Abstract

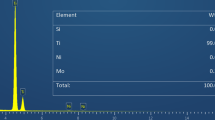

The cylindrical wire electrical discharge turning (CWEDT) process was developed to generate precise cylindrical forms on hard, difficult to machine materials. A precise, flexible, and corrosion-resistant submerged rotary spindle was designed and added to a conventional five-axis CNC wire electrical discharge machine (EDM) to enable the generation of free-form cylindrical geometries. The hardness and strength of the work material are no longer the dominating factors that affect the tool wear and hinder the machining process. In this study, the effect of machining parameters on surface roughness (R a) and roundness in cylindrical CWEDT of a AISI D3 tool steel is investigated. The selection of this material was made taking into account its wide range of applications in tools, dies, and molds and in industries such as punching, tapping, reaming, and so on in cylindrical forms. Surface roughness and roundness are chosen as two of the machining performances to verify the process. In addition, power, pulse off-time, voltage, and spindle rotational speed are adopted for evaluation by full factorial design of experiments. In this case, a 22 × 32 mixed full factorial design has been selected considering the number of factors used in the present study. The main effects of factors and interactions were considered in this paper, and regression equations were derived using response surface methodology. Finally, the surfaces of the CWEDT parts were examined using scanning electron microscopy (SEM) to identify the macro-ridges and craters on the surface. Cross sections of the EDM parts were examined using the SEM and microhardness tests to quantify the sub-surface recast layers and heat-affected zones under specific process parameters.

Similar content being viewed by others

References

Tosun N, Cogu C, Tosun G (2004) A study on kerf and material removal rate in wire electrical discharge machining based on Tagushi method. J Mater Process Technol 152:313–322

Qu J, Shih AJ, Scattergood RO (2002) Development of the cylindrical wire electrical discharge machining process, part 1: concept, design, and material removal rate. J Manuf Sci Eng 124(3):702–707

Qu J, Shih AJ, Scattergood RO (2002) Development of the cylindrical wire electrical discharge machining process, part 2: surface integrity and roundness. J Manuf Sci Eng 124(3):708–714

A. Mohammadi, A. Fadaie Tehrani, E. Emanian, D. Karimi, H. Jafarpisheh, A new approach in turning by wire electrical discharge machining to evaluate the effects of machining parameters on MRR, in Tehran International Congress on Manuf. Eng, Proc. TICME, Tehran, Iran 12–15 Dec., 2005

Masuzawa T, Fujino M, Kobayashi K, Suzuki T (1985) Study on micro-hole drilling by EDM. Bull Jpn Soc Precis Eng 20(2):117–120

Masuzawa T, Kuo C-L, Fujino M (1994) A combined electrical machining process micronozzel fabrication. CIRP Ann 43:189–192

Masuzawa T, Tonshoff HK (1997) Three-dimensional micromachining by machine tools. CIRP Ann 46:621–628

Rajurkar KP, Yu ZY (2000) 3D micro-EDM using CAD/CAM. CIRP Ann 49:127–130

Schoth A, Förster R, Menz W (2005) Micro wire EDM for high aspect ratio 3D microstructuring of ceramics and metals. Microsyst Technol 11:250–253

Rhoney BK, Shih AJ, Scattergood RO, Akemon JL, Grant DJ, Grant MB (2002) Wire electrical discharge machining of metal bond diamond wheels for ceramic grinding. Int J Mach Tools Manuf 42(12):1355–1362

Rhoney BK, Shih AJ, Scattergood RO, Ott R, McSpadden SB (2002) Wear mechanism of metal bond diamond wheels trued by wire electrical discharge machining. Wear 252(7–8):644–653

A. Mohammadi, A. Fadaie Tehrani, E. Emanian, D. Karimi, A new approach in surface roughness and roundness improvement in wire electrical discharge turning based on statistical analysis, in ASME International Conference on Manuf. Science & Eng., Proc. ASME, USA, Oct. 8–11, 2006

Rajurkar KP, Wang WM (1993) Thermal modelling and on-line monitoring of wire-EDM. J Mater Process Technol 38(1–2):417–430

Gokler MI, Ozanozgu AM (2000) Experimental investigation of effects of cutting parameters on surface roughness in the WEDM process. Int J Mach Tools Manuf 40(13):1831–1848

Tosun N, Cogun C, Inan A (2003) The effect of cutting parameters on workpiece surface roughness in wire EDM. Mach Sci Technol 7(2):209–219

Anand KN (1996) Development of process technology in wire-cut operation for improving machining quality. Total Qual Manag 7(1):11–28

Spedding TA, Wang ZQ (1997) Parametric optimization and surface characterization of wire electrical discharge machining process. Precis Eng 20(1):5–15

Montgomery DC (2000) Design and analysis of experiments. Wiley, New York

M.J. Haddad, Statistical analysis of the results of the cylindrical wire electrical discharge turning process, M.Sc. dissertation, Mechanical Engineering Department, Isfahan University of Technology, Isfahan, Iran (2006) (in Persian)

Williams RE, Rajurkar KP (1991) Study of wire electrical discharge machined surface characteristics. J Mater Process Technol 28(1–2):127–138

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Haddad, M.J., Alihoseini, F., Hadi, M. et al. An experimental investigation of cylindrical wire electrical discharge turning process. Int J Adv Manuf Technol 46, 1119–1132 (2010). https://doi.org/10.1007/s00170-009-2171-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2171-z