Abstract

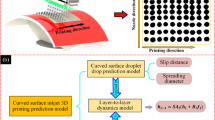

Printing with inkjet technology has found new forms of application in the industry and in this article we study this technology focused on printing on non-flat surfaces. Since there is no print history over distances greater than 1 mm due to the rupture phenomenon, an initial quality standard is defined to measure achievements in a relative manner. An interactive method is used that requires the user to approach the machine in multiple analyzes of different types. The first approach is a mathematical model this model was constructed to predict the drop distance of the drop in the non-planar substrate with respect to the planned one in the flat substrate, taking into account that most of the drops fall to different heights presenting a greater or lesser state of development the phenomena present in the flight. The results allow to initiate a process of compensation that avoids the distortion of the figure to improve the printing resolution. The results are validated using a relative quality through industrial ink-jet printer with heads capable of injecting functional fluids. The initial result indicates that in standard surface printing with print relative quality already defined, it can be used only for low resolution formats with thick lines, and the result can be improved when the original figure is treated by compensating the distance between the numerical prediction and the initial objective.

Similar content being viewed by others

References

Wang, C.-T., Huang, K.-Y., Lin, D.T., Liao, W.-C., Lin, H.W., Hu, Y.-C.: A flexible proximity sensor fully fabricated by inkjet printing. Sensors 10(5), 5054–5062 (2010)

Komuro, N., Takaki, S., Suzuki, K., Citterio, D.: Inkjet printed (bio) chemical sensing devices. Anal. Bioanal. Chem. 405(17), 5785–5805 (2013)

Lorber, B., Hsiao, W.-K., Hutchings, I.M., Marti, K.R.: Adult rat retinal ganglion cells and glia can be printed by piezoelectric inkjet printing. Biofabrication 6(1), 015001 (2013)

Xu, T., Jin, J., Gregory, C., Hickman, J.J., Boland, T.: Inkjet printing of viable mammalian cells. Biomaterials 26(1), 93–99 (2005)

Shirazi, S.F.S., Gharehkhani, S., Mehrali, M., Yarmand, H., Metselaa, H.S.C., Kadri, N.A., Osman, N.A.A.: A review on powder-based additive manufacturing for tissue engineering: selective laser sintering and inkjet 3d printing. Sci. Technol. Adv. Mater. 16(3), 033502 (2015)

Ozkol, E.: Rheological characterization of aqueous 3y-tzp inks optimized for direct thermal ink-jet printing of ceramic components. J. Am. Ceram. Soc. 96(4), 1124–1130 (2013)

Arango, I., Betancur, M., Bonil, L., Acevedo, D.: Impresion digital inkjet sobre formas cilındricas con tintas uv. Manufactura flexible, p. 109

Rahul, S.H., Balasubramanian, K., Venkatesh, S.: Optimizing inkjet printing process to fabricate thick ceramic coatings. Ceram. Int. 43, 4513 (2016)

Arazn, A., Janeczek, K., Futera, K.: Mechanical and thermal reliability of conductive circuits inkjet printed on flexible substrates. Circuit World 43(1), 9 (2017)

Ikegaw, M., Ishii, E., Harada, N., Takagishi, T.: Development of ink-particle flight simulation for continuous inkjet printers. J. Manuf. Sci. Eng. 136(5), 051021 (2014)

Yeo, L.P., Lok, B.K., Nguyen, Q.M.P., Lu, C.W., Lam, Y.C.: Selective surface modification of pet substrate for inkjet printing. Int. J. Adv. Manuf. Technol. 71(912), 1749–1755 (2014)

Fathi, S., Dickens, P.: Droplet analysis in an inkjet-integrated manufacturing process for nylon 6. Int. J. Adv. Manuf. Technol. 69(1–4), 269–275 (2013)

Ozkan, M., Dimic-Misic, K., Karakoc, A., Hashmi, S.G., Lund, P., Maloney, T., Paltakari, J.: Rheological characterization of liquid electrolytes for dropon-demand inkjet printing. Organic Electron. 38, 307–315 (2016)

Wijshoff, H.: Structure-and Fluid-Dynamics in Piezo Inkjet Printheads. University of Twente, Enschede (2008)

Vaezi, M., Seitz, H., Yan, S.: A review on 3d microadditive manufacturing technologies. Int. J. Adv. Manuf. Technol. 67(5–8), 1721–1754 (2013)

Huang, S.H., Liu, P., Mokasdar, A., Hou, L.: Additive manufacturing and its societal impact: a literature review. Int. J. Adv. Manuf. Technol. 67(5–8), 1191–1203 (2013)

Campbell, P.G., Weiss, L.E.: Tissue engineering with the aid of inkjet printers. Expert Opin. Biol. Therapy 7(8), 1123–1127 (2007)

Subbaraman, H., Pham, D.T., Xu, X., Chen, M.Y., Hosseini, A., Lu, X., Chen, R.T.: Inkjet-printed twodimensional phased-array antenna on a flexible substrate. IEEE Antennas Wirel. Propag. Lett. 12, 170–173 (2013)

Perelaer, J., Hendriks, C.E., de Laat, A.W.M., Schubert, U.S.: One-step inkjet printing of conductive silver tracks on polymer substrates. Nanotechnology 20(16), 165303 (2009)

Y-a, J., He, Y., Gao, Q., J-z, F., G-q, F.: Droplet deviation modeling and compensation scheme of inkjet printing. Int. J. Adv. Manuf. Technol. 75(9–12), 1405–1415 (2014)

Friederich, A., Binder, J.R., Bauer, W.: Rheological control of the coffee stain effect for inkjet printing of ceramics. J. Am. Ceram. Soc. 96(7), 2093–2099 (2013)

Arango, I., Canas, M.: Dynamic analysis of a recirculation system of micro functional fluids for ink-jet applications. Microsyst. Technol. 23(5), 1485–1494 (2017)

Krieger, I.M., Dougherty, T.J.: A mechanism for non-newtonian flow in suspensions of rigid spheres. Trans. Soc. Rheol. 3(1), 137–152 (1959)

Poletto, M., Joseph, D.D.: Effective density and viscosity of a suspension. J. Rheol. 39(2), 323–343 (1995)

Rodriguez-Rivero, C., Castrejon-Pita, J.R., Hutchings, I.M.: Aerodynamic effects in industrial inkjet printing. J. Imaging Sci. Technol. 59(4), 40401–1 (2015)

Barnett, D., McDonald, M.: Evaluation and reduction of elevated height printing defects. In: NIP and Digital Fabrication Conference, vol. 2014, pp. 38–43. Society for Imaging Science and Technology (2014)

Hsiao, W.K., Martin, G.D., Hoath, S.D., Hutchings, I.M., Hook, M., Massucci, M.: Evidence of print gap airflow affecting web printing quality. In: Society for Imaging Science and Technology, NIP and Digital Fabrication Conference, vol. 2013, pp. 303–306 (2013)

Link, N., Lampert, S., Gurka, R., Liberzon, A., Hetsroni, G., Semiat, R.: Ink drop motion in wide-format printers: ii. airflow investigation. Chem. Eng. Process. Process Intensif. 48(1), 84–91 (2009)

Pilch, M., Erdman, C.A.: Use of breakup time data and velocity history data to predict the maximum size of stable fragments for acceleration-induced breakup of a liquid drop. Int. J. Multiph. Flow 13(6), 741–757 (1987)

Theofanous, T.G., Mitkin, V.V., Ng, C.L.: The physics of aerobreakup. iii. Viscoelastic liquids. Phys. Fluids 25(3), 032101 (2013)

Barone, S., Casinelli, M., Frascaria, M., Paoli, A., Razionale, A.V.: Interactive design of dental implant placements through cad-cam technologies: from 3d imaging to additive manufacturing. International Journal on Interactive Design and Manufacturing (IJIDeM) 10(2), 105–117 (2016)

Wu, H.-C., Shan, T.-R., Hwang, W.-S., Lin, H.-J.: Study of micro-droplet behavior for a piezoelectric inkjet printing device using a single pulse voltage pattern. Mater. Trans. 45(5), 1794–1801 (2004)

Guildenbecher, D.R., Lopez-Rivera, C., Sojka, P.E.: Secondary atomization. Exp. Fluids 46(3), 371 (2009)

Hsiang, L.-P., Faeth, G.M.: Near-limit drop deformation and secondary breakup. Int. J. Multiph. Flow 18(5), 635–652 (1992)

Dadvand, A., Shervani Tabar, M.T., Khoo, B.C.: A note on spark bubble drop-on-demand droplet generation: simulation and experiment. Int. J. Adv. Manuf. Technol. 56(1–4), 245–259 (2011)

Roisman, I.V., Rioboo, R., Tropea, C.: Normal impact of a liquid drop on a dry surface: model for spreading and receding. In: Proceedings of the Royal Society of London A: Mathematical, Physical and Engineering Sciences, vol. 458, pp. 1411–1430. The Royal Society, London (2002)

Chandra, S., Avedisian, C.T.: On the collision of a droplet with a solid surface. Proc. R. Soc. Lond. A 432(1884), 13–41 (1991)

Hutchings, I.M., Martin, G.D.: Inkjet Technology for Digital Fabrication. Wiley, London (2012)

Perelaer, J., Smith, P.J., van den Bosch, E., van Grootel, S.C., Ketelaars, P.H.J.M., Schubert, U.S.: The spreading of inkjet-printed droplets with varying polymer molar mass on a dry solid substrate. Macromol. Chem. Phys. 210(6), 495–502 (2009)

Tong, W., Cheung, E.H.: Enhanced stl. Int. J. Adv. Manuf. Technol. 29(11–12), 1143–1150 (2006)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Arango, I., Bonil, L., Posada, D. et al. Prediction of a flying droplet landing over a non-flat substrates for ink-jet applications. Int J Interact Des Manuf 13, 967–980 (2019). https://doi.org/10.1007/s12008-019-00547-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-019-00547-w