Abstract

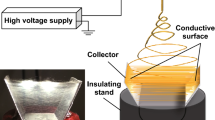

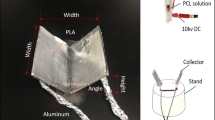

Latest bioinspired approaches in tissue engineering focus on the creation of biomaterials with micro- and nanoscale topographical features. Various additive manufacturing techniques have been applied for scaffold fabrication; however, creating three dimensional (3D) nanofiber structure within a scaffold remains to be challenging. This paper presented an innovative divergence electrospinning strategy to fabricate 3D polycaprolactone (PCL) scaffolds comprised of uniaxially aligned nanofibers. The effects of collector geometry on the nanofiber structure were characterized by polynomial regression analysis. The length-to-width ratio and inclination angle of the collector were found to be critical to nanofiber distribution within the 3D scaffold. The nanofiber orientation was consistent with the direction of electric field vectors between the two bevels of the collector. After a continuous culturing for 7 days, fibroblast cells were uniaxially organized within the 3D scaffolds, closely resembling the fibrous structure in musculoskeletal tissues. This study provided a novel approach to biomimetic native tissue microstructures and showed a great potential as a future fabrication additive manufacturing platform for tissue engineering.

Similar content being viewed by others

References

Baker BM, Gee AO, Metter RB, Nathan AS, Marklein RA, Burdick JA, Mauck RL (2008) The potential to improve cell infiltration in composite fiber-aligned electrospun scaffolds by the selective removal of sacrificial fibers. Biomaterials 29(15):2348–2358

Bettinger CJ, Langer R, Borenstein JT (2009) Engineering substrate topography at the micro-and nanoscale to control cell function. Angew Chem Int Ed 48(30):5406–5415

Billiet T, Gevaert E, De Schryver T, Cornelissen M, Dubruel P (2014) The 3D printing of gelatin methacrylamide cell-laden tissue-engineered constructs with high cell viability. Biomaterials 35(1):49–62

Bonino CA, Efimenko K, Jeong SI, Krebs MD, Alsberg E, Khan SA (2012) Three-dimensional electrospun alginate nanofiber mats via tailored charge repulsions. Small 8(12):1928–1936

Fisher MB, Henning EA, Söegaard N, Esterhai JL, Mauck RL (2013) Organized nanofibrous scaffolds that mimic the macroscopic and microscopic architecture of the knee meniscus. Acta Biomater 9(1):4496–4504

Fricain J-C, De Olivera H, Devillard R, Kalisky J, Remy M, Keriquel V et al (2017) 3D bioprinting in regenerative medicine and tissue engineering. Medecine sciences: M/S 33(1):52–59

Fridrikh SV, Jian HY, Brenner MP, Rutledge GC (2003) Controlling the fiber diameter during electrospinning. Phys Rev Lett 90(14):144502

Gauvin R, Chen Y-C, Lee JW, Soman P, Zorlutuna P, Nichol JW et al (2012) Microfabrication of complex porous tissue engineering scaffolds using 3D projection stereolithography. Biomaterials 33(15):3824–3834

Hashizume R, Fujimoto KL, Hong Y, Amoroso NJ, Tobita K, Miki T et al (2010) Morphological and mechanical characteristics of the reconstructed rat abdominal wall following use of a wet electrospun biodegradable polyurethane elastomer scaffold. Biomaterials 31(12):3253–3265

He X, Feng B, Huang C, Wang H, Ge Y, Hu R et al (2015) Electrospun gelatin/polycaprolactone nanofibrous membranes combined with a coculture of bone marrow stromal cells and chondrocytes for cartilage engineering. Int J Nanomedicine 10:2089

Hutmacher DW, Schantz T, Zein I, Ng KW, Teoh SH, Tan KC (2001) Mechanical properties and cell cultural response of polycaprolactone scaffolds designed and fabricated via fused deposition modeling. J Biomed Mater Res A 55(2):203–216

Hwang NS, Kim MS, Sampattavanich S, Baek JH, Zhang Z, Elisseeff J (2006) Effects of three-dimensional culture and growth factors on the chondrogenic differentiation of murine embryonic stem cells. Stem Cells 24(2):284–291

Jiang T, Carbone EJ, Lo KW-H, Laurencin CT (2015) Electrospinning of polymer nanofibers for tissue regeneration. Prog Polym Sci 46:1–24

Kang H-W, Lee SJ, Ko IK, Kengla C, Yoo JJ, Atala A (2016) A 3D bioprinting system to produce human-scale tissue constructs with structural integrity. Nat Biotechnol 34(3):312–319

Khil MS, Bhattarai SR, Kim HY, Kim SZ, Lee KH (2005) Novel fabricated matrix via electrospinning for tissue engineering. J Biomed Mater Res B Appl Biomater 72(1):117–124

Kim G, Son J, Park S, Kim W (2008) Hybrid process for fabricating 3D hierarchical scaffolds combining rapid prototyping and electrospinning. Macromol Rapid Commun 29(19):1577–1581

Lee S-J, Nowicki M, Harris B, Zhang LG (2017) Fabrication of a highly aligned neural scaffold via a table top stereolithography 3D printing and electrospinning. Tissue Eng A 23(11–12):491–502

Liu H, Lin J, Roy K (2006) Effect of 3D scaffold and dynamic culture condition on the global gene expression profile of mouse embryonic stem cells. Biomaterials 27(36):5978–5989

Madurantakam PA, Rodriguez IA, Garg K, McCool JM, Moon PC, Bowlin GL (2013) Compression of multilayered composite electrospun scaffolds: a novel strategy to rapidly enhance mechanical properties and three dimensionality of bone scaffolds. Adv Mater Sci Eng 2013:1–9

Malda J, Woodfield T, Van Der Vloodt F, Wilson C, Martens D, Tramper J et al (2005) The effect of PEGT/PBT scaffold architecture on the composition of tissue engineered cartilage. Biomaterials 26(1):63–72

Martins A, Chung S, Pedro AJ, Sousa RA, Marques AP, Reis RL, Neves NM (2009) Hierarchical starch-based fibrous scaffold for bone tissue engineering applications. J Tissue Eng Regen Med 3(1):37–42

Mazzoli A (2013) Selective laser sintering in biomedical engineering. Medical & biological engineering & computing 51(3):245–256

Melchels FP, Domingos MA, Klein TJ, Malda J, Bartolo PJ, Hutmacher DW (2012) Additive manufacturing of tissues and organs. Prog Polym Sci 37(8):1079–1104

Mendes PM (2013) Cellular nanotechnology: making biological interfaces smarter. Chem Soc Rev 42(24):9207–9218

Mota C, Puppi D, Chiellini F, Chiellini E (2015) Additive manufacturing techniques for the production of tissue engineering constructs. J Tissue Eng Regen Med 9(3):174–190

Nam J, Huang Y, Agarwal S, Lannutti J (2007) Improved cellular infiltration in electrospun fiber via engineered porosity. Tissue Eng 13(9):2249–2257

Narayanan LK, Huebner P, Fisher MB, Spang JT, Starly B, Shirwaiker RA (2016) 3D-bioprinting of polylactic acid (PLA) nanofiber–alginate hydrogel bioink containing human adipose-derived stem cells. ACS Biomaterials Science & Engineering 2(10):1732–1742

Niu H, Zhang J, Xie Z, Wang X, Lin T (2011) Preparation, structure and supercapacitance of bonded carbon nanofiber electrode materials. Carbon 49(7):2380–2388

Nowlin, J., Bismi, M. A., Delpech, B., Dumas, P., Zhou, Y., & Tan, G. Z. (2018). Engineering the hard–soft tissue interface with random-to-aligned nanofiber scaffolds. N anobiomedicine

Pan H, Li L, Hu L, Cui X (2006) Continuous aligned polymer fibers produced by a modified electrospinning method. Polymer 47(14):4901–4904

Peng S, Jin G, Li L, Li K, Srinivasan M, Ramakrishna S, Chen J (2016) Multi-functional electrospun nanofibres for advances in tissue regeneration, energy conversion & storage, and water treatment. Chem Soc Rev 45(5):1225–1241

Pham QP, Sharma U, Mikos AG (2006) Electrospun poly (ε-caprolactone) microfiber and multilayer nanofiber/microfiber scaffolds: characterization of scaffolds and measurement of cellular infiltration. Biomacromolecules 7(10):2796–2805

Rinker TE, Temenoff JS (2014) Micro-and nanotechnology engineering strategies for tissue interface regeneration and repair. In: Tissue and organ regeneration: advances in micro-and nanotechnology, p 105

Sakaguchi, H., Amoroso, N., & Wagner, W. (2014). Engineering electrospun scaffolds to encourage cell infiltration Engineered Cell Manipulation for Biomedical Application (pp. 75–94): Springer

Selimis A, Mironov V, Farsari M (2015) Direct laser writing: principles and materials for scaffold 3D printing. Microelectron Eng 132:83–89

Shin S-H, Purevdorj O, Castano O, Planell JA, Kim H-W (2012) A short review: recent advances in electrospinning for bone tissue regeneration. Journal of tissue engineering 3(1):2041731412443530

Shirazi SFS, Gharehkhani S, Mehrali M, Yarmand H, Metselaar HSC, Kadri NA, Osman NAA (2015) A review on powder-based additive manufacturing for tissue engineering: selective laser sintering and inkjet 3D printing. Sci Technol Adv Mater 16(3):033502

Silva NA, Salgado AJ, Sousa RA, Oliveira JT, Pedro AJ, Leite-Almeida H et al (2009) Development and characterization of a novel hybrid tissue engineering–based scaffold for spinal cord injury repair. Tissue Eng A 16(1):45–54

Sun B, Long Y-Z, Yu F, Li M-M, Zhang H-D, Li W-J, Xu T-X (2012) Self-assembly of a three-dimensional fibrous polymer sponge by electrospinning. Nanoscale 4(6):2134–2137

Sun Z, Zussman E, Yarin AL, Wendorff JH, Greiner A (2003) Compound core–shell polymer nanofibers by co-electrospinning. Adv Mater 15(22):1929–1932

Teo W, Kotaki M, Mo X, Ramakrishna S (2005) Porous tubular structures with controlled fibre orientation using a modified electrospinning method. Nanotechnology 16(6):918–924

Thompson C, Chase GG, Yarin A, Reneker D (2007) Effects of parameters on nanofiber diameter determined from electrospinning model. Polymer 48(23):6913–6922

Xu L, Wang L, Si N, He J (2013a) Aligned nanofibers by magnetic-electrospinning for biomedical applications. J Control Release 172(1):e131–e132

Xu T, Zhao W, Zhu J-M, Albanna MZ, Yoo JJ, Atala A (2013b) Complex heterogeneous tissue constructs containing multiple cell types prepared by inkjet printing technology. Biomaterials 34(1):130–139

Yang X, Shah JD, Wang H (2008) Nanofiber enabled layer-by-layer approach toward three-dimensional tissue formation. Tissue Eng A 15(4):945–956

Yokoyama Y, Hattori S, Yoshikawa C, Yasuda Y, Koyama H, Takato T, Kobayashi H (2009) Novel wet electrospinning system for fabrication of spongiform nanofiber 3-dimensional fabric. Mater Lett 63(9):754–756

Zhou, Y., & Tan, G. Z. (2017). Fabrication of nanofiber mats with microstructure gradient by cone electrospinning. Nanomaterials and Nanotechnology, 7, 1847980417748478, 184798041774847

Zhou, Y., & Tan, G. Z. (2018). Generation of 3D nanofiber structure by divergence electrospinning for tissue engineering scaffold. Paper presented at the ASME 2018 13th International Manufacturing Science and Engineering Conference

Funding

This work was financially supported by the Foundation of the Whitacre College of Engineering and the Office of Vice President for Research at Texas Tech University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, Y., Hu, Z., Du, D. et al. The effects of collector geometry on the internal structure of the 3D nanofiber scaffold fabricated by divergent electrospinning. Int J Adv Manuf Technol 100, 3045–3054 (2019). https://doi.org/10.1007/s00170-018-2899-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2899-4