Abstract

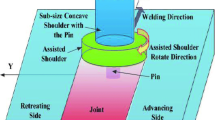

Reverse dual-rotation friction stir welding (RDR-FSW) is a novel modification of conventional friction stir welding (FSW) process. During the RDR-FSW process, the tool pin and the assisted shoulder are separated and rotate with opposite direction independently, so that there are two material flows with reverse direction. The material flow and heat transfer in RDR-FSW have significant effects on the microstructure and properties of the weld joint. A 3D model is developed to quantitatively analyze the effects of the separated tool pin and the assisted shoulder which rotate in reverse direction on the material flow and heat transfer during RDR-FSW process. Numerical simulation is conducted to predict the temperature profile, material flow field, streamlines, strain rate, and viscosity distributions near the tool. The calculated results show that as the rotation speed of the tool pin increases, the temperature near the tool gets higher, the zone with higher temperature expands, and approximately symmetric temperature distribution is obtained near the tool. Along the workpiece thickness direction, the calculated material flow velocity and its layer thickness near the tool get lowered because the effect of the shoulder is weakened as the distance away from the top surface increases. The model is validated by comparing the predicted values of peak temperature at some typical locations with the experimentally measured ones.

Similar content being viewed by others

References

R.S. Mishra and Z.Y. Ma, Friction Stir Welding and Processing, Mater. Sci. Eng. R., 2005, 50(1), p 1–78

L.E. Murr, A Review of FSW Research on Dissimilar Metal and Alloy Systems, J. Mater. Eng. Perform., 2010, 19(8), p 1071–1089

Z. Kiss and T. Czigány, Applicability of Friction Stir Welding in Polymeric Materials, Period. Polytech. Mech. Eng., 2007, 51, p 15–18

N. Mendes, A. Loureiro, C. Martins, P. Neto, and J.N. Pires, Effect of Friction Stir Welding Parameters on Morphology and Strength of Acrylonitrile Butadiene Styrene Plate Welds, Mater. Des., 2014, 58, p 457–464

R. Nandan, T. DebRoy, and H.K.D.H. Bhadeshia, Recent Advances in Friction Stir Welding—Process, Weldment Structure and Properties, Prog. Mater. Sci., 2008, 53(6), p 980–1023

G.Q. Chen, Q.Y. Shi, Y. Fujiya, and T. Horie, Simulation of Metal Flow During Friction Stir Welding Based on the Model of Interactive Force Between Tool And Material, J. Mater. Eng. Perform., 2014, doi:10.1007/s11665-014-0886-y

P.A. Colegrove and H.R. Shercliff, CFD Modelling of Friction Stir Welding of Thick Plate 7449 Aluminium Alloy, Sci. Technol. Weld. Join., 2006, 11(4), p 429–441

M. Grujicic, G. Arakere, B. Pandurangan, J.M. Ochterbeck, C.-F. Yen, B.A. Cheeseman, A.P. Reynolds, and M.A. Sutton, Computational Analysis of Material Flow During Friction Stir Welding of AA5059 Aluminum Alloys, J. Mater. Eng. Perform., 2012, 21(9), p 1824–1840

C.S. Wu, T. Zhang, and Y.H. Feng, Numerical Analysis of the Heat and Fluid Flow in a Weld Pool with a Dynamic Keyhole, Int. J. Heat Fluid Flow, 2013, 40, p 186–197

P. Vilaça and W. Thomas, Friction Stir Welding Technology, Struct. Connect. Lightweight Met. Struct., 2012, 8, p 85–124

S. Zimmer, L. Langlois, J. Laye, and B. Régis, Experimental Investigation of the Influence of the FSW Plunge Processing Parameters on the Maximum Generated Force and Torque, Int. J. Adv. Manuf. Technol., 2010, 47(1–4), p 201–215

C. Chen and R. Kovacevic, Thermomechanical Modelling and Force Analysis of Friction Stir Welding by the Finite Element Method, Proc. IME C J. Mech. Eng. Sci., 2004, 218(5), p 509–519

R. Rai, A. De, H.K.D.H. Bhadeshia, and T. DebRoy, Review: Friction Stir Welding Tools, Sci. Technol. Weld. Join., 2011, 16(4), p 325–342

J.Q. Li and H.J. Liu, Effects of Welding Speed on Microstructures and Mechanical Properties of AA2219-T6 Welded by the Reverse Dual-Rotation Friction Stir Welding, Int. J. Adv. Manuf. Technol., 2013, 68, p 2071–2083

W.M. Thomas, I.M. Norris, D.G. Staines, and E.R. Watts, Friction Stir Welding—Process Developments and Variant Techniques, The SME Summit, Oconomowoc, Milwaukee, USA, August 3-4, 2005.

J.Q. Li and H.J. Liu, Characteristics of the Reverse Dual-Rotation Friction Stir Welding Conducted on 2219-T6 Aluminum Alloy, Mater. Des., 2013, 45, p 148–154

R.K. Uyyuru and S.V. Kailas, Numerical Analysis of Friction Stir Welding Process, J. Mater. Eng. Perform., 2006, 15(5), p 505–518

W. Li, Z. Zhang, J. Li, and Y.J. Chao, Numerical Analysis of Joint Temperature Evolution During Friction Stir Welding Based on Sticking Contact, J. Mater. Eng. Perform., 2012, 21(9), p 1849–1856

H.H. Cho, S.T. Hong, J.H. Roh, H.S. Choi, S.H. Kang, R.J. Steel, and H.N. Han, Three-Dimensional Numerical and Experimental Investigation on Friction Stir Welding Processes of Ferritic Stainless Steel, Acta Mater., 2013, 60, p 2649–2661

C.S. Wu, W.B. Zhang, L. Shi, and M. Chen, Visualization and Simulation of Plastic Material Flow in Friction Stir Welding of 2024 Aluminium Alloy Plates, Trans. Nonferrous Met. Soc. China, 2012, 22(6), p 1445–1451

D.M. Neto and P. Neto, Numerical Modeling of Friction Stir Welding Process: A Literature Review, Int. J. Adv. Manuf. Technol., 2013, 65, p 115–126

R. Nandan, G.G. Roy, T.J. Liener, and T. DebRoy, Three-Dimensional Heat and Material Flow During Friction Stir Welding of Mild Steel, Acta Mater., 2007, 55(3), p 883–895

S.D. Giudice, C. Nonino, and S. Savino, Effects of Viscous Dissipation and Temperature Dependent Viscosity in Thermally and Simultaneously Developing Laminar Flows in Microchannels, Int. J. Heat Fluid Flow, 2007, 28, p 15–27

R. Nandan, G.G. Roy, and T. DebRoy, Numerical Simulation of Three-Dimensional Heat Transfer and Plastic Flow During Friction Stir Welding, Metall. Mater. Trans. A, 2006, 37(4), p 1247–1259

T. Sheppard and A. Jackson, Constitutive Equations for Use in Prediction of Flow Stress During Extrusion of Aluminium Alloys, Mater. Sci. Technol., 1997, 13(3), p 203–209

A. Arora, R. Nandan, A.P. Reynolds, and T. DebRoy, Torque, Power Requirement and Stir Zone Geometry in Friction Stir Welding Through Modeling and Experiments, Scr. Mater., 2009, 60(1), p 13–16

H. Schmidt and J. Hattel, Modelling Heat Flow Around Tool Probe in Friction Stir Welding, Sci. Technol. Weld. Join., 2005, 10(2), p 176–186

T.J. Lienert, W.L. Stellwag, Jr., B.B. Grimmett, and R.W. Warke, Friction Stir Welding Studies on Mild Steel, Weld. J., 2003, 82, p 1s–9s

M. Mehta, K. Chatterjee, and A. De, Monitoring Torque and Traverse Force in Friction Stir Welding from Input Electrical Signatures of Driving Motors, Sci. Technol. Weld. Join., 2013, 18(3), p 191–197

H. Atharifar, D. Lin, and R. Kovacevic, Numerical and Experimental Investigations on the Loads Carried by the Tool During Friction Stir Welding, J. Mater. Eng. Perform., 2009, 18(4), p 339–350

S.V. Patankar and D.B. Spalding, A Calculation Procedure for Heat, Mass and Momentum Transfer in Three-Dimensional Parabolic Flows, Int. J. Heat. Mass. Transf., 1972, 15, p 1787–1806

H. Schmidt, T.L. Dickerson, and J. Hattel, Material Flow in Butt Friction Stir Welds in AA2024-T3, Acta Mater., 2006, 54, p 1199–1209

Acknowledgment

The authors are grateful to the financial support for this research from the State Key Laboratory of Advanced Welding and Joining at Harbin Institute of Technology in China (Grant No. AWJ-Z13-02), and the Sino-German Center for the Promotion of Science (Grant No. GZ-739).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, L., Wu, C.S. & Liu, H.J. Modeling the Material Flow and Heat Transfer in Reverse Dual-Rotation Friction Stir Welding. J. of Materi Eng and Perform 23, 2918–2929 (2014). https://doi.org/10.1007/s11665-014-1042-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-014-1042-4