Abstract

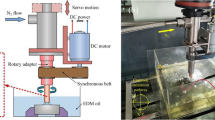

A micro electrical discharge machining (μEDM) method that utilizes liquid phase alloy as the processing electrode is proposed and developed to solve various issues arising from electrode wear. The liquid alloy is held in a microcapillary needle such that a liquid microelectrode forms at the bottom of the needle. A discharge pulse generator is connected to the liquid and a workpiece for generating pulses thermally erodes the workpiece material. During the machining process, the liquid electrode is continuously supplied to the needle to eliminate effects of liquid consumption on the erosion process. Experimental results show that discharge pulses can be stably generated and sustained with the liquid electrode and that these pulses generated on the silicon sample are effective in implementing microcavities on its surface. Coating an electrically passivated material on the needle will protect the needle tip from the thermal action of the pulse discharge. The process is also evaluated under various experimental conditions for revealing the dependence of the material removal rate (MRR) and liquid alloy consumption rate (LACR) on the parameters.

Similar content being viewed by others

References

Brousseau EB, Dimov SS, Pham DT (2010) Some recent advances in multi-material micro- and nano-manufacturing. Int J Adv Manuf Technol 47(1–4):161–180. https://doi.org/10.1007/s00170-009-2214-5

Mascaraque-Ramírez C, Franco P (2018) Experimental study of tool degradation in EDM processes: electrode material loss at the border and central zones. Int J Adv Manuf Technol 95(9–12):3497–3511. https://doi.org/10.1007/s00170-017-1469-5

Narasimhan J, Yu ZY, Rajurkar KP (2005) Tool Wear compensation and path generation in micro and macro EDM. J Manuf Process 7(1):75–82. https://doi.org/10.1016/S1526-6125(05)70084-0

Yu ZY, Masuzawa T, Fujino M (1998) Micro-EDM for three dimensional cavities-development of uniform wear method. CIRP Ann–Manuf Techn 47(1):169–172. https://doi.org/10.1016/S0007-8506(07)62810-8

Rajurkar KP, Yu ZY (2000) 3D micro-EDM using CAD/CAM. CIRP Ann Manuf Technol 49:127–130. https://doi.org/10.1016/S0007-8506(07)62911-4

Yu H, Luan J, Li J, Zhang Y, Yu Z, Guo D (2010) A new electrode wear compensation method for improving performance in 3D micro EDM milling. J Micromech Microeng 20:1–7. https://doi.org/10.1088/0960-1317/20/5/055011

Li JZ, Xiao L, Wang H, Yu HL, Yu ZY (2013) Tool Wear compensation in 3D micro EDM based on the scanned area. Prec Eng 37(3):753–757. https://doi.org/10.1016/j.precisioneng.2013.02.008

Tong H, Li Y, Zhang L (2016) On-machine process of rough-and-finishing servo scanning EDM for 3D micro cavities. Int J Adv Manuf Technol 82(5–8):1007–1015. https://doi.org/10.1007/s00170-015-7416-4

Yu ZY, Kozak J, Rajurkar KP (2003) Modelling and simulation of micro EDM process. CIRP Ann Manuf Technol 52(1):143–146. https://doi.org/10.1016/S0007-8506(07)60551-4

Zhang LN, Du JY, Zhuang XS, Wang Z, Pei JY (2015) Geometric prediction of conic tool in micro-EDM milling with fix-length compensation using simulation. Int J Mach Tools Manuf 89:86–94. https://doi.org/10.1016/j.ijmachtools.2014.11.007

Pham DT, Dimov SS, Bigot S, Ivanov A, Popov K (2004) Micro-EDM—recent developments and research issues. J Mater Process Technol 149(1–3):50–57. https://doi.org/10.1016/j.jmatprotec.2004.02.008

Bissacco G, Valentincic J, Hansen HN, Wiwe BD (2010) Towards the effective tool Wear control in micro-EDM milling. Int J Adv Manuf Technol 47(1–4):3–9. https://doi.org/10.1007/s00170-009-2057-0

Nguyen VQ, Duong TH, Kim HC (2015) Precision micro EDM based on real-time monitoring and electrode wear compensation. Int J Adv Manuf Technol 79(9–12):1829–1838. https://doi.org/10.1007/s00170-015-6964-y

Aligiri E, Yeo SH, Tan PC (2010) A new tool Wear compensation method based on real-time estimation of material removal volume in micro-EDM. J Mater Process Technol 210(15):2292–2303. https://doi.org/10.1016/j.jmatprotec.2010.08.024

Puthumana G, Bissacco G, Hansen HN (2017) Modeling of the effect of tool wear per discharge estimation error on the depth of machined cavities in micro-EDM milling. Int J Adv Manuf Technol 92(9–12):3253–3264. https://doi.org/10.1007/s00170-017-0371-5

Modica F, Basile V, Marrocco V, Fassi I (2016) A new process combining micro-electro-discharge-machining milling and sinking for fast fabrication of microchannels with draft angle. J Micro Nano-Manuf 4(2) 24501):1–8. https://doi.org/10.1115/1.4032324

Yan MT, Huang KY, Lo CY (2009) A study on electrode Wear sensing and compensation in micro-EDM using machine vision system. Int J Adv Manuf Technol 42(11–12):1065–1073. https://doi.org/10.1007/s00170-008-1674-3

Huang RN, Yi Y, Yu WB, Takahata K (2018) Liquid-phase alloy as a microfluidic electrode for micro-electro-discharge patterning. J Mater Process Tech 258:1–8. https://doi.org/10.1016/j.jmatprotec.2018.03.012

Liu TY, Sen P, Kim CJ (2012) Characterization of nontoxic liquid-metal alloy galinstan for applications in microdevices. J Microelectromech S 21(2):443–450. https://doi.org/10.1109/JMEMS.2011.2174421

Liu K, Lauwers B, Reynaerts D (2010) Process capabilities of micro-EDM and its applications. Int J Adv Manuf Technol 47(1–4):11–19. https://doi.org/10.1007/s00170-009-2056-1

Hassler C, von Metzen R, Stieglitz T (2009) Deposition parameters determining insulation resistance and crystallinity of parylene C in neural implant encapsulation. 4th European conference of the International Federation for Medical and Biological Engineering (IFMBE). Springer, Berlin, Heidelberg, 2439–2442. https://doi.org/10.1007/978-3-540-89208-3_585

Acknowledgments

The author would like to thank Prof. K. Takahata from the University of British Columbia for providing technical support for this research.

Funding

This work was partially supported by the National Natural Science Foundation of China (No. 51975155, No.51475107) and Shenzhen Basic Research Program (No. JCYJ20170811160440239).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Huang, R., Xiong, X., Yi, Y. et al. Liquid alloy electrode for no-wear micro electrical discharge machining. Int J Adv Manuf Technol 106, 1281–1290 (2020). https://doi.org/10.1007/s00170-019-04693-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04693-z