Abstract

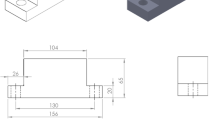

This paper presents models related to the manufacturing of ball-nosed end mills of solid carbide (BEMSC) with a chamfered cutting edge (CCE). A parallel grinding wheel (PGW) is selected, and the relationship between CCE face and PGW working face is determined. Based on the geometry models of BEMSC established in our previous work, the centre and axis vectors of PGW are calculated for the grinding of CCE face on bath the ball-nosed end and the cylinder, which is validated through a numerical simulation. In order to produce the tool, a grinding machine, SAACKE UMIF, is chosen. Targeting the grinding data of BEMSC, the transformations are carried out between the coordinate systems of workpiece and the NC programme according to the structural features of the machine. An algorithm is derived for dispersing grinding paths. As a result, the centre data and axis vector are generated with respect to the grinding machine. The BEMSC with CCE is machined using the selected machine, which demonstrates the correctness of the established models. Finally, the performance of the machined cutting tool is validated in comparison with a common BEMSC without CCE in the milling of a mould of a multi-hardness joint structure.

Similar content being viewed by others

References

Kaldor S, Rafael AM, Messinger D (1988) On the CAD of profiles for cutters and helical flutes—geometrical aspects. CIRP Ann Manuf Technol 37(1):53–56. doi:10.1016/S0007-8506(07)61584-4

Wu DR (1977) Course for differential geometry. People Education Press, Beijing

Hsieh JM (2006) Manufacturing models for design and NC grinding of truncated-cone ball-end cutters. Int J Adv Manuf Technol 35(11–12):1124–1135. doi:10.1007/s00170-006-0794-x

Lai HY, Chen WF (2002) Precision design and numerical control machining of tapered ball-end milling cutters. Proc Inst Mech Eng B J Eng Manuf 216(2):183–197. doi:10.1243/0954405021519834

Bao QS, Wang YT, Tang YY (2002) A new cutting edge of the conical ball-nosed milling cutter. J Hebei Univ Sci Technol 23(2):40–42

Shang QH, Sun CH, Tang YY, Liu HM (2001) Study on geometrical modeling for elliptical edge of ball-end milling cutters. Tool Eng 35(5):7–8

Wu CT, Chen CK (2001) Manufacturing models for the design and NC grinding of a revolving tool with a circular arc generatrix. J Mater Process Technol 116:114–123

Chen WY, Chang PC, Liaw SD, Chen WF (2005) A study of design and manufacturing models for circular-arc ball-end milling cutters. J Mater Process Technol 161(3):467–477. doi:10.1016/j.jmatprotec.2004.07.086

Chen WF, Lai HY, Chen CK (2002) Design and NC machining of concave-arc ball-end milling cutters. Int J Adv Manuf Technol 20:169–179

Yuan JP, Yu YT (2002) Virtual manufacturing models for 2-axis NC machining of ball-end milling cutters. Tool Eng 36(7):16–21

Chen CK, Lin RY (2011) A study of manufacturing models for ball-end type rotating cutters with constant pitch helical grooves. Int J Adv Manuf Technol 18:157–167

Lin SW, Lai HY (2001) A mathematical model for manufacturing ball-end cutters using a two-axis NC machine. Int J Adv Manuf Technol 17(12):881–888. doi:10.1007/s001700170099

Chen WF (2004) A mathematical solution to the design and manufacturing problems of ball-end cutters having a cutting edge with constant angle to the axis. Proc Inst Mech Eng C J Mech Eng Sci 218(3):301–308. doi:10.1243/095440604322900426

Tsai Y-C, Hsieh J-M (2001) A study of a design and NC manufacturing model of ball-end cutters. J Mater Process Technol 117(1–2):183–192. doi:10.1016/S0924-0136(01)01068-8

Chen C-B (2007) Discussion on the problems related to NC machining of toroid-shaped taper cutter with constant angle between cutting edge and the cutter axis. Int J Adv Manuf Technol 35(5–6):493–504. doi:10.1007/s00170-006-0725-x

Chen WF, Lai HY, Chen CK (2001) A precision tool model for concave cone-end milling cutters. Int J Adv Manuf Technol 18(8):567–578. doi:10.1007/s001700170033

Feng X, Hongzan B (2003) CNC rake grinding for a taper ball-end mill with a torus-shaped grinding wheel. Int J Adv Manuf Technol 21(8):549–555. doi:10.1007/s00170-002-1298-y

Pham T, Ko S (2010) A manufacturing model of an end mill using a five-axis CNC grinding machine. Int J Adv Manuf Technol 48(5–8):461–472. doi:10.1007/s00170-009-2318-y

Rababah M, Almagableh A, Aljarrah M (2013) Five-axis rake face grinding of end-mills with circular-arc generators. Int J Interact Des Manuf (IJIDeM):1–9. doi:10.1007/s12008-013-0198-8

Karpuschewski B, Jandecka K, Mourek D (2011) Automatic search for wheel position in flute grinding of cutting tools. CIRP Ann Manuf Technol 60(1):347–350. doi:10.1016/j.cirp.2011.03.113

Chen F, Bin H (2009) A novel CNC grinding method for the rake face of a taper ball-end mill with a CBN spherical grinding wheel. Int J Adv Manuf Technol 41(9–10):846–857. doi:10.1007/s00170-008-1554-x

Chen J-Y, Lee B-Y, Chen C-H (2008) Planning and analysis of grinding processes for end mills of cemented tungsten carbide. J Mater Process Technol 201(1–3):618–622. doi:10.1016/j.jmatprotec.2007.11.214

Kim JH, Park JW, Ko TJ (2008) End mill design and machining via cutting simulation. Comput Aided Des 40(3):324–333. doi:10.1016/j.cad.2007.11.005

Chen F, Hu S, Yin S (2012) A novel mathematical model for grinding ball-end milling cutter with equal rake and clearance angle. Int J Adv Manuf Technol 63(1–4):109–116. doi:10.1007/s00170-011-3889-y

Nguyen H, Ko S-L (2014) A mathematical model for simulating and manufacturing ball end mill. Comput Aided Des 50:16–26. doi:10.1016/j.cad.2014.01.002

Li G, Sun J, Li J (2014) Modeling and analysis of helical groove grinding in end mill machining. J Mater Process Technol 214(12):3067–3076. doi:10.1016/j.jmatprotec.2014.07.009

Lu Y, Takeuchi Y, Takahashi I, Anzai M (2005) An integrated system development for ball end mill design, creation and evaluation. Int J Adv Manuf Technol 25(7–8):628–646. doi:10.1007/s00170-004-2259-4

Ji W, Liu X, Wang L, Meng Y, Wu X (2015) A study on geometry modelling of a ball-end mill with chamfered cutting edge. J Manuf Process 19:205–211. doi:10.1016/j.jmapro.2014.10.003

Zhou Y, Liu Y (2012) Error analysis for the non-circular curve discretization method in CNC machining. Mech Res Appl 4:54–56

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ji, W., Liu, X., Wang, L. et al. Research on modelling of ball-nosed end mill with chamfered cutting edge for 5-axis grinding. Int J Adv Manuf Technol 87, 2731–2744 (2016). https://doi.org/10.1007/s00170-016-8631-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8631-3