Abstract

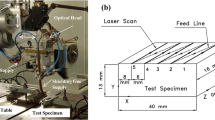

An increasing number of recent technological advancement is linked to the widespread adoptions of ultra-short picosecond (ps) pulsed laser in various applications of material processing. The superior capability of this laser is associated with the precise control of laser–material interaction as an outcome of extremely short interaction times resulting in almost-negligible heat affected zones. In this context, the present study explores the applicability of a picosecond laser in laser micro-polishing (LμP) of Ni-based superalloy Inconel 718 (IN718). The specific research goals of the present study constitute determination of melting regime—a mandatory phase for LμP, establishing the concept of polishability of the spatial contents of the initial surface topography and experimental demonstration of the process capability of a ps laser for potential micro-polishing applications. The initial surface topography was prepared by micromilling operation with a step-over of 50 μm and scallop height of 2 μm. The LμP experiments were performed at five different levels of fluence associated with the melting regime by changing the focal offset, a parameter denoting the working distance between workpiece surface and focusing lens focal plane. The LμP performance was evaluated based on the line profiling average surface roughness (R a) spectrum distributed at different spatial wavelength intervals along the laser path trajectory. Furthermore, additional statistical metrics such as material ratio and power spectral density functions were analyzed in order to establish the process parameters associated with best achievable surface finish. The applicability of ps LμP was demonstrated in two regimes—1D (line) and 2D (area) polishing. During 1D LμP, significant (∼52 %) improvement of the surface quality was achieved by reducing an R a value from 0.50 μm before polishing to an R a value of 0.24 μm across the laser path trajectory on initially ground surface. In addition, an initially micromilled area of 4.5 × 4.5 mm was LμPed resulting in the reduction of an areal topography surface roughness (S a) value from 0.435 to 0.127 μm (70.8 % surface quality improvement).

Similar content being viewed by others

References

Tay BY, Liu L, Loh NH, Tor SB, Murakoshi Y, Maeda R (2005) Surface roughness of microstructured component fabricated by μMIM. Mat Sci Eng 396(1–2):311–319

Perry TL, Werschmoeller D, Li X, Pfefferkorn FE, Duffie NA (2009) Pulsed laser polishing of micromilled Ti6Al4V samples. J Manu Proc 11(2):74–81

Nüsser C, Wehrmann I, Willenborg E (2011) Influence of intensity distribution and pulse duration on laser micro polishing. Physics Procedia 1:462–471

Mai TA, Lim GC (2004) Micromelting and its effects on surface topography and properties in laser polishing of stainless steel. J Laser App 16(4):221–228

Willenborg E, Ostholt R (2009) Polishing metals with laser radiation. Industrial laser solutions Vol. 24, Issue 11

Temmler A, Graichen K, Donath J (2010) Laser polishing in medical engineering. Laser Technik J 7(2):53–57

Qiu TQ, Tien CL (1992) Short-pulse laser heating on metals. Int J Heat Mass Trans 35(3):719–726

Willis DA, Xu X (2002) Heat transfer and phase change during picosecond laser ablation of nickel. Int J Heat Mass Trans 45(19):3911–3918

Weingarten K (2009) High energy picosecond lasers: ready for prime time. Laser Technik J 6(3):51–54

Risch A, Hellmann R (2011) Picosecond laser patterning of ITO thin films. Physics Procedia 12(part B):133–140

Qiu TQ, Tien CL (1993) Heat transfer mechanism during short-pulsed laser heating of metals. ASME J Heat Trans 115:835–841

Kuo LS, Qiu TQ (1996) Microscale energy transfer during picosecond laser melting of metal films. ASME HTD 323(1):149–157

Linde D (2003) A picosecond view of melting. Science 302:1345–1346

Dudzinski D, Devillez A, Moufki A, Larrouquère D, Zerrouki V, Vigneau J (2003) A review of developments towards dry and high speed machining of Inconel 718 alloy. Int J Mach Tools Manu 44(4):439–456

Rahman M, Seah WKH, Teo TT (1997) The machinability of Inconel 718. J Mat Proc Technol 63(1–3):199–204

Ezugwu EO, Bonney J, Yamane Y (2003) An overview of the machinability of aero engine alloy. J Mat Proc Technol 134(2):233–253

Pawade RS, Joshi SS, Brahmankar PK (2008) Effect of machining parameters and cutting edge geometry on surface integrity of high-speed turned Inconel 718. Int J Mach Tools Manu 48(1):15–28

Hu W, Shin YC, King GB (2010) Micromachining of metals, alloys, and ceramics by picosecond laser ablation. J Manu Sci Eng 132(1):1–7

Wolynskia A, Herrmanna T, Muchab P, Hatim H, L’huilliera J (2011) Laser ablation of CFRP using picosecond laser pulses at different wavelengths from UV to IR. Physics Procedia 12:292–301

Pirch N, Höges S, Wissenbach K (2006) Mechanisms of surface rippling during laser polishing, Proceedings of the 8th Int. Seminar on Numerical Analysis of Weldability Graz-Seggau, Austria, 25–27

Temmler A, Willenborg E, Wissenbach K (2011) Design surfaces by laser remelting. Physics Procedia Part A 12:419–430

Hafiz AMK, Bordatchev EV, Tutunea-Fatan RO (2012) Influence of overlap between the laser beam tracks on surface quality in laser polishing of AISI H13 tool steel. J Manu Proc 14(4):425–434

ISO 4288 (1996) Geometrical Product Specifications (GPS)—Surface texture: Profile method—Rules and procedures for the assessment of surface texture. International Organization for Standardization, Geneva

Wieland M, Hänggi P, Hotz W, Textor M, Keller BA, Spencer ND (2000) Wavelength-dependent measurement and evaluation of surface topographies: application of a new concept of window roughness and surface transfer function. Wear 237(2):231–252

Yuan YB, Vorburger TV, Song JF, Renegar TB (2000) A simplified realization for the Gaussian filter in surface metrology. International Colloquium on Surfaces, Chemnitz, pp 133–144

ASME B46.1 (1995) Surface texture: surface roughness, waviness, and lay. ASME, New York

ISO 16610 (2011) Geometrical Product Specifications (GPS)—Filtration—Part 21: Linear profile filters: Gaussian filters. International Organization for Standardization, Geneva

Chow MTC, Hafiz AMK, Bordatchev EV, Tutunea-Fatan OR, Knopf GK (2010) Experimental statistical analysis of laser micropolishing process, Proceedings of the ISOT 2010 International Symposium on Optomechatronic Technologies, Toronto, Ontario, Canada, Paper No. LPTI-1, 6p

Chow M, Bordatchev EV, Knopf GK (2013) Experimental study on the effect of varying focal offset distance on laser micro-polished surfaces. Int J Adv Manuf Technol 67:2607–2617

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hafiz, A.M.K., Bordatchev, E.V. & Tutunea-Fatan, R.O. Experimental analysis of applicability of a picosecond laser for micro-polishing of micromilled Inconel 718 superalloy. Int J Adv Manuf Technol 70, 1963–1978 (2014). https://doi.org/10.1007/s00170-013-5408-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-5408-9