Abstract

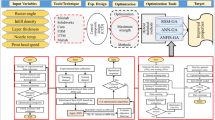

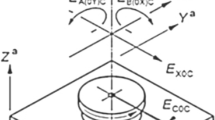

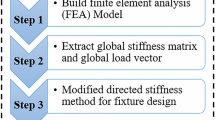

The planetary roller screw mechanism (PRSM) is a novel precision transmission mechanism that realizes the conversion between linear and rotary motions. The contact characteristics of helical surfaces directly determine PRSM’s performance in load-carrying capacity and transmission accuracy. Therefore, studying the contact characteristics of PRSM forms the fundamental basis for enhancing its transmission performance. In this study, a three-dimensional parametric analysis method of contact characteristics is proposed based on the PRSM meshing principle and PyVista (a high-level API to the Visualization Toolkit). The proposed method considers the influence of machining errors among various thread teeth. The effects of key machining errors on contact positions and axial clearance, as well as their sensitivities, are analyzed. With excellent solution accuracy, this method exhibits higher calculation efficiency and stronger robustness than the analytical and numerical meshing models. The influence of nominal diameter and pitch errors of the screw, roller, and nut on the axial clearance follows a linear relationship, whereas flank angle errors have negligible effects on the axial clearance. The corresponding influence coefficients for these three machining errors on the axial clearance are 0.623, 0.341, and 0.036. The variations in contact positions caused by individual errors are axisymmetric. Flank angle errors and roller diameter errors result in linear displacements of the contact points, whereas pitch errors cause the contact points to move along the arc of the roller diameter. Based on the proposed three-dimensional parametric contact characteristics analysis method, the Fuzzy C-Means clustering algorithm considering error sensitivity is utilized to establish a component grouping technique in the selective assembly of critical PRSM components, ensuring the rational and consistent clearances based on the given component’s machining errors. This study provides effective guidance for analyzing contact characteristics and grouping in selective assembly for PRSM components. It also presents the proposed method’s potential applicability to similar calculation problems for contact positions and clearances in other transmission systems.

Similar content being viewed by others

Abbreviations

- CNC:

-

Computer numerical control

- FCM:

-

Fuzzy C-Means

- OBB:

-

Oriented bounding box

- PRSM:

-

Planetary roller screw mechanism

- VTK:

-

Visualization toolkit

- A iBi (i = S, R, N):

-

Thread root arc segment in the axial thread profile of screw, roller, or nut

- axes :

-

Three coordinate axis vectors of the meshing model’s OBB

- B i E i (i = S, R, N):

-

Contact profile segment in the axial thread profile of screw, roller, or nut

- c i (i = S, R, N):

-

Half thread tooth thickness of screw, roller, or nut

- cc i :

-

Cluster center of the ith group of samples

- C i (i = 1,2,…,K):

-

ith group group of samples

- c :

-

Vertex coordinates matrix of the meshing model’s OBB

- cell i (i = 1,2,…,n):

-

Cell of the meshing model’s OBB

- d i (i = S, R, N):

-

Nominal diameter of screw, roller, or nut

- \(d_{ij}^{\rm{w}}\) :

-

Weighted Euclidean distance between cluster center cci and the jth sample Xj

- Δd i (i = S, R, N):

-

Nominal diameter error of screw, roller, or nut

- e n :

-

nth sample

- E sam :

-

Sample set

- EE ij (i = 1,2,…,9; j = 1,2,…,N sam):

-

Axial clearance variation resulting from consecutive runs in which only the ith error xij of the jth sample is changed to (Xij + Δ)

- K :

-

Number of clusters

- L int :

-

Overlapping region between the meshing model and v

- L m :

-

Projection ranges of the meshing model along the axes

- L v :

-

Projection ranges of v along the axes

- n i (i = S, R, N):

-

Number of starts of screw, roller, or nut

- N j (j = 1,2,…,K):

-

Total number of samples in the jth group

- N sam :

-

Number of samples in Esam

- n i (i = 1,2,3):

-

Normal vectors of meshing model cell

- p i (i = S, R, N):

-

Pitch of screw, roller, or nut

- Δp i (i = S, R, N):

-

Pitch error of screw, roller, or nut

- P :

-

Clustering center

- P i (i = S, R, N):

-

Point sets for the screw, roller, or nut thread profiles

- p i1, p i2, p i3 (i = 1,2,…,n):

-

Three vertices of meshing model cell

- p int :

-

Intersection point between celli and v

- \(p_{{\mathop{\rm int}}}^{\rm{N}}\) :

-

Intersection points between v and the nut

- \(p_{{\mathop{\rm int}}}^{{\rm{R - N}}}\) :

-

Intersection points between v and the roller on nut side

- \(p_{{\mathop{\rm int}}}^{{\rm{R - S}}}\) :

-

Intersection points between v and the roller on screw side

- \(p_{{\mathop{\rm int}}}^{\rm{S}}\) :

-

Intersection points between v and the screw

- r Nm :

-

Nut contact radius

- r root_i (i = S, R, N):

-

Root arc radius of screw, roller, or nut

- r Rar :

-

Roller arc radius

- \(r_{{\rm{Rm}}}^{\rm{N}}\) :

-

Roller contact radius on the nut–roller side

- \(r_{{\rm{Rm}}}^{\rm{S}}\) :

-

Roller contact radius on the screw–roller side

- r Sa, r Ra, r Nf :

-

Major diameters of the screw, roller, and nut, respectively

- r Sm :

-

Screw contact radius

- R 1, R 2 :

-

Random numbers within the range [0, 1]

- S error :

-

Weighting coefficients of errors

- S clearance :

-

Weighting coefficients of axial clearance

- s i (i = 1,2,…,9):

-

Sensitivity coefficient of 9 errors

- s k (k = 1,2,…,10):

-

Weight coefficient of the kth sample attribute

- SSE :

-

Sum of square errors

- t :

-

Intersection coefficient between celli and v

- T :

-

Iteration times

- u ij (i = 1,2,…,K):

-

Membership of the jth sample to the ith group Ci

- U :

-

Membership matrix

- v = b 1 − b 2 :

-

Ray vector and its starting point vector and ending point vector

- x n1, x n2, …, x n9 :

-

Sampling values of 9 errors in en

- \(Z_{\rm{N}}^{i{\rm{U}}},\,Z_{\rm{N}}^{i{\rm{B}}},\,Z_{{\rm{R - N}}}^{i{\rm{U}}},\,Z_{{\rm{R - N}}}^{i{\rm{B}}}\) (i = 1,2,…,n):

-

z-coordinate of the intersection point between v and the upper and lower contact surfaces of the ith pair of meshing threads on the nut–roller side, corresponding to the minimum axial distance

- \(Z_{\rm{S}}^{i{\rm{U}}},\,Z_{\rm{S}}^{i{\rm{B}}},\,Z_{{\rm{R - S}}}^{i{\rm{U}}},\,Z_{{\rm{R - S}}}^{i{\rm{B}}}\) (i = 1,2,…,n):

-

z-coordinate of the intersection point between v and the upper and lower contact surfaces of the ith pair of meshing threads on the screw–roller side, corresponding to the minimum axial distance

- α:

-

Significance level of hypothesis testing

- β i (i = S, R, N):

-

Flank angle of screw, roller, or nut

- Δα i (i = S, R, N):

-

Flank angle error of screw, roller, or nut

- ΓUi, ΓBi (i = S, R, N):

-

Upper and lower profile curves of the screw, roller, or nut, respectively

- \(\Gamma _{{\rm{SR}}}^{\rm{U}},\,\Gamma _{{\rm{SR}}}^{\rm{B}},\,\Gamma _{{\rm{NR}}}^{\rm{U}},\,\Gamma _{{\rm{NR}}}^{\rm{B}}\) :

-

Contact pairs on the upper and lower sides of the roller threads

- δ g :

-

Overall global axial clearance of PRSM

- δ ij, δ j (i = 1,2,…,N j; j = 1,2,…,K):

-

Clearance values of sample within the group and their mean value

- δ n :

-

Axial clearance value with 9 errors in en

- \(\delta _{{\rm{NR}}}^{i{\rm{U}}},\,\,\delta _{{\rm{NR}}}^{i{\rm{B}}}\) (i = 1,2,…,n):

-

Axial clearances between the upper and lower contact surfaces of the ith pair of meshing threads on the nut–roller side, respectively

- \(\delta _{{\rm{Rm}}}^{\rm{N}}\) :

-

Axial clearances on the nut–roller side

- \(\delta _{{\rm{Rm}}}^{\rm{S}}\) :

-

Axial clearances on the screw–roller side

- \(\delta _{{\rm{SR}}}^{i{\rm{U}}},\,\,\delta _{{\rm{SR}}}^{i{\rm{B}}}\) (i = 1,2,…,n):

-

Axial clearances between the upper and lower contact surfaces of the ith pair of meshing threads on the screw–roller side, respectively

- ε :

-

Iterative threshold

- λ i (i = S, R, N):

-

Helix angle of screw, roller, or nut

- μ :

-

Location parameter of errors distribution

- μ i (i = 1, 2,…, 10):

-

Sensitivity factor of each error

- σ :

-

Scale parameter of errors distribution

- φ Nm :

-

Nut contact angle

- \(\varphi _{{\rm{Rm}}}^{\rm{N}}\) :

-

Roller contact angle on the nut–roller side

- \(\varphi _{{\rm{Rm}}}^{\rm{S}}\) :

-

Roller contact angle on the screw–roller side

- φ Sm :

-

Screw contact angle

References

Falkner M, Nitschko T, Supper L, Traxler G, Zemann J V, Roberts E W. Roller screw lifetime under oscillatory motion: from dry to liquid lubrication. In: Proceedings of the 10th European Space Mechanisms and Tribology Symposium. San Sebastian: ESA, 2003, 297–301

Wander J, Byrd V, Parker J. Initial disturbance accommodating control system analysis for prototype electromechanical space shuttle steering actuator. In: Proceedings of 1995 American Control Conference. Seattle: IEEE, 1995, 3961–3964

Garcia A, Cusido J, Rosero J A, Ortega J A, Romeral L. Reliable electro-mechanical actuators in aircraft. IEEE Aerospace and Electronic Systems Magazine, 2008, 23(8): 19–25

Wang H, Tong M H, Zheng P. Research on contact strength between roller screw pair on hoisting mechanism applied in deep sea crane. Applied Mechanics and Materials, 2013, 423–426: 2001–2005

Richter L, Kroemer O. Application of a remote controlled hammering drill from space to deep sea. In: Proceedings of OCEANS 2009-EUROPE. Bremen: IEEE, 2009, 1–4

Dupont P E. Friction modeling in dynamic robot simulation. In: Proceedings of IEEE International Conference on Robotics and Automation. Cincinnati: IEEE, 1990, 1370–1376

Lohmeier S, Buschmann T, Ulbrich H. Humanoid robot LOLA. In: Proceedings of 2009 IEEE International Conference on Robotics and Automation. Kobe: IEEE, 2009, 775–780

Andrade A, Nicolosi D, Lucchi J, Biscegli J, Arruda A C F, Ohashi Y, Mueller J, Tayama E, Glueck J, Nosé Y. Auxiliary total artificial heart: a compact electromechanical artificial heart working simultaneously with the natural heart. Artificial Organs, 1999, 23(9): 876–880

Takatani S, Takami Y, Nakazawa T, Jacobs G, Nose Y. Double chamber ventricular assist device with a roller screw linear actuator driven by left and right latissimus dorsi muscles. ASAIO Journal, 1995, 41(3): M475–M480

Rosenberg G, Pierce W S, Snyder A J, Weiss W J, Lamson T. The pennsylvania state university roller screw electric total artificial heart: 205 days survival in the calf. In: Proceedings of the Annual International Conference of the IEEE Engineering in Medicine and Biology Society. Orlando: IEEE, 1991, 2087–2089

Zago L, Droz S. Small parallel manipulator for the active alignment and focusing of the secondary mirror of the VLTI ATS. In: Proceedings of Optical Design, Materials, Fabrication, and Maintenance. Munich: SPIE, 2000, 4003: 450–455

Worthington M S, Beets T A, Beno J H, Mock J R, Murphy B T, South B J, Good J M. Design and development of a high-precision, high-payload telescope dual-drive system. In: Proceedings of Ground-Based and Airborne Telescopes III. San Diego: SPIE, 2010, 77335G

Zheng S C, Fu Y L, Wang D Y, Zhang W S, Pan J L. Investigations on system integration method and dynamic performance of electromechanical actuator. Science Progress, 2020, 103(3): 1–35

Du X, Chen B K, Zheng Z D. Investigation on mechanical behavior of planetary roller screw mechanism with the effects of external loads and machining errors. Tribology International, 2021, 154: 106689

Hu R, Wei P T, Liu H J, Du X S, Zhou P L, Zhu C C. Investigation on load distribution among rollers of planetary roller screw mechanism considering machining errors: analytical calculation and machine learning approach. Mechanism and Machine Theory, 2023, 185: 105322

Jones M H, Velinsky S A. Kinematics of roller migration in the planetary roller screw mechanism. Journal of Mechanical Design, 2012, 134(6): 061006

Ma S J, Cai W, Wu L P, Liu G, Peng C. Modelling of transmission accuracy of a planetary roller screw mechanism considering errors and elastic deformations. Mechanism and Machine Theory, 2019, 134: 151–168

Wu H L, Wei P T, Hu R, Liu H J, Du X S, Zhou P L, Zhu C C. Study on the relationship between machining errors and transmission accuracy of planetary roller screw mechanism using analytical calculations and machine-learning model. Journal of Computational Design and Engineering, 2023, 10(1): 398–413

Xie Z J, Wang Y, Ni J, Yin J H, Yu D, Liu J Q. Friction torque analysis of planetary roller screw based on the creepage theory. Tribology International, 2023, 178: 108059

Liu Y Q, Shang Y, Wang J S. Mathematical analysis of the meshing performance of planetary roller screws applying different roller thread shapes. Advances in Mechanical Engineering, 2017, 9(5): 1687814017703009

Hu R, Wei P T, Du X S, Zhou J, Liu H J, Liu G S, Zhu C C. Investigation of loaded contact characteristics of planetary roller screw mechanism based on influence coefficient method and machine learning. Advanced Engineering Informatics, 2023, 58: 102146

Blinov D S, Ryakhovsky O A, Sokolov P A. Numerical method of determining the point of initial thread contact of two screws with parallel axes and different thread inclinations. Mashinostr, 1996, 3: 93–97 (in Russian)

Ryakhovskiy O A, Sorokin F D, Marokhin A S. Calculation of radial displacements of nut and rollers axes and the position of a contact between the nut and the roller thread in an inverted planetary roller screw mechanism. BMSTU Journal of Mechanical Engineering, 2013, 11(644): 12–19 (in Russian)

Fedosovsky M E, Aleksanin S A, Puctozerov R V. Use of numerical method for determination of contact points position in roller screw threads. Biosciences Biotechnology Research Asia, 2015, 12(1): 721–730

Jones M H, Velinsky S A. Contact kinematics in the roller screw mechanism. Journal of Mechanical Design, 2013, 135(5): 051003

Liu Y Q, Wang J S, Cheng H X, Sun Y P. Kinematics analysis of the roller screw based on the accuracy of meshing point calculation. Mathematical Problems in Engineering, 2015, 2015: 303972

Fu X J, Liu G, Ma S J, Tong R T. Meshing properties of planetary roller screw mechanism within misalignments. Journal of Mechanical Engineering, 2017, 53(3): 25–33 (in Chinese)

Fu X J, Liu G, Ma S J, Tong R T, Lim T C. A comprehensive contact analysis of planetary roller screw mechanism. Journal of Mechanical Design, 2017, 139(1): 012302

Wang S M, Xu Q, Luo Z W, Huang Y P, Pi L P. Effect of profile error on meshing state of planetary roller screw. In: Proceedings of 2017 Chinese Automation Congress. Jinan: IEEE, 2017, 7472–7477

Litvin F L, Fuentes A. Gear Geometry and Applied Theory. 2nd ed. Cambridge: Cambridge University Press, 2004

Wu L P, Ma S J, Fu X J, Zhang J X, Liu G. A review of planetary roller screw mechanism for development and new trends. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science, 2022, 236(21): 10822–10840

Zhang C Q, Shao J Y, Chen K, Ren C Z. A robotic manipulator control and simulation system with Qt and VTK. Advanced Materials Research, 2012, 462: 712–719

Hong L, Wang B S, Yang X L, Wang Y G, Lin Z. Offline programming method and implementation of industrial robot grinding based on VTK. Industrial Robot, 2020, 47(4): 547–557

Liu Q, Qiao Z, Lv Y. PyVT: a Python-based open-source software for visualization and graphic analysis of fluid dynamics datasets. Aerospace Science and Technology, 2021, 117: 106961

Wheeler G, Deng S J, Toussaint N, Pushparajah K, Schnabel J A, Simpson J M, Gomez A. Virtual interaction and visualisation of 3D medical imaging data with VTK and Unity. Healthcare Technology Letters, 2018, 5(5): 148–153

Chaudhary A, Jhaveri S J, Sanchez A, Avila L S, Martin K M, Vacanti A, Hanwell M D, Schroeder W. Cross-platform ubiquitous volume rendering using programmable shaders in VTK for scientific and medical visualization. IEEE Computer Graphics and Applications, 2019, 39(1): 26–43

Velinsky S A, Chu B, Lasky T A. Kinematics and efficiency analysis of the planetary roller screw mechanism. Journal of Mechanical Design, 2009, 131(1): 011016

Lemor P C. The roller screw, an efficient and reliable mechanical component of electro-mechanical actuators. In: Proceedings of the 31st Intersociety Energy Conversion Engineering Conference. Washington DC: IEEE, 1996, 215–220

Sun L J, Ren J J, Xu X G. A data-driven machining errors recovery method for complex surfaces with limited measurement points. Measurement, 2021, 181: 109661

Xu H W, Wei P T, Zhou P L, Du X S. Non-contact detection and deviation evaluation method of small pitch roller profile. Journal of Chongqing University, 2023, 46(3): 45–57 (in Chinese)

Ishizaki K, Shamoto E. A new real-time trajectory generation method modifying trajectory based on trajectory error and angular speed for high accuracy and short machining time. Precision Engineering, 2022, 76: 173–189

Wu Y F. Correlated sampling techniques used in Monte Carlo simulation for risk assessment. International Journal of Pressure Vessels and Piping, 2008, 85(9): 662–669

Liu G, Ma S J, Fu X J. Planetary Roller Screw Transmission-Meshing Principle. Beijing: Science Press, 2019 (in Chinese)

Cheng Q, Feng Q N, Liu Z F, Gu P H, Zhang G J. Sensitivity analysis of machining accuracy of multi-axis machine tool based on POE screw theory and Morris method. The International Journal of Advanced Manufacturing Technology, 2016, 84(9–12): 2301–2318

Kumar M S, Kannan S M. Optimum manufacturing tolerance to selective assembly technique for different assembly specifications by using genetic algorithm. The International Journal of Advanced Manufacturing Technology, 2007, 32(5–6): 591–598

Raj M V, Sankar S S, Ponnambalam S G. Minimizing assembly variation in selective assembly by using particle swarm optimization. In: Proceedings of the 3rd International Conference on Computer Engineering and Technology. Kuala Lumpur: ASME, 2011, 91–96

Zhang Y, Wang X D, Chen Z T, Zhu Z Q, Ye H. A synchronous polishing method for aero-engine blade based on multi-spindle machine tool. The International Journal of Advanced Manufacturing Technology, 2022, 123(5): 1669–1678

Shi X R, Cui W, Zhu P, Yang Y H. Research on automobile assembly line optimization based on industrial engineering technology and machine learning algorithm. Wireless Communications and Mobile Computing, 2021, 2021: 2658090

Li B C, Liu Y. The study of fuzzy clustering analysis in the determination of assembly process for hull block module. Hydraulic Equipment and Support Systems for Mining, 2012, 619: 329–335

Kodinariya T M, Makwana P R. Review on determining number of cluster in k-means clustering. International Journal of Advance Research in Computer Science and Management Studies, 2013, 1(6): 90–95

Bezdek J C, Ehrlich R, Full W. FCM: the Fuzzy C-Means clustering algorithm. Computers & Geosciences, 1984, 10(2–3): 191–203

Acknowledgement

The work was supported by the National Key R&D Program of China (Grant No. 2023YFB3406404).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

He, H., Wei, P., Liu, H. et al. Three-dimensional parametric contact analysis of planetary roller screw mechanism and its application in grouping for selective assembly. Front. Mech. Eng. 19, 2 (2024). https://doi.org/10.1007/s11465-023-0775-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11465-023-0775-x