Abstract

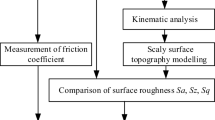

Surface texture plays an important role in sliding contact cases, and texture pattern has a direct link to the tribological behavior of a component. In the present investigation, the ultrasonic vibration-assisted milling (UVAM) method was used to produce uniform scaly textured surfaces with different scale size, and then, the friction and wear properties of these machined scaly surfaces were experimentally studied on a pin-on-plate tribometer under a starved oil lubrication condition. Experimental results indicate that compared with a smooth surface machined by conventional milling, both the fluctuation of friction coefficient curve and average friction coefficient value of a scaly surface produced in UVAM become smaller, and there are also obvious improvements in their wear resistance capability and bearing capacity. Using the forced ultrasonic vibration-assisted milling method to produce a textured surface can open up a new realm for the investigation of surface texture.

Similar content being viewed by others

References

Etsion I, Kligerman Y, Halerpin G (1999) Analytical and experimental investigation of laser-textured mechanical seal faces. Tribol Trans 42(3):511–516

Etsion I (2004) Improving tribological performance of mechanical components by laser surface texturing. Tribol Lett 17(4):733–737

Kligerman Y, Etsion I, Shinkarenko A (2005) Improving tribological performance of piston rings by partial surface texturing. J Tribol ASME 127:632–638

Murthy AN, Etsion I, Talke FE (2007) Analysis of surface textured air bearing sliders with rarefaction effects. Tribol Lett 28:251–261

Malayappan S, Narayanasamy R (2004) An experimental analysis of upset forging of aluminium cylindrical billets considering the dissimilar frictional conditions at flat die surfaces. Int J Adv Manuf Technol 23(9-10):636–643

Knigge B, Zhao Q, Talke FE, Baumgart P (1998) Tribological properties and environmental effects of nano and pico sliders on laser textured media. IEEE Trans Magn 34(4):1732–1734

Tan AH, Cheng SW (2006) A novel textured design for hard disk tribology improvement. Tribo Int 39:506–511

Pettersson U, Jacobson S (2004) Friction and wear properties of micro textured DLC coated surfaces in boundary lubricated sliding. Tribol Lett 17(3):553–559

Suh AY, Lee S-C, Polycarpou AA (2004) Adhesion and friction evaluation of textured slider surfaces in ultra-low flying head-disk interfaces. Tribol Lett 17(4):739–749

Nanbu T, Yasuda Y, Ushijima K, Watanabe J, Zhu D (2008) Increase of traction coefficient due to surface microtexture. Tribol Lett 29(2):105–118

Wakuda M, Yamauchi Y, Kanzaki S, Yasuda Y (2003) Effect of surface texturing on friction reduction between ceramic and steel materials under lubricated sliding contact. Wear 254:356–363

Tong J, Ren LQ, Chen BC (1995) Chemical constitution and abrasive wear behaviour of pangolin scales. Mater Sci Lett 14:1468–1470

Tong J, Ma YH, Ren LQ, Li JQ (2000) Tribological characteristics of pangolin scales in dry sliding. J Mater Sci Lett 19:569–572

Tong J, Wang H, Ma Y, Ren L (2005) Two-body abrasive wear of the outside shell surfaces of mollusk Lamprotula fibrosa Heude, Rapana venosa Valenciennes and Dosinia anus Philippi. Tribol Lett 19(4):331–338

Etsion I (2005) State of the art in laser surface texturing. J Tribol Trans ASME 127:248–253

Etsion I (2010) State of the art in laser surface texturing. Advanced Tribology 4:761–762. doi:10.1007/978-3-642-03653-8_252, Part 3

Wu Z, Deng JX, Chen Y, Xing YQ, Zhao J (2012) Performance of the self-lubricating textured tools in dry cutting of Ti-6Al-4 V. Int J Adv Manuf Technol. doi:10.1007/s00170-011-3853-x

Shen XH, Zhang JH, Xing DL (2011) A study of surface roughness variation in ultrasonic vibration-assisted milling. Int J Adv Manuf Technol 58(5–8):553–561

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shen, X., Zhang, J. Studies on friction and wear properties of surface produced by ultrasonic vibration-assisted milling. Int J Adv Manuf Technol 67, 349–356 (2013). https://doi.org/10.1007/s00170-012-4488-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4488-2