Abstract

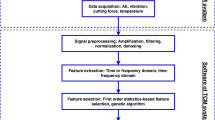

Data-driven methods provided smart manufacturing with unprecedented opportunities to facilitate the transition toward Industry 4.0–based production. Machine learning and deep learning play a critical role in developing intelligent systems for descriptive, diagnostic, and predictive analytics for machine tools and process health monitoring. This paper reviews the opportunities and challenges of deep learning (DL) for intelligent machining and tool monitoring. The components of an intelligent monitoring framework are introduced. The main advantages and disadvantages of machine learning (ML) models are presented and compared with those of deep models. The main DL models, including autoencoders, deep belief networks, convolutional neural networks (CNNs), and recurrent neural networks (RNNs), were discussed, and their applications in intelligent machining and tool condition monitoring were reviewed. The opportunities of data-driven smart manufacturing approach applied to intelligent machining were discussed to be (1) automated feature engineering, (2) handling big data, (3) handling high-dimensional data, (4) avoiding sensor redundancy, (5) optimal sensor fusion, and (6) offering hybrid intelligent models. Finally, the data-driven challenges in smart manufacturing, including the challenges associated with the data size, data nature, model selection, and process uncertainty, were discussed, and the research gaps were outlined.

Similar content being viewed by others

Availability of data and materials

Not applicable. There is no data associated with this manuscript.

References

Zhong RY, Ge W (2018) Internet of things enabled manufacturing: a review. Int J Agile Syst Manag 11(2):126–154

Yang C, Shen W, Wang X (2018) The internet of things in manufacturing: key issues and potential applications. IEEE Syst Man Cybern Mag 4(1):6–15

Yang C, Shen W, Wang X (2016, May) Applications of Internet of Things in manufacturing. In: 2016 IEEE 20th International Conference on Computer Supported Cooperative Work in Design (CSCWD). IEEE, pp 670–675

Siderska J, Jadaan KS (2018) Cloud manufacturing: a service-oriented manufacturing paradigm. A review paper. Eng Manag Produc Serv 10(1):22–31

Lee J, Davari H, Singh J, Pandhare V (2018) Industrial artificial intelligence for Industry 4.0-based manufacturing systems. Manuf Lett 18:20–23

Li BH, Hou BC, Yu WT, Lu XB, Yang CW (2017) Applications of artificial intelligence in intelligent manufacturing: a review. Frontiers Inf Technol Electron Eng 18(1):86–96

Kumar SL (2017) State of the art-intense review on artificial intelligence systems application in process planning and manufacturing. Eng Appl Artif Intell 65:294–329

Tao F, Qi Q, Liu A, Kusiak A (2018) Data-driven smart manufacturing. J Manuf Syst 48:157–169

Lin YC, Wu KD, Shih WC, Hsu PK, Hung JP (2020) Prediction of surface roughness based on cutting parameters and machining vibration in end milling using regression method and artificial neural network. Appl Sci 10(11):3941

Bhogal SS, Sindhu C, Dhami SS, Pabla BS (2015) Minimization of surface roughness and tool vibration in CNC milling operation. J Opt 2015:1–13. https://doi.org/10.1155/2015/192030

Silge, M., & Sattel, T. (2018). Design of contactlessly powered and piezoelectrically actuated tools for non-resonant vibration assisted milling. In Actuators (Vol. 7, 2, p. 19). Multidisciplinary Digital Publishing Institute.

Omair M, Sarkar B, Cárdenas-Barrón LE (2017) Minimum quantity lubrication and carbon footprint: a step towards sustainability. Sustainability 9(5):714

Wang B, Liu Z (2018) Influences of tool structure, tool material and tool wear on machined surface integrity during turning and milling of titanium and nickel alloys: a review. Int J Adv Manuf Technol 98(5-8):1925–1975

Yeganefar A, Niknam SA, Asadi R (2019) The use of support vector machine, neural network, and regression analysis to predict and optimize surface roughness and cutting forces in milling. Int J Adv Manuf Technol 105(1):951–965

Nasir V, Mohammadpanah A, Cool J (2018) The effect of rotation speed on the power consumption and cutting accuracy of guided circular saw: experimental measurement and analysis of saw critical and flutter speeds. Wood Mater Sci Eng 15(3):1–7

Nasir V, Cool J (2020) Intelligent wood machining monitoring using vibration signals combined with self-organizing maps for automatic feature selection. Int J Adv Manuf Technol 108:1811–1825. https://doi.org/10.1007/s00170-020-05505-5

Nasir V, Cool J (2019) Optimal power consumption and surface quality in the circular sawing process of Douglas-fir wood. Eur J Wood Wood Produc 77(4):609–617

Serin G, Sener B, Ozbayoglu AM, Unver HO (2020) Review of tool condition monitoring in machining and opportunities for deep learning. Int J Adv Manuf Technol:1–22

Wang M, Wang J (2012) CHMM for tool condition monitoring and remaining useful life prediction. Int J Adv Manuf Technol 59(5-8):463–471

Brecher C, Esser M, Witt S (2009) Interaction of manufacturing process and machine tool. CIRP Ann 58(2):588–607

Chen W, Liu H, Sun Y, Yang K, Zhang J (2017) A novel simulation method for interaction of machining process and machine tool structure. Int J Adv Manuf Technol 88(9-12):3467–3474

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376

Hegab HA, Darras B, Kishawy HA (2018) Towards sustainability assessment of machining processes. J Clean Prod 170:694–703

Mia M, Gupta MK, Singh G, Królczyk G, Pimenov DY (2018) An approach to cleaner production for machining hardened steel using different cooling-lubrication conditions. J Clean Prod 187:1069–1081

Zhou Z, Yao B, Xu W, Wang L (2017) Condition monitoring towards energy-efficient manufacturing: a review. Int J Adv Manuf Technol 91(9-12):3395–3415

Said Z, Gupta M, Hegab H, Arora N, Khan AM, Jamil M, Bellos E (2019) A comprehensive review on minimum quantity lubrication (MQL) in machining processes using nano-cutting fluids. Int J Adv Manuf Technol 105(5-6):2057–2086

Nasir V, Cool J (2020) Characterization, optimization, and acoustic emission monitoring of airborne dust emission during wood sawing. Int J Adv Manuf Technol 109(9):2365–2375. https://doi.org/10.1007/s00170-020-05842-5

Licow R, Chuchala D, Deja M, Orlowski KA, Taube P (2020) Effect of pine impregnation and feed speed on sound level and cutting power in wood sawing. J Clean Prod 272:122833

Teti R, Jemielniak K, O’Donnell G, Dornfeld D (2010) Advanced monitoring of machining operations. CIRP Ann 59(2):717–739

Abellan-Nebot JV, Subirón FR (2010) A review of machining monitoring systems based on artificial intelligence process models. Int J Adv Manuf Technol 47(1-4):237–257

Zhu K, San Wong Y, Hong GS (2009) Wavelet analysis of sensor signals for tool condition monitoring: a review and some new results. Int J Mach Tools Manuf 49(7-8):537–553

Lauro CH, Brandão LC, Baldo D, Reis RA, Davim JP (2014) Monitoring and processing signal applied in machining processes–a review. Measurement 58:73–86

Kusiak A (2019) Fundamentals of smart manufacturing: a multi-thread perspective. Annu Rev Control 47:214–220

Kim DH, Kim TJ, Wang X, Kim M, Quan YJ, Oh JW et al (2018) Smart machining process using machine learning: a review and perspective on machining industry. Int J Precis Eng Manuf Green Technol 5(4):555–568

Ayvaz S, Alpay K (2021) Predictive maintenance system for production lines in manufacturing: a machine learning approach using IoT data in real-time. Expert Syst Appl 173:114598

Morariu C, Morariu O, Răileanu S, Borangiu T (2020) Machine learning for predictive scheduling and resource allocation in large scale manufacturing systems. Comput Ind 120:103244

Adi E, Anwar A, Baig Z, Zeadally S (2020) Machine learning and data analytics for the IoT. Neural Comput & Applic 32:16205–16233

Peng ZK, Chu FL (2004) Application of the wavelet transform in machine condition monitoring and fault diagnostics: a review with bibliography. Mech Syst Signal Process 18(2):199–221

Chandrashekar G, Sahin F (2014) A survey on feature selection methods. Comput Electr Eng 40(1):16–28

Nasir V, Cool J, Sassani F (2019) Acoustic emission monitoring of sawing process: artificial intelligence approach for optimal sensory feature selection. Int J Adv Manuf Technol 102(9-12):4179–4197. https://doi.org/10.1007/s00170-019-03526-3

Sick B (2002) On-line and indirect tool wear monitoring in turning with artificial neural networks: a review of more than a decade of research. Mech Syst Signal Process 16(4):487–546

Roth JT, Djurdjanovic D, Yang X, Mears L, Kurfess T (2010) Quality and inspection of machining operations: tool condition monitoring. J Manuf Sci Eng 132(4)

Stavropoulos P, Papacharalampopoulos A, Vasiliadis E, Chryssolouris G (2016) Tool wear predictability estimation in milling based on multi-sensorial data. Int J Adv Manuf Technol 82(1-4):509–521

Nasir V, Kooshkbaghi M, Cool J, Sassani F (2020) Cutting tool temperature monitoring in circular sawing: measurement and multi-sensor feature fusion-based prediction. Int J Adv Manuf Technol 112:2413–2424. https://doi.org/10.1007/s00170-020-06473-6

Nasir V, Cool J, Sassani F (2019) Intelligent machining monitoring using sound signal processed with the wavelet method and a self-organizing neural network. IEEE Robot Autom Lett 4(4):3449–3456

Bhuiyan MSH, Choudhury IA, Dahari M (2014) Monitoring the tool wear, surface roughness and chip formation occurrences using multiple sensors in turning. J Manuf Syst 33(4):476–487

Ahmadi H, Dumont G, Sassani F, Tafreshi R (2003) Performance of informative wavelets for classification and diagnosis of machine faults. Int J Wavelets Multiresolution Inf Process 1(03):275–289

Tafreshi R, Sassani F, Ahmadi H, Dumont G (2009) An approach for the construction of entropy measure and energy map in machine fault diagnosis. J Vib Acoust 131(2)

Wuest T, Weimer D, Irgens C, Thoben KD (2016) Machine learning in manufacturing: advantages, challenges, and applications. Produc Manuf Res 4(1):23–45

Hermann G (1990) Artificial intelligence in monitoring and the mechanics of machining. Comput Ind 14(1-3):131–135

Rangwala SS (1987) Integration of sensors via neural networks for detection of tool wear states. Proc Winter Annu Meet ASME 25:109–120

Dornfeld DA, DeVries MF (1990) Neural network sensor fusion for tool condition monitoring. CIRP Ann 39(1):101–105

Rangwala, S., & Dornfeld, D. (1990). Sensor integration using neural networks for intelligent tool condition monitoring, 219-228.

Park KS, Kim SH (1998) Artificial intelligence approaches to determination of CNC machining parameters in manufacturing: a review. Artif Intell Eng 12(1-2):127–134

Dimla DE Jr, Lister PM, Leighton NJ (1997) Neural network solutions to the tool condition monitoring problem in metal cutting—a critical review of methods. Int J Mach Tools Manuf 37(9):1219–1241

Ademujimi TT, Brundage MP, Prabhu VV (2017, September) A review of current machine learning techniques used in manufacturing diagnosis. In: IFIP International Conference on Advances in Production Management Systems. Springer, Cham, pp 407–415

Panchal G, Ganatra A, Shah P, Panchal D (2011) Determination of over-learning and over-fitting problem in backpropagation neural network. Int J Soft Comput 2(2):40–51

Montavon, G., Orr, G., & Müller, K. R. (Eds.). (2012). Neural networks: tricks of the trade (Vol. 7700). springer.

Lopez C (1999) Looking inside the ANN “black box”: classifying individual neurons as outlier detectors. In: IJCNN'99. International Joint Conference on Neural Networks. Proceedings (Cat. No. 99CH36339, vol 2. IEEE, pp 1185–1188

Palczewska A, Palczewski J, Robinson RM, Neagu D (2014) Interpreting random forest classification models using a feature contribution method. In: Integration of reusable systems. Springer, Cham, pp 193–218

Nasir V, Kooshkbaghi M, Cool J (2020) Sensor fusion and random forest modeling for identifying frozen and green wood during lumber manufacturing. Manuf Lett 26:53–58

Bengio Y, Courville A, Vincent P (2013) Representation learning: a review and new perspectives. IEEE Trans Pattern Anal Mach Intell 35(8):1798–1828

Faust O, Hagiwara Y, Hong TJ, Lih OS, Acharya UR (2018) Deep learning for healthcare applications based on physiological signals: a review. Comput Methods Prog Biomed 161:1–13

Miotto R, Wang F, Wang S, Jiang X, Dudley JT (2018) Deep learning for healthcare: review, opportunities and challenges. Brief Bioinform 19(6):1236–1246

LeCun Y, Bengio Y, Hinton G (2015) Deep learning. Nature 521(7553):436–444

Khan S, Yairi T (2018) A review on the application of deep learning in system health management. Mech Syst Signal Process 107:241–265

Wang J, Ma Y, Zhang L, Gao RX, Wu D (2018) Deep learning for smart manufacturing: methods and applications. J Manuf Syst 48:144–156

Zhang N, Ding S, Zhang J, Xue Y (2018) An overview on restricted Boltzmann machines. Neurocomputing 275:1186–1199

Fu Y, Zhang Y, Qiao H, Li D, Zhou H, Leopold J (2015) Analysis of feature extracting ability for cutting state monitoring using deep belief networks. Procedia Cirp 31(Suppl. C):29–34

Chen Y, Jin Y, Jiri G (2018) Predicting tool wear with multi-sensor data using deep belief networks. Int J Adv Manuf Technol 99(5-8):1917–1926

Yu Y, Si X, Hu C, Zhang J (2019) A review of recurrent neural networks: LSTM cells and network architectures. Neural Comput 31(7):1235–1270

Xu X, Tao Z, Ming W, An Q, Chen M (2020) Intelligent monitoring and diagnostics using a novel integrated model based on deep learning and multi-sensor feature fusion. Measurement 165:108086

Zhao R, Yan R, Chen Z, Mao K, Wang P, Gao RX (2019) Deep learning and its applications to machine health monitoring. Mech Syst Signal Process 115:213–237

Hahn TV, Mechefske CK (2021) Self-supervised learning for tool wear monitoring with a disentangled-variational-autoencoder. Int J Hydromechatron 4(1):69–98

Xiangyu Z, Lilan L, Xiang W, Bowen F (2021) Tool wear online monitoring method based on DT and SSAE-PHMM. J Comput Inf Sci Eng 21(3):034501

Dou J, Xu C, Jiao S, Li B, Zhang J, Xu X (2020) An unsupervised online monitoring method for tool wear using a sparse auto-encoder. Int J Adv Manuf Technol 106(5):2493–2507

Kim J, Lee H, Jeon JW, Kim JM, Lee HU, Kim S (2020) Stacked auto-encoder based CNC tool diagnosis using discrete wavelet transform feature extraction. Processes 8(4):456

Moldovan OG, Dzitac S, Moga I, Vesselenyi T, Dzitac I (2017) Tool-wear analysis using image processing of the tool flank. Symmetry 9(12):296

Ochoa LEE, Quinde IBR, Sumba JPC, Guevara AV Jr, Morales-Menendez R (2019) New approach based on autoencoders to monitor the tool wear condition in HSM. IFAC-PapersOnLine 52(11):206–211

Proteau A, Zemouri R, Tahan A, Thomas M (2020) Dimension reduction and 2D-visualization for early change of state detection in a machining process with a variational autoencoder approach. Int J Adv Manuf Technol 111(11):3597–3611

Ou J, Li H, Huang G, Zhou Q (2020) A novel order analysis and stacked sparse auto-encoder feature learning method for milling tool wear condition monitoring. Sensors 20(10):2878

Ou J, Li H, Huang G, Yang G (2021) Intelligent analysis of tool wear state using stacked denoising autoencoder with online sequential-extreme learning machine. Measurement 167:108153

Shi C, Panoutsos G, Luo B, Liu H, Li B, Lin X (2018) Using multiple-feature-spaces-based deep learning for tool condition monitoring in ultraprecision manufacturing. IEEE Trans Ind Electron 66(5):3794–3803

He Z, Shi T, Xuan J, Li T (2021) Research on tool wear prediction based on temperature signals and deep learning. Wear 478:203902

Shi C, Luo B, He S, Li K, Liu H, Li B (2019) Tool wear prediction via multidimensional stacked sparse autoencoders with feature fusion. IEEE Trans Ind Informatics 16(8):5150–5159

Sun C, Ma M, Zhao Z, Tian S, Yan R, Chen X (2018) Deep transfer learning based on sparse autoencoder for remaining useful life prediction of tool in manufacturing. IEEE Trans Ind Informatics 15(4):2416–2425

Dun Y, Zhus L, Yan B, Wang S (2021) A chatter detection method in milling of thin-walled TC4 alloy workpiece based on auto-encoding and hybrid clustering. Mech Syst Signal Process 158:107755

Yu J, Liu G (2020) Knowledge-based deep belief network for machining roughness prediction and knowledge discovery. Comput Ind 121:103262

Brili N, Ficko M, Klančnik S (2021) Automatic identification of tool wear based on thermography and a convolutional neural network during the turning process. Sensors 21(5):1917

Lee CH, Jwo JS, Hsieh HY, Lin CS (2020) An intelligent system for grinding wheel condition monitoring based on machining sound and deep learning. IEEE Access 8:58279–58289

Gouarir A, Martínez-Arellano G, Terrazas G, Benardos P, Ratchev SJPC (2018) In-process tool wear prediction system based on machine learning techniques and force analysis. Procedia CIRP 77:501–504

Cao XC, Chen BQ, Yao B, He WP (2019) Combining translation-invariant wavelet frames and convolutional neural network for intelligent tool wear state identification. Comput Ind 106:71–84

Song K, Wang M, Liu L, Wang C, Zan T, Yang B (2020) Intelligent recognition of milling cutter wear state with cutting parameter independence based on deep learning of spindle current clutter signal. Int J Adv Manuf Technol 109(3):929–942

Terrazas G, Martínez-Arellano G, Benardos P, Ratchev S (2018) Online tool wear classification during dry machining using real time cutting force measurements and a CNN approach. J Manuf Mater Process 2(4):72

Martínez-Arellano G, Terrazas G, Ratchev S (2019) Tool wear classification using time series imaging and deep learning. Int J Adv Manuf Technol 104(9):3647–3662

Zheng, H., & Lin, J. (2019). A deep learning approach for high speed machining tool wear monitoring. In 2019 3rd International Conference on Robotics and Automation Sciences (ICRAS) (pp. 63-68). IEEE.

Cao X, Chen B, Yao B, Zhuang S (2019) An intelligent milling tool wear monitoring methodology based on convolutional neural network with derived wavelet frames coefficient. Appl Sci 9(18):3912

Mamledesai H, Soriano MA, Ahmad R (2020) A qualitative tool condition monitoring framework using convolution neural network and transfer learning. Appl Sci 10(20):7298

Zhi G, He D, Sun W, Yuqing Z, Pan X, Gao C (2021) An edge-labeling graph neural network method for tool wear condition monitoring using wear image with small samples. Meas Sci Technol 32:064006

Xu X, Wang J, Zhong B, Ming W, Chen M (2021) Deep learning-based tool wear prediction and its application for machining process using multi-scale feature fusion and channel attention mechanism. Measurement 177:109254

Zhang X, Wang S, Li W, Lu X (2021) Heterogeneous sensors-based feature optimisation and deep learning for tool wear prediction. Int J Adv Manuf Technol:1–25

Ambadekar PK, Choudhari CM (2020) CNN based tool monitoring system to predict life of cutting tool. SN Appl Sci 2(5):1–11

Xu X, Wang J, Ming W, Chen M, An Q (2021) In-process tap tool wear monitoring and prediction using a novel model based on deep learning. Int J Adv Manuf Technol 112:453–466

Li P, Jia X, Feng J, Zhu F, Miller M, Chen LY, Lee J (2020) A novel scalable method for machine degradation assessment using deep convolutional neural network. Measurement 151:107106

Huang Z, Zhu J, Lei J, Li X, Tian F (2019) Tool wear predicting based on multi-domain feature fusion by deep convolutional neural network in milling operations. J Intell Manuf:1–14

Huang Z, Zhu J, Lei J, Li X, Tian F (2019) Tool wear predicting based on multisensory raw signals fusion by reshaped time series convolutional neural network in manufacturing. IEEE Access 7:178640–178651

Wu X, Liu Y, Zhou X, Mou A (2019) Automatic identification of tool wear based on convolutional neural network in face milling process. Sensors 19(18):3817

Tran MQ, Liu MK, Tran QV (2020) Milling chatter detection using scalogram and deep convolutional neural network. Int J Adv Manuf Technol 107(3):1505–1516

Zhu W, Zhuang J, Guo B, Teng W, Wu F (2020) An optimized convolutional neural network for chatter detection in the milling of thin-walled parts. Int J Adv Manuf Technol 106(9):3881–3895

Rifai AP, Aoyama H, Tho NH, Dawal SZM, Masruroh NA (2020) Evaluation of turned and milled surfaces roughness using convolutional neural network. Measurement 161:107860

Liu Y, Hu X, Jin J (2019) Remaining useful life prediction of cutting tools based on deep adversarial transfer learning. In: Proceedings of the 2019 8th International Conference on Computing and Pattern Recognition, pp 434–439

Liu H, Liu Z, Jia W, Lin X, Zhang S (2020) A novel transformer-based neural network model for tool wear estimation. Meas Sci Technol 31(6):065106

Zhao R, Wang J, Yan R, Mao K (2016) Machine health monitoring with LSTM networks. In: 2016 10th international conference on sensing technology (ICST), IEEE, pp 1–6

Aghazadeh F, Tahan AS, Thomas M (2019, July) Tool condition monitoring method in milling process using wavelet transform and long short-term memory. In Surveillance, Vishno and AVE conferences

Cai W, Zhang W, Hu X, Liu Y (2020) A hybrid information model based on long short-term memory network for tool condition monitoring. J Intell Manuf 31(6):1497–1510

Zhou JT, Zhao X, Gao J (2019) Tool remaining useful life prediction method based on LSTM under variable working conditions. Int J Adv Manuf Technol 104(9):4715–4726

Gugulothu N, Tv V, Malhotra P, Vig L, Agarwal P, Shroff G (2017) Predicting remaining useful life using time series embeddings based on recurrent neural networks. arXiv preprint arXiv 1709:01073

Yu W, Kim IY, Mechefske C (2019) Remaining useful life estimation using a bidirectional recurrent neural network based autoencoder scheme. Mech Syst Signal Process 129:764–780

Wu X, Li J, Jin Y, Zheng S (2020) Modeling and analysis of tool wear prediction based on SVD and BiLSTM. Int J Adv Manuf Technol 106(9):4391–4399

Wang, J., Yan, J., Li, C., Gao, R. X., & Zhao, R. (2019). Deep heterogeneous GRU model for predictive analytics in smart manufacturing: application to tool wear prediction. Comput Ind, 111, 1-14, 1.

Marani M, Zeinali M, Songmene V, Mechefske CK (2021) Tool wear prediction in high-speed turning of a steel alloy using long short-term memory modelling. Measurement 177:109329

Vashisht RK, Peng Q (2021) Online chatter detection for milling operations using LSTM neural networks assisted by motor current signals of ball screw drives. J Manuf Sci Eng 143(1)

Guo W, Wu C, Ding Z, Zhou Q (2021) Prediction of surface roughness based on a hybrid feature selection method and long short-term memory network in grinding. Int J Adv Manuf Technol 112(9):2853–2871

Chen Q, Xie Q, Yuan Q, Huang H, Li Y (2019) Research on a real-time monitoring method for the wear state of a tool based on a convolutional bidirectional LSTM model. Symmetry 11(10):1233

Ma J, Luo D, Liao X, Zhang Z, Huang Y, Lu J (2021) Tool wear mechanism and prediction in milling TC18 titanium alloy using deep learning. Measurement 173:108554

Zhang X, Lu X, Li W, Wang S (2021) Prediction of the remaining useful life of cutting tool using the Hurst exponent and CNN-LSTM. Int J Adv Manuf Technol 112(7):2277–2299

An Q, Tao Z, Xu X, El Mansori M, Chen M (2020) A data-driven model for milling tool remaining useful life prediction with convolutional and stacked LSTM network. Measurement 154:107461

Babu GS, Zhao P, Li XL (2016) Deep convolutional neural network based regression approach for estimation of remaining useful life. In: International conference on database systems for advanced applications. Springer, Cham, pp 214–228

Qiao H, Wang T, Wang P (2020) A tool wear monitoring and prediction system based on multiscale deep learning models and fog computing. Int J Adv Manuf Technol 108:2367–2384

Niu, J., Liu, C., Zhang, L., & Liao, Y. (2019). Remaining useful life prediction of machining tools by 1D-CNN LSTM network. In 2019 IEEE Symposium Series on Computational Intelligence (SSCI) (pp. 1056-1063). IEEE.

Zhao R, Yan R, Wang J, Mao K (2017) Learning to monitor machine health with convolutional bi-directional LSTM networks. Sensors 17(2):273

Qiao H, Wang T, Wang P, Qiao S, Zhang L (2018) A time-distributed spatiotemporal feature learning method for machine health monitoring with multi-sensor time series. Sensors 18(9):2932

Wang B, Lei Y, Yan T, Li N, Guo L (2020) Recurrent convolutional neural network: a new framework for remaining useful life prediction of machinery. Neurocomputing 379:117–129

Zhang X, Lu X, Li W, Wang S (2021) Prediction of the remaining useful life of cutting tool using the Hurst exponent and CNN-LSTM. Int J Adv Manuf Technol:1–23

Misaka T, Herwan J, Kano S, Sawada H, Furukawa Y (2020) Deep neural network-based cost function for metal cutting data assimilation. Int J Adv Manuf Technol 107(1):385–398

Qiao H, Wang T, Wang P, Zhang L, Xu M (2019) An adaptive weighted multiscale convolutional neural network for rotating machinery fault diagnosis under variable operating conditions. IEEE Access 7:118954–118964

Jiang G, He H, Yan J, Xie P (2018) Multiscale convolutional neural networks for fault diagnosis of wind turbine gearbox. IEEE Trans Ind Electron 66(4):3196–3207

Li DC, Wen IH, Chen WC (2016) A novel data transformation model for small data-set learning. Int J Prod Res 54(24):7453–7463

Kusiak A (2017 Apr) Smart manufacturing must embrace big data. Nature. 544(7648):23–25

Taiebat M, Sassani F (2017 Sep) Distinguishing sensor faults from system faults by utilizing minimum sensor redundancy. Trans Can Soc Mech Eng 41(3):469–487

Nasir V, Cool J (2020) A review on wood machining: characterization, optimization, and monitoring of the sawing process. Wood Material Sci Eng 15(1):1–16

Diez-Olivan A, Del Ser J, Galar D, Sierra B (2019 Oct 1) Data fusion and machine learning for industrial prognosis: trends and perspectives towards Industry 4.0. Inf Fusion 50:92–111

Ferguson MK, Ronay AK, Lee YTT, Law KH (2018) Detection and segmentation of manufacturing defects with convolutional neural networks and transfer learning. Smart Sustain Manuf Systems 2:20180033. https://doi.org/10.1520/SSMS20180033

Imoto K, Nakai T, Ike T, Haruki K, Sato Y (2018) A CNN-based transfer learning method for defect classification in semiconductor manufacturing. In: 2018 International Symposium on Semiconductor Manufacturing (ISSM). IEEE, pp 1–3

Wang P, Gao RX (2020) Transfer learning for enhanced machine fault diagnosis in manufacturing. CIRP Ann 69(1):413–416

Caggiano A (2018) Cloud-based manufacturing process monitoring for smart diagnosis services. Int J Comput Integr Manuf 31(7):612–623

Funding

Not applicable

Author information

Authors and Affiliations

Contributions

Conceptualization: Vahid Nasir (V. N.) and Farrokh Sassani (F. S.); literature review (V. N.); manuscript writing (V. N. and F. S.); editing and final review (F. S.).

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent to publish

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nasir, V., Sassani, F. A review on deep learning in machining and tool monitoring: methods, opportunities, and challenges. Int J Adv Manuf Technol 115, 2683–2709 (2021). https://doi.org/10.1007/s00170-021-07325-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-021-07325-7