Abstract

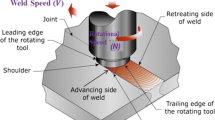

This paper presents a new developed fully coupled thermo-mechanical model of the friction stir welding process. Results indicate that the rotation of the shoulder can accelerate the material flow behavior near the top surface. The material deformation and the temperature field can have relations with the microstructural evolution. The texture of the appearance of the friction stir welds can correlate well with the equivalent plastic strain distributions on the top surface. The temperature field in the friction stir welding process is approximately symmetric to the welding line. The material flows in different thicknesses are different. The shoulder can have a significant effect on material behaviors on the top surface, but this effect is greatly weakened when the material gets closer to the bottom surface of the welding plate.

Similar content being viewed by others

References

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78

Jones MJ, Heurtier P, Desrayaud C, Montheillet F, Allehaux D, Driver JH (2005) Correlation between microstructure and microhardness in a friction stir welded 2024 aluminum alloy. Scr Mater 52:693–697

Sato YS, Takauchi H, Park SHC, Kokawa H (2005) Characteristics of the kissing-bond in friction stir welded Al alloy 1050. Mater Sci Eng A 405:333–338

Fonda RW, Bingert JF, Colligan KJ (2004) Development of grain structure during friction stir welding. Scr Mater 51:243–248

Attallah MM, Salem HG (2005) Friction stir welding parameters: a tool for controlling abnormal grain growth during subsequent heat treatment. Mater Sci Eng A 391:51–59

Reynolds AP, Tang W, Gnaupel-Herold T, Prask H (2003) Structure, properties and residual stress of 304L stainless steel friction stir welds. Scr Mater 48:1289–1294

Liu HJ, Fujii H, Maeda M, Nogi K (2003) Tensile properties and fracture locations of friction stir welded joints of 6061-T6 aluminum alloy. J Mater Sci Lett 22:1061–1063

Boz M, Kurt A (2004) The influence of stirrer geometry on bonding and mechanical properties in friction stir welding process. Mater Des 25:343–347

Su JQ, Nelson TW, Mishra R, Mahoney M (2003) Microstructural investigation of friction stir welded 7050-T651 aluminum. Acta Mater 51:713–729

Guerra M, Schmidt C, McClure JC, Murr LE, Nunes AC (2003) Flow patterns during friction stir welding. Mater Charact 49:95–101

Muthukumaran S, Mukherjee SK (2006) Two modes of metal flow phenomenon in friction stir welding, process. Science and Technology in Welding and Joining 11(3):337–340

Liu HJ, Feng JC, Fujii H, Nogi K (2005) Wear characteristics of a WC-Co tool in friction stir welding of ac4ac30 vol%SiCp composite. Int J Mach Tools Manuf 45:1635–1639

Chen CM, Kovacevic R, Jandgric D (2003) Wavelet transform analysis of acoustic emission in monitoring friction stir welding of 6061 aluminum. Int J Mach Tools Manuf 43:1383–1390

Fratini L, Zuccarello B (2006) An analysis of through-thickness residual stresses in aluminum FSW butt joints. Int J Mach Tools Manuf 46:611–619

Cavaliere P, Nobile R, Panella FW, Squillace A (2006) Mechanical and microstructural behaviour of 2024–7075 aluminium alloy sheets joined by friction stir welding. Int J Mach Tools Manuf 46:588–594

Xu S, Deng XM (2005) A three-dimensional model for the friction stir welding process. Proceedings of the 21st Southeastern Conference on Theoretical and Applied Mechanics (Section XXI), Orlando, Florida, May 19–21

Xu S, Deng X, Reynolds AP, Seidel TU (2001) Finite element simulation of material flow in friction stir welding. Science and Technology of Welding and Joining 6(3):191–193

Deng XM, Xu SW (2001) Solid mechanics simulation of friction stir welding process. Transactions of NAMRI/SME, Society of Manufacturing Engineers XXIX:631–638

Deng XM, Xu SW (2004) Two-dimensional finite element simulation of material flow in the friction stir welding process. J Manuf Process 6(2):125–133

Crawford R, Cook GE, Strauss AM, Hartman DA, Stremler MA (2006) Experimental defect analysis and force prediction simulation of high weld pitch friction stir welding. Sci Technol Weld Join 11(6):657–665

Buffa G, Hua J, Shivpuri R, Frantini L (2006) A continuum based fem model for friction stir welding-model development. Mater Sci Eng A 419:389–396

Mandal S, Williamson K (2006) A thermomechanical hot channel approach for friction stir welding. J Mater Process Technol 174:190–194

Khandkar MZH, Khan JA, Reynolds AP, Sutton MA (2006) Predicting residual thermal stresses in friction stir welded metals. J Mater Process Technol 174:195–203

Zhang HW, Zhang Z, Chen JT (2005) The finite element simulation of the friction stir welding process. Mater Sci Eng A 403:340–348

Zhang HW, Zhang Z, Chen JT (2005) Effect of angular velocity of the pin on material flow during the friction stir welding. Acta Metall Sin 41:853–859

Zhang HW, Zhang Z (2006) Numerical simulation of friction stir welding by using semi-coupled model. International Conference on Enhancement and Promotion of Computational Methods in Engineering Science and Mechanics, Changchun, China, August 10–12

Zhang Z, Chen JT, Zhang HW (2005) The 3D simulation of friction stir welding process. International Conference on Mechanical Engineering and Mechanics, Nanjing, China, October 26–28

Zhang Z, Zhang HW. Material behaviors and mechanical features in friction stir welding process. Int J Adv Manuf Technol (in press). DOI 10.1007/s00170-006-0707-z

Song M, Kovacevic R (2003) Thermal modeling of friction stir welding in a moving coordinate system and its validation. Int J Mach Tools Manuf 43:605–615

Schmidt H, Hattel J (2005) A local model for the thermomechanical conditions in friction stir welding. Model Simul Mater Sci Eng 13:77–93

Belystchko T, Liu WK, Moran B (2000) Nonlinear finite elements for continua and structures. John Wiley, New York

ABAQUS theory manual, version 6.4, Hibbit, Karlsson and Sorensen Inc., 2003

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Z., Zhang, H.W. A fully coupled thermo-mechanical model of friction stir welding. Int J Adv Manuf Technol 37, 279–293 (2008). https://doi.org/10.1007/s00170-007-0971-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-0971-6