Abstract

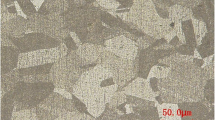

Friction plays a major role in all bulk metal forming processes, except in a few isolated cases such as die-less wire drawings, etc. In upset cold forging, the existence of frictional constraints between the dies and the work-piece directly affect the plastic deformation of the latter. When a solid cylinder is compressed axially between the top and bottom platen, the work piece material in contact with their surfaces undergoes heterogeneous deformation resulting in “barrelling” of the cylinder. The friction at the faces of contact retards the plastic flow of metal on the surface and in its vicinity. A conical wedge of a relatively undeformed metal is formed which suffers high strain hardening and bulges out in the form of a barrel. This experimental work has been undertaken to study the bulging effect of aluminium solid cylinders, varying the frictional conditions at the flat die surfaces. Flat dies of different surface finish were produced by different machining processes like grinding, milling, electro-spark machining, and lathe turning and finishing with ‘0’ grade emery paper. Experiments were conducted for two aspect ratios. The radius of curvature of bulge was measured and found to conform to the calculated bulge using experimental data. The calculations are made with the assumption that the curvature of the bulge followed the form of a circular arc. A relationship was established between the various bulge parameters including new hoop strain, hydrostatic stress, geometrical shape factor, and stress ratio factor, considering the dissimilar frictional conditions.

Similar content being viewed by others

References

Johnson W, Mellor PB (1975) Engineering plasticity. Van Nostrand Rehinhold, London, pp 110–114

Shaw MC, Avery JP (1980) Forming limits—reliability, stress analysis and failure prevention methods in mechanical design. Century, Chicago, pp 297–303

Kulkarni KM, Kalpakjian S (1969) A study of barrelling as an example of free deformation. J Eng Ind—T ASME 91:743–754

Schey JA, Venner TR, Takomana SL (1982) Shape changes in the upsetting of slender cylinders. J Eng Ind—T ASME 104:79–83

Banerjee JK (1985) Barrelling of solid cylinders under axial compression. J Eng Mater—T ASME 107:138–144

Narayanasamy R, Murthy RSN, Viswanatham K, Chary GR (1988) Prediction of the barrelling of solid cylinders under axial compressive load. J Mech Work Technol 16:21–30

Yang DY, Choi Y, Kim JH (1991) Analysis of upset forging of cylindrical billets considering the dissimilar frictional conditions at two flat die surfaces. Int J Mach Tool Manu 31:397–404

Chen FK, Chen CJ (2000) On the non uniform deformation of the cylinder compression test. J Eng Mater—T ASME 122:192–197

Gokler MI, Darendeliler H, Elmaskay N (1999) Analysis of tapered preforms in cold upsetting. Int J Mach Tool Manu 39:1–16

Sowerby R, O’Reilly I, Chandrasekaran N, Dung NL (1984) Materials testing for cold forging. J Eng Mater—T ASME 106:101–106

Narayanasamy R (2000) Barrelling of solid cylinders during cold forging. REC, Trichy-15, India (unpublished)

Narayanasamy R, Pandey KS (1997) Phenomenon of barrelling in Al solid cylinders during cold upset-forging. J Mater Process Tech 70:17–21

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A

As explained by Narayanasamy [11], the expression for a single bulge can be written as follows, under the condition that it adheres to the circular arc-barrelling effect:

where D b is the bulged diameter, D c is the contact diameter, h f is the height of the barrelled cylinder after deformation, D 0 is the initial diameter of the cylinder, and h 0 is the initial height of the cylinder.

The above equation can be written as follows:

Taking the natural logarithm on both sides, the equation becomes

where

and

The expression for the radius of curvature of a barrel is as follows [8]:

where x=(D b −D c)/2 and R is the radius of curvature of the barrel. Simplifying this equation, an expression for barrel radius (R) can be obtained by neglecting the x 2 term (because the quantity of x is very small)

Therefore,

Otherwise,

Multiplying by h 0, the following expression can be obtained.

From Eqs. A2 and A7, the barrel radius becomes:

The right hand side of this expression is used as the new geometrical shape factor of the bulge.

Appendix B

As explained by Sowerby et al. [10], the various stresses are calculated as follows.

Hoop stress:

Representative stress:

Hydrostatic stress:

Usually σ z is negative because it is compressive in nature.

The true axial stress (σ z ) is calculated as follows:

The true axial strain (ε z ) is calculated with:

Rights and permissions

About this article

Cite this article

Malayappan, S., Narayanasamy, R. An experimental analysis of upset forging of aluminium cylindrical billets considering the dissimilar frictional conditions at flat die surfaces. Int J Adv Manuf Technol 23, 636–643 (2004). https://doi.org/10.1007/s00170-003-1584-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-003-1584-3