Abstract

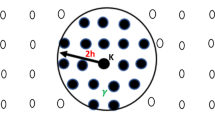

Abrasive waterjet machining has been widely used because of flexibility, but the cutting accuracy is difficult to ensure due to the lack of dynamic analysis in the forming process of the kerf. In this paper, a coupled SPH-DEM-FEM method is proposed to predict the cutting qualities of the abrasive water jet machining under different process parameters and reveal the mechanism of the kerf formation. Compared with previous simulation methods, the new simulation method has advantages in the simulations for long-term water jet cutting. The abrasive particles and waterjet particles are continuously generated during calculations to reduce the model size and raise the calculation efficiency. The discrete element method (DEM) is utilized to characterize the flow of abrasive particles, which follows the Gaussian distribution. The collisions of non-spherical particles are concerned by the friction factors. The water flow with large deformation is expressed in the smoothed particle hydrodynamics (SPH) method. And the erosion contact is set between particles and the target. Finally, experiments are conducted to verify the authenticity of the simulation model. The cutting depths and kerf top widths obtained by the simulations are consistent with the experimental results.

Similar content being viewed by others

References

Liu HT (2017) Precision machining of advanced materials with waterjets. IOP Conf Ser Mater Sci Eng 164:012008. https://doi.org/10.1088/1757-899x/164/1/012008

Wang F, Ji K, Guo Z (2020) Microstructural analysis of failure progression for coated carbide tools during high-speed milling of Ti-6Al-4V. Wear 456-457:203356. https://doi.org/10.1016/j.wear.2020.203356

Liu X, Liang Z, Wen G, Yuan X (2019) Waterjet machining and research developments: a review. Int J Adv Manuf Technol 102:1257–1335. https://doi.org/10.1007/s00170-018-3094-3

Li X, Ruan X, Zou J, Long X, Chen Z (2020) Experiment on carbon fiber–reinforced plastic cutting by abrasive waterjet with specific emphasis on surface morphology. Int J Adv Manuf Technol 107(1–2):145–156. https://doi.org/10.1007/s00170-020-05053-y

Hashish M (1991) Optimization factors in abrasive-waterjet machining. J Eng Ind 113(1):29–37

Hlavacova IM, Geryk V (2017) Abrasives for waterjet cutting of high-strength and thick hard materials. Int J Adv Manuf Technol 90(5):1217–1224. https://doi.org/10.1007/s00170-016-9462-y

Yu Y, Sun T, Yuan Y, Gao H, Wang X (2020) Experimental investigation into the effect of abrasive process parameters on the cutting performance for abrasive waterjet technology: a case study. Int J Adv Manuf Technol 107(5–6):2757–2765. https://doi.org/10.1007/s00170-020-05183-3

Lebar A, Junkar M (2004) Simulation of abrasive water jet cutting process: part 1. Unit event approach. Model Simul Mater Sci Eng 12(6):1159–1170

Liang Z, Xie B, Liao S, Zhou J (2015) Concentration degree prediction of AWJ grinding effectiveness based on turbulence characteristics and the improved ANFIS. Int J Adv Manuf Technol 80(5–8):887–905. https://doi.org/10.1007/s00170-015-7027-0

Lv Z, Hou R, Chen X, Huang C (2019) Numerical research on erosion involved in ultrasonic-assisted abrasive waterjet machining. Int J Adv Manuf Technol 103:617–630. https://doi.org/10.1007/s00170-019-03584-7

Feng L, Liu GR, Li Z, Dong X, Du M (2018) Study on the effects of abrasive particle shape on the cutting performance of Ti-6Al-4V materials based on the SPH method. Int J Adv Manuf Technol 101(9–12):3167–3182. https://doi.org/10.1007/s00170-018-3119-y

Pozzetti G, Peters B (2018) A numerical approach for the evaluation of particle-induced erosion in an abrasive waterjet focusing tube. Powder Technol 333:229–242. https://doi.org/10.1016/j.powtec.2018.04.006

Qiang Z, Wu M, Miao X, Sawhney R (2018) CFD research on particle movement and nozzle wear in the abrasive water jet cutting head. Int J Adv Manuf Technol 95(9–12):4091–4100. https://doi.org/10.1007/s00170-017-1504-6

Nyaboro JN, Ahmed MA, El-Hofy H, El-Hofy M (2018) Numerical and experimental characterization of kerf formation in abrasive waterjet machining. In: ASME International Mechanical Engineering Congress and Exposition, vol 52019. American Society of Mechanical Engineers, p V002T02A050. https://doi.org/10.1115/IMECE2018-88617

Liu H, Wang J, Kelson N, Brown RJ (2004) A study of abrasive waterjet characteristics by CFD simulation. J Mater Process Technol 153-154:488–493. https://doi.org/10.1016/j.jmatprotec.2004.04.037

Eltobgy MS, Ng E, Elbestawi MA (2005) Finite element modeling of erosive wear. Int J Mach Tools Manuf 45(11):1337–1346. https://doi.org/10.1016/j.ijmachtools.2005.01.007

Anwar S, Axinte DA, Becker AA (2013) Finite element modelling of abrasive waterjet milled footprints. J Mater Process Technol 213(2):180–193. https://doi.org/10.1016/j.jmatprotec.2012.09.006

Jianming W, Na G, Wenjun G (2010) Abrasive waterjet machining simulation by SPH method. Int J Adv Manuf Technol 50(1–4):227–234. https://doi.org/10.1007/s00170-010-2521-x

Feng Y, Jianming W, Feihong L (2011) Numerical simulation of single particle acceleration process by SPH coupled FEM for abrasive waterjet cutting. Int J Adv Manuf Technol 59(1–4):193–200. https://doi.org/10.1007/s00170-011-3495-z

Wenjun G, Jianming W, Na G (2010) Numerical simulation for abrasive water jet machining based on ALE algorithm. Int J Adv Manuf Technol 53(1–4):247–253. https://doi.org/10.1007/s00170-010-2836-7

Anwar S, Axinte DA, Becker AA (2013) Finite element modelling of overlapping abrasive waterjet milled footprints. Wear 303(1–2):426–436. https://doi.org/10.1016/j.wear.2013.03.018

Lozano Torrubia P, Axinte DA, Billingham J (2015) Stochastic modelling of abrasive waterjet footprints using finite element analysis. Int J Mach Tools Manuf 95:39–51. https://doi.org/10.1016/j.ijmachtools.2015.05.001

Dong X, Li Z, Jiang C, Liu Y (2019) Smoothed particle hydrodynamics (SPH) simulation of impinging jet flows containing abrasive rigid bodies. Comput Part Mech 6(3):479–501

Xu J, Wang J (2013) Node to node contacts for SPH applied to multiple fluids with large density ratio. In: Proceedings of the 9th European LS-DYNA Users’ Conference, Manchester, UK, pp 2–4

Yreux E (2018) Fluid flow modeling with SPH in LS-DYNA®. In: Proceedings of the 15th International LS_DYNA Users Conference, Dearborn, MI, USA

Flores-Johnson EA, Wang S, Maggi F, El Zein A, Gan Y, Nguyen GD, Shen L (2016) Discrete element simulation of dynamic behaviour of partially saturated sand. Int J Mech Mater Des 12(4):495–507. https://doi.org/10.1007/s10999-016-9350-5

Karajan N, Han Z, Teng H, Wang J (2014) On the parameter estimation for the discrete-element method in LS-DYNA®. In: Proceedings of the 13th International LS_DYNA Users Conference, Dearborn, MI, USA, pp 8–10

Karajan N, Han Z, Ten H, Wang J (2013) Interaction possibilities of bonded and loose particles in LS-DYNA. In: Proceedings of the 9th European LS-DYNA Users’ Conference, Manchester, UK, no 1, pp 1–27

LSTC (2019) LS-DYNA keyword user's manual, vol I. Livemore Software Technology Corporation, Livermore

Tokura S (2015) Validation of fluid analysis capabilities in LS-DYNA Based on experimental eesult. In: Proceedings of the 10th European LS-DYNA Users’ Conference, Würzburg

Wang F, Wang R, Zhou W, Chen G (2017) Numerical simulation and experimental verification of the rock damage field under particle water jet impacting. Int J Impact Eng 102:169–179. https://doi.org/10.1016/j.ijimpeng.2016.12.019

Johnson GR, Cook WH (1985) Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng Fract Mech 21(1):31–48. https://doi.org/10.1016/0013-7944(85)90052-9

Crocker L (2017) Good practice guide to the application of finite element analysis to erosion modelling. National Physical Laboratory, Teddington

Momber AW, Kovacevic R (2012) Principles of abrasive water jet machining. Springer Science & Business Media, London

Eitobgy M, Ng EG, Elbestawi MA (2005) Modelling of abrasive waterjet machining: a new approach. CIRP Ann 54(1):285–288. https://doi.org/10.1016/s0007-8506(07)60104-8

Chen FL, Siores E (2001) The effect of cutting jet variation on striation formation in abrasive water jet cutting. Int J Mach Tools Manuf 41(10):1479–1486. https://doi.org/10.1016/S0890-6955(01)00013-X

Schwartzentruber J, Spelt JK, Papini M (2018) Modelling of delamination due to hydraulic shock when piercing anisotropic carbon-fiber laminates using an abrasive waterjet. Int J Mach Tools Manuf 132:81–95. https://doi.org/10.1016/j.ijmachtools.2018.05.001

Funding

This work was supported by the National Natural Science Foundation of China (No. 51805476).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Du, M., Wang, H., Dong, H. et al. Numerical research on kerf characteristics of abrasive waterjet machining based on the SPH-DEM-FEM approach. Int J Adv Manuf Technol 111, 3519–3533 (2020). https://doi.org/10.1007/s00170-020-06340-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-020-06340-4