Abstract

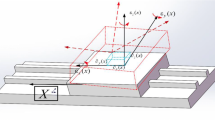

Geometric errors have a comprehensive influence on the volumetric error of the five-axis machine tool. The identification of the vital geometric errors that have major effect on the volumetric error is the key problem to improve the machine tool accuracy. Therefore, a sensitivity analysis method to identify the vital geometric errors is proposed in this paper. The volumetric error model of a five-axis machine tool with 41 geometric errors is established based on the multi-body system method. Through the projection of the error vectors and the introduction of the effective cutting length, LSIL and GSIL are defined as the sensitivity indices for the local and global sensitivity analysis, respectively. Simulations are conducted for the local and global sensitivity analysis in which the LSIL and GSIL are used. And the analysis results have proven the validity of the proposed sensitivity analysis method. Compared with the conventional sensitivity analysis method, the proposed sensitivity analysis method has considered the position and posture error of the cutting tool simultaneously, which is more effective and efficient. The analysis results are helpful to improve the accuracy of the five-axis machine tool.

Similar content being viewed by others

References

Ramesh R, Mannan MA, Poo AN (2000) Error compensation in machine tools - a review Part I: Geometric, Cutting Force induced and fixture depend errors. Int J Mach Tools Manuf 40(9):1235–1256

Khan AW, Chen W (2011) A methodology for systematic geometric error compensation in five-axis machine tools. Int J Adv Manuf Technol 53(5):615–628

Liu H, Li B, Wang X, Tan G (2011) Characteristics of and measurement methods for geometric errors in CNC machine tools. Int J Adv Manuf Technol 54(1–4):195–201

Nojedeh MV, Habibi M, Arezoo B (2011) Tool path accuracy enhancement through geometrical error compensation. Int J Mach Tools Manuf 51(6):471–482

Schwenke H, Knapp W, Haitjema H, Weckenmann A, Schmitt R, Delbressine F (2008) Geometric error measurement and compensation of machines-an update. CIRP Ann - Manuf Technol 57(2):660–675

Xu Y, Zhang L, Wang S, Du H, Chai B, Hu SJ (2015) Active precision design for complex machine tools : methodology and case study. Int J Mach Tools Manuf 80(1):581–590

Cui G, Lu Y, Li J, Gao D (2012) Geometric error compensation software system for CNC machine tools based on NC program reconstructing. Int J Adv Manuf Thechnol 63(1–4):169–180

Cui G, Lu Y, Gao D, Yao Y (2012) A novel error compensation implementing strategy and realizing on Siemens 840D CNC systems. Int J Mach Tools Manuf 61(5–8):595–608

Creamer J, Bristow DA, Landers RG (2017) Selection of limited and constrained compensation tables for five-axis machine tools. Int J Adv Manuf Technol 92:1315–1327

Donmez MA, Blomquist DS, Hocken RJ, Liu CR, Barash MM (1986) A general methodology for machine tool accuracy enhancement by error compensation. Precis Eng 8(4):187–196

Fu G, Fu J, Gao H, Yao X (2017) Squareness error modeling for multi-axis machine tools via synthesizing the motion of the axes. Int J Adv Manuf Technol 89(9):2993–3008

Chen GS, Mei XS, Li HL (2013) Geometric error modeling and compensation for large-scale grinding machine tools with multi-axes. Int J Adv Manuf Technol 69(9–12):2583–2592

Lee JH, Liu Y, Yang SH (2006) Accuracy improvement of miniaturized machine tool: geometric error modeling and compensation. Int J Mach Tools Manuf 46(12–13):1508–1516

Zhu S, Ding G, Qin S, Lei J, Zhuang L, Yan K (2012) Integrated geometric error modeling, identification and compensation of CNC machine tools. Int J Mach Tools Manuf 52(1):24–29

Zhang Z, Liu Z, Cheng Q, Qi Y, Cai L (2017) An approach of comprehensive error modeling and accuracy allocation for the improvement of reliability and optimization of cost of a multi-axis NC machine tool. Int J Adv Manuf Technol 89(1):561–579

Zhu W, Wang Z, Yamazaki K (2010) Machine tool component error extraction and error compensation by incorporating statistical analysis. Int J Mach Tools Manuf 50(1):798–806

Zhang H, Yang J, Zhang Y, Shen J, Wang C (2011) Measurement and compensation for volumetric positioning errors of CNC machine tools considering thermal effect. Int J Adv Manuf Technol 55(1):275–283

He Z, Fu J, Zhang X, Shen H (2016) A uniform expression model for volumetric errors of machine tools. Int J Mach Tools Manuf 100:93–104

Saltelli A, Ratto M, Tarantola S, Campolongo F (2006) Sensitivity analysis practices : strategies for model-based inference. Reliab Eng Syst Saf 91(10–11):1109–1125

Wang S, Ehmann KF (1999) Measurement methods for the position errors of a multi-axis machine. Part 1 : principles and sensitivity analysis. Int J Mach Tools Manuf 39(6):951–964

Fan K, Wang H, Zhao J, Chang T (2003) Sensitivity analysis of the 3-PRS parallel kinematic spindle platform of a serial-parallel machine tool. Int J Mach Tools Manuf 43(15):1561–1569

Chen G, Liang Y, Sun Y, Chen W, Wang B (2013) Volumetric error modeling and sensitivity analysis for designing a five-axis ultra-precision machine tool. Int J Adv Manuf Technol 68(9–12):2525–2534

Li J, Xie F, Liu XJ (2016) Geometric error modeling and sensitivity analysis of a five-axis machine tool. Int J Adv Manuf Technol 82(9):2037–2051

Cheng Q, Zhao H, Zhang G (2014) An analytical approach for crucial geometric errors identification of multi-axis machine tool based on global sensitivity analysis. Int J Adv Manuf Technol 75(1–4):107–121

Cheng Q, Feng Q, Liu Z, Gu P, Zhang G (2016) Sensitivity analysis of machining accuracy of multi-axis machine tool based on POE screw theory and Morris method. Int J Adv Manuf Technol 84(9–12):2301–2318

Cheng Q, Sun B, Liu Z, Li J, Dong X, Gu P (2017) Key geometric error extraction of machine tool based on extended Fourier amplitude sensitivity test method. Int J Adv Manuf Technol 90(9–12):3369–3385

Zhang X, Zhang Y, Pandey MD (2015) Global sensitivity analysis of a CNC machine tool : application of MDRM. Int J Adv Manuf Technol 81(1–4):159–169

Guo S, Jiang G (2017) Investigation of sensitivity analysis and compensation parameter optimization of geometric error for five-axis machine tool. Int J Adv Manuf Technol 93(1):3229–3243

Lee DM, Zhu Z, Lee KI, Yang SH (2011) Identification and measurement of geometric errors for a five-axis machine tool with a tilting head using a double ball-bar. Int J Precis Eng Manuf 12(2):337–343

International Standards Organization (ISO). ISO 230–7: Test code for machine tools, Part 7: Geometric accuracy of axes of rotation, 2006

International Standards Organization (ISO). ISO 230–6: Test code for machine tools, Part 6: Determination of positioning accuracy on body and face diagonals (Diagonal displacement tests), 2002

Acknowledgements

This research is supported by the National Key Scientific and Technological Project (Grant No. 2015ZX04001002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Q., Wang, W., Jiang, Y. et al. A sensitivity method to analyze the volumetric error of five-axis machine tool. Int J Adv Manuf Technol 98, 1791–1805 (2018). https://doi.org/10.1007/s00170-018-2322-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2322-1