Abstract

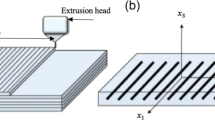

Multi-gripper flexible stretch forming (MGFSF) is a novel flexible forming process of sheet metal based on the multi-point forming principle. The straight jaws in traditional transverse stretch forming (TSF) are replaced by several discrete clamping mechanisms on both sides. To help understand the forming characters of MGFSF, spherical and concave–convex parts were selected as the research objects and finite element analyses on TSF and MGFSF were implemented using an explicit nonlinear finite element code. The influence of the transition length on the forming results in MGFSF was also taken into account in the present work. The simulation results reveal that a shorter transition length in MGFSF would result in an easier conformability of the sheet metal to the desired shape as well as a smaller strain variation in the forming zone. It is also found that, compared to TSF, the sheet metal can be formed without transition zone by utilizing MGFSF, which could significantly improve the material utilization and save the manufacturing costs. Finally, experimental validations were conducted on the self-developed MGFSF apparatus and the experimental results show a good agreement with the numerical results.

Similar content being viewed by others

References

Polen LA, Harkey JT (2007) Stretch-forming machine and method. US Patent US20070163323A1.

Hardt DE, Olsen BA, Allison BT, Pasch K (1981) Sheet metal forming with discrete die surfaces. Proceedings of Ninth American Manufacturing Research Conference 140–144

Hardt DE, Boyce MC, Walczky DF (1993) A flexible forming system for rapid response production of sheet metal parts. Proceedings of IBEC’93, Detroit, Michagan, USA, 61–69.

Hardt DE, Webb RD (1982) Sheet metal die forming using closed loop shape control. Ann CIRP 31:165–169

Walczyk DF, Hardt DE (1998) Design and analysis of reconfigurable discrete dies for sheet metal forming. J Manuf Syst 17(6):436–454

Walczyk DF, Lakshmikanthan J, Kirt DR (1998) Development of a reconfigurable tool for forming aircraft body panels. J Manuf Syst 17(4):287–296

Valjavec M, Hardt, DE (1999) Closed-loop shape control of the stretch forming process over a reconfigurable tool: precision airframe skin fabrication. Proceedings of the ASME, Manufacturing Engineering Division, MED, 909–919

Li MZ, Nakamura, K, Watanabe S, Akutsu Y (1992) Study of the basic principles (1st report: research on multi-point forming for sheet metal). Proceedings of the Japanese Spring conference for Technology of Plasticity 519–522 (in Japanese)

Li MZ, Liu YH, Su SZ, Li GQ (1999) Multi-point forming: a flexible manufacturing method for a 3D surface sheet. J Mater Process Technol 87:277–280

Li MZ, Cai ZY, Sui Z, Yang QG (2002) Multi-point forming technology for sheet metal. J Mater Process Technol 129:333–338

Liu CG, Li MZ, Fu WZ (2008) Principles and apparatus of multi-point forming for sheet metal. Int J Adv Manuf Technol 35:707–708

Tan FX, Li MZ, Cai ZY (2007) Research on the process of multi-point forming for the customized titanium alloy cranial prosthesis. J Mater Process Technol 187–188:453–457

Wang SH, Cai ZY, Li MZ, Lan YW (2012) Numerical simulation on the local stress and local deformation in multi-point stretch forming process. Int J Adv Manuf Technol 60:901–911

Cai ZY, Wang SH, Li MZ (2008) Numerical investigation of multi-point forming process for sheet metal: wrinkling, dimpling and springback. Int J Adv Manuf Technol 37(9–10):927–936

Cai ZY, Li MZ (2006) A finite element method to generate digitized-die shape from the measured data of desired part. Int J Adv Manuf Technol 30:61–69

Cai ZY, Li MZ (2005) Finite element simulation of multi-point sheet forming process based on implicit scheme. J Mater Process Technol 161(3):449–455

Cai ZY, Li MZ, Chen XD (2006) Digitized die forming system for sheet metal and springback minimizing technique. Int J Adv Manuf Technol 28(11–12):1089–1096

Cai ZY, Wang SH, Xu XD, Li MZ (2009) Numerical simulation for the multi-point stretch forming process of sheet metal. J Mater Process Technol 209(1):396–407

Liu W, Yang YY, Li MZ (2010) Numerical simulation of multi-point stretch forming and controlling on accuracy of formed workpiece. Int J Adv Manuf Technol 50:61–66

Wang SH, Cai ZY, Li MZ (2010) Numerical investigation of the influence of punch element in multi-point stretch forming process. Int J Adv Manuf Technol 48(5–8):475–483

Li MZ, Han QG, Fu WZ, Feng PX, Liu YH (2011) Study of a flexible stretch forming machine. Proc 10th Int Techn Plast (ICTP2011) Aachen, Germany, 655–658

Chen X, Li MZ, Fu WZ, Feng PX (2010) Research on multi-head stretch forming technology of sheet metal. ICECE 2010: International Conference on Electrical and Control Engineering, June 25-27, Wuhan, China. Wuhan: ICECE, 720:2952-2955

Chen X, Li MZ, Zhang HH, Peng HL (2012) The effect of discrete grippers on sheet metal flexible-gripper stretch forming. Applied Mechanics and Materials 121–126:488–492

Chen X, Li MZ, Fu WZ, Cai ZY (2011) Numerical simulation of different clamping modes on stretch forming parts. Advanced Materials Research 189–193:1922–1925

Peng HL, LiMZ HQG, Feng PX, Zhang HH (2011) Design of flexible multi-gripper stretch forming machine by FEM. Advanced Materials Research 328–330:13–17

Socrate S, Boyce MC (2001) A finite element based die design algorithm for sheet metal forming on reconfigurable tools. J of Eng Mater and Techn 123:489–495

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Li, Mz. Research on three-dimensional surface parts in multi-gripper flexible stretch forming. Int J Adv Manuf Technol 71, 1701–1707 (2014). https://doi.org/10.1007/s00170-014-5610-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-5610-4