Abstract

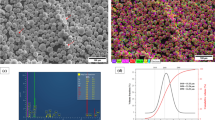

This paper investigates the microstructure and mechanical properties of 1420 aluminum–lithium (Al-Li) alloy joints before and after heat treatment by CO2 laser-metal inter gas (MIG) hybrid welding. The 5-mm-thick 1420 Al-Li alloy plates were welded by CO2 laser-MIG hybrid welding. Full penetration joints without any defects were produced. Optic and scanning electron microscopy were used to study the microstructure and fractograph characteristics. The results show that the microstructures of the heat-affected zone (HAZ) and fusion zone exist as a predominantly discontinuous equiaxed dendritic structure and as a fine cellular dendritic structure, respectively. After heat treatment, the microstructures change from dendritic structure to a spheroidal crystal; the grain size of fusion zone is obviously larger than that of the base metal and the HAZ. Furthermore, the hardness recovers substantially to a level similar to that of the parent material. The tensile strengths of the joints in the as-welded condition and after heat treatment are 223 and 267 MPa, reaching up to 57 and 68 % of the parent materials’ strength, respectively. The fractographs show that the joint as-welded condition exhibits the characteristics of dominated dimples and a small amount tear ridges, which are associated with the mixed ductile and brittle facture mechanisms. The fracture mode transforms from a transgranular to an intergranular after heat treatment; cleavage cracking coupled with an intergranular microvoid coalescence fracture mechanism occurs.

Similar content being viewed by others

References

Pickens JR (1985) Review: the weldability of lithium-containing aluminum alloys. J Mater Sci 20:4247–4258

Madhusudhan RG, Amol AG (1997) Weld microstructure refinement in a 1441 grade aluminium–lithium alloy. J Mater Sci 32:4117–4126

Chen SC, Huang JC (1999) Influence of welding parameters on microstructures and mechanical properties of electron beam welded aluminum–lithium plates. Mater Sci Tech-Lond 15(8):965–978

Wei ST, Hao CY, Chen JC (2007) Study of friction stir welding of 1420 aluminum–lithium alloy. Mat Sci Eng A-Struct 452:170–177

Shi YW, Zhong F, Li XY, Gong SL, Chen L (2007) Effect of laser beam welding on tear toughness of a 1420 aluminum alloy thin sheet. Mat Sci Eng A-Struct 465:153–159

Padmanabham G, Pandey S, Schaper M (2005) Pulsed gas metal arc welding of Al-Cu-Li alloy. Sci Technol Weld Joi 10(1):67–74

Cavaliere P, Cabibbo M, Panella F, Squillace A (2009) 2198 Al-Li plates joined by friction stir welding: mechanical and microstructural behavior. Mater Design 30:3622–3631

Kanwer SA, Sunil P, Michael S, Rajneesh K (2010) Effect of process parameters on friction stir welding of aluminum alloy 2219-T87. Int J Adv Manuf Technol 50:941–952

Reinhold B (2006) Nd:YAG laser butt welding of AA6013 using silicon and magnesium containing filler powders. Mat Sci Eng A-Struct 426:250–262

Aalderinka BJ, Aarts RGKM, Lange DFD, Meijer J (2007) Experimental observation of keyhole shapes in the laser welding of aluminum blanks. J Laser Appl 19(4):245–251

Lee MF, Huang JC, Ho NJ (1996) Microstructural and mechanical characterization of Laser beam welding of a 8090 AI-Li thin sheet. J Mater Sci 35:1455–1468

Xu GX, Wu CS, Qin GL, Wang XY, Lin SY (2011) Adaptive volumetric heat source models for laser beam and laser + pulsed GMAW hybrid welding processes. Int J Adv Manuf Technol 57:245–255

Zhang DQ, Li J, Joo HG, Lee KY (2009) Corrosion properties of Nd:YAG laser-GMA hybrid welded AA6061 Al alloy and its microstructure. Corros Sci 51(6):1399–1404

Kim YP, Alam N, Bang HS, Bang HS (2006) Observation of hybrid (cw Nd:YAG laser MIG) welding phenomenon in AA 5083 butt joints with different gap condition. Sci Technol Weld Joi 11(3):295–307

Campana G, Ascari A, Fortunato A, Tani G (2009) Hybrid laser-MIG welding of aluminum alloys: the influence of shielding gases. Appl Surf Sci 255:5588–5590

Tong H, Ueyama T, Nakata K, Ushio M (2003) High speed welding of aluminum alloy sheets using laser assisted alternating current pulsed metal inert gas process. Sci Technol Weld Joi 8(3):229–234

Casalino G (2007) Statistical analysis of MIG-laser CO2 hybrid welding of Al-Mg alloy. J Mater Process Tech 191:106–110

Wang JG, Lu P, Wang HY, Liu JF, Jiang QC (2005) Semisolid microstructure evolution of the predeformed AZ91D alloy during heat treatment. J Alloys Compd 395:108–112

Lakshminarayanan AK, Balasubramanian V, Elangovan K (2009) Effect of welding processes on tensile properties of AA6061aluminium alloy joints. Int J Adv Manuf Technol 40:286–296

Balasubramanian V, Ravisankar V, Madhusudhan Reddy G (2008) Effect of pulsed current welding on mechanical properties of high strength aluminum alloy. Int J Adv Manuf Technol 36:254–262

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, J., Gao, M., Li, G. et al. Microstructure and mechanical properties of laser-MIG hybrid welding of 1420 Al-Li alloy. Int J Adv Manuf Technol 66, 1467–1473 (2013). https://doi.org/10.1007/s00170-012-4431-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-012-4431-6