Abstract

Hydroforming is a relatively new metal forming process with many advantages over traditional cold forming processes including the ability to create more complicated components with fewer operations. For certain geometries, hydroforming technology permits the creation of parts that are lighter weight, have stiffer properties, are cheaper to produce and can be manufactured from fewer blanks which produces less material waste. This paper provides a detailed survey of the hydroforming literature of both established and emerging processes in a single taxonomy. Recently reported innovations in hydroforming processes (which are incorporated in the taxonomy) are also detailed and classified in terms of “technology readiness level”. The paper concludes with a discussion on the future of hydroforming including the current state of the art techniques, the research directions, and the process advantages to make predictions about emerging hydroforming technologies.

Similar content being viewed by others

Introduction

Hydroforming is a near net shape metal forming process whereby complicated shapes are created by the utilization of fluid pressure instead of (or in conjunction with) traditional mechanical forces. The hydroforming process has several advantages over other forming processes which has helped establish it in a range of specific applications. These are: the ability to create re-entrant features, reduced thinning [1], enhanced mechanical properties, better surface finish [2], fewer components required in an assembly [3], and less required rework due to the creation of geometries which are closer to the final shape, [4]. These advantages primarily stem from the ability of the working fluid to exert pressure evenly over the entire surface of a material and for the equipment to vary this fluid pressure during the forming cycle based upon an optimized load path.

Hydroforming subcategories

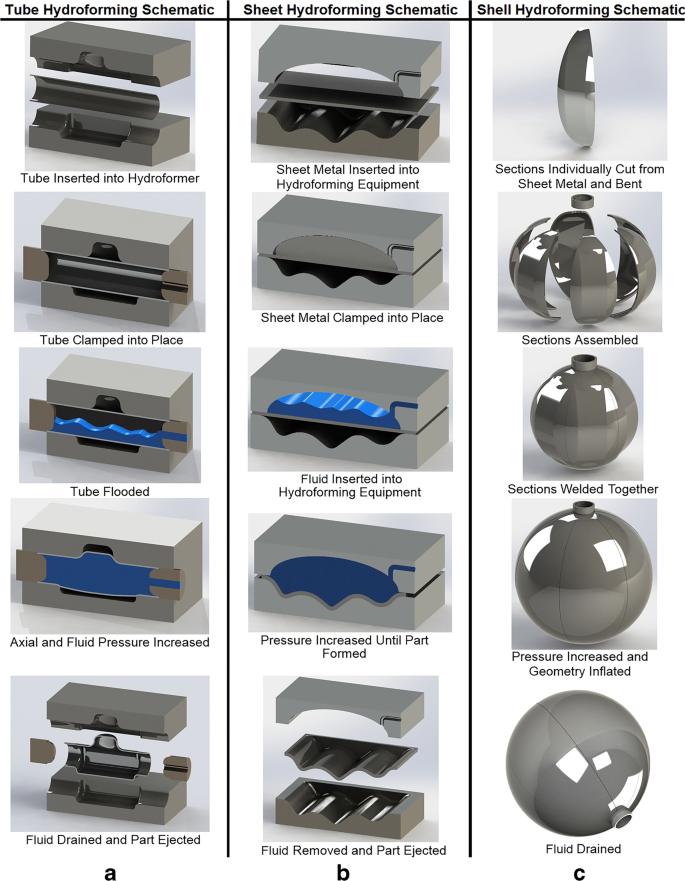

Hydroforming has been exploited in many manufacturing sectors including the automotive and aerospace industries to produce components which otherwise would be difficult or impossible to form. The fluid pressure allows for more even material expansion and for pressure generation in orientations other than the forming direction which enable creation of additional or more prominent features. Thus, hydroforming fills a manufacturing gap by allowing higher material formability than conventional cold forming [4] with less cost and cycle time as compared to other specialized and nontraditional sheet metal forming technologies like superplastic forming or creep forming, [5]. This increased formability is seen (and quantified by) an increase in the limit draw ratio from 2 with deep drawing to as much as 3.2 with hydroforming [6]. The hydroforming process can be split into three distinct categories: tube, sheet and shell as shown in Fig. 1. This division is based upon the geometry of the blank used during the operation. Each of these three categories are distinct processes that have different key process variables and usually require different equipment. While the advantages and disadvantages will be gone over in detail in "Discussion" section after the process has been fully described, all of these categories utilize the advantages of forming with fluids to produce a more complicated and higher quality final product [3] than traditional pressing processes can provide [2]. An example of how quality can improve with hydroforming is if the increased complexity allowed from the manufacturing process is used to simply design by removing weld lines from fabrications reducing potential weak points in their designs [7].

The tube hydroforming process shown in Fig. 2a:

-

Starts with a hollow cylindrical metal tube

-

The tube is filled with fluid and expanded to a more complicated geometry

-

Often tube hydroforming equipment is fitted with rams which axially feed new material in by pushing on the edges of the tubes during the operation

-

By simultaneously increasing the fluid pressure on the inside of the tube while feeding new material, axial feeding can reduce material thinning

The sheet hydroforming process shown in Fig. 2b:

-

Starts with a sheet metal blank

-

Deforms the sheet metal into a final geometry by applying fluid pressure, sometimes in conjunction with mechanical pressure

-

The process can either use a male or a female die, these are referred to as a punch or cavity die respectively

-

The process bears resemblance to deep drawing, stamping (pressing), and rubber pad forming

Shell hydroforming or “integrated hydro-bulge forming” (IHBF) shown in Fig. 2c:

-

Starts with sheet metal blanks each of which is bent into position

-

The sheets are then welded into a spherical, oval, or custom hollow shell

-

A nozzle is welded on to the exterior

-

The interior is filled with fluid which is expanded to bulge the fabricated shape outwards

-

Shell hydroforming is a dieless process, meaning expansion takes place in free space and not against a die

There have been a number of recent reviews of each of these categories: for example Koç, et al. 2001 [10] gave an overall review of tube hydroforming technology which included materials and applications. The same author also wrote a dissertation on creating design guidelines for the THF process [11]. In 2003 Harjinder Singh [12] authored a book summarizing sheet and tube hydroforming history and principles of the nineteenth century. Lang, et al. [13] published a review of specific technologies of interest in sheet, tube and shell hydroforming in 2004. Wang. et al. published a review of shell hydroforming technology in 2005 which covered the development of the technology including its applications and information concerning finite element simulations of the process. An edited volume published in 2008 by Koç et al. [6] summarized sheet and tube hydroforming, giving current applications also identified a few research trends such as warm hydroforming and gave an in depth look at the tube and sheet hydroforming process including governing equations. Similarly a tube hydroforming review in 2012 by Alaswad, et al. [2] summarized the recent experiments and literature in tube hydroforming technology. A tube and sheet hydroforming review was written by Lee, et al. who looked into recent technical work and simulations of tube and sheet hydroforming [14].

The aim of this contribution is to: 1. Provide a comprehensive overview of the state of the art in all forms of hydroforming. 2. Identify emerging hydroforming technologies. 3. Place all the reported systems in a single taxonomy (shown later in Fig. 46) that clearly identify the generic similarities and differences between the processes. 4. Classify the emerging technologies in terms of their technology readiness level (i.e. process maturity). 5. Characterize the position of hydroforming with regard to manufacturing and state the likely future of hydroforming in industry.

Methodology

Hydroforming literature was included in the analysis if it met one of the following 3 criteria: 1. Source is a conference or journal publication reporting on a hydroforming or closely related process. 2. Source has relevant peer reviewed information pertaining to hydroforming or related technology. 3. Because much of the development of hydroforming is commercially driven, sources outside the conventional literature were considered if the source was: a professional, website, or an interview/communication from a known hydroforming component supplier, equipment vendor, or expert. Entries were excluded if they met one of the following 2 exclusion criteria: 1. 1. Source was written in a language other than English. 2. Source did not refer to hydroforming or a closely related technology or field.

The rest of this paper is structured as follows: "Historical context and industrial applications" section summarizes the history and applications of the tube sheet and shell processes and how their applications have changed over time. This is followed by the identification of the key process variables and their importance to the hydroforming process for each category. "Process parameters" section discusses hydroforming techniques which allow for complicated feature generation that are already used in industry. "Materials" section discusses various different metals that have been formed. "Geometry" section discusses geometries including what geometries are possible, basic geometric calculations, and geometries that should be avoided if possible. "Development directions" section discusses the research areas in the different branches of hydroforming including the relative maturity of new hydroforming technologies and the new taxonomy which will help to characterize future hydroforming processes. "Discussion" section discusses the future of hydroforming technology with emphasis on its future in the aerospace sector. And finally "Conclusion" section is a conclusion that states how and where the aims were addressed within the text.

Historical context and industrial applications

Tube hydroforming history

The first references of tube hydroforming date back to the early 1900s when a patent for an “Apparatus for forming serpentine hollow bodies” [15] was filed at the US patent office [12]. The patent called for using fluid instead of the previous method of interlocking mandrels to form cylindrical components and specified that the fluid “is preferably of melted lead” [15]. It is unclear if the patent was ever physically tested and optimized, but was almost certainly never put to any serious commercial use. A few decades later, in 1939, a process for manufacturing “seamless copper fittings with T protrusions using a combination of internal pressure and axial load” [2] was patented which allowed for T fittings to be manufactured from straight lengths of pipe using hydroforming with axial feeding [16]. And although initially limited to the manufacture of plumbing fittings, the process was essentially the same physical process that is used today. In subsequent decades the applications of tube hydroforming slowly expanded to include various fittings, simple airplane blades, and bicycle frame joints [12].

In 1986 a patent was issued in North America [17] to the predecessor of a company now called Veri-Form for “the applications of hydroforming technique to larger frame members” [12]. This technology led to the manufacture of large structural components and caused sales of equipment to grow rapidly after 1990 as lots of applications were found in the automotive industry. Sales carried through until about 2006 when new equipment purchases started to match machine obsolescence. Component production continued on the available equipment with one company reporting an increase in 10% per year from 2010 to 2013 [18], but this increase in production appears to be primarily accounted for by increased machine throughput. Figure 3 shows the approximate number of tube hydroforming machines installed in Europe from 1990 to present.

Automotive tube hydroforming equipment available in Europe; courtesy of Salzgitter Hydroforming [19]

The data suggests that the hydroforming boom of the late 20th and early 21st centuries caused by the adoption of the technology for the manufacture of structural elements of automotive products has reached current market saturation.

Sheet hydroforming history

The first instances of sheet hydroforming operations took place in the 1890s although most of the industrial development did not start for several decades [3]. Based upon the limited amount of technical information and lack of patents during this time it is likely that industrial applications were limited until the Cincinnati Milacron group (now Milacron LLC) created and sold simple sheet hydroforming machines in the 1940s in the United States. Once available, these machines became a standard piece of equipment in the forming industry and worked well in low volume areas as they used one tool instead of two which dramatically reduces the “per part” cost of manufacturing. Cheaper overall costs for smaller quantities are still one of the reasons that companies choose hydroforming technology as demonstrated by one recent breakeven analysis which estimates that under normal circumstances hydroforming is cheaper per part until sizes of around 35–40 thousand parts [20]. In certain cases hydroforming can also use one tool when it would take conventional cold forming processes several iterative tools to create a specific geometry. This means that cost is dependent on both volume and complexity [21].

Other companies tried to copy this technology without infringing upon the intellectual property, some did this by locating the fluid below the part and using the blank as a bladder, but this was ultimately commercially unsuccessful which allowed for Cincinnati to become the predominant vendor of SHF equipment in the United States in the mid-twentieth century. Many of the early punch hydroforming machines generated fluid pressure in large part from the punch engaging and deforming the metal which displaced the fluid and increased the pressure. These kinds of machines lacked the fine detail and control available on modern equipment in part due to the design constraint imposed by the punch applying a large quantity of the required fluid pressure. While any pressure combination could be set, it would not necessarily be achievable because the punch would move quickly and displace a large volume of fluid which rapidly builds pressure. Also early machines were each quirky in individual ways and in order to run a forming shop efficiently it took operators with experience not just with Cincinnati machines, but with a single particular machine to know quirks of that specific machine and use it effectively. The pressures on different machines would not behave in the exact same fashion and a single machine would perform differently throughout the day as the oil heated up and the resulting change in viscosity affected the forming process. This meant that the operator would have to change the settings slightly throughout the day to compensate and over or under set the pressure based upon experience [21].

Shortly after Cincinnati introduced punch hydroforming equipment in the United States, fluid cell presses were developed in the 1950’s which enabled small size forming operations in cavity and punch. This technology was limited in draw depth but had a superior ability to draw in material as compared to rubber pad forming because the fluid cell could exert pressure in other orientations than the forming direction, and the technology was much more consistent than hand forming. Fluid cell presses were accepted into the aerospace industry in the 1960’s [6]. Current technologies do not have the same technical limitations that earlier sheet hydroforming machines were encumbered by. Newer machines can generally hit ± 0.002 of an inch with draw depths and ± 2% with regard to the fluid pressure [21] and have the capacity for deeper draws.

Shell hydroforming history

Shell hydroforming is the smallest of the three categories and was only invented in 1985 (patented in China in 1988) [9]. Reported applications are limited in scope to small scale projects, academic research, and small batch industrial projects. Shell hydroformed structures are manufactured individually by fabricating (e.g. welding) sheet metal blanks and then inflating the resulting geometries [13] with either specialized equipment or in some cases with high-pressure washers [22]. However, because this process makes components one at a time it appears to be highly labor intensive.

Tube hydroforming applications

While hydroforming technology is currently used in the manufacturing sectors of many different industries, the development has been pushed most notably by the automotive industry which has used hydroforming technology to greatly improve the manufacturing processes of many different components. Many of the structural members of the automobile are now made via a manufacturing method that includes hydroforming. Tube hydroforming examples of these would include: cradles [10], pillars, [23] and undercarriages [24]. Undercarriages for vehicles were previously (and are still sometimes) “made of U-shaped or channel sections carefully shaped and then welded or riveted together” [25]. The U-shaped sections were produced by rolling and bending sheet metal or by directly rolling a U-shaped channel and cutting and welding it to others. But these sections can not be customized to the same extent as hydroformed components. This is because even though channels can be shaped, their overall cross section can not be dramatically changed. Furthermore because a weld is a compromise in the design, it will introduce a change in material properties and is often a source of increased manufacturing cost and potential defects. This means welds require thicker sections and wider safety margins which add cost and weight. Tube hydroforming removes these problems as it allows for tubes to be bent (instead of welded) while in a tubular shape, and then expanded to final geometry while becoming more rigid through strain hardening. Actual examples of large tube hydroforming chassis structures can be seen in Fig. 4.

Automotive undercarriage tube hydroforming applications; reprinted by permission from Springer Nature: Int J Mater Form, [23]

Other examples of automotive components changed to a THF based manufacturing processes can be seen in Fig. 5. These examples contain automotive structures found in various locations around a car including manifolds, pipes, shafts, rotating engine components, bumpers, engine cradles and structural members.

Various tube hydroforming automotive applications; reprinted with permission from [24]

Because of the complicated geometries involved in engine cradles, the implementation of tube hydroforming in the manufacturing process has greatly simplified the steps in fabrication and reduced the part count. This is because tube hydroforming allows for the creation of geometries which have variable cross sections. This helps in a few ways, for example the variable cross sections can have many flat areas which can be drilled and tapped into, and this would eliminate the need for brackets in those locations. In this way tube hydroforming simplifies the fastening methods required to attach it to the engine and chassis. In one specific tube hydroforming example, a Buick Le Sabre engine cradle had its part count reduced from 40 to 18 when it switched from a conventional to a tube hydroforming manufacturing process [6].

Sheet hydroforming applications

There are also many sheet hydroforming components found in the automotive including door panels [26], roofs, [23] and various structural frames [27], but because the process is more expensive than regular pressing operations the applications are fewer and more specialized. Still, sheet hydroforming can be an attractive manufacturing process because of its higher formability and superior surface finish. Sheet hydroforming is a near net shape manufacturing process which means that the parts it produces are close to the final specified geometry and require minimal rework. Sheet hydroforming can also be used to produce semi-finished geometries which are parts that will be later used in an assembly to make a final component. In this way, the advantages of hydroforming can be realized in a complicated assembly while minimizing the impact of the increased costs imposed by the longer cycle times. Some automotive examples are shown in Fig. 6 and include various structural members, panels, hoods, and doors. Other representative geometries are shown in Fig. 7.

Automotive sheet hydroforming applications; Reprinted by permission from Springer: Int J Mater Form, [23]

Shell hydroforming applications

Shell hydroforming appears to have few industrial applications. This is most likely due to the manufacturing method being labor intensive with each geometry being created individually and the relatively recent invention of the subcategory as a whole [9]. There are references in the literature to the creation of fluid holding vessels, fuel tanks and other hollow geometries but these references are few in number which indicates the applications of the technology.

Process parameters

During any manufacturing processes there are certain process parameters that need to be set and controlled in order to have a working process. Often in a manufacturing process the more important of these parameters are known as “key process variables” and the less important are dismissed as negligible or are considered impractical to change. The following section outlines the key process variables and different kinds of operations available for each hydroforming subcategory.

Indicative values for the key process variables in hydroforming are as follows. Cycle times in hydroforming operations can be anywhere between 15 s for very simple operations to over a minute [28]. Pressures in simple lower pressure hydroforming operations are generally kept under 1000 bar but pressure intensification systems on high pressure hydroforming equipment can reach between 1000 to 4000 bar. Exceeding 4000 bar is possible but decreases the service life of the equipment while drastically increasing its complexity [6]. Hydroforming has historically been a cold forming operation because it is difficult to have high temperature surfaces in close proximity to fluids and rubbers but higher temperature applications have recently become more commonplace. Warm hydroforming can still use fluids in temperatures a few hundred degrees above ambient conditions while suffering moderately more damage to wear pads. However, for temperatures over 350 °C, fluids are generally not acceptable [29] and using hot gas or an alternate media (e.g. ceramic beads) is required.

Tube hydroforming process

The THF operation starts with a tubular blank and expands it into a predefined shape of larger and more complicated cross section by filling the tube with fluid and increasing the pressure to bulge the tube outwards against a die. In most cases the tubes are also forced axially inwards through the use of rams during the process. This feeds in new material which replaces the material that would otherwise be thinning during the expansion. This process along with a typical pressure cycle can be seen in Fig. 8.

Tube hydroforming schematic & cycle; reprinted/adapted by permission from Springer Nature [30]

Tube hydroforming blanks & key process variables

Both seamed and seamless tube can be used for hydroforming, although the latter must be oriented so that the join is subjected to minimal strain during the forming process (e.g. downward in Fig. 8). In cases with more complicated shapes, preforming operations such as bending must occur before the tubes can be loaded into the dies. In specific cases specialized tailor welded blanks can be used but this adds weld lines, manufacturing complexities, simulation complexities, and other costs. The main variables in tube hydroforming are: fluid pressure cycle, axial pressure (or displacement), lubrication condition (friction), and temperature [6]. There is also a decision of whether or not crushing or bending operations will take place before the actual hydroforming operation. Processes like axial upsetting can create some of the same features and can also use axial feeding to replace material in a similar fashion to tube hydroforming [31] (as well as create tube flanges [32]).

Tube crushing

It can be advantageous to have the closing action of the press either crush the tube or carry out some of the forming action while the dies close together. This allows a larger diameter tube to be used then would otherwise physically fit inside the die, which in turn allows for more material to be present during forming (Fig. 9). However a crushing operation work hardens the tube which consumes material formability during the crushing operation [6] and may create pinch points or geometric features (like wrinkles) that will not expand properly in the forming stage.

For an industrial example, one study by Saboori et al. documents the effectiveness of a tube crushing operation followed by a hydroforming operation to produce a 0.9 mm thick Inconel 718 turbine blade [33]. The process was crushed and expanded through hydroforming to see how much of a V could be introduced into the tube before the tube burst (Fig. 9 and 10)

Crushing and tube hydroforming process of a turbine blade in the initial and final stages; reprinted by permission from ASME: ASME Turbo Expo 2015: Turbine Technical Conference and Exposition [34]

Low versus high pressure hydroforming

Tube hydroforming operations can either be carried out at high or low pressures. Higher pressures allow for more expansion, but material thinning increases in direct proportion to geometric expansion. Low pressure hydroforming takes advantage of the tube crushing concept by first filling the tube with pressurized fluid, and then using the closing force of the press to get the tube either close to, or in to its final shape. When comparing a finite element analysis (FEA) simulation of high vs low pressure tube hydroforming of high strength steels Nikhare et al., 2009 found a smaller press is required for a low pressure tube hydroforming operation [35]. A similar result is also stated by Morphy et al., 1998 who present a comparison of two similar engine cradles, one made by high and one by low pressure THF. The research found that low pressure hydroforming (referred to as pressure sequence hydroforming in the source) was advantageous in “processing steps, hydroforming equipment, energy consumption, cycle time, and floor space” [36].

Sheet hydroforming process

Sheet hydroforming blanks & key process variables

Blanks come in the form of rolled sheet metal which is pre-cut to an appropriate size for the operation. Generally, the size and shape of the blank is determined by the results of iterative simulations which can optimize the blank size to allow for maximum material flow around a punch or in to a cavity [37]. In both sheet and punch hydroforming the key process variables to be considered are: the pressure cycle (i.e. the variation of pressure over time), and the temperature, and additionally for punch hydroforming the punch displacement is a key process variable. There are also a few different setup variables such as: whether or not spacers or draw-beads are used [38], the pressure from a counter punch (if applicable), the blank holding force (if the blank is physically held), lubrication condition (friction), blank shape [38], and whether a bladder is used between the fluid and workpiece [1].

Cavity vs punch sheet hydroforming

The sheet hydroforming process is typically performed by use of either a cavity die or a punch, and punch hydroforming is presently commonly known as hydromechanical deep drawing [39]. Both of these processes can be seen schematically in Fig. 11. Which process is chosen is dependent upon the geometrical complexity and draw depth of the part being formed. If a part has a complicated surface (e.g. with many different bulges) then it will likely require a cavity die. If a part has a cylindrical geometry and simple (flat or curved) surface then a punch will be beneficial as it can perform a deeper draw [3]. The tradeoff is generally that presses which use a punch have a smaller bed size as compared to those with a cavity and can only draw simpler shapes, but can make deeper draws with less material thinning.

Bladder vs direct fluid contact

Some sheet hydroforming systems such as ones manufactured by Quintus Technologies [40] or Triform Presses [41] use a flexible bladder as an intermediary between the fluid and blank, while other equipment vendors like FF FluidForming [42] allow the fluid to be in direct contact with the blank. Bladders can reduce degreasing operations by keeping working fluid away from blanks. This also keeps lubricant from getting into the working fluid. They also improve surface quality and possibly allow for more intricate feature generation, but rubber bladders have a finite life, need to be replaced, and sometimes break unexpectedly, they also lower process efficiency and require heavier presses [1]. While each equipment manufacturer has their own rationale about why they do or do not use bladders, the impact they make on the draw ratio appears to be minimal.

One important point to note about the use of a bladder is that it can enable the use of certain forming techniques such as a circular pressure intensifier that tightens radii (discussed and shown in detail later in Fig. 33). Without a bladder, the fluid would leak around the pressure intensifier instead of applying a forming force. A schematic of hydroforming with a punch and bladder can be seen in Fig. 12.

Fluid cell presses

There is also a relatively new type of hydroforming press (developed in the 1950’s) called a “fluid cell press” which is quite versatile as it has an extendable fluid cell tray on which lots of various blanks and dies can be laid out [6]. After it has been loaded up, the bed slides into a press and underneath a pressurized bladder [40]. With these machines the bed size is large and both cavity and punch dies can be used. Also all of the tools that the operator can fit on the bed can be used simultaneously [20]. While versatile, these presses generally are limited by a relatively shallow draw depth. This concept can be seen before and after pressurization in Figs. 13 and 14 respectively.

Fluid cell presses are efficient for light duty hydroforming operations especially in industrial applications which require versatility as they accommodate quick tooling changes, offer multiple operations per pressurization and do not suffer from alignment issues. Additionally, they also excel at large sheet metal components which contain many fine details.

Shell hydroforming process

A shell hydroforming process is generally die-less and is useful for creating custom hollow geometries especially in large sizes where dies and presses are expensive. The shell hydroforming operation starts with sheet metal blanks which are cut and welded together and inflated through use of a nozzle. Like the other hydroforming categories, shell hydroforming can be subcategorized into smaller groups based upon the geometry and pattern of the blanks used.

The fluid pressure cycle, and the blank welding pattern are the main key process variables in shell hydroforming. Various options for shell hydroforming welding patterns can be seen in Fig. 15.

Process windows and loading paths

A “process window” has a range of values that work for a given process and are displayed graphically. These windows are generated through simulation and experimentation and are governed by the material properties and the geometry of the parts. In specific circumstances, companies can also set the physical limitations of their equipment as boundaries to the process window. A schematic example of a simple process window can be seen in Fig. 16 and an empirically derived process window created by Hashemi et al., can be seen in Fig. 17. In this context, a “sound” part is one of an acceptable quality (free of wrinkles and ruptures) and a desired forming area is identified in the middle of the sound part area.

Typical schematic of a tube hydroforming process window; as described in [43]

Empirically derived tube hydroforming process window; reprinted by permission from Elsevier: Transactions of Nonferrous Metals Society of China [44]

Load paths are similar to process windows except instead of defining the range of viable process parameters they produce a specific sequence of values employed during a forming operation to produce a desired result. The load path is the critical setting in a hydroforming operation as it is the forces applied on a blank to go from a piece of sheet metal to a final component. A load path is a statement of how much fluid pressure (and axial force in the case of tube hydroforming) is applied at a given time through a forming process. They are created by “iterative finite element analyses with adjustments based on forming experience… due to the highly nonlinear nature of the tube hydroforming process” [45]. There are numerous studies in the relevant literature which explore how process windows and load paths are created and how they can be expanded or optimized but there are many challenges in doing so. For example, Bagherzadeh et al. formed bimetallic sheets in a SHF process and constructed a process window based upon FEA results and trials [39]. Wang et al. calculated a process window with “the stress analytical model combining material properties with workpiece geometrical features” in a SHF operation and relate which parts of the pressure cycle are important to which features in the component [46]. Shin et al. devised a process window for a THF operation and then enlarged it by reducing localized strain in vulnerable areas inhibited necking and subsequent failure [47].

Several studies cite process variability as a key difficulty in load path optimization and have proposed various means to take this into account. For example, Abdessalem et al. use a probabilistic approach to account for variation during load path creation [48], while Huang et al. propose a kriging-based non-probability system [49] which only requires the bounds of uncertainty instead of a probabilistic function (presumably because this information is generally easier to acquire). Other studies tried to optimize load paths with fuzzy logic, [50] or by statistical means [51] or with metamodeling techniques to cut down on computational time [52].

One key area which is repeatedly described in the recent literature (albeit by different names) is the process of optimizing a load path using multivariable optimization functions. This differs from classic simulation methods which perform an analysis given a predefined set of parameters and determine the outcome. Multivariable load path optimization instead steps through the process and optimizes at each step. Abdessalem et al. performed a multi-objective optimization of the loading path in a tube hydroforming operation (using metamodeling) [52]. Brooghani et al. used a “multilevel response surface method” for optimization of a load path which found the optimal point (based on minimal thinning in FEA simulation) at each interval and proceeded accordingly [51]. Alternately, instead of designing a specific function ahead of time, Xiang et al. looked at 9 different theoretical load paths and made a determination about which was best by looking at their effects on the results of an FEA analysis [53]. Intarakumthornichai et al. used a genetic algorithm based upon a two part quality criteria (minimization of thinning and elimination of wrinkles) [45]. Ge et al. used a similar multi-objective optimization function with differential evolution in a tube hydroforming operation to optimize a loading path [54].

Analytical methods and numerical simulations

Once reserved for specialized scientists, finite element analysis is now an integral part of complicated forming operations due to the increase in computational power and the increased diversity, accessibility, and user friendliness of software packages. That said, in comparison to other forming processes such as stamping, hydroforming is a difficult process to simulate because of the addition of fluid pressure, rubber diaphragms and the combination of axial forces and fluid pressure present in tube hydroforming.

As mentioned in the previous section, a key component in recent hydroforming research is the accurate optimization of the loading path and a lot of the recent research in analytical methods has been directed towards that ends. In general, the fluid pressure is assumed to be hydrostatic and universal throughout the application and follow the pressure curve. These kinds of simulations enable the hydroforming process by allowing for the optimization of a function (often based upon minimal material thinning and wrinkling) [45] instead of a more traditional empirically derived equation method, e.g. a calculation of a pressure curve that suppresses buckling using the energy method [55]. These simulations progress systematically and choose the optimum fluid pressure based upon the best outcome at each iteration. Muhammad et al., describe in their review of forming processes the preference of using continuum elements in hydroforming as they are “capable of describing deformation in thickness directions” [56].

Many new papers suggest applying the concept of “simulated annealing” to the optimization of hydroforming processes. Simulated annealing is one of the most popular metaheuristic algorithms used to solve optimization problems [57] and gets its name from classical annealing (the process of softening metal by heating and slowly cooling to freeze the structure at a minimum energy state) [58]. Simulated annealing is a probabilistic technique for approximating the global optimum which is used in complicated situations where finding an exact maximum is not realistic. Hashemi et al. successfully used a sheet hydroforming process to form bilayer composite sheets and simulated the process using a simulated annealing algorithm [57]. Mirzaali et al. used a simulated annealing optimization algorithm along with a 2D FEA simulation to optimize axisymmetric tubes in a THF operation [59].

Another key area in the research is the implementation of “fuzzy logic” which, as opposed to Boolean logic, can use any value between 0 and 1 [50] this means it can handle information that is partially true. Öztürk et al., implemented a fuzzy logic technique to optimize the loading profile in a sheet hydroforming operation using a punch to deep draw aluminum alloy sheets [60]. Similarly Ge et al. used fuzzy logic theory to create load path in a tube hydroforming operation [50], and Manabe et al. used an in-process fuzzy control system to hydroform T-shaped tubes [61] proving that fuzzy logic can be used during the process as well.

There is no straight forward answer to which of these methods generates the best results during these loading paths. The techniques are not necessarily mutually exclusive and all have their own cost in terms of computational requirements. Multi objective optimization can be performed in probabilistic or non-probabilistic environments and can take tolerances and variation into account. Having a probability function for the variables in the hydroforming process produces better results in finite element analysis [48] but is not required and other recent examples of using only the bounds of uncertainty have also been successful [49]. Success has been had with simulations that use fuzzy logic, simulated annealing, and traditional modelling techniques and so selection choose comes down to a mix of application, complexity, and experience. For further reference numerous reviews have been written on the topic of finite element modelling in sheet metal forming such as: Ablat and Qattawi [62] who review and categorize each type of numerical simulation as well as the yield criteria and software available. Additionally Mackerle et al. [63] describe and list numerous forming papers in different areas, and section 1.1 above lists numerous review papers on hydroforming which include finite element modelling aspects.

Forming limit diagrams and curves

Although process windows provide valuable insight into the functional range of a particular hydroforming machine they are by their nature only applicable to specific machines. In contrast forming limit curves (FLC represent limits in terms of the material parameters (e.g. stress, strain) and consequently provide a machine independent view of process capability. The forming limit curve is produced by analyzing the way a material stretches during a forming operation and observing the limits of a material’s behavior. To do this, many samples of a given material are deformed in a variety of orientations while optically analyzing the surface such as in a Nakajima or Marciniak test [64].

Nakajima tests, (Fig. 18) use photogrammetry to calculate the major and minor strains during a forming process. Forming limit diagrams have been adapted to be suitable for use with newer hydroforming methods such as pulsating fluid loads (explained in section 6) [65] . Examples of FLDs can be seen in (Figs. 19 and 20).

Nakajima test rig and various assessed geometries; redrawn from [64]

FLD with areas explained; redrawn from [66]

The resulting curves can play an important role as they can be used in combination with simulation software to predict failure during a forming process.

Tribology

The interaction of surfaces and lubricants is a key factor in the performance of a hydroforming process. While generally the objective in a forming operation is to reduce friction to allow material flow (usually by adding lubricant), friction can be useful in controlling material flow by reducing thinning in important areas. Several large studies have been carried out to investigate tribological issues in the THF process such as Koç who proposes guidelines for lubricant selection and concludes that axial feeding, axial force, and part thickness are strong indicators of lubricant performance [67]. Similarly Ngaile et al. provide an overview of the challenges of tribology in tube hydroforming operations and discuss tests to evaluate friction conditions [68]. Ma et al. look into the recent research for measuring the friction coefficient for high strain rate forming and evaluate the methods in the literature for measuring friction coefficients for tube hydroforming at high strain rates [69].

Other studies focus on specific applications or optimization of tribological conditions such as Abdelkefi et al. who evaluated the friction coefficient by using a tube hydroforming operation in a square die (similar to the corner filling test shown later in Fig. 23) with numerical and experimental means [70]. They found that critical thinning took place in the transition zone between the wall and the corner radius. Rudraksha and Gawande looked at the coefficient of friction in a THF operation and tried to optimize the other process parameters (including geometry) to lower friction. While this approach might not always be possible in industry due to fixed geometric requirements, they were able to reduce the friction coefficient from 0.15 to 0.03 [71]. Wang et al. study tribological factors which influence micro forming (which can be quite different from macro scale tribology during forming) and develop an equation for estimating friction in a micro upsetting procedure [72].

Materials

Hydroformed materials and alloys available in the literature

Like all forming/forging operations, hydroforming has greatly differing outcomes depending on which material is used. Stronger materials take a higher forging force to achieve a final shape, and certain materials like Ti-6-4 are extremely difficult to form at room temperature. There is a large body of work concerning the hydroforming of standard steel, stainless, and aluminum, especially automotive grades of materials as can be seen in a table of common sizes created by Koç, et Al., 2001 [10]. What follows is a representative cross section of the large body of published work on hydroforming materials. Oh, et al., 2006 [73] summarized various tube hydroforming and sheet hydroforming applications in the automotive industry. They gave examples of a tube hydroforming process which produced a tie bar of diameter 48 mm and thickness 2 mm using steel grade STKM11A, and a similar operation to produce an engine cradle made from SAPH38P steel. They also discussed a sheet hydroforming operation that produced an engine mount bracket which was also made from SAPH38P steel. Lastly they discussed sheet and tube operations that could produce an engine mount subframe assembly which was also made from SAPH38P steel.

Palumbo, et al., 2006 [74] formed stainless steel samples using a cavity sheet hydroforming operation which utilized a moveable die (or a counterpunch) to produce hemi-toroidal (donut-like) shapes. Parsa & Darbandi, 2008 [75] used a hydromechanical deep drawing operation to produce an automotive fender in three different materials: St14 steel, IF steel and 2024 aluminum sheet. Abedrabbo, et al., 2009 [76] used a tube hydroforming operation to form high strength steels in various grades (namely DDQ-T1, HSLA350-T1, HSLA350-T1, DP600-T1, DP780-T1) and found maximum material thinning at around 10–15% for an operation that expanded a circular cross section into a box cross section. This research was aimed at tube hydroforming applications in lightweighting automobiles and based on the cross section of the geometries and alloys in question were likely chassis related geometries.

For other more exotic aerospace materials such as nickel and titanium alloys, information is less readily available in the literature because the commercial opportunities have not been as sufficiently explored. Examples of more exotic materials include Mirzaali, et al., 2012 [77] who optimized loading paths through simulation and validated their results experimentally using ASTM C11000 copper tubes. Choi, et al., 2007 [78] optimized a loading path for AZ31 which is a magnesium alloy but did not validate their results experimentally, only numerically. Djavanroodi & Derogar, 2010 [79] used a hydromechanical deep drawing process which implemented a small floating disc to produce and evaluate samples of Ti-6-4 and AL6061-T6 aluminum alloy sheets. Mohamed, et al., 2016 [37] performed an FEA simulation and an experiment which consisted of a sheet hydroforming deep drawing operation on Inconel 718. This experiment required a two-phase operation with an annealing stage in the middle as well as an advanced pressure cycle to form an oval shaped deep drawn component.

As a general rule of thumb, if a material is appropriate for other cold forming operations then it will perform well in a hydroforming process. Of specific benefit to hydroforming are material characteristics such as high ductility, uniform elongation, a large strain hardening coefficient, a fine grain structure [6], and a large difference between yield and tensile strength. During material selection, designers should consider these factors alongside the other application specific design requirements of the component. Furthermore, the pressure which will be required should be calculated and compared to the available equipment before deciding a material (for tube hydroforming Koç et al. suggests using \( Pk=1.2\ast \sigma \ast \frac{\mathrm{t}0}{\mathrm{rc}} \); where pk is final calibration pressure, σ is tensile strength, t0 is thickness and rc is the smallest corner radius) [6]. For a quick reference, Fig. 21 compares hydroformability by material type versus the required forces (press requirements) to form a given material [80].

Forces required to hydroform versus hydroformability by metal; redrawn, translated & adapted from [80]

Typical hydroforming material properties, microstructures and tolerances

This section gives a qualitative description of the typical material properties and microstructures associated with hydroformed components. General hydroforming operation can be considered to make changes to the components microstructure that are typical of cold forming operations as seen in Fig. 22 (i.e. a grain structure distorted to follow the contours of a components cross-section). Hydroforming (performed at room temperature) like other cold forming processes results in high levels of work hardening (or strain hardening) [81]. This means that it has several advantages over other processes in terms of mechanical and microstructural properties. In cold forming operations, the forces required to form the object are high (as materials are less malleable at low temperatures) but the accuracy is high and the operational costs are low. In hot forming operations, the costs generally increase as the operation becomes more complicated. High temperatures must be induced and maintained, the tendency for oxidization increases so inert gasses (nitrogen or argon) become more relevant and sometimes the accuracy lowers (although this is not always the case) as thermal expansion and contraction becomes relevant. However, the strength and stiffness is still higher than machining or casting as strain hardening occurs [81].

Material characterization

While tensile tests are traditionally used to characterize materials, more advanced techniques have proven to yield different and often superior information. Examples of these tests are the Nakajima and Marciniak tests described earlier in section 3.4 but also fluid bulging tests that are more physically similar to hydroforming. The hydraulic bulge test is similar to the Nakajima test except instead of a punch, fluid pressure is used to bulge a sheet metal sample (Fig. 23a). The fluid pressure is increased until the specimen fractures in the middle of the bulge while the strain levels on the top are monitored. This allows for the determination of stress strain curves in biaxial stress state [82]. It is now recognized that for tube hydroforming a tube bulging test (Fig. 23b) produces superior data than tensile tests for finite element simulations [83]. The main challenge in industry is the lack of availability of measurement hardware, so while the data is superior, according to Vitu et al., most manufacturers still use tensile information for designing forming operations [83]. The test works in a similar fashion to the hydraulic bulge test (increasing pressure until a rupture at the middle of the tube while measuring strain) except the stock is a tube and axial feeding may or may not be used depending on the setup. Other, more representative tests include using a “corner filling test” (Fig. 23c) which can provide a more representative value for a Coulomb’s coefficient than a standard pin on disk test [84] when used in a tube hydroforming operation. A corner fill test pushes metal into a square corner to see how far into the corner the material will form before the material breaks to give an idea of the minimum formable radius possible in a tube hydroforming operation. Other tests for measuring friction in metal forming applications include devices based on stretching of a strip around a pin, or apparatuses that use strain measurements to infer friction forces [85]. A corner fill test uses a tube in a die with a square cross section and gauges how easily or how well the tube conforms to the square corners of the die when the interior fluid pressure is increased. Additionally, tube-drift-expanding tests (Fig. 23d)gauge formability by forcing a cone into a tube until fracture [86]. Eventually the cone will force itself into the tube far enough to cause a split to form on the exterior. The value of the circumference of the tube at the onset of fracture as compared to the original material gives an indication of formability. Examples of some of these tests can be seen in Fig. 23.

Geometry

Limitations

There are certain features that make a hydroforming operation difficult or impossible and these features should be avoided during the design phase of a component if at all possible. These limits are general limits for the hydroforming process, but are also dependent on materials to a certain extent. For example, there is always a limit to how deep a draw can be, but a material such as stainless steel will draw far deeper than Ti 6–4 because of the material’s superior formability (higher ductility). Features to design out are shown in Fig. 24 and some rules of thumb and limits are identified thereafter from the relevant literature.

Features that limit hydroformability; 24c redrawn from [43]

Multiple bends

With a tube hydroforming operation, multiple bends (or bulges/protrusions) in a single tube decrease the ability for the axial feeding motion to replace material that thins during the operation. An illustration of a figure with bends that would inhibit axial feeding can be seen in Fig. 24a. If a tube has one or two sharp bends then it may still be possible to use axial feeding but “if a part has more than two severe bends, axial feeding in the central part of the tube becomes virtually impossible” [6]. Severe bends in this case are 90 degrees or more. Furthermore, pre-bending a tube before hydroforming consumes the formability and can greatly reduce the amount of deformation possible during the hydroforming process. A 2D bend (a bend with a radius of twice the tube’s diameter) leads to approximately 20% axial strain on the outside of the bend, 1.5D leads to 25% and 1D leads to 33%. Koç et al., recommend a minimum bend radius of 1.5D wherever possible [6]. The extent to which axial feeding assists hydroforming is quantified in section 5.1.5 through use of an equation in the literature.

Sharp bends

With both sheet and tube hydroforming, sharp bends (as shown in Fig. 24b) should be avoided. With a sheet hydroforming operation, a sharp bend may eliminate the possibility of using a punch. Furthermore, when using a cavity die, the material will have difficulty feeding inwards from the flange if there is a sharp bend. With a tube hydroforming operation, sharp bends will require a large pre-bending operation prior to hydroforming which will consume formability and limit axial flow [6].

Deep draws

Draws which are exceptionally deep are difficult to create and may require many steps or stress relieving annealing stages. Also special equipment with large draw depths or multiple sets of dies could be necessary. This adds considerable cost in areas such as: development, trials, cycle times, labor, and equipment costs.

One of the benefits of sheet hydroforming is that it allows for more formability which is expressed in terms of an increased draw ratio or aspect ratio. The biggest draw ratio that can be realized in a given operation is known as the “limit draw ratio” (or LDR). Larger LDRs allow for larger blanks to be used and for more material to be drawn in to the working area from the flange. This means a deeper draw made with less material thinning is possible. For normal cold sheet forming operations the limit draw ratio is around 2, but for hydroforming the value can reach 2.5 [1] or even in specific circumstances over 3, [6]. While this is a generalization (because the limit drawing ratio is dependent on material characteristics as well as geometry) the underlying point is that a component can be drawn more in a hydroforming process than a conventional deep drawing process. This benefit stems from the fact that fluid exerts pressure evenly in all directions over an entire surface and therefore it has an advantage over a traditional pressing operations which employ a metal blank holder controlled by a “blank holder force.” Hydroforming controls the fluid system which supplies pressure over the entire blank instead of only at the circumference which increases drawability of the material in the process. This is valuable because if more material draws in from the flange, there is less material thinning in the final component. Similarly, researchers also suggest limiting phenomena such as a “critical fluid-pressure locus above which rupture by tensile instability may occur” [87].

The LDR calculation is a quick calculation that is particularly useful for a designer that has a specific geometry in mind and has to source equipment (or vice versa). The LDR calculation is shown schematically in Fig. 25 where the draw ratio would be: Draw Ratio = D0/Df; [6] and the maximum D0/Df achievable would be the LDR.

The hydroforming process is generally limited to a LDR of 2 to 3 [1], and the draw depth is generally set to be roughly twice as deep as the punch diameter [21]. If the geometry calls for a larger draw ratio than is possible with the hydroforming process, an alternate manufacturing process must be pursued or multiple drawing stages considered. In certain cases multiple hydroformed components could be drawn to an acceptable draw ratio and welded together.

In a recent study involving the calculation of limit drawing ratio for AZ31B magnesium alloy sheet in a warm deep drawing process Wang et al. [88] investigated the draw ratio by looking at various blank size diameters during the operation as can be seen in Fig. 26. By allowing more material to flow into the cup during the forming operation, the minor strain (ε2) becomes compressive allowing for more tensile strain in the major direction (ε1). This would be visually represented as a shift of points on the surface of the material to the right in Fig. 19. The balance with hydroforming is that the larger the blank size is, the larger the force on the surface of the blank will be as the more area the fluid will be exerting force over. Too large of a blank size leads to too high of a force which inhibits material draw in and causes the punch to pierce the material. Too small of a blank size leads to the material being formed without hitting the correct draw depth.

Experimental Assessment of Draw Ratios [88]

Sharp radii

It is very difficult to bulge or draw material into a tight internal radius or around a tight external radius (the latter shown in Fig. 24e) without tearing. While some companies solve this by using more advanced forming techniques, it still adds cost and complexity. Because the pressure required to form a component increases in direct proportion with the component’s smallest radius, whenever possible, large radii should be used to reduce the required pressure of the hydroforming operation. Depending on the source there are different rules about how sharp a radius can be. Subsequent operations, annealing or pressure intensifiers can help tighten up the radii after the forming operation, but as a general rule keeping radii at least 3 to 5 times larger than the material thickness is advisable whenever possible for high pressure hydroforming operations, [12] and 10 times larger for low pressure operations [4]. That said, more recent work has shown that in certain circumstances the edging technique [89] or a subsequent coining operation can produce radii as small as 2 times the material thickness in certain circumstances (explained in detail in "Advanced hydroforming techniques"section).

There is also a difference between interior and exterior corners of a component and what happens with insufficient material pressures in each of these locations. These corners are shown schematically below in a cavity hydroforming operation in Fig. 27. Interior corners are governed by pressure and insufficient pressure will mean the corner is improperly filled and has a larger radius than desired [6] or more fatally will cause wrinkling [4]. Exterior corners are made by bending/stretching and smaller radii on these kinds of corners will inhibit material flow around them. Occasionally interior and exterior corners are called “male” and “female” corners respectively. If an interior corner is formed with insufficient pressure for the radius, then there is a problem with the material properly filling the corner [6]. If an exterior corner has a sharp radius then it can be difficult for material to pull in from the flange causing excessive thinning and tearing.

Excessive bulging

There is only a certain amount that a tube is physically capable of expanding and this expansion is governed by the material properties, the initial blank size, and the final geometry. One good estimation of the possible expansion a tube can undergo before failure is called the “rapid feasibility check” described in Koç, et al. 2008 [6]. This equation determines the expansion that a tube undergoes during an operation and compares it to a calculated theoretical limit. If the tube expands less than this limit then it will most likely form successfully, if it expands more than the limit it will most likely fail. It is important to realize that this is a heuristic value (so it is imperfect) and failures can possibly be overcome by geometry changes or stress relieving heat treatments. Also this equation was likely developed for automotive applications using grades of steel and aluminum. The equation uses the maximum possible cross sectional perimeter (Pcsmax) which is shown in Fig. 28.

Rapid feasibility check; reprinted/adapted by permission from Elsevier: Woodhead Publishing [6]

This equation quantifies the benefits of axial feeding by using the stain hardening coefficient to predict formability. For example, if a strain hardening coefficient is assumed to be 0.45 for annealed stainless steel then the formability with axial feeding is 5.65220.45–1 = 1.18 and without is 2.71830.45–1 = 0.568. The reason for this is that the additional material forced in during the axial feeding replaces material which was thinned during the process. From a materials perspective, axial feeding promotes compressive minor strain (ε2) which enhances material formability. For a visual understanding of this, the strain path taken is further to the right of the forming limit curve shown back in Fig. 19. The compressive minor strains allow for a higher acceptable level of major tensile strains.

Typical dimensional accuracy and tolerances of sheet and tube

Thicker and thinner sections are an unintentional by-product of any cold forming process which must be managed. For interior corners wall thinning should be expected in proportion to the sharpness of the corner and the depth of the draw, i.e. the sharper the corner and deeper the draw, the more the thinning should be expected. This is due to the increased friction that results in stretching material into a tight corner and the additional material required for a deep draw. Counter-intuitively, the material has been reported to actually thicken in certain points during the operation. Generally, this thickening is most pronounced in a tube hydroforming operation (although has been reported in sheet hydroforming as well [90]) where axial feeding is used and is seen on the opposite side of a bulge [91]. Two examples of tube hydroforming thickness distribution can be seen in Figs. 29 and 30.

Wall Thickness variation in an axisymmetric aluminum alloy 6061-T6 THF component with 1.65 mm initial thickness; reprinted by permission from Elsevier: Journal of Materials Processing Technology [92]

Contours of wall thickness variation in Y shaped THF stainless steel component with 2 mm initial thickness; reprinted by permission from Elsevier: Materials Science & Engineering [93]

In these examples the thinning is most pronounced in the areas that are stretched the most and the thickening occurs most in areas where material feeding is present but local material expansion is not.

An example of achievable tolerances during a sheet hydroforming operation with a cavity die was given by Wesselmann et al. (at FF Fluid Forming GmbH) [94]. A customer tasked them with hydroforming a satellite dish with an overall tolerance of ± 0.5 mm and after simulation, trials, and geometric measurement they optimized the process to perform the operation with a resulting part within ± 0.3 mm of the nominal value. The satellite dish as well as the tolerance which was measured at multiple locations is seen in Fig. 31.

Example of sheet hydroforming tolerances achieved on a Satellite dish (mm) [94]

Tolerances for tube, sheet, and shell hydroforming can vary based upon final component size but suppliers generally quote tolerances of between ± 0.01 and ± 0.005 of an inch (± 0.25 or ± 0.125 mm). These tolerances are achievable with modern controls which are able to achieve ± 0.002 of an inch with regard to punch height and ± 2% with regard to fluid pressure [21]. Like all engineering tolerances, tighter tolerances become increasingly difficult to achieve with larger part sizes.

Advanced hydroforming techniques

This section reviews some of the more advanced techniques used currently in the hydroforming industry. Many different forming techniques have been discovered which aid in the creation of complicated geometries, or add in additional features. Some of the most popular are listed with descriptions, schematics, and governing principles.

Pressure intensifiers

In cases of insufficient available pressure, pressure intensifiers can be used for finishing operations. They are used as a second step in the hydroforming process [95] and work by enhancing pressure in a given area particularly when a piece of equipment does not have sufficient pressure capacity to create a tight enough radius on its own. A simple example of a pressure intensifier is that of a coining ring which is a large disc that sits on top of the component during a secondary forming operation (although technically the operation bears more resemblance to ironing than coining). A hydroforming operation which produces a part with a large flange radius can be seen in Fig. 32.

A pressure intensifier works by converting the fluid pressure to an acting force concentrated in a corner which is greater than what fluid pressure can achieve alone. This is done by converting the pressure of the fluid exerted on the ring to mechanical pressure which is concentrated into the radius. There are also other kinds of intensifiers that can be used including interior intensifiers that work with cavities and rubber intensifiers. If the example given in Fig. 32 was subjected to a pressure intensifier, the result would sharpen the radius as seen in Fig. 33.

Pressure intensifier as described in [95]

For a radius on the top of the geometry, restriking operations have been suggested in the literature for forming a tighter radius. Also, in a new study Wang et al. suggests using a secondary operation with a counter punch on the opposite side which has a small radius [96].

Multiple stages

In cases of deep drawing or the creation of finer details in a drawn component, hydroforming operations can use multiple sets of dies which change size. In the case of multiple stage deep drawing, shown schematically in Fig. 34, the first punch is larger and deforms more material so that the operation does not exceed the LDR. Then the flange is trimmed off of the part, and it is set over a tube shaped ring. Then the punch is changed to a narrower punch which can make use of the material generated in the first operation and draw it further [21].

Hydroforming using a holding ring and multiple stages [21]

In process trimming, cutting & Hydropiercing

After a component undergoes a tube hydroforming operation to its final geometry, it can be “hydropierced” which is a process whereby a final component is pierced while still being subjected to internal fluid pressure (Fig. 35). This means that hydropiercing is not a secondary operation as it takes place in situ after the forming operations have completed and while the component is still inside the die. Tube hydroformed components used in automotive applications often make use of holes through which fastening devices are inserted and in such cases hydropiercing can be a cost effective alternative to drilling, milling, cutting or mechanical punching [6]. When hydropiercing care should be given as to what happens to the punched material and how it is removed or bent. While this technology may theoretically be possible with a bladderless sheet hydroforming process, the examples in the literature are limited to hydropiercing of tube hydroformed components.

Various types of hydropiercing; redrawn from [6]

In a cavity sheet hydroforming process, dies can be designed in such a way as to shear components after the forming operation has completed which removes the need for subsequent cutting or shearing operations [20]. A sharp edge is created in the die whereby when the forming operation completes, the pressure builds around a sharp edge, and the formed metal is forced over which shears the component in situ as shown in the industrial example from Quintus Technologies (Fig. 36).

In process trimming; republished with permission from [20]

Predrilled hole applications

There are a few different ways in which drilling holes in the blank prior to the forming operation can be beneficial to creating more complicated geometries or enhancing physical characteristics such as stiffness. If a hole is drilled into a component before a pressing or hydroforming operation, then the material can be pulled into the hole to create a circular protrusion [21]. Hole flanges are a common sheet forming operation and are “used for appearance, rigidity, hidden joints, and strengthening the edge of sheet metal parts” [97]. Also, predrilling a hole prior to a forming operation is a punch hydroforming (and deep drawing) technique that can allow for less material thinning in a wall by allowing material to flow into the wall from both the top and flange sections. However, it is generally only useful when the thickness in the walls is important and the top of the geometry is to be removed after the operation. Lastly, this process is only viable in deep drawing or with hydroforming equipment that has a bladder. If there is fluid acting directly on the blank, the fluid will likely find a path through the hole. This process is shown in (Fig. 37).

Expansion forming

One technique developed for manufacturing tube components in a hydroforming machine is known as “expansion forming”. This technique utilizes a fluid cell press with a specially made tube die inside. A tube is inserted into the die and rubber is fitted inside the tube. Upon initiation of the pressure cycle, the fluid pressure will push the rubber inside of the tube outwards, expanding it into the die and creating a tube hydroformed component on sheet hydroforming equipment. The dies used generally have to be split dies which increases labor costs and cycle times and axial feeding is generally not possible but this is a proven way to form tube components on SHF equipment, [20] (Fig. 38).

Expansion forming schematic; redrawn from [20]

Edging

An alternate technique to the coining operation described earlier in 5.3.1 is to increase the position of the punch higher than necessary and then back it down to the final position at the end of the operation while always maintaining high fluid pressure. This technique, as described by Triform presses (an equipment vendor) is called edging and allows for extra material to stretch in from the flange on the upwards stroke and be pushed into the corner when the punch travels back down. Bell et al. showed that a flange radius could be reduced significantly by using the edging process and provided an empirically derived equation for calculating flange radii [89]. Edging, unlike a coining operation, does not require extra tooling or an additional forming cycle but it is not quite as accurate or repeatable. If the tolerance on the radius is critical, a coining operation is preferred, but if it not then a punch hydroforming operation with an edging step at the end is likely acceptable [21] (Fig. 39).

Hydroforming process automation

In related sheet metal forming processes, equipment manufacturers have invested heavily in automation in order to reduce cycle times. Schuler, a press manufacturer, have incorporated many servo presses together to accommodate more complicated operations which optimize transfer taking into movement overlaps. This new technology can produce up to 100 car body parts per minute which is nearly twice as fast as conventional lines [98]. AIDA, another press manufacturer, has also adopted servo drive systems in conjunction with new transfer presses to increase efficiency. Because of the increasing amount of electrification and hybridization of modern vehicles, sheet metal components are increasingly in demand and require increasing levels of complexity. Therefore AIDA have aimed to combine many presses into one system to ensure that future systems are versatile.

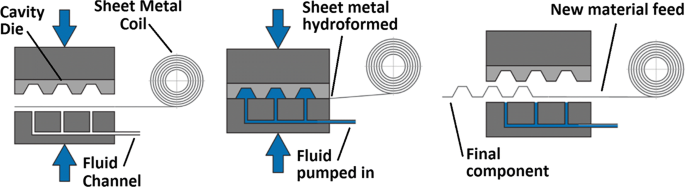

Hydroforming operations are also likely to follow the same trend of increasing automation, but because the technology is newer and more complicated it has a more stringent set of challenges. However, there are developments in efficiency aimed at reducing cycle times by increasing machine utilization with press automation. For example, Borit NV, a metal forming company based in Belgium, has developed an advanced process called Hydrogate™ which is based on hydroforming and allows an automated material feed which feeds material from rolled sheets automatically. This significantly reduces cycle time and increases output [99] (Fig. 40).

Automated SHF schematic [99]

Hybrid Pressing & Hydroforming

Certain sheet hydroforming technologies utilize both traditional pressing and hydroforming actions to form sheet. As seen in Fig. 41, a deep drawing operation can be combined with a hydroforming operation to bulge a sheet metal component in multiple directions in the same machine.

Dual process mechanical pressing with hydroforming; redrawn from [38]

Hybrid double blank hydroforming

The use of two blanks during a hybrid hydroforming operation is also possible. This allows for the press to essentially double its productivity, but can usually only be applied to two geometries which can be formed with the same pressure cycle and blank holding force (however [100] looked at using counter pressure on one blank to compensate). The operation shown would be a hybrid dual sheet hydroforming process and would work by first pressing both sheets and then pumping fluid in between them while the punch backs off. This is depicted schematically in Fig. 42.

Double blank sheet hydroforming; redrawn from [38]

Micro hydroforming

Micro manufacturing is a promising research area with a large amount of commercial potential due to an increasing demand in telecom, electronics and medical device sectors [43]. In hydroforming, there are many different research areas looking into both sheet and tube hydroforming applications. While the same principles apply, there are challenges which are inherent to micro manufacturing that are not present in similar macro sized applications. In general, the main challenges to micro manufacturing are cost, accuracy, precision, and standardization. [101] These challenges stem from a number of different technical concerns, for example in industrial forming operations, grain sizes are generally considered small and homogenous but with micro manufacturing grains can be considered anisotropic which adds complexity to forming operations as shown in Fig. 43. Anisotropy causes variation in material properties depending on orientation which is shown most frequently in the literature as mechanical property changes with regard to rolling direction. At the macro scale this can lead to typical values like a 5.5% difference in yield strength depending on orientation [89] which could impact forming and on the micro scale these differences are more pronounced. Other technical concerns include: extreme tribological conditions caused by high surface to volume ratios, achieving tolerances [102], inapplicability of available lubrication products, excessive forces on miniature dies, and handling concerns, [103].

To address these manufacturing challenges, many streams of research are underway at various academic and private institutions. Some of the research areas are based upon new techniques or hardware, for example, Sato et al. improved the accuracy of drawing titanium, bronze and stainless steel micro cups by utilizing a servo drive in a micro SHF operation [104]. Sato et al. concluded that adding counter pressure can improve formability [105]. Ngaile and Lowrie [103] introduced a new hydroforming system with a floating die assembly to improve sealing by decoupling the sealing and material feed requirements and verified the invention on stainless steel tubes. Nakamori et al. designed a highly accurate contact sensor which was built into the die to improve the accuracy the bulged section in a THF operation which created a Y shaped component [106].

Furthermore, other researchers are performing work that addresses identifying the key process variables in different operations and how they interact with one another. A better understanding of the key process variables Manabe et al. performed a study on T and cross shaped micro tubes to determine what the most influential factors in the micro forming process for these shapes were and concluded that they were: lubrication condition, material property, formed shape and grain size [107]. In SHF, Liang et al. studied how the hydraulic pressure in micro hydromechanical deep drawing effects wrinkling and earing and determined that “ultra-high” pressure can avoid wrinkling [108].

In order for micro hydroforming to overcome the aforementioned challenges these advances need to continue in conjunction with other supporting manufacturing technologies. Process parameters need to be further investigated with emphasis on the interactions between key process variables to ascertain a better understanding of the process and how to design for hydroforming operations. New tooling innovations are needed to provide sufficient force to seal while not harming the die [103]. New lubrication methods need to be developed which work well and repeatably on the micro scale.

The development of supporting technologies could also be crucial in the development of micro hydroforming as they could ensure commercial viability of end products. For example, in T shaped THF operations with axial feeding there is generally an increase in wall thickness on the non-T side [91]. In macro hydroforming this is usually evenly distributed and not of any major concern, but with micro THF it is more of an issue because of the higher friction due to the close proximity of the fluid to the walls and the relatively large walls as compared to the diameter of the tube. This juxtaposition in wall thickness can be seen in Figs. 44 and 45 where the tube walls are about 10% of the outside diameter [91] whereas with the micro tube, the walls comprise roughly 40–50% of outside diameter [107]. Micro machining could help ensure the micro tube is fit for purpose by removing the aforementioned protrusion and possibly skimming the walls to reduce friction, but only if the micro machining technology is compatible. Furthermore, punches used for axial feed often have a hole drilled in the middle for fluid to travel through to pressurize the tube during forming. This can be an issue if the punch has a small diameter and a comparatively long length [103].