Abstract

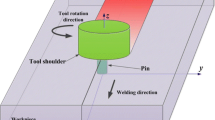

A fully coupled thermo-mechanical model is adopted to study the effect of shoulder size on the temperature distributions and the material deformations in friction stir welding. Numerical results indicate that the maximum temperature can be increased with the increase of the shoulder diameter. The stirring zone can be enlarged by the increase of the shoulder size. With consideration of the recrystallization formula, it is found that the temperature variation is the main factor for controlling the grain growth near the welding line. But, when the strain and the strain rate become smaller near the border of the stirring zone, the recrystallization process is dominated by the material deformations instead of the temperature rise.

Similar content being viewed by others

References

Thomas WM, Nicholas ED, Needham JC, Murch MG, Templesmith P, Dawes CJ (1991) GB Patent Applications No. 9125978.8

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng Rep 50:1–78. doi:10.1016/j.mser.2005.07.001

Liu HJ, Fujii H, Maeda M, Nogi K (2003) Tensile properties and fracture locations of friction-stir welded joints of 6061-T6 aluminum alloy. J Mater Sci Lett 22:1061–1063. doi:10.1023/A:1024970421082

Chen YC, Feng JC, Liu HJ (2007) Stability of the grain structure in 2219-O aluminum alloy friction stir welds during solution treatment. Mater Charact 58:174–178. doi:10.1016/j.matchar.2006.04.015

Xie GM, Ma ZY, Geng L (2008) Effect of microstructural evolution on mechanical properties of friction stir welded ZK60 alloy. Mater Sci Eng A 486:49–55. doi:10.1016/j.msea.2007.08.043

Lee WB, Yeon YM, Jung SB (2003) Evaluation of the microstructure and mechanical properties of friction stir welded 6005 aluminum alloy. Mater Sci Technol 19:1513–1518. doi:10.1179/026708303225008068

Booth DPP, Starink MJ, Sinclair I (2007) Analysis of local microstructure and hardness of 13 mm gauge 2024–T351 AA friction stir welds. Mater Sci Technol 23:276–284. doi:10.1179/174328407X157290

Zhang Z, Chen JT (2008) The simulation of material behaviors in friction stir welding process by using rate-dependent constitutive model. J Mater Sci 43:222–232. doi:10.1007/s10853-007-2129-1

Zhang HW, Zhang Z, Chen JT (2005) The finite element simulation of the friction stir welding process. Mater Sci Eng A 403:340–348. doi:10.1016/j.msea.2005.05.052

Zhang HW, Zhang Z, Chen JT (2007) 3D modelling of material flow in friction stir welding under different process parameters. J Mater Process Technol 183:62–70. doi:10.1016/j.jmatprotec.2006.09.027

Zhang Z, Zhang HW (2007) The simulation of residual stresses in friction stir welds. J Mech Mater Struct 2:951–964

Li T, Shi QY, Li HK (2007) Residual stresses simulation for friction stir welded joint. Sci Technol Weld Join 12:634–640. doi:10.1179/174329307X236832

Zhang Z, Zhang HW (2007) Material behaviors and mechanical features in friction stir welding process. Int J Adv Manuf Technol 35:86–100. doi:10.1007/s00170-006-0707-z

Zhang Z, Zhang HW (2008) A fully coupled thermo-mechanical model of friction stir welding. Int J Adv Manuf Technol 37:279–293. doi:10.1007/s00170-007-0971-6

Zhang Z, Zhang HW (2007) Numerical studies on the effect of axial pressure in friction stir welding. Sci Technol Weld Join 12:226–248. doi:10.1179/174329307X177919

Zhang Z, Zhang HW (2007) Numerical studies of pre-heating time effect on temperature and material behaviors in friction stir welding process. Sci Technol Weld Join 12:436–448. doi:10.1179/174329307X214386

Schmidt H, Hattel J (2005) A local model for the thermomechanical conditions in friction stir welding. Model Simul Mater Sci Eng 13:77–93. doi:10.1088/0965-0393/13/1/006

Colegrove P, Shercliff HR (2006) 3-Dimensional CFD modelling of flow round a threaded friction stir welding tool profile. J Mater Process Technol 169:320–327. doi:10.1016/j.jmatprotec.2005.03.015

Arora A, Nandan R, Reynolds AP, DebRoy T (2009) Torque, power requirement and stir zone geometry in friction stir welding through modeling and experiments. Scr Mater 60:13–16. doi:10.1016/j.scriptamat.2008.08.015

Song M, Kovacevic R (2003) Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int J Mach Tools Manuf 43:605–615. doi:10.1016/S0890-6955(03)00022-1

Elangovan K, Balasubramanian V (2008) Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminium alloy. Mater Des 29:362–373. doi:10.1016/j.matdes.2007.01.030

Elangovan K, Balasubramanian V, Valliappan M (2008) Influences of tool pin profile and axial force on formation of friction stir processing zone in AA6061 aluminium alloy. Int J Adv Manuf Technol 38:285–295. doi:10.1007/s00170-007-1100-2

Zhang H, Lin SB, Wu L, Feng JC, Ma SL (2006) Defects formation procedure and mathematic model for defect free friction stir welding of magnesium alloy. Mater Des 27:805–809. doi:10.1016/j.matdes.2005.01.016

Zhang Z, Zhang HW (2009) Numerical studies on the effect of transverse speed in friction stir welding. Mater Des 30:900–907. doi:10.1016/j.matdes.2008.05.029

Belytschko T, Liu WK, Moran B (2000) Nonlinear finite elements for continua and structures. Wiley, New York

Zhang HW, Wang H, Wriggers P, Schrefler BA (2005) A finite element model for contact analysis of multiple Cosserat bodies. Comput Mech 36:444–458. doi:10.1007/s00466-005-0680-7

Zhang HW, Zhong WX, Wu CH, Liao AH (2006) Some advances and applications in quadratic programming method for numerical modeling of elastoplastic contact problems. Int J Mech Sci 48:176–189. doi:10.1016/j.ijmecsci.2005.08.003

Zhang HW, Liao AH, Wu CH (2007) Numerical simulation of contact problems in vane machinery by a parametric quadratic programming method. Arch Appl Mech 77:421–437. doi:10.1007/s00419-006-0099-4

Zhang Z, Zhang HW (2009) Numerical studies on controlling of process parameters in friction stir welding. J Mater Process Technol 209:241–270. doi:10.1016/j.jmatprotec.2008.01.044

Soundararajan V, Zekovic S, Kovacevic R (2005) Thermo-mechanical model with adaptive boundary conditions for friction stir welding of Al 6061. Int J Mach Tools Manuf 45:1577–1587. doi:10.1016/j.ijmachtools.2005.02.008

Guerra M, Schmidt C, McClure JC, Murr LE, Nunes AC (2003) Flow patterns during friction stir welding. Mater Charact 49:95–101. doi:10.1016/S1044-5803(02)00362-5

Colligan K (1999) Material flow behavior during friction stir welding of aluminium. Weld J 78:229–237

Muthukumaran S, Mukherjee SK (2006) Two modes of metal flow phenomenon in friction stir welding process. Sci Technol Weld Join 11:337–340. doi:10.1179/174329306X107665

Muthukumaran S, Mukherjee SK (2008) Multi layered metal flow and formation of onion rings in friction stir weld. Int J Adv Manuf Technol 38:68–73. doi:10.1007/s00170-007-1071-3

Reynolds AP (2000) Visualisation of material flow in autogenous friction stir welds. Sci Technol Weld Join 5:120–124. doi:10.1179/136217100101538119

McQueen HJ, Cabibbo M, Evangelista E (2007) Piercing/extrusion and FSW nugget microstructure formation in Al alloys. Mater Sci Technol 23:803–809. doi:10.1179/174328407X161178

Fratini L, Buffa G (2007) Continuous dynamic recrystallization phenomena modelling in friction stir welding of aluminium alloys: a neural-network-based approach. Proc IMechE-Part B: J Eng Manuf 221:857–864

Buffa G, Fratini L, Shivpuri R (2007) CDRX modelling in friction stir welding of AA7075–T6 aluminum alloy: analytical approaches. J Mater Process Technol 191:356–359. doi:10.1016/j.jmatprotec.2007.03.033

Murr LE, Liu G, McClure JC (1997) Dynamic recrystallization in friction-stir welding of aluminium alloy 1100. J Mater Sci Lett 16:1801–1803. doi:10.1023/A:1018556332357

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., Liu, Y.L. & Chen, J.T. Effect of shoulder size on the temperature rise and the material deformation in friction stir welding. Int J Adv Manuf Technol 45, 889–895 (2009). https://doi.org/10.1007/s00170-009-2034-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-009-2034-7