-563. http://doi.org/10.1007/s11837-015-1300-4

Seyda V, Kaufmann N, Emmelmann C (2012) Investigation of aging processes of Ti-6Al-4V powder material in laser melting. Phys Procedia 39:425-431. http://doi.org/10.1016/j.phpro.2012.10.057

Meier B, Skalon M, Warchomicka F, Belei C, Gortler M, Kaindl R, Sommitsch C (2019) Effect of the reuse of powder on material properties of Ti6Al4V processed by SLM. AIP Conf Proc 2113:150006. http://doi.org/10.1063/1.5112682

Popov VV, Katz-Demyanetz A, Garkun A, Bamberger M (2018) The effect of powder recycling on the mechanical properties and microstructure of electron beam melted Ti-6Al-4V specimens. Addit Manuf 22:834-843. http://doi.org/10.1016/j.addma.2018.06.003

Vojislav P (2015) Powder recyclability in electron beam melting for aeronautical use. Aircr Eng Aerosp Technol 87(2):147-155. http://doi.org/10.1108/AEAT-11-2013-0212

Ghods S, Schur R, Schultz E, Pahuja R, Montelione A, Wisdom C, Arola D, Ramulu M (2021) Powder reuse and its contribution to porosity in additive manufacturing of Ti6Al4V. Materialia 15:100992. http://doi.org/10.1016/j.mtla.2020.100992

Denti L, Sola A, Defanti S, Sciancalepore C, Bandioli F (2019) Effect of Powder Recycling in Laser-based Powder Bed Fusion of Ti-6Al-4V. Manuf Technol 19(2):190-196. http://doi.org/10.21062/ujep/268.2019/a/1213-2489/MT/19/2/190

Harkin R, Wu H, Nikam S, Quinn J, McFadden S (2020) Reuse of grade 23 Ti6Al4V powder during the laser-based powder bed fusion process. Metals 10:1700. http://doi.org/10.3390/met10121700

Carrion PE, Soltani-Tehrani A, Phan N, Shamsaei N (2019) Powder Recycling Effects on the Tensile and Fatigue Behavior of Additively Manufactured Ti-6Al-4V Parts. JOM 71(3):963-973. http://doi.org/10.1007/s11837-018-3248-7

Alamos FJ, Schiltz J, Kozlovsky K, Attardo R, Tomonto C, Pelletiers T, Schmid SR (2020) Effect of powder reuse on mechanical properties of Ti-6Al-4V produced through selective laser melting. Int J Refract Met H 91:105273. http://doi.org/10.1016/j.ijrmhm.2020.105273

Gatto ML, Groppo R, Bloise N,Fassina L, Visai L, Galati M, Iuliano L, Mengucci P (2021) Topological, mechanical and biological properties of Ti6Al4V scaffolds for bone tissue regeneration fabricated with reused powders via electron beam melting. Materials 14:224. http://doi.org/10.3390/ma14010224

Shanbhag G, Vlasea M (2021) Powder reuse cycles in electron beam powder bed fusion-variation of powder characteristics. Materials 14(16):4602. http://doi.org/10.3390/ma14164602

Soundarapandiyan G, Johnston C, Khan RHU, Leung CLA, Lee PD, Hernandez-Nava E, Chen B, Fitzpatrick ME (2021) The effects of powder reuse on the mechanical response of electron beam additively manufactured Ti6Al4V parts. Addit Manuf 46:102101. http://doi.org/10.1016/j.addma.2021.102101

Powell D, Rennie AEW, Geekie L, Burns N (2020) Understanding powder degradation in metal additive manufacturing to allow the upcycling of recycled powders. J Cleaner Prod 268:122077. http://doi.org/10.1016/j.jclepro.2020.122077

Montgomery DC (2019) Design and Analysis of Experiments. John Wiley & Sons: Hoboken, NJ, USA. ISBN 978-1-119-49244-3

Coleman DE, Montgomery DC (1993) A systematic approach to planning for a designed industrial experiment. Technometrics 35(1):25-27. http://doi.org/10.2307/1269285

Palumbo B, Marrone R, De Chiara G (2009) Technological process innovation via engineering and statistical knowledge integration. In: Statistics for Innovation. Erto P, Ed.; Springer: Milan, Italy. http://doi.org/10.1007/978-88-470-0815-1_10

Palumbo B, Del Re F, Martorelli M, Lanzotti A, Corrado P (2017) Tensile properties characterization of AlSi10Mg parts produced by Direct Metal Laser Sintering via Nested Effects Modeling. Materials 10(2):144. http://doi.org/10.3390/ma10020144

Del Re F, Dix M, Tagliaferri F (2019) Grinding burn on hardened steel: characterization of onset mechanisms by design of experiments. Int J Adv Manuf Technol 101:2889-2905. http://doi.org/10.1007/s00170-018-3156-6

ASTM (2015) B215-15 Standard practices for sampling metal powders. ASTM International. http://doi.org/10.1520/B0215-15

Sutton AT, Kriewall CT, Leu MC, Newkirk JW (2017) Powder characterisation techniques and effects of powder characteristics on part properties in powder-bed fusion processes. Virtual Phys Prototyp 12(1):3-29. http://doi.org/10.1080/17452759.2016.1250605

ASTM (2017) B822-17 Standard test method for particle size distribution of metal powders and related compounds by light scattering. ASTM International. http://doi.org/10.1520/B0822-17

ASTM (2013) E2371-13 Standard test method for analysis of titanium and titanium alloys by direct current plasma and inductively coupled plasma atomic emission spectrometry (Performance-Based Test Methodology). ASTM International. http://doi.org/10.1520/E2371-13

ASTM (2014) E1019-11 Standard test methods for determination of carbon, sulfur, nitrogen, and oxygen in steel, iron, nickel, and cobalt alloys by various combustion and fusion techniques. ASTM International. http://doi.org/10.1520/E1019-11

ISO EN (2016) Standard 6892-1:2016 Metallic Materials, Tensile Testing, Part 1: Method of Test at Room Temperature. International Organization for Standardization. ICS 77(040):10

DIN EN (2011) 6072:2011 Aerospace series, metallic materials, test methods, constant amplitude fatigue testing. German institute for Standardization. www.beuth.de/en/standard/din-en-6072/140066421

ASTM (2016) E8/E8M-16a Standard test methods for tension testing of metallic materials. ASTM International. http://doi.org/10.1520/E0008_E0008M-16A

ASTM (2015) E466-15 Standard practice for conducting force controlled constant amplitude axial fatigue tests of metallic materials. ASTM International. http://doi.org/10.1520/E0466-15

ASTM (2015) E739-10 Standard practice for statistical analysis of linear or linearized stress-life (S-N) and strain-life (Ε-N) fatigue data. ASTM International. http://doi.org/10.1520/E0739-10

Montgomery DC, Runger GC (2019) Applied Statistics and Probability for Engineers. John Wiley & Sons: Hoboken, NJ, USA. ISBN 978-1-119-58559-6

Santecchia E, Mengucci P, Gatto A, Bassoli E, Defanti S, Bazzucca G (2019) Cross-contamination quantification in powders for additive manufacturing: A study on Ti-6Al-4V and maraging steel. Materials 12:2342. http://doi.org/10.3390/ma12152342

Murray JL (1981) The Cr-Ti (Chromium-Titanium) system. Bull Alloy Phase Diagrams 2:174-181. http://doi.org/10.1007/BF02881474

Murray JL (1981) The Fe-Ti (Iron-Titanium) system. Bull Alloy Phase Diagrams 2:320-334. http://doi.org/10.1007/BF02868286

Lee KJ, Nash P (1991) The Al-Ni-Ti system (Aluminum-Nickel-Titanium). J Phase Equilib 12:551-562. http://doi.org/10.1007/BF02645068

Zeng L, Liu L, Huang S, Zhang L (2017) Experimental investigation of phase equilibria in the Ti-Fe-Cr ternary system. Calphad 58:58-69. http://doi.org/10.1016/j.calphad.2017.05.006

Takahashi K, Sato E (2012) Mechanical Properties of Ti-6Al-4V Alloy Using Off Grade Sponge Titanium as Raw Material. Tetsu-to-Hagane 98(9):491-496. http://doi.org/10.2355/tetsutohagane.98.491

Lutjering G, Williams JC (2007) Titanium. Springer-Verlag, Berlin, Germany. 978-3-540-71397-5

Acknowledgements

The authors are grateful to Giuseppe La Sala and Luca Di Matteo (MBDA Italia S.p.A.) for their support in the technological interpretation of the statistical results.

Funding

The experimental activities presented above were co-funded by "PON ARS01_00758 Additive Manufacturing e automazione processo per materiali Ibridi e Compositi (AMICO)" research project, led by Distretto sull'Ingegneria dei Materiali Polimerici e Compositi e Strutture (IMaST).

Author information

Authors and Affiliations

Contributions

All authors contributed equally to this work.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Provided by IMaST.

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Contaldi, V., Corrado, P., Del Re, F. et al. Direct metal laser sintering of Ti-6Al-4V parts with reused powder. Int J Adv Manuf Technol 120, 1013–1021 (2022). https://doi.org/10.1007/s00170-022-08807-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-022-08807-y