Abstract

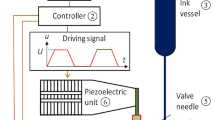

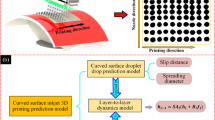

The depositing quality accomplished by inkjet printing process is significantly affected by droplet positioning accuracy which plays an essential role in formation performance and printing efficiency. However, the droplet deviation induced by various factors is rarely studied specifically because most researchers mainly concentrate on the dynamics and mechanics of droplet and ink-substrate interaction to enhance the printing precision. In fact, among all the contributing factors to droplet deviation, the relative motion between nozzle and substrate tends to cause the ejected droplet to deflect from its desired position and the deviation is inevitable as long as the existence of horizontal velocity. The error brought about by this phenomenon is commonly negligible in the majority of current studies with the assumption of slow relative horizontal speed between nozzle and substrate. But it is not always acceptable to keep a quite low horizontal translation speed which would result in inefficiency of printing. In order to satisfy the demanding requirements in efficiency and accuracy of inkjet printing, some strategies are proposed to mitigate the droplet deviation out of the above phenomenon in this paper. An adaptive approach to nozzle feedrate control with a look-ahead algorithm is presented in this paper to compensate the errors by means of reconstructing the tool paths with deviation prediction in advance based on the feedrate profile and the geometrical characteristics of tool paths. The error model is established with full consideration of different circumstances influenced by droplet deviation and is subsequently integrated into the control process of the nozzle feedrate. The practical implementation demonstrates the effectiveness and feasibility of the proposed method.

Similar content being viewed by others

References

Williams C (2006) Ink-Jet printers go beyond paper. Phys World 19(1):24–29

Xu C, Chai W, Huang Y, Markwald RR (2012) Scaffold-free inkjet printing of three-dimensional zigzag cellular tubes. Biotechnol Bioeng 109(12):3152–3160

Zhang H-Y, Wang J, Lu G-D (2012) Numerical investigation of the influence of companion drops on drop-on-demand ink jetting. J Zhejiang Univ Sci A 13(8):584–595

Sun W, Lal P (2002) Recent development on computer aided tissue engineering—a review. Comput Methods Prog Biomed 67(2):85–103

Herran CL, Wang W, Huang Y, Mironov V, Markwald R (2010) Parametric Study of Acoustic Excitation-Based Glycerol-Water Microsphere Fabrication in Single Nozzle Jetting. J Manuf Sci Eng Trans ASME 132(5)

Xu C, Christensen K, Zhang Z, Huang Y, Fu J, Markwald RR (2013) Predictive compensation-enabled horizontal inkjet printing of alginate tubular constructs. Manuf Lett 1(1):28–32

Chen SC, Yeh YC, Chen WL (2002) Control of ink-jet firing for bubble-jet printer. Int J Electron 89(1):19–34

Shen H, Fu J, He Y, Yao X (2012) On-line asynchronous compensation methods for static/quasi-static error implemented on CNC machine tools. Int J Mach Tools Manuf 60:14–26

Fan K, Yang J, Jiang H, Wang W, Yao X (2012) Error prediction and clustering compensation on shaft machining. Int J Adv Manuf Technol 58(5-8):663–670

Cui G, Lu Y, Li J, Gao D, Yao Y (2012) Geometric error compensation software system for CNC machine tools based on NC program reconstructing. Int J Adv Manuf Technol 63(1-4):169–180

Ni J (1997) CNC machine accuracy enhancement through real-time error compensation. J Manuf Sci Eng Trans ASME 119(4B):717–725

Kono D, Matsubara A, Yamaji I, Fujita T (2008) High-precision machining by measurement and compensation of motion error. Int J Mach Tools Manuf 48(10):1103–1110

Khan AW, Chen W (2011) A methodology for systematic geometric error compensation in five-axis machine tools. Int J Adv Manuf Technol 53(5–8):615–628

Jing HJ, Yao YX, Chen SD, Wang XP (2006) Machining accuracy enhancement by modifying NC program. In: Yuan ZJ et al (eds) Advances in Machining & Manufacturing Technology Viii., pp 71–75

Barakat NA, Elbestawi MA, Spence AD (2000) Kinematic and geometric error compensation of a coordinate measuring machine. Int J Mach Tools Manuf 40(6):833–850

Song S-J, Choi J, Park Y-D, Lee J-J, Hong SY, Sun K (2010) A three-dimensional bioprinting system for use with a hydrogel-based biomaterial and printing parameter characterization. Artif Organs 34(11):1044–1048

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, Ya., He, Y., Gao, Q. et al. Droplet deviation modeling and compensation scheme of inkjet printing. Int J Adv Manuf Technol 75, 1405–1415 (2014). https://doi.org/10.1007/s00170-014-6224-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6224-6