Abstract

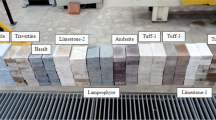

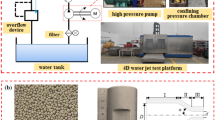

The paper discusses abrasive water-jet cutting of hard-to-cut materials represented by high carbon steel DIN norm No.1.2436 (CSN EN 19437) plate 61–mm-thick and high-strength concrete cube sized 150 mm. Four relatively hard minerals with different densities not commonly used in water-jet technology were tested and their cutting results compared to those of three types of almandine garnets: Ukraine, Australian, and sorted Australian. Cutting efficiency was evaluated utilizing declination angle. Dependence of cutting efficiency on abrasive density and hardness was investigated. High density of abrasive appeared to be disadvantageous in our experiment. Cutting efficiency dependence on hardness exhibited nearly linear course, the increase was much more significant for concrete than for steel. Evaluation of experimental results led to the conclusion that cutting mechanism in case of very thick samples is different from common abrasive waterjet cutting. The limit declination angle for thick samples is significantly smaller, it was found to be approximately 22°. This result represents entirely new finding. The most promising finding from the economical point of view appears to be behavior of corundum, when cutting concrete. Our experimental results promise 20 % increase in cutting speed for brittle materials.

Similar content being viewed by others

References

Chatterjee P, Chakraborty S (2013) Nontraditional machining processes selection using evaluation of mixed data method. Int J Adv Manuf Tech 68(5–8):1613–1626

Krajcarz D (2014) Comparison metal water jet cutting with laser and plasma cutting. Procedia Engineering 69:838–843

Marcon A, Melkote SN, Castle J, Sanders DG, Yoda M (2016) Effect of jet velocity in co-flow water cavitation jet peening. Wear 360:38–50

Saleem M, Zitoune R, El Sawi I, Bougherara H (2015) Role of the surface quality on the mechanical behavior of CFRP bolted composite joints. Int J Fatigue 80:246–256

Hashish M (2015) Waterjet machining process. In: Nee AYC (ed) Handbook of manufacturing engineering and technology. Springer, London, pp. 1651–1686

Hlaváč L (1994) Physical model of jet—abrasive interaction. In: Rakowski Z (ed) Geomechanics 93. A.A.Balkema, Rotterdam, pp. 301–304

Tazibt A, Abriak H, Parsy F (1996) Interaction of abrasive water jet with cut material at high velocity of impact—development of an experimental correlation. Eur J Mech A-Solid 15:1037–1047

Tazibt A, Abriak H, Parsy F (1996) Prediction of abrasive particle velocity in a high pressure water jet and effect of air on acceleration process. Eur J Mech B-Fluids 15:527–543

Raissi K, Cornier A, Kremer D, Simonin O (1996) Mixing tube geometry influence on abrasive water jet flow. In: Gee C (ed) Proc. jetting technology. BHR Group, Mech. Eng. Pub. Ltd, Cagliari, pp. 247–261

Weule H, Suchy U (2000) Mixing head for abrasive-water-jet cutting with an annular driving jet. In: Ciccu R (ed) Proc. jetting technology. BHR Group, Prof. Eng. Pub. Ltd., Ronneby, pp. 47–56

Dong Y, Tyler LJ, Summers DA, Johnson M (2004) Experimental study of particle velocity measurement in abrasive water jet cutting in the nozzle and jet stream using multiple sensing elements. In: Gee C (ed) Proc. water jetting. BHR Group, Mainz, pp. 137–147

Annoni M (2012) Water jet velocity uncertainty in laser Doppler velocimetry measurements. Measurement 45(6):1639–1650

Hlaváč LM (1996) Interaction of grains with water jet - the base of the physical derivation of complex equation for jet cutting of rock materials. In: Gee C (ed) Jetting technology. BHR Group, Mech. Eng. Pub. Ltd., London, pp. 471–485

Jandačka P, Hlaváč LM, Mádr V, Šancer J, Staněk F (2009) Measurement of specific fracture energy and surface tension of brittle materials in powder form. Int J Fracture 159(1):103–110

Hlaváč LM, Hlaváčová IM, Vašek J, Jandačka P, Mádr V (2010) Material grinding by water jets—feasibility and limits. J Sci Conf Proc 2(1):8–14

Hlaváč LM, Hlaváčová IM, Vašek J, Jandačka P, Zegzulka J, Viliamsová J, Mádr V (2010) Comminution of material particles by water jets—influence of the inner shape of the mixing chamber. Int J Miner Process 95(1–4):25–29

Pramanik A (2014) Developments in the non-traditional machining of particle reinforced metal matrix composites. Int J Mach Tool Manu 86:44–61

de Abreu e Lima CE, Lebron R, de Souza AJ, Ferreira NF, Neis PD (2016) Study of influence of traverse speed and abrasive mass flowrate in abrasive water jet machining of gemstones. Int J Adv Manuf Tech 83(1–4):77–87

Engin IC, Özkan E, Kulaksiz S (2011) Investigation on the usage of some non-almandine garnet minerals as abrasive material in waterjet cutting. GU J Sci 24(3):535–545

Kohorst P, Tegtmeyer S, Biskup C, Bach F-W, Stiesch M (2014) Machining human dentin by abrasive water jet drilling. Bio-med. Mater Eng 24(2):1485–1495

Srinivasa PR, Ramulu M (1994) Predicting hydro-abrasive erosive wear during abrasive water jet cutting: part I—a mechanistic formulation and its solution. Manuf Sci Eng ASME 1 68(1):339–351

Li WY, Wang J, Zhu H, Li H, Huang C (2013) On ultrahigh velocity micro-particle impact on steels—a single impact study. Wear 305(1–2):216–227

Li WY, Wang J, Zhu H, Huang C (2014) On ultrahigh velocity micro-particle impact on steels—a multiple impact study. Wear 309(1–2):52–64

Ahmed DH, Naser J, Deam RT (2016) Particles impact characteristics on cutting surface during the abrasive water jet machining: numerical study. J Mater Process Technol 232:116–130

Salenko AF, Shchetinin VT, Fedotiev AN, Dudyuk VA, Klimenko SA, Borimsky AI, Sorochenko TA (2015) Methods of cutting for workpieces of hardmetal and cBN-based polycrystalline superhard material. J superhard. Mater 37(4):271–281

www.minerals.net/MineralMain.aspx. Accessed 23 April 2015

http://geology.com/minerals/. Accessed 8 April 2016

Hlaváč LM, Strnadel B, Kaličinský J, Gembalová L (2012) The model of product distortion in AWJ cutting. Int J Adv Manuf Tech 62(1–4):157–166

Haddad M, Zitoune R, Bougherara H, Castanié B (2014) Study of trimming damages of CFRP structures in function of the machining processes and their impact on the mechanical behavior. Compos Part B 57:136–143

Hlaváč LM (2009) Investigation of the abrasive water jet trajectory curvature inside the kerf. J Mater Process Technol 209(8):4154–4161

Strnadel B, Hlaváč LM, Gembalová L (2013) Effect of steel structure on the declination angle in AWJ cutting. Int J Mach Tool Manu 64:12–19

Jandačka P, Šancer J, Vojtková H, Besta P, Brázda R, Količová P, Šimková L (2011) Fracture energy of selected brittle silicates. Ceramics - Silikáty 55(4):355–361

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hlavacova, I., Geryk, V. Abrasives for water-jet cutting of high-strength and thick hard materials. Int J Adv Manuf Technol 90, 1217–1224 (2017). https://doi.org/10.1007/s00170-016-9462-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-9462-y