Abstract

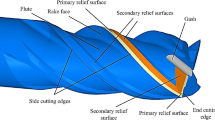

This paper presents a set of mathematical models for the design and manufacture of the helical flute and cutting-edge curve of a pair of truncated-cone ball-end cutters. The section profile and relative feeding velocities of the grinding wheel in NC machining of the cutter are deduced. In addition, the deviation of the cutting-edge curve, residual material and the land lack caused by the modified radial feeding velocity are taken into consideration. In order to finish the residual material and rebuild the land of the cutter, the technique for compensation has been developed in this research. The accuracy of the theoretical models is verified by means of an experimental machining test using a WALTER CNC grinding machine. The experimental results are in good agreement with those predicted theoretically, thereby confirming the accuracy and reliability of the proposed models. This study serves as a valuable reference for researchers investigating the NC machining of cutters with special forms.

Similar content being viewed by others

References

Batlle JA, Cardona SC, Sanz VN (1985) On the Design of Milling Cutters or Grinding Wheels for Twist Drill Manufacture A CAD Approach. Proc Of the 25th Int MTDR Conf 25:315–320

Bedi S, Gravelle S, Chen YH (1997) Principal Curvature Alignment Technique for Machining Complex Surfaces. J Manuf Sci Eng Trans ASME 119:756–765

Choi BK, Jun CS (1989) Ball-End Cutter Interference Avoidance in NC Machining of Sculptured Surfaces. Comput-Aided Des 21(6):371–378

Ehmann KF (1990) Grinding Wheel Profile Definition for The Manufacture of Drill Flutes. Ann CIRP 39(1):153–156

Elber G (1995) Freeform Surface Region Optimization for 3-Axis and 5-Axis Milling. Comput-Aided Des 27(6):465–470

Kang SK, Ehmann KF, Lin C (1996) A CAD Approach to Helical Flute Machining-I. Mathematical Model and Model Solution Int J Mach Tools Manuf 36(1):141–153

Li LF (1995) Calculating the Normal Section of Helical Flute of the Cutter by Computer. Tool Eng 9:15–19

Liu JY, Liu HM (1997) The Mathematical Model of Helical Flute of Cone-type Ball-end Cutter. Tool Eng 4:3–6

Sheth DS, Malkin S (1990) CAD/CAM for Geometry and Process Analysis of Helical Flute Machining. Ann CIRP 39(1):129–132

Tang YY, Cheng CK et al (1996) Geometry Model and 2-axis NC Machining of Milling Cutters with Constant Helical Angle. J Harb Instit Technol 28(5):5–7

Zhang H, Yao NX et al (1997) The General Algorithm of Cutting Edge of Revolving Cutter with Constant Helical Angle. J Dal Instit Technol 37(1):63–67

Tsai YC, Hsieh JM (2001) A Study of A Design and NC Manufacturing Model of Ball-End Cutters. J Mater Process Technol 177:183–192

Chen W-F, Lai H-Y, Chen C-K (2002) Design and NC Machining of Concave-Arc Ball-end Milling Cutters. Adv Manuf Technol 20(3):169–179

Chen W-F, Lai H-Y, Chen C-K (2001) A Precision Tool Model for Concave Cone-End Milling Cutters. Adv Manuf Technol 18(8):567–578

Chen W-F, Lai H-Y, Chen C-K (2002) A Comprehensive Engineering Model for the Design, Manufacture and Assembly of Helical Carpenter Shapers. Proc Inst Mech Eng, B J Eng Manuf 216(11):1493–1504

Chen W-F, Lai H-Y, Chen C-K (2003) Quality Assurance for Concave-Arc Ball-End Milling Cutters. Proc Inst Mech Eng, B J Eng Manuf 217(2):181–191

Tsai YC, Hsieh JM (2005) An analysis of cutting-edge curves and machining performance in the Inconel 718 machining process. Int J Adv Manuf Technol 25:248–261

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hsieh, JM. Manufacturing models for design and NC grinding of truncated-cone ball-end cutters. Int J Adv Manuf Technol 35, 1124–1135 (2008). https://doi.org/10.1007/s00170-006-0794-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-006-0794-x