Abstract

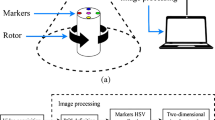

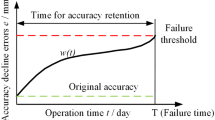

The hydrostatic spindle is widely applied in the field of high-precision machine tools, which has some advantages such as high stiffness, high rotary precision, and the high damping shock absorption. The spindle rotation error is an important index to measure the machining accuracy of machine tools. Due to the installing eccentric error of the test bar, conventional method based on the standard test bar to measure the rotation error indirectly is applied to the precision machine tools and common machine tools whose rotation error is greater than 1 μm only. In order to eliminate the installing eccentric error of the standard test bar, it presents a self-reference approach that takes the online finish turning test bar, rather than that of the standard test bar, as the measuring datum. Using the capacitive micro-displacement sensor and the LMS data acquisition equipment as the test platform, it designs a set of spindle rotation error measurement system. Then it studies the frequency domain three-point method and has the rotation error and roundness error of high-precision hydrostatic spindle separated. Experimental study shows that the rotation error and the roundness error of the spindle are 0.9 and 0.3 μm, respectively, under the circumstance of conventional standard test bar as the measuring datum. However, if it takes the online finish turning test bar as the measuring datum, the rotation error and the roundness error of the spindle are only 0.3 and 0.1 μm, respectively. The self-reference method is able to eliminate the installing eccentric error of standard test bar directly, and the measurement system has realized the accurate measurements of the rotation error and roundness error of the high-precision hydrostatic spindle.

Similar content being viewed by others

References

Xudong Z, Zenghao X, Wenjun S, Hao L (2010) Testing research on rotation error of machine tool spindle. Machinery 48(9):68–70 (In Chinese)

Tlusty J (1959) System and methods of testing machine tools. Microtechnic 13:162

Bryan JB, Clouser RW, Holland E (1967) Spindle accuracy. Am Mach 612:149–164

ASME (1985) Axes of Rotation ANSI/ASME B89.3.4. American Society of Mechanical Engineers, New York

Murthy TSR, Mallanna C, Visveswaran ME (1978) New methods of evaluating axis of rotation error. Ann CIRP 27:365–369

Goddard EJ, Cowley A, Burdekin M (1972) A measuring system for the evaluation of spindle rotation accuracy. In: Proceeding of the 13th MTDR conference 125–131

Kakino Y, Yamamoto Y, Ishii N (1977) New measuring method of rotation accuracy of spindle. Ann CIRP 26:241–244

Swann AC, Harrison JC, Talke FE (1996) Non-repeatable runout measurement and simulation of fluid lubricated spindles. IEEE Trans Magn 32(3/2):1727–1732

Kim K (1985) Development of Microprocessor-based spindle error motion measurement system. Microcomput Appl 10–14

Gao W, Sato E, Ohnuma T et al. (2002) Roundness and spindle error measurement by angular three-probe method. J Jpn Soc Precis Eng 1195–1199

Marsh ER, Arneson DA, Martin DL (2010) A comparison of reversal and multi probe error separation. Precis Eng 34:p85–p91

Marsh E, Couey J, Vallance R (2006) Nanometer-level comparison of three spindle error motion separation techniques. Trans ASME 180–187

Marsh ER (2008) Precision spindle metrology. DEStech Publications, Lancaster

Zhang X, Dong A, Han J-h (1999) Analysis of the measuring signals applied to the error separation technique (EST) of three points. J Zibo Univ (Nat Sci Eng Ed) 11(11):30–32, In Chinese

Huang J, Ma P (2011) Research on spindle error measurement method and application based on the frequency domain three-point method. Guangdong University of Technology master thesis 5 (In Chinese)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, P., Zhao, C., Lu, X. et al. Rotation error measurement technology and experimentation research of high-precision hydrostatic spindle. Int J Adv Manuf Technol 73, 1313–1320 (2014). https://doi.org/10.1007/s00170-014-5905-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5905-5